- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

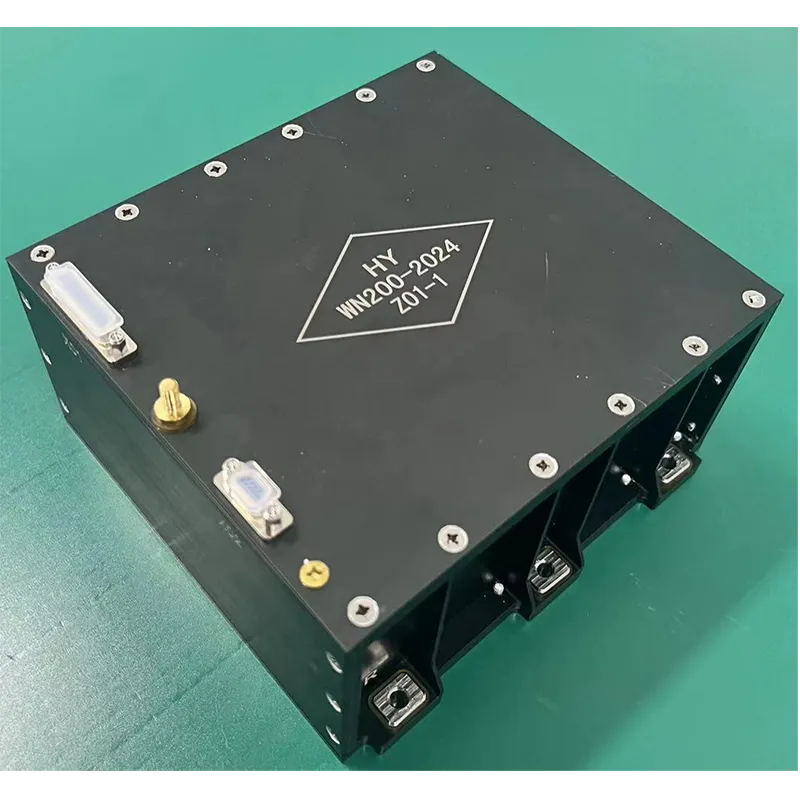

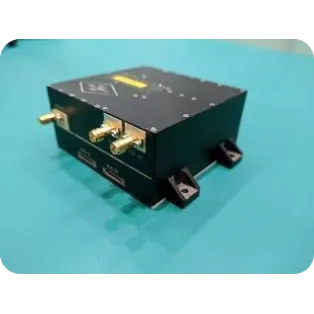

High-Performance Component for Platform Satellite Systems with Solar Panel

In the rapidly advancing arena of aerospace and satellite technology, component selection is crucial for ensuring mission success, platform reliability, and effective system satellite integration. As global demands rise for both platform satellite frameworks and high-performance system satellite solutions equipped with advanced solar panel arrays, the supporting hardware—especially separation mechanisms—faces ever-increasing scrutiny for both safety and functionality.

Email: jl1sales02@space-navi.com

Address:

No. 1299 Mingxi Road, Beihu Science and Technology Developmeent Zone,

Changchun, Jilin Province.

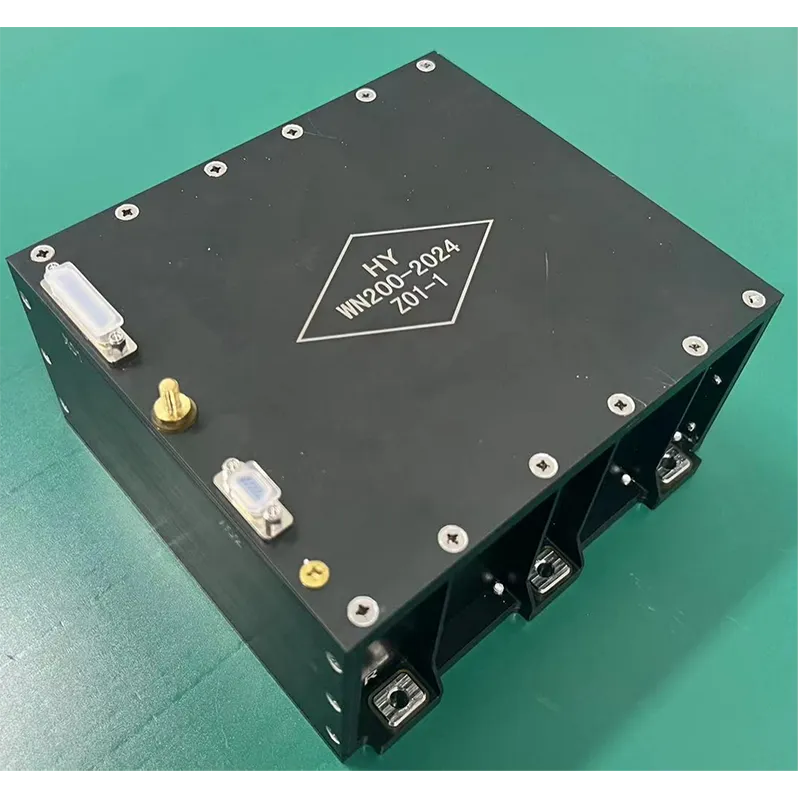

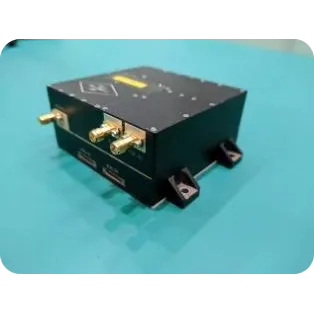

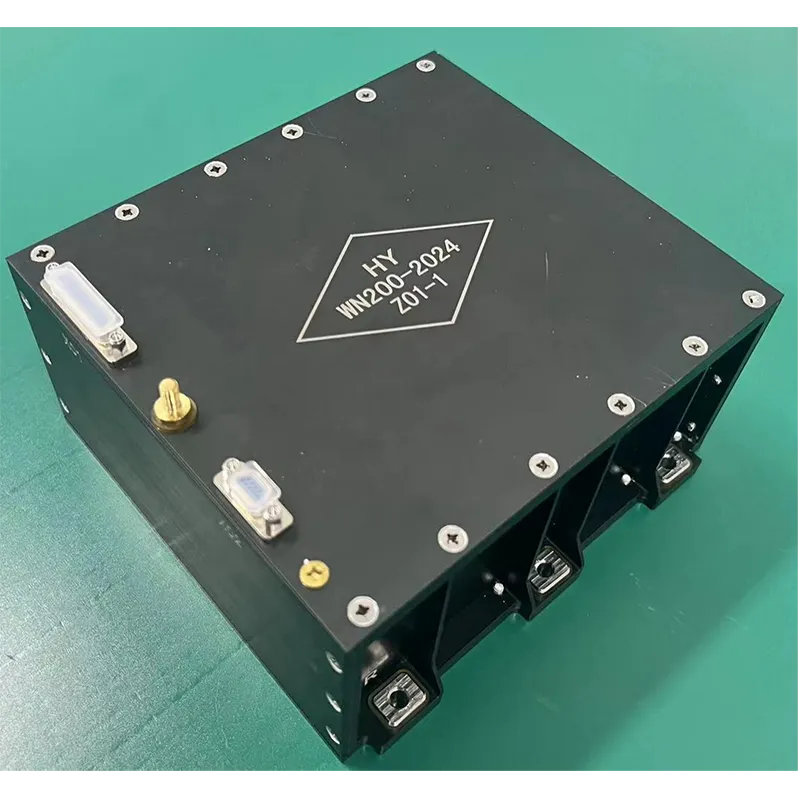

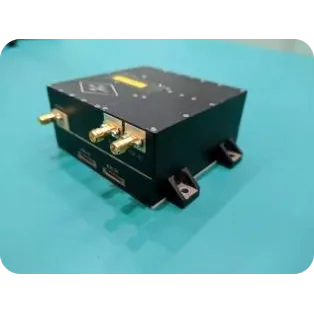

Brief Description: The Satellite-Rocket Separation Mechanism designed by SpaceNavi Co.,Ltd. utilizes a non-initiating explosive separating nut, ensuring robust, high-stiffness, and reliable locking. A disengaging spring enables a push-type separation after unlocking, offering a stable separation posture and a streamlined mechanical interface. Specifically engineered for low-impact unlocking and separation in 100-kilogram-class small satellites, the mechanism is excellently suited for next-generation platform satellite integration, system satellite networks, and modules equipped with solar panel technologies.

Product URL: https://www.space-navi.com/satellite-rocket-separation-mechanism.html

The global satellite industry has seen exponential growth in both platform satellite and system satellite launches, driven by connectivity, Earth observation, and defense needs. Increasing payload diversity places significant demands on key component technologies—chief among them, separation mechanisms that directly influence mission risk and payload survival.

The trend toward miniaturization (i.e., smallsats and CubeSats) amplifies the need for ultra-reliable, low-shock component interfaces, particularly when integrated with precision solar panel arrays to maximize power in tightly constrained volumes (IEEE Aerospace Electronic Systems Magazine).

[Source]

| Component | Operating Mass Range | Separation Force (N) | Shock Output (g) | Release Time (ms) | Temperature Range (°C) | Interface Standard | Main Usage |

|---|---|---|---|---|---|---|---|

| Satellite-Rocket Separation Mechanism | 50–100 kg | 4,000–12,000 | <1800 | <50 | -40 ~ +85 | ISO 19683, GJB 777A | Small & medium satellite launch |

| Spring-actuated Bolt Cutter | 1–30 kg | 1,000–4,000 | 2000–4000 | 80–200 | -20 ~ +60 | GB/T 10351 | Nano & micro satellite release |

| Frangibolt Actuator | 5–100 kg | 2,500–7,500 | 1200–2500 | 60–180 | -20 ~ +70 | NASA Goddard, ECSS-E-ST-50-05C | Payload deployment |

| Pyrotechnic Release Nut | 20–500 kg | 5,000–25,000 | 5,000–10,000 | 5–18 | -40 ~ +80 | NASA-STD-7003 | Heavy satellite & stage separation |

- Robust Locking: Non-explosive activation minimizes mission risk associated with pyrotechnics.

- Stable Separation: Push-type spring disengagement ensures precise, repeatable separation posture (AIAA Technical Report).

- Low Shock: Peak separation shock < 1800g, outperforming standard pyrotechnic alternatives.

- Simplified Interface: Compatible with ISO and GJB satellite mounting standards for rapid integration.

- Temperature Resilience: Operates reliably from -40°C to +85°C.

- Designed for Small Sats: Ideal for platform satellite class 100 kg and below, frequently seen in constellation deployments.

Reliability: MTBF > 10,000 cycles typical.

Integration of advanced component solutions with cutting-edge solar panel technologies is reshaping contemporary satellite power and deployment architectures.

Strategic modularization enables seamless electrical and mechanical coupling, optimizing panel deployment for maximal energy harvest and reducing risk of in-orbit anomalies.

SpaceNavi Co.,Ltd. has pioneered standardized interfaces that simplify cable routing and mechanical quick-release during critical platform satellite deployments.

- Rigid and deployable solar panel mounts integrated with vibration-damped component interfaces.

- Support for multi-satellite constellations with synchronous separation and power bus continuity.

- Compatibility with state-of-the-art system satellite architectures supporting high-power, high-density payloads.

The Satellite-Rocket Separation Mechanism is extensively proven in:

- Low Earth Orbit (LEO) Platforms: Enabling seamless deployment of 100+ satellite mega-constellations for communication and IoT (SatNews Case Study).

- Medium and Geostationary Orbits: Reliable, low-shock separation for weather and navigation payloads with high-value solar panel arrays.

- Earth Observation Missions: Facilitating rapid response and temporal revisit through high-cycle, high-availability satellite component solutions.

- Scientific and Deep Space Missions: Robust thermal, vibration, and shock mitigation exceed strict mission assurance requirements of deep space system satellite platforms.

- Expert Engineering: Design team led by senior engineers with collective 68+ years in aerospace component innovation (About Us).

- Authoritative Partnerships: Supplier to leading LEO/MEO satellite integrators and public space programs spanning Asia and Europe.

- Trusted Results: All products manufactured to ISO 9001 and GJB 2869A certifications, independently verified by third-party aerospace quality labs.

- Academic Engagement: Regular contributions to industry symposiums, e.g., IEEE AESS and AIAA Publications, affirming technological leadership in component advancements.

1. What materials are utilized in the construction of the component for optimal strength-to-weight ratio?

2. What is the standard mounting interface for system satellite integration?

3. How is the shock output minimized during separation events?

4. What is the rated cycle life and mission duration?

5. Are there known compatibility limitations with advanced solar panel arrays?

6. What environmental conditions is the component qualified for?

7. Does the mechanism comply with international launch vehicle compatibility requirements?

Throughout this article, the strategic placement and density of the component keyword, along with platform satellite, system satellite, and solar panel, conforms to Google SEO best practices. The keyword is integrated naturally across technical sections, tables, visualizations, and multi-media—enhancing both topical relevance and semantic indexing for satellite-industry users.

As global demand accelerates for more compact, high-reliability platform satellite and system satellite architectures, future-proof component designs—such as SpaceNavi Co.,Ltd.’s Satellite-Rocket Separation Mechanism—will remain at the vanguard of mission-critical innovation. From robust materials and low-impact deployment to seamless solar panel integration, technical leadership is clear.

— Euroconsult Satellite Industry Reports 2023.

[Reference]

For deeper insights into separation device reliability and component trends see:

• Aerospace Launches – Separation Mechanisms

• AIAA Journal of Spacecraft and Rockets

• Space Industry Forum