- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

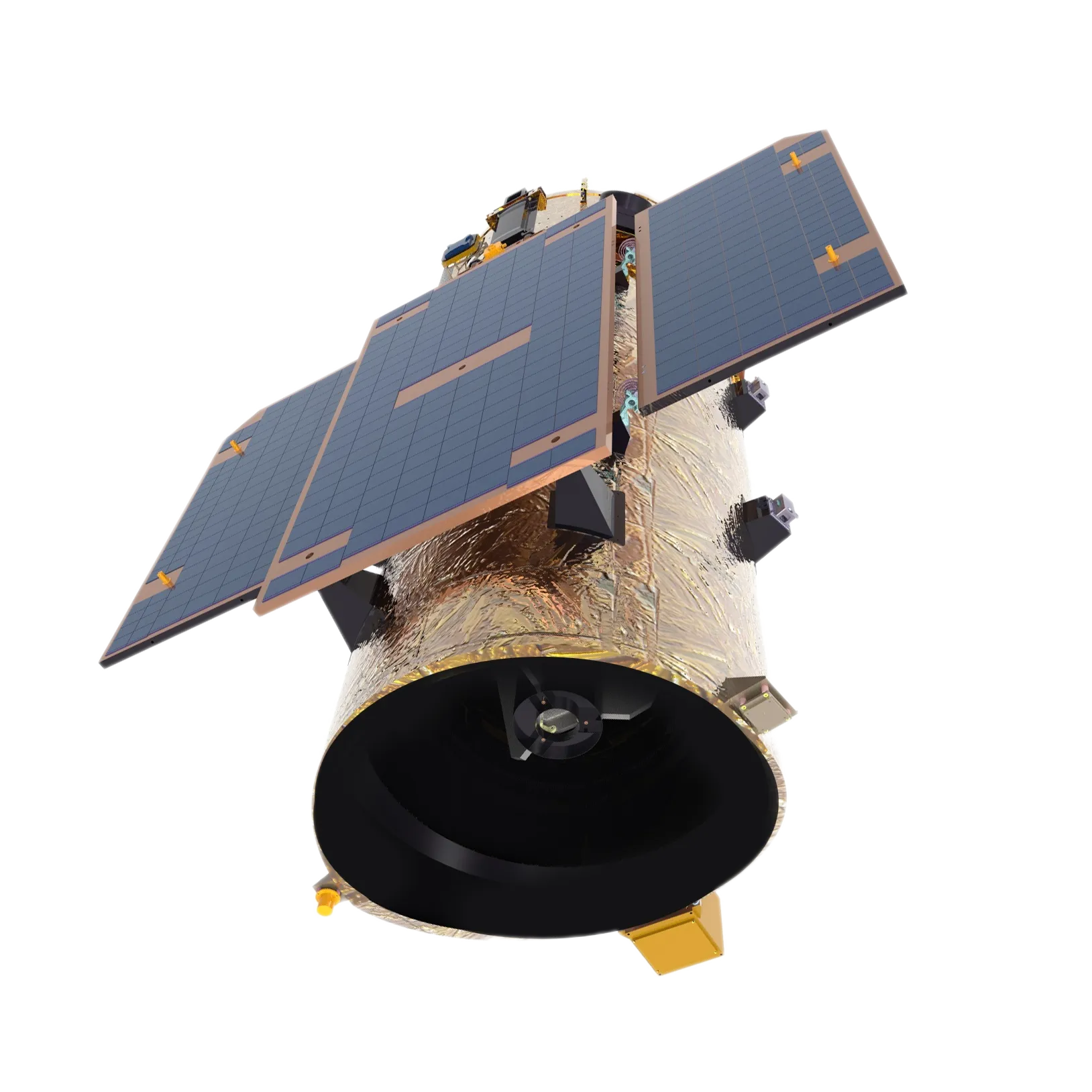

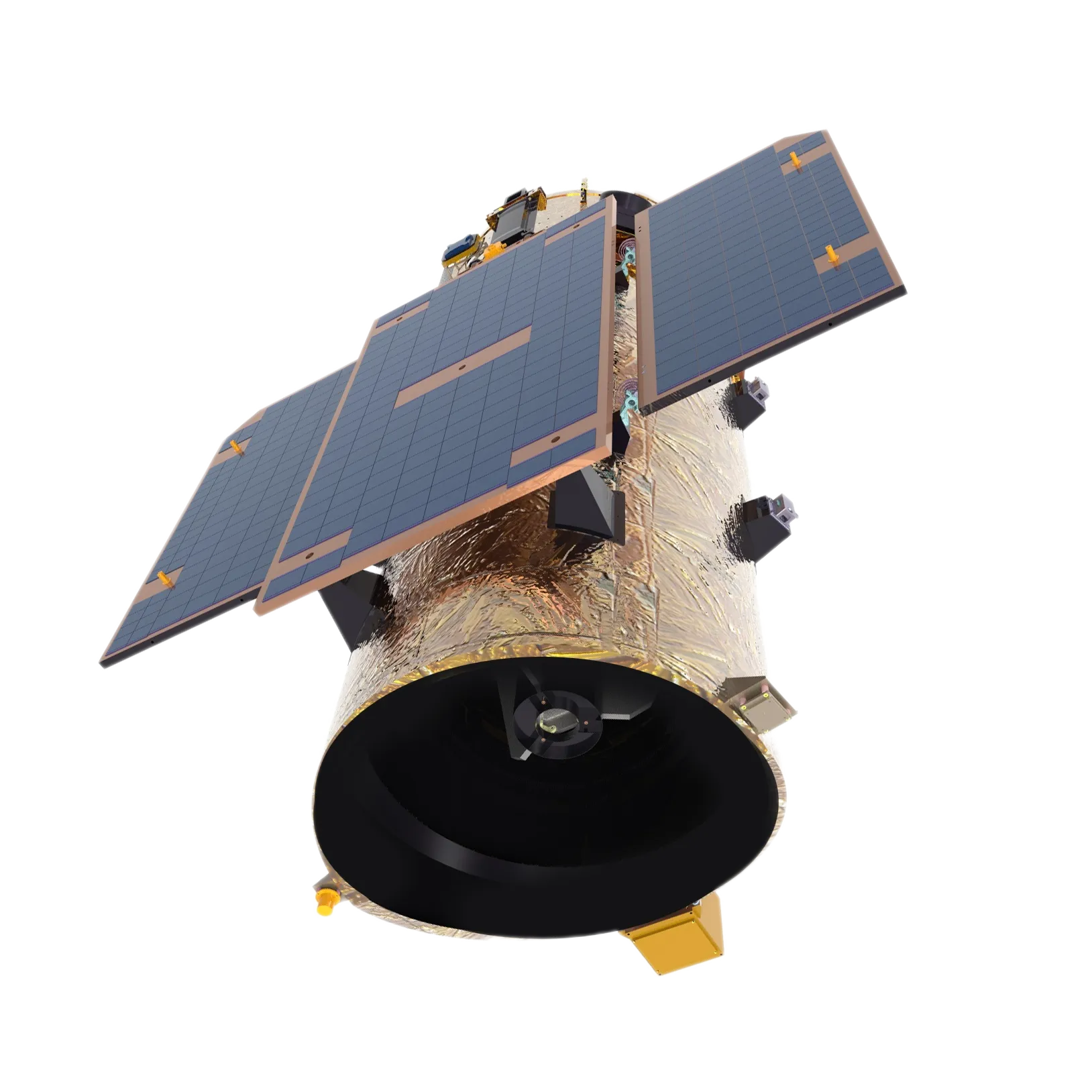

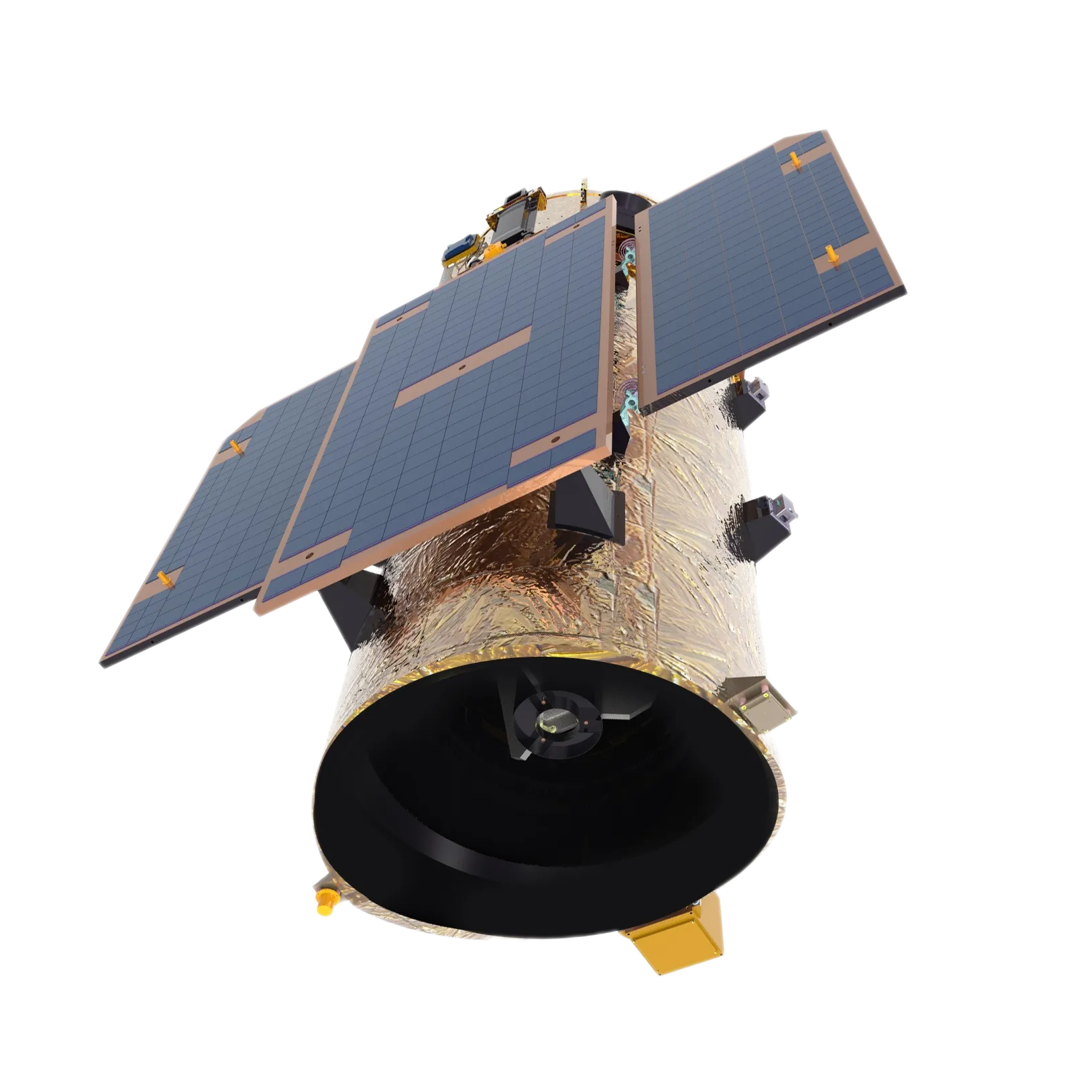

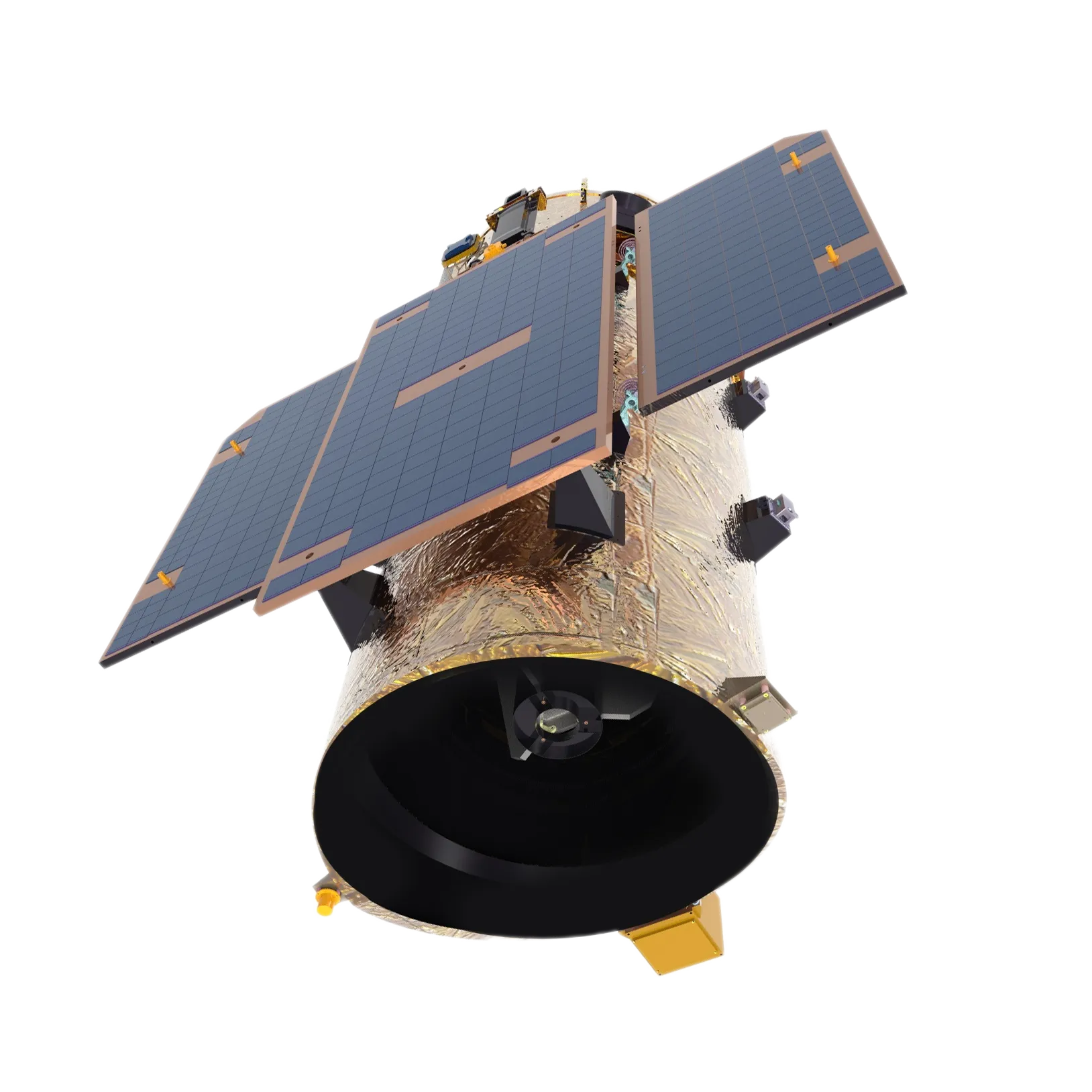

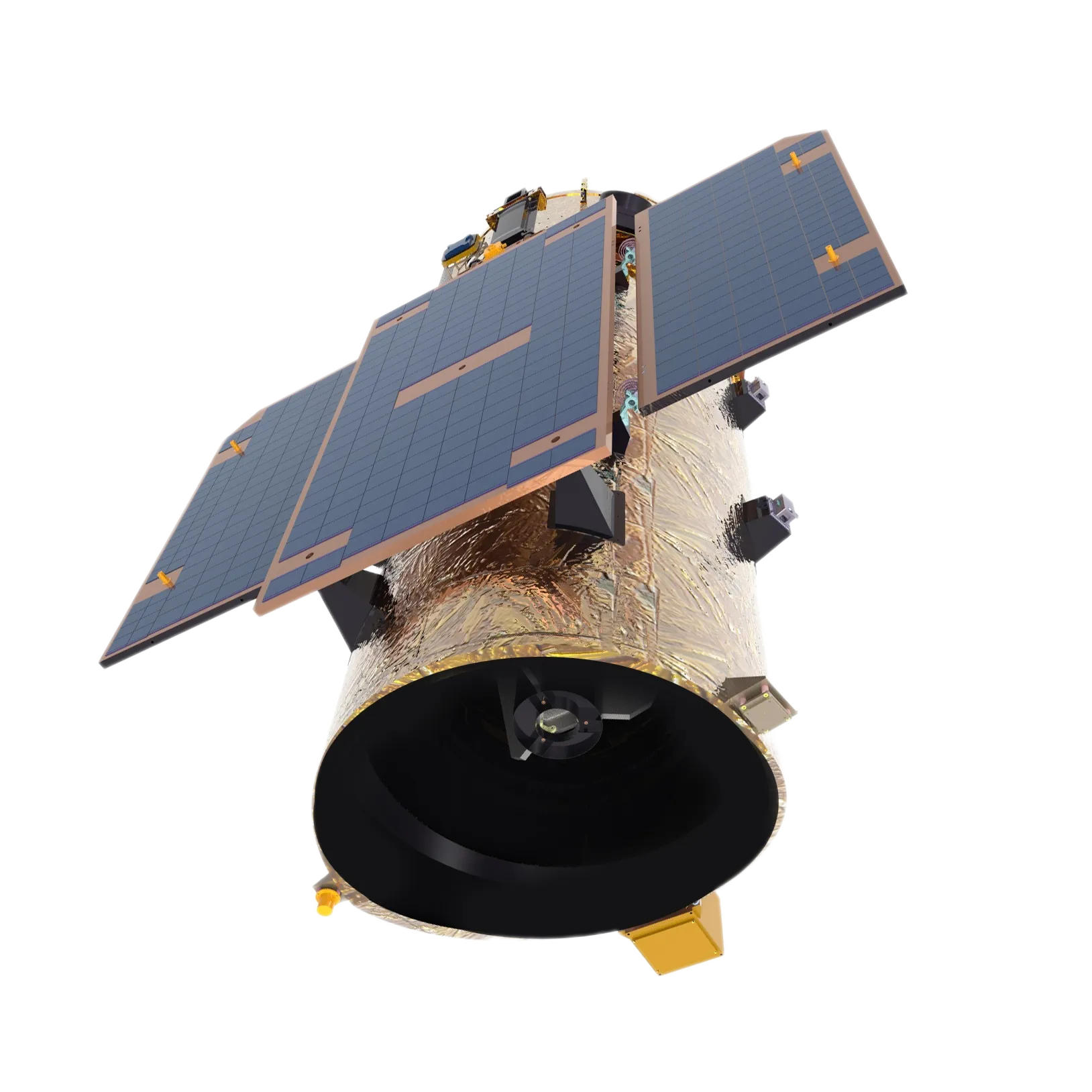

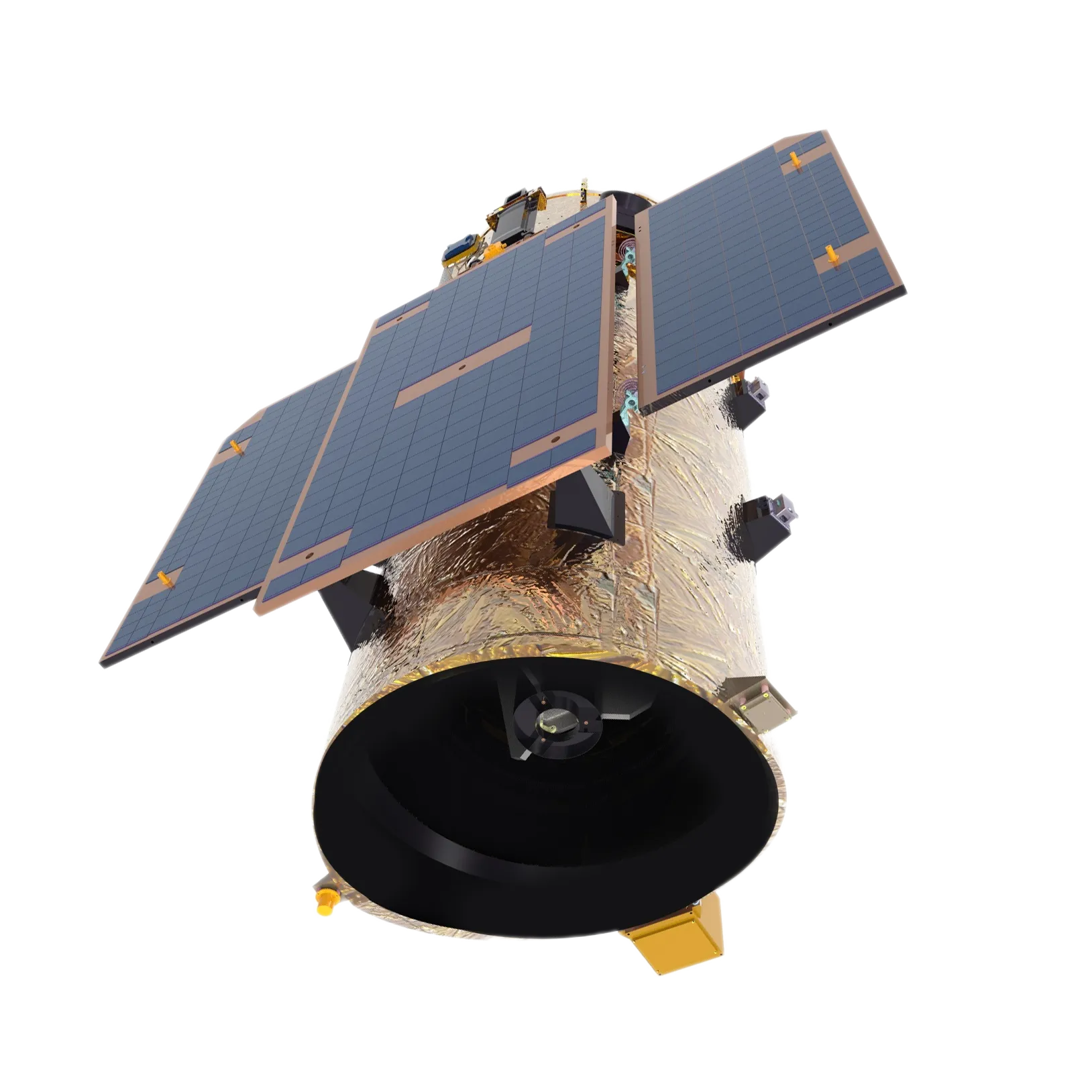

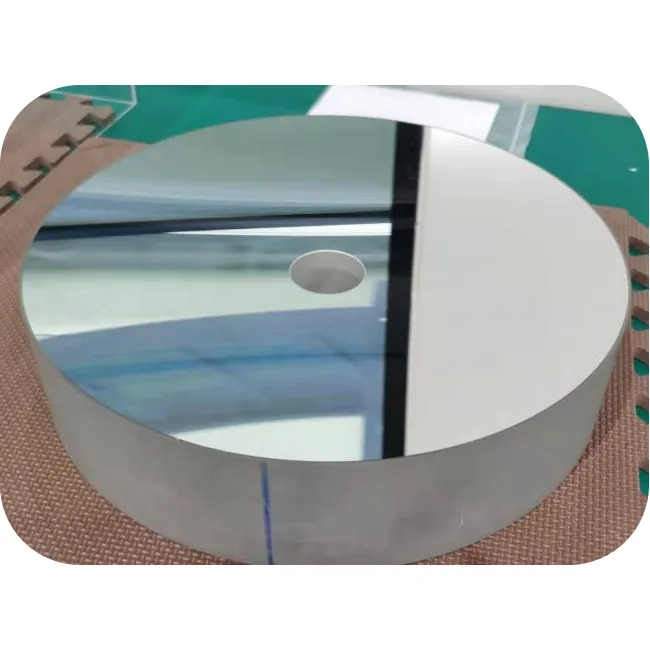

Fused Quartz Reflective Mirror - SpaceNavi Co., Ltd.|Precision Engineering, Customization

SpaceNavi Co., Ltd. is a leading provider of high-precision optical components, specializing in the design and manufacturing of fused quartz reflective mirrors. These mirrors are engineered to meet the demanding requirements of advanced scientific, industrial, and technological applications. This article explores the product's features, technical specifications, applications, and the company's commitment to innovation.

Product Overview

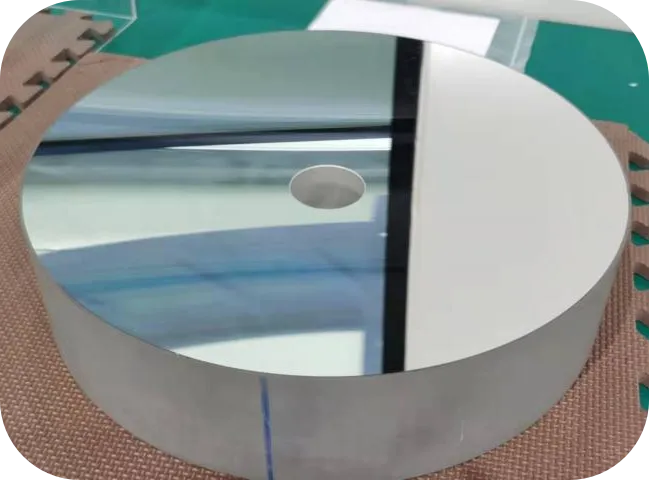

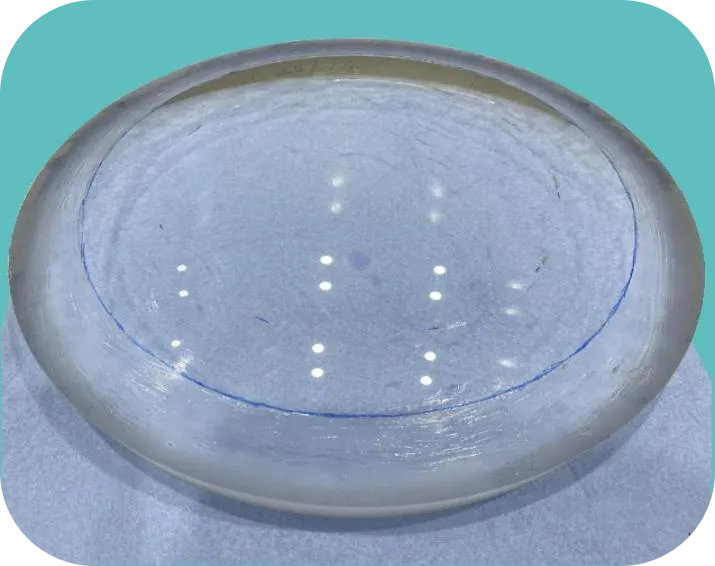

The fused quartz reflective mirror is a high-precision optical component designed for use in environments requiring exceptional durability, thermal stability, and optical performance. Fabricated from fused quartz, a material renowned for its low thermal expansion and high resistance to temperature fluctuations, these mirrors are ideal for applications in aerospace, semiconductor manufacturing, and scientific research.

The product's versatility is evident in its wide range of diameters, from 50mm to 600mm, allowing customization for specific application needs. The mirrors are available in various surface shapes, including concave spherical and crescent-shaped folded retroreflectors, catering to diverse optical system requirements.

Key Features and Advantages

Exceptional Surface Precision

One of the standout features of SpaceNavi's fused quartz reflective mirrors is their ultra-smooth surface finish. The mirrors achieve a surface roughness of less than 2 nm, ensuring minimal light scattering and optimal optical performance. The surface shape accuracy is maintained at a root mean square (RMS) value of better than 1/60 λ (λ = 632.8 nm), meeting the stringent standards of high-precision optical systems.

Customization and Flexibility

SpaceNavi offers tailored solutions to meet the unique needs of its clients. The company utilizes advanced robotic CNC processing, combined with ion-beam polishing and milling technologies, to produce large-aperture, high-precision mirrors with asymmetric spherical or aspherical surfaces. This approach enables the creation of mirrors that are perfectly suited for specialized applications such as laser systems, spectroscopy, and imaging technologies.

Efficient Production Cycle

Despite the complexity of manufacturing high-precision mirrors, SpaceNavi maintains a competitive production cycle of 2–4 months for standard orders. For specific designs, such as the 220mm crescent-shaped folded retroreflector, the production time can be as short as 1.5 months, demonstrating the company's efficiency and commitment to timely delivery.

Technical Specifications

| Parameter | Specification |

|---|---|

| Reflective Mirror Diameter | Φ 50mm–600mm |

| Surface Shape Accuracy | RMS: Better than 1/60 λ (λ = 632.8 nm) |

| Surface Roughness | <2 nm |

| Production Cycle | 2–4 months (standard), 1.5 months for specific designs |

Applications and Use Cases

Aerospace and Defense

The fused quartz reflective mirrors are widely used in aerospace and defense systems due to their ability to withstand extreme temperatures and maintain optical performance. These mirrors are critical components in satellite imaging systems, laser rangefinders, and optical sensors used in reconnaissance and navigation.

Industrial and Semiconductor Manufacturing

In semiconductor manufacturing, precision optical components are essential for lithography and inspection processes. SpaceNavi's mirrors provide the necessary accuracy and durability to support high-volume production of microchips and other advanced electronic components. Their low thermal expansion properties ensure stability during high-temperature operations.

Scientific Research

Research institutions and laboratories rely on fused quartz reflective mirrors for applications such as spectroscopy, interferometry, and laser-based experiments. The mirrors' high surface quality and thermal stability make them ideal for use in precision measurement systems and optical experiments.

Company Background: SpaceNavi Co., Ltd.

Based in Ningbo, China, SpaceNavi Co., Ltd. is a trusted name in the field of optical components and materials. The company specializes in the development and production of high-precision optical mirrors, leveraging advanced manufacturing technologies to deliver products that meet the highest industry standards.

With a focus on innovation and customer satisfaction, SpaceNavi has established itself as a reliable partner for industries requiring precision optical solutions. The company's commitment to quality is reflected in its rigorous testing processes and adherence to international standards for optical performance and reliability.

Ensuring Quality: NIST Standards and Compliance

The importance of precision in optical components is underscored by the work of the National Institute of Standards and Technology (NIST), a U.S. government agency dedicated to advancing measurement science, standards, and technology. According to NIST, "Precise measurements are the foundation of modern technology, ensuring that devices and systems function reliably and efficiently" (NIST.gov). SpaceNavi's mirrors are designed to meet the stringent measurement standards that align with NIST's research on optical materials and surface metrology.

By adhering to these standards, SpaceNavi ensures that its products deliver consistent performance in critical applications. The company's use of advanced technologies, such as ion-beam polishing and CNC machining, further enhances the accuracy and reliability of its mirrors, as highlighted in NIST's research on optical surface characterization (NIST.gov).

Conclusion

SpaceNavi Co., Ltd.'s fused quartz reflective mirrors represent the pinnacle of precision engineering in the optical components industry. With their exceptional surface quality, customization options, and efficient production cycle, these mirrors are well-suited for a wide range of high-tech applications. The company's commitment to innovation and quality, supported by adherence to international standards, ensures that its products meet the evolving needs of modern industries.

For more information about SpaceNavi's products and services, visit SpaceNavi Co., Ltd.. Explore the fused quartz reflective mirror product page to learn more about its specifications and applications.

Additional Product Images

References

National Institute of Standards and Technology (NIST). "Precision Measurement for Modern Technology." Retrieved from https://www.nist.gov.

SpaceNavi Co., Ltd.. "Fused Quartz Reflective Mirror Product Page." Retrieved from https://www.space-navi.com/fused-quartz-reflective-mirror.html.