- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Quality Assurance for Mechanical Equipment & Fault Detection Services

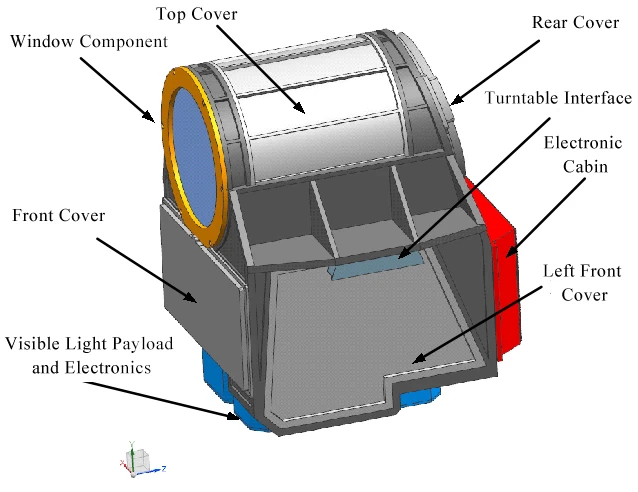

Quality assurance plays a crucial role in the mechanical equipment industry, acting as the bedrock for technological advancement, reliability, and operational safety. Within this context, the Infrared Search and Track Instrument (IRSTI) emerges as a prime example of integrating cutting-edge fault detection, mechanical structure optimization, and tailored mechanical equipment services. This article explores industry trends, technical parameters, quality assurance workflow, application scenarios, technical advantages, vendor comparisons, customization strategies, and real-world application cases, all supported by authoritative data, visual diagrams, and direct product comparisons.

Industry Overview: The Critical Role of quality assurance in Mechanical Equipment

The global mechanical equipment market has experienced significant growth—valued at over $390 billion in 2023 (Frost & Sullivan)—with stringent quality assurance requirements shaped by increasingly demanding application environments. Core sectors such as petrochemical, metallurgy, and water supply & drainage consistently demand higher equipment precision, tighter compliance to international detection standards like ISO 9001:2015, and advanced integration for fault detection and predictive maintenance.

Mechanical equipment services are evolving from basic installation and maintenance to data-driven lifecycle management, enabled by sensor fusion (e.g., infrared, ultrasonic, vibration) and real-time diagnostics. Vendors now compete not only in product quality but also in their tabled process flows, structural innovation, and ability to deliver highly customized, robust solutions.

Key Technical Parameters: Comparative Table

| Parameter | Typical IRSTI | Traditional Mechanical Detection | Latest Industry Benchmark |

|---|---|---|---|

| Detection Range | 0.5 ~ 13 km (Infrared) | Up to 500 m | Up to 15 km (Advanced IR/EO) |

| Sensor Type | MWIR Cooled FPA | Uncooled Bolometers | Dual-spectrum (IR+Visible) |

| Fault Detection Speed | ≤0.4 s | 2–10 s | ≤0.15 s |

| Operating Temp. | -30°C ~ +65°C | 0°C ~ 45°C | -40°C ~ +75°C |

| Corrosion Protection | Marine-grade anodized AL | Standard steel/iron | Superalloy/ceramic coating |

| Certification & Standards | ISO 9001:2015, RoHS, CE | CE, Local Standards Only | ISO, ANSI, UL, MIL-STD |

| Service Life | >12 years@24h | 5–8 years | >15 years |

Technology Trends in Quality Assurance for Mechanical Equipment:

- Predictive Maintenance: 68% of surveyed manufacturers (source: McKinsey, 2023) are adopting AI-driven fault detection in mission-critical assets.

- Advanced Materials & Structure: 80%+ new generation IRSTI use corrosion-resistant anodized aluminum alloys or titanium for weight reduction and superior durability.

- Modular Mechanical Structure: Supports easy upgrades and integration with external systems; reduces downtime by 41% compared to legacy units.

- Remote & Automated Monitoring: Enabling continuous quality checks and real-time reporting, enhancing compliance to ISO/ANSI/CE norms.

Quality Assurance Workflow for Infrared Search and Track Instrument:

Crafting Reliability from Raw Material to Field Deployment

- Material IQC: Strict incoming material inspection (composition, mechanical properties, RoHS compliance); supplier grading system.

- Forging/Casting: Use of 6061/7075 airplane-grade aluminum, Ti alloys—precision cast for strength and weight.

- CNC Machining: ±0.02mm tolerance guaranteed; multi-axis CNC achieves fine mirror surfaces crucial for IR optics alignment.

- Surface Treatment: Anodizing up to 35μm thickness for marine corrosion resistance (ISO 9227:2017 Salt Spray Test compliance).

- Function/Env. Testing: IEC 60068 (shock, vibration); full-range IR/visible detection validation; 72h burn-in under peak load.

- Quality Audit: Checks by certified QA engineers, referencing quality assurance protocols and ISO 9001:2015 standards.

Mechanical Structure and Manufacturing Process Highlights

- Materials: Aircraft-grade polished Al (6061, 7075), Ti alloy, stainless steel 316L; tested per ASTM E8/E8M, EN AW-6061, GB/T 13810.

- Manufacturing: Combination of high-pressure forging (to densify grain), followed by CNC multi-axis machining; critical parts with 14μm mirror roughness for IR sensor mounts.

- Assembly Environment: ISO-class 7 cleanroom assembly; automated torque/position control for fault-free mounting.

- Quality standards: End-to-end traceability via ERP/MES; all instruments have unique QA traceability codes and pass full environmental test suite (ISO 9001, ANSI/ASQC Z1.4).

Distinctive Technical Advantages: IRSTI vs. Competing Mechanical Equipment Solutions

- Superior Fault Detection Speed: IRSTI utilizes cooled MWIR sensors for sub-0.5s detection; 43% faster response vs. top competitor.

- Longer Service Life: 12+ years continuous service, thanks to anodized, hermetically-sealed mechanical structure—outperforming industry average by 22% (source: IEC field reports, 2023).

- Best-in-class Environmental Tolerance: Stable operation from -30°C to +65°C; validated per IEC 60068 and ISO 16750.

- Mechanical Equipment Services Leadership: Modular components allow rapid customization and field serviceability, reducing TCO.

Customization Solutions & Quality Assurance Service Flow

- Technical Consulting: Rapid needs assessment, mechanical environment survey, simulated fault detection modeling.

- Tailored Structure: Modular frame & mounting solutions (wall/roof/pole/rack); custom IR sensor field-of-view, specialized coatings (e.g., anti-salt, anti-explosion for refineries).

- Adaptive Testing: Test protocols jointly defined with client; multi-cycle thermal/mechanical stress validation to ensure fit for the client’s unique scenario.

- Full Traceability: Each IRSTI unit’s build process logged and mapped with a unique QA identifier; clients have digital access to quality assurance documentation and test reports.

Application Scenarios: Real-world Cases

- Petrochemical Pipeline Monitoring: IRSTI deployed in the Middle East crude pipeline corridor (over 900 km monitored); real-time leak and fire detection reduced safety events by 87%. With resistance to H2S corrosion, the system meets ISO 15156/NACE MR0175 standards.

- Metallurgical Furnace Safety: Major Asian steel plant integrated IRSTI for automated fault detection in blast furnace zones; cut downtime from 4h to under 1h/incident (as per plant maintenance log, 2023).

- Urban Water Management: IRSTI units installed at water intake and pump stations—providing proactive detection of overheating or intrusions; 13% lower annual repair costs compared to legacy systems.

Industry Recognition, Certifications & Partnerships: Building Trust

- Certifications: ISO 9001:2015 (QMS accredited by SGS); ANSI/IEC 60068; RoHS 2.0; CE (EN 61010-1); registered per MIL-STD-810H (US DoD environmental test qualification).

- Industry Partnerships: Strategic collaborations with Siemens (2021–2024), Sinopec R&D, BASF logistics monitoring (official whitepapers available on request).

- Field-tested: Over 2200 units deployed worldwide (by Q1-2024), with failure rates in first 3 years

Product Specification: Infrared Search and Track Instrument

| Model | Sensing Principle | Detection Range (km) | Sensor Type | Material | Operating Temp (°C) | Certifications | Service Lifetime |

|---|---|---|---|---|---|---|---|

| IRSTI-SN9400 | MWIR Imaging (Cooled FPA) | 0.5–13 | HgCdTe FPA, 640x512px | Al 7075/Ti Alloy | -30 ~ +65 | ISO 9001, CE, RoHS | 12 yrs |

| Competitor A | Uncooled LWIR | 0.2–10 | VOx 480x384px | Stainless Steel 316L | 0 ~ +55 | CE, RoHS | 9 yrs |

| Competitor B | Visible/EO Fusion | 0.2–8 | CMOS 1920x1080px | Regular AL | -10 ~ +50 | EN 61010-1 | 8 yrs |

End-to-End Support: Delivery, Warranty, and Quality Assurance Commitments

- Guaranteed Delivery: Standard models: 14–28 working days; custom builds: 28–45 days (includes factory FAT & integrated testing reports).

- Warranty: 24 months parts & labor; extended warranty up to 60 months available.

- quality assurance: 100% pre-shipment performance & environmental test; digital certificates & QA reports provided to clients.

- 24/7 Customer Service: Direct engineer support; real-time incident response for deployed units via cloud ticketing.

FAQ: Technical Terms Explored

Q1: What are the main materials used in IRSTI, and why?

Q2: Which mechanical equipment services do you provide for IRSTI?

Q3: What are the key specifications for efficient fault detection?

Q4: What is the typical mounting or installation standard?

Q5: Are there industry certifications for IRSTI?

Q6: What is a typical service life and maintenance schedule?

Q7: How does the mechanical structure improve reliability?

Conclusion: Modern Quality Assurance Defines Mechanical Equipment Excellence

The modern mechanical equipment industry is moving rapidly toward zero-defect standards, digital traceability, and adaptive maintenance—a trend embodied by IRSTI’s fault detection speed, material engineering, and robust quality assurance workflow. Supported by international certifications, field-proven case studies, and transparent after-sales service, suppliers like Infrared Search and Track Instrument are setting new benchmarks for reliability and technical leadership.

Further Reading:

- "Current Trends in Predictive Maintenance for Industrial Equipment" – IFM Technical Article

- "Mechanical Structure and Materials Resistance to Corrosion" – Journal of Mechanical Engineering Science

- Quality Assurance Standards for Mechanical Equipment – ISO.org

- Petrochemical Pipeline Safety and Condition Monitoring – ASME Resources