- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

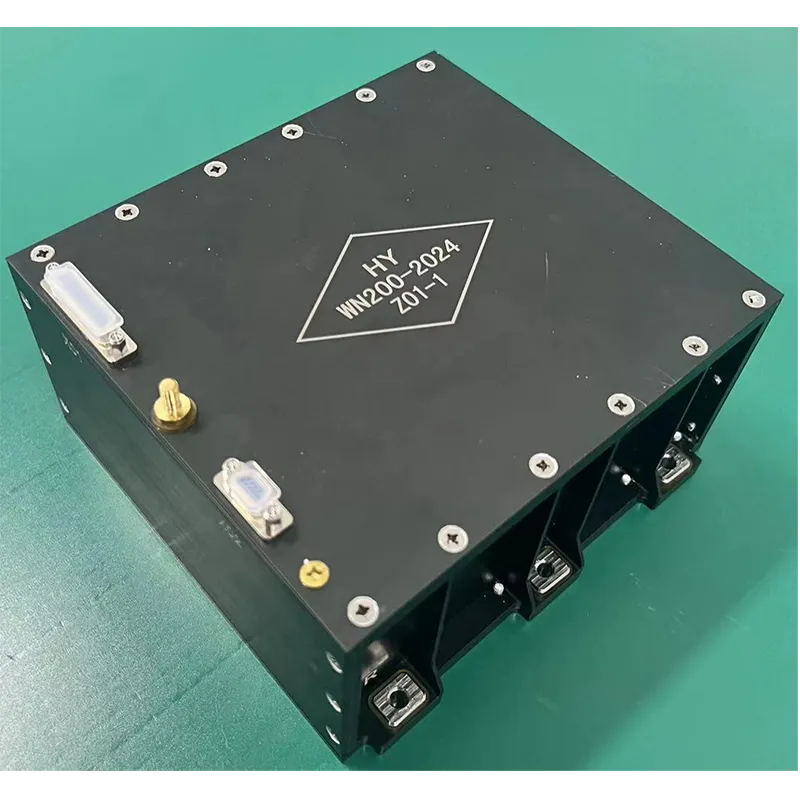

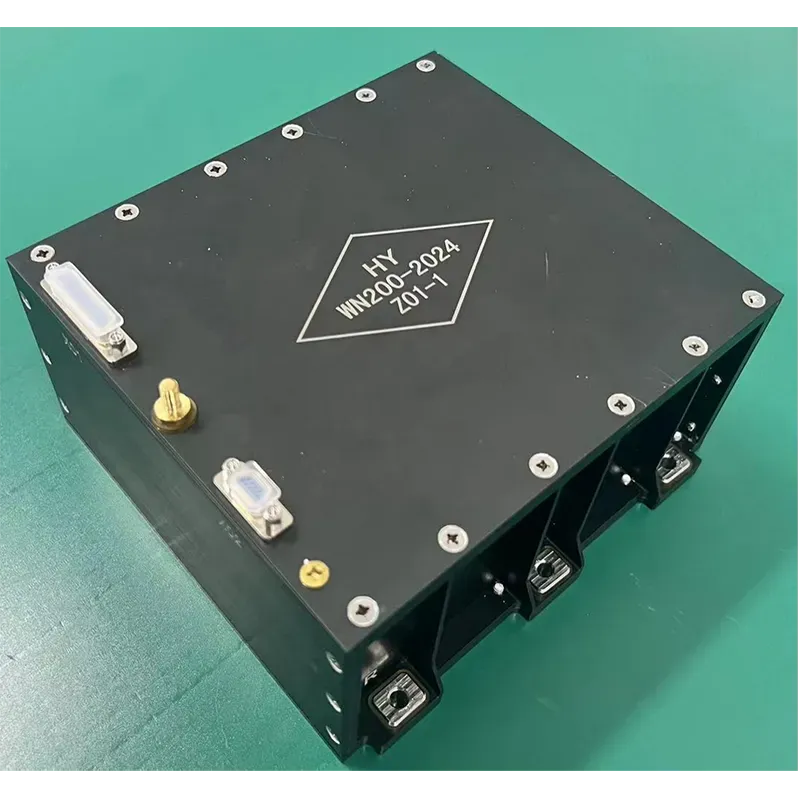

Innovations and Applications in Optical Instrumentation for Precision Measurement

As technology advances, the role of optical measuring instruments becomes increasingly vital in scientific research and industrial applications. Instruments such as the optical profilometer, 3d optical profilometer, and optical surface profiler have revolutionized surface characterization by offering precise, non-contact measurement capabilities. These devices enable industries to enhance quality control, optimize manufacturing processes, and drive innovation.

Advancements in Optical Profilometry

The optical profilometer utilizes light-based methods like interferometry and confocal microscopy to map the surface topography of materials with nanometer resolution. This technique is indispensable in sectors where surface properties directly impact functionality, such as semiconductor wafer fabrication, precision optics, and biomedical implants.

Expanding on this, the 3d optical profilometer provides three-dimensional surface data, offering comprehensive insights into texture, roughness, and defects. Such detailed profiling assists engineers in understanding wear patterns, coating thickness variations, and microstructural features, enabling proactive adjustments in manufacturing processes.

Spectroscopy: Unveiling Material Composition

Spectroscopic techniques remain foundational in materials analysis. The optical emission spectrometer and optical spectrometer analyze the light emitted or absorbed by a sample to identify its elemental or molecular composition. This capability is crucial for applications in metallurgy, environmental monitoring, pharmaceuticals, and chemical manufacturing.

These instruments support rapid, accurate assessments, helping ensure material compliance with industry standards and regulations. Integration of advanced optics and detectors continues to enhance their sensitivity and resolution.

Particle Analysis with Optical Counters and Sizers

Ensuring environmental and product purity often requires detailed particle measurement. The optical particle counter and optical particle sizer enable real-time detection and sizing of particles in air, water, or process streams. This functionality is critical in cleanrooms, pharmaceutical production, HVAC monitoring, and aerosol research.

These instruments use light scattering principles to count and size particles, providing data essential for contamination control, health and safety compliance, and process optimization.

Surface Roughness Testing and Profiling

The optical surface roughness tester and optical surface profilometer provide high-resolution analysis of surface texture without physically contacting the sample. This non-destructive method is especially valuable for delicate or soft materials, where traditional contact probes might cause damage.

Accurate surface roughness measurement helps manufacturers meet strict specifications, reduce failure rates, and improve product lifespan. Applications span automotive parts, electronics, aerospace components, and medical devices.

Future Perspectives and Integration

The integration of optical measuring instruments with digital analytics and automation is transforming data acquisition and interpretation. Modern systems feature user-friendly interfaces, cloud connectivity, and AI-driven analysis, facilitating faster decision-making and predictive maintenance.

Miniaturization trends are leading to portable optical profilometers and handheld optical particle counters, expanding their usability beyond laboratories into field inspections and on-site quality assessments.

In conclusion, cutting-edge optical instruments such as optical profilometers, optical emission spectrometers, and optical particle sizers are indispensable in modern scientific and industrial contexts. Their precision, versatility, and non-invasive operation continue to drive advancements in quality control, research, and environmental monitoring.