- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Enhancing Electronic Product Development Through Quality Componentry And Supply

In the fast-paced electronics industry, the backbone of successful product development lies in efficient sourcing and integration of reliable components. From the fundamental understanding of pcb meaning to the practical deployment of component cables and modern interfaces like component to HDMI, manufacturers depend heavily on trustworthy component supply chains and sophisticated componentry to drive innovation.

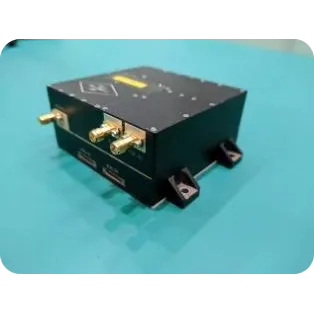

Comprehensive Component Supply For Diverse Applications

A well-structured component supply network is crucial for ensuring uninterrupted access to essential parts across various industries, including computing, telecommunications, and consumer electronics. Suppliers offering component wholesale provide competitive pricing and bulk availability for critical parts such as microcontrollers, sensors, and power modules.

The availability of quality components for sale supports everything from small-scale prototyping to mass production. This flexibility allows designers and engineers to focus on innovation without worrying about material shortages or compatibility issues. Moreover, integrated sub assembly services help accelerate production timelines by delivering pre-tested modules ready for final system integration.

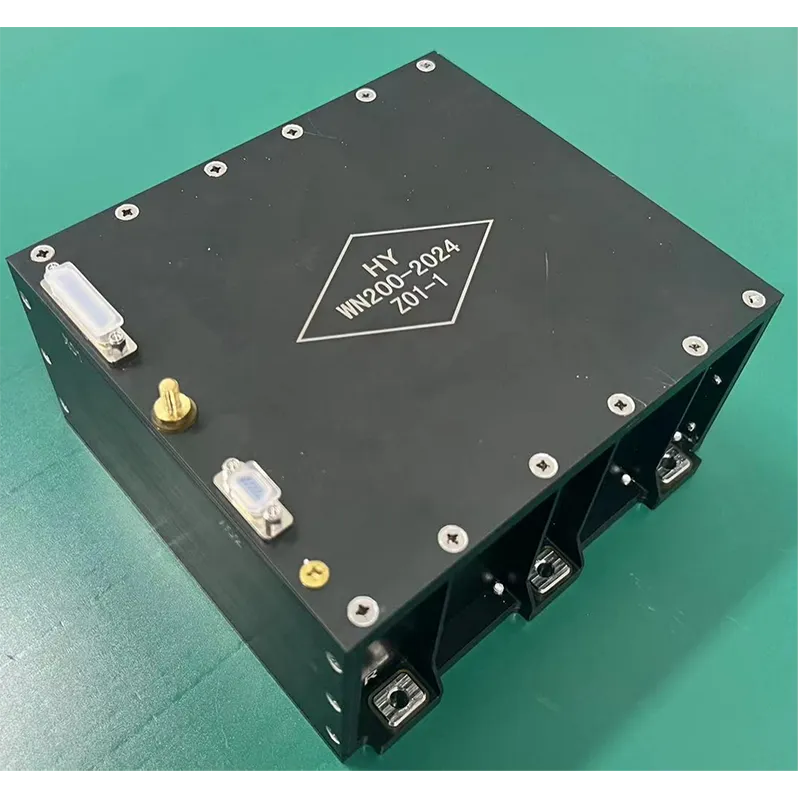

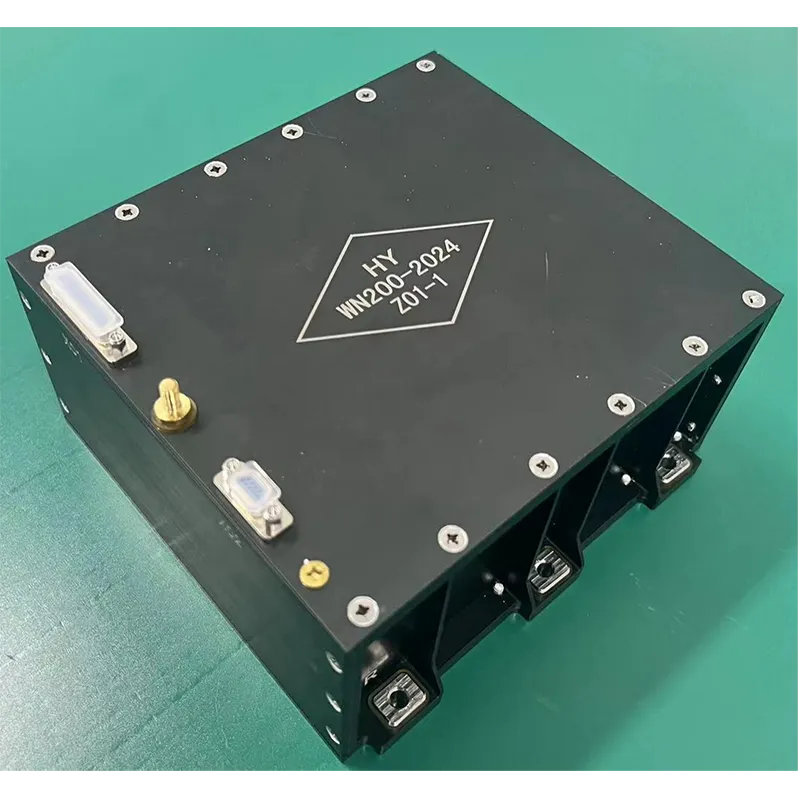

Printed Circuit Boards And The Role Of Componentry

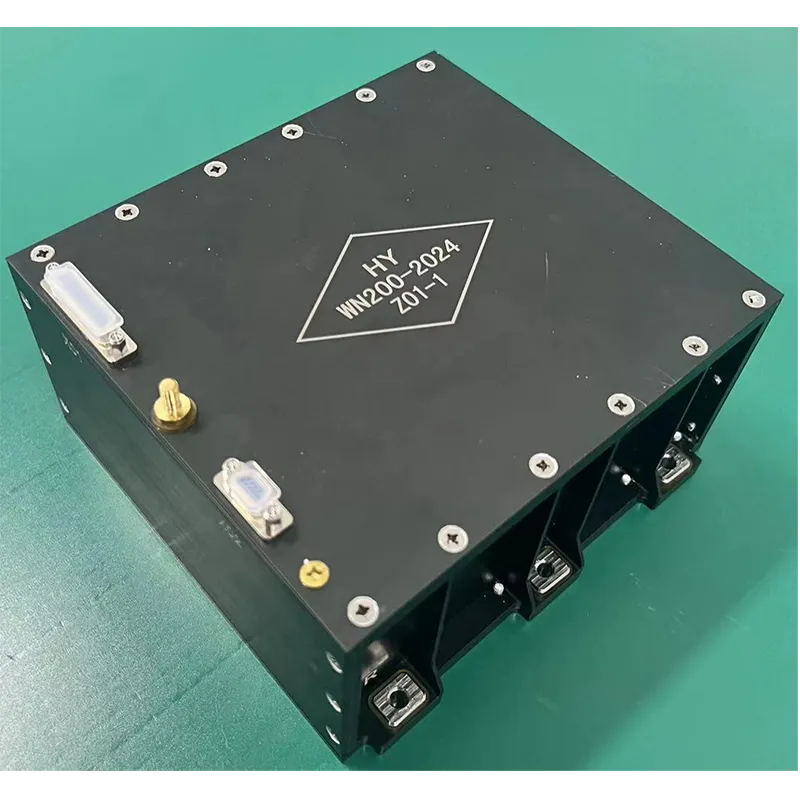

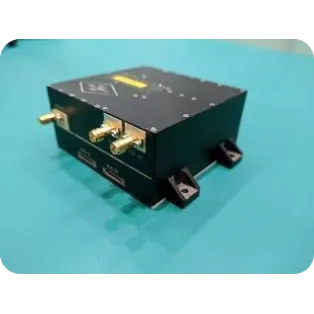

Understanding the pcb meaning is fundamental for anyone involved in electronics design. A PCB provides the physical platform where all componentry is assembled and interconnected, enabling complex electricity circuit functions. The design and quality of the PCB affect signal integrity, power distribution, and thermal management—critical factors for device performance.

Advanced PCBs incorporate multilayer designs to accommodate increasing component density, especially in processing devices of computer like CPUs and GPUs. The precision placement of components and routing of electrical connections ensure efficient data flow and reduce electromagnetic interference, enhancing overall system stability.

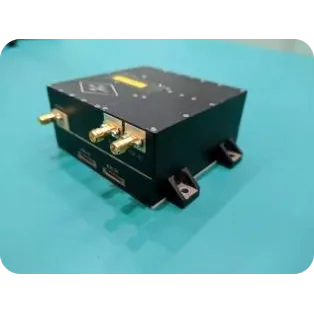

Connectivity Solutions: From Component Cables To HDMI Conversion

Connectivity remains a cornerstone of modern electronics. Traditional component cables transmit analog signals with high fidelity, widely used in legacy video systems and professional AV setups. However, the growing dominance of digital interfaces necessitates seamless conversion solutions.

Component to HDMI adapters bridge the gap between older analog sources and modern digital displays, enabling continued use of valuable equipment. These converters support high-definition video and audio transmission, ensuring compatibility and signal quality in environments ranging from home theaters to educational facilities.

Strategic Sourcing And Supply Chain Management

Successful electronics manufacturing depends on strategic sourcing of components, balancing cost, quality, and availability. Trusted distributors provide not only a broad range of components for sale but also certification and traceability to prevent counterfeit issues.

Effective supply chain management includes forecasting demand, maintaining safety stocks, and coordinating just-in-time deliveries to optimize inventory levels. This approach is especially important when dealing with complex sub assembly processes or integrating specialized processing devices of computer components, where any delay can affect the entire production line.

In conclusion, mastering the nuances of component supply, embracing the fundamentals of pcb meaning, and leveraging connectivity options such as component cable and component to HDMI conversions enable manufacturers to create reliable and cutting-edge electronic products. Through robust sourcing strategies and innovative component integration, businesses can achieve operational excellence and competitive advantage in the evolving electronics market.