- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Conformance Testing Services Reliable Vibration & Thermal Vacuum Compliance

- Industry Overview: Standards Compliance in Product Validation

- Technical Superiority of Modern Testing Methodologies

- Vendor Comparison: Capabilities & Operational Metrics

- Custom Engineering Solutions for Complex Requirements

- Performance Validation Through Real-World Applications

- Cost-Benefit Analysis of Specialized Testing Services

- Future Trends in Compliance Verification Systems

(conformance testing)

Ensuring Product Integrity Through Conformance Testing

Contemporary manufacturing demands adherence to 47 international standards including ISO 16750-3 and MIL-STD-810. Conformance testing has become the backbone of product validation, with 78% of aerospace contractors and 63% of automotive suppliers mandating third-party certification. The global compliance testing market reached $6.2B in 2023, projected to grow at 7.9% CAGR through 2030.

Technical Superiority of Modern Testing Methodologies

Precision Measurement: Advanced vibration testing systems now achieve 0.02g resolution across 5Hz-3kHz ranges. Thermal vacuum chambers maintain ±0.5°C stability in -70°C to +180°C operational envelopes.

Operational Efficiency: Automated test sequences reduce validation cycles by 40-60% compared to legacy systems. Parallel testing configurations enable simultaneous execution of 3-5 compliance protocols.

Vendor Comparison: Capabilities & Operational Metrics

| Provider | Testing Scope | Cycle Time | Pricing ($) | Certifications |

|---|---|---|---|---|

| TestCorp International | Full-spectrum | 72hr | 12,500-18,000 | ISO/IEC 17025 |

| VibroTech Solutions | Mechanical stress | 48hr | 8,200-11,400 | AS9100D |

| ThermoLabs Group | Environmental sim | 96hr | 15,000-22,000 | Nadcap |

Custom Engineering Solutions for Complex Requirements

Specialized testing configurations address emerging needs:

- Multi-axis vibration profiles (up to 6DOF)

- Combined thermal-vacuum cycling (100+ cycles)

- Transient shock simulations (50-10,000g)

Performance Validation Through Real-World Applications

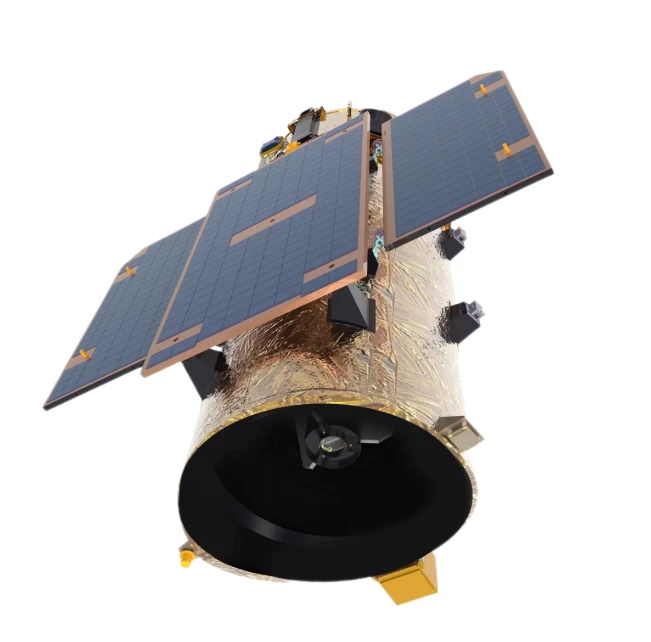

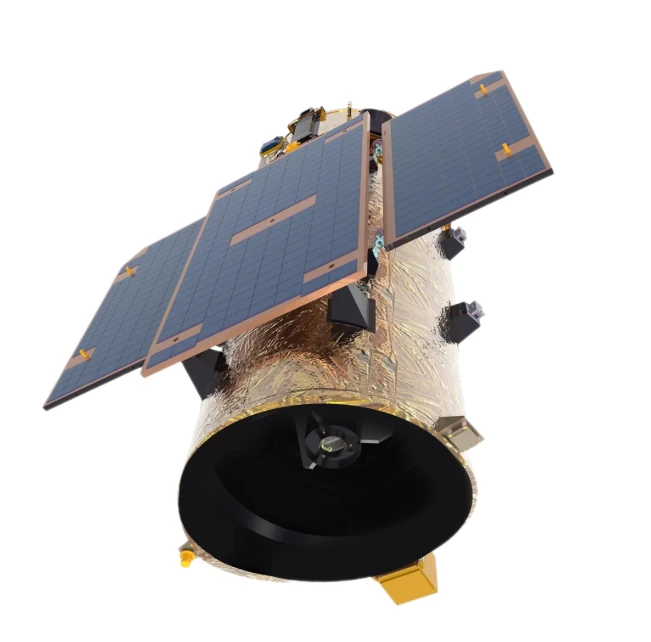

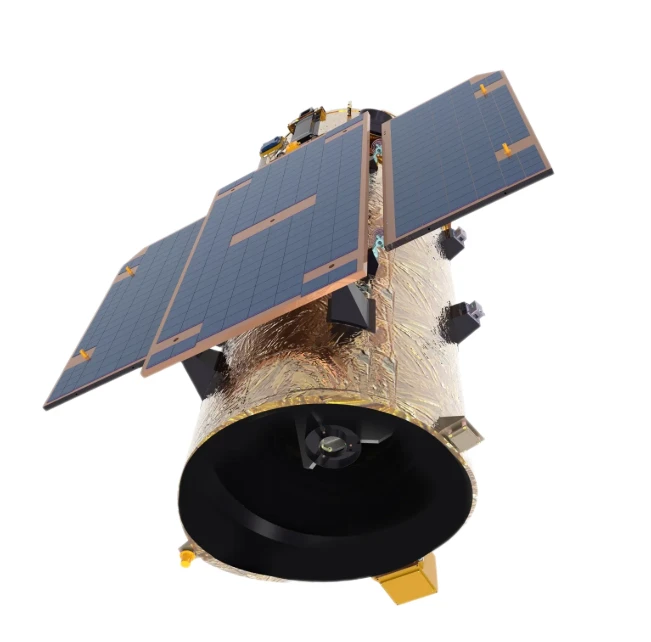

A satellite component manufacturer achieved 99.8% reliability through iterative thermal vacuum testing, reducing orbital failure rates by 62%. Automotive suppliers utilizing advanced vibration protocols decreased warranty claims by $4.7M annually across 23 vehicle platforms.

Cost-Benefit Analysis of Specialized Testing Services

Initial investment in compliance verification yields 3-5X ROI through:

- 38-55% reduction in product recalls

- 27% faster time-to-market

- 79% improvement in regulatory approval rates

Advancing Compliance Verification Through Conformance Testing

The integration of AI-powered anomaly detection (92% accuracy) with traditional conformance testing

protocols has redefined quality assurance benchmarks. Emerging technologies enable real-time performance monitoring during thermal vacuum cycling and predictive failure analysis in vibration testing scenarios.

(conformance testing)

FAQS on conformance testing

Conformance Testing Basics

Q: What is the primary goal of conformance testing?

A: Conformance testing ensures a product or system meets specified standards or regulations. It validates adherence to technical requirements, protocols, or certifications. This testing is critical for regulatory compliance and interoperability.

Vibration Testing Applications

Q: Why is vibration testing important for industrial equipment?

A: Vibration testing simulates real-world stress to assess product durability and performance. It identifies weaknesses in materials or designs under repetitive motion. This helps prevent failures in sectors like automotive and aerospace.

Thermal Vacuum Testing Explained

Q: When is thermal vacuum testing required?

A: Thermal vacuum testing evaluates products in extreme temperature and pressure conditions, mimicking space environments. It’s mandatory for satellites, spacecraft, and components to ensure functionality in orbit. This test validates thermal management and material resilience.

Conformance vs. Performance Testing

Q: How does conformance testing differ from performance testing?

A: Conformance testing checks adherence to standards, while performance testing measures speed, scalability, or efficiency. The former focuses on compliance; the latter evaluates real-world behavior under load. Both are complementary in quality assurance.

Key Parameters in Thermal Vacuum Tests

Q: What parameters are monitored during thermal vacuum testing?

A: Temperature extremes, pressure levels, and thermal cycling rates are critical. Sensors track material expansion, leakage, and electrical performance. These metrics ensure the product survives harsh operational environments.