- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

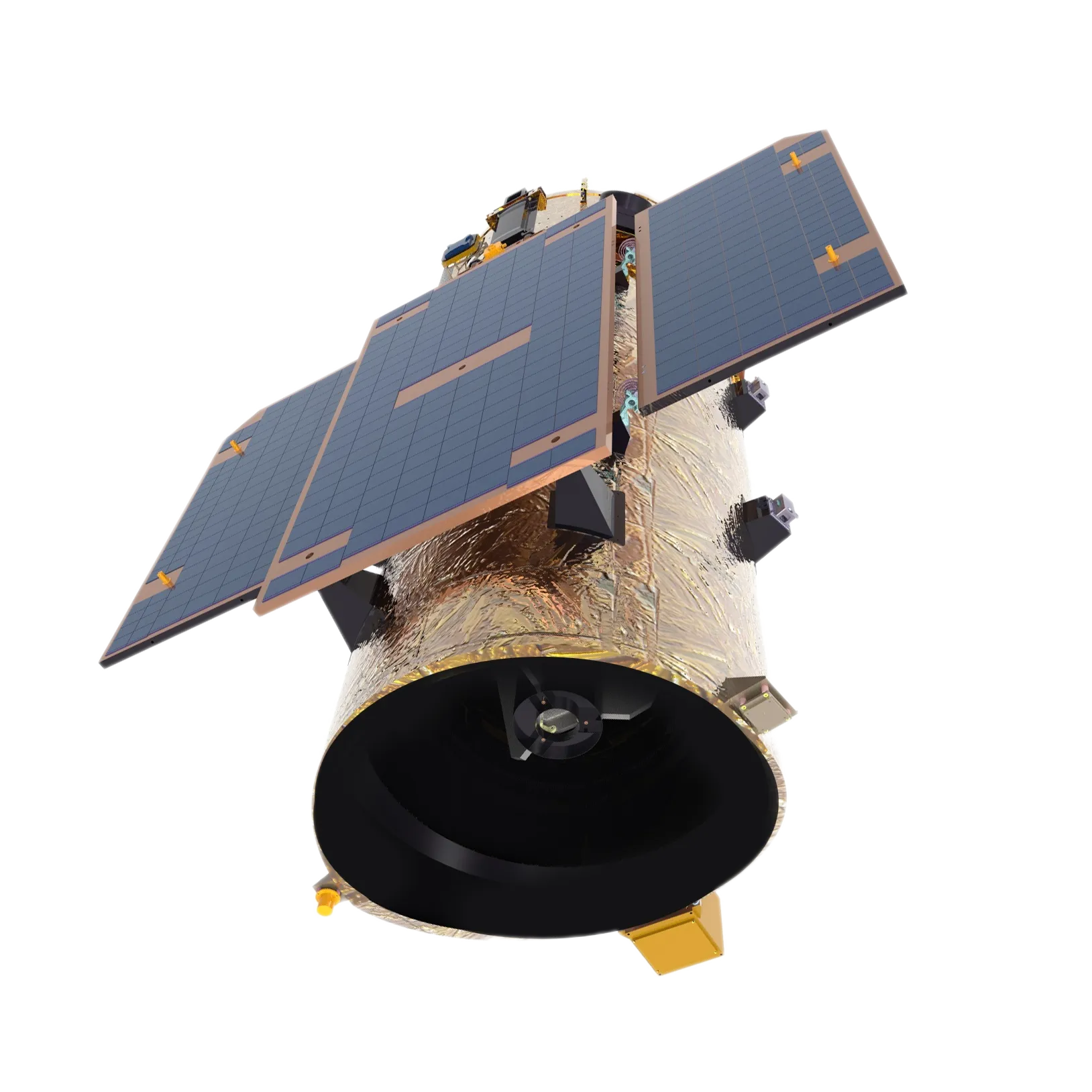

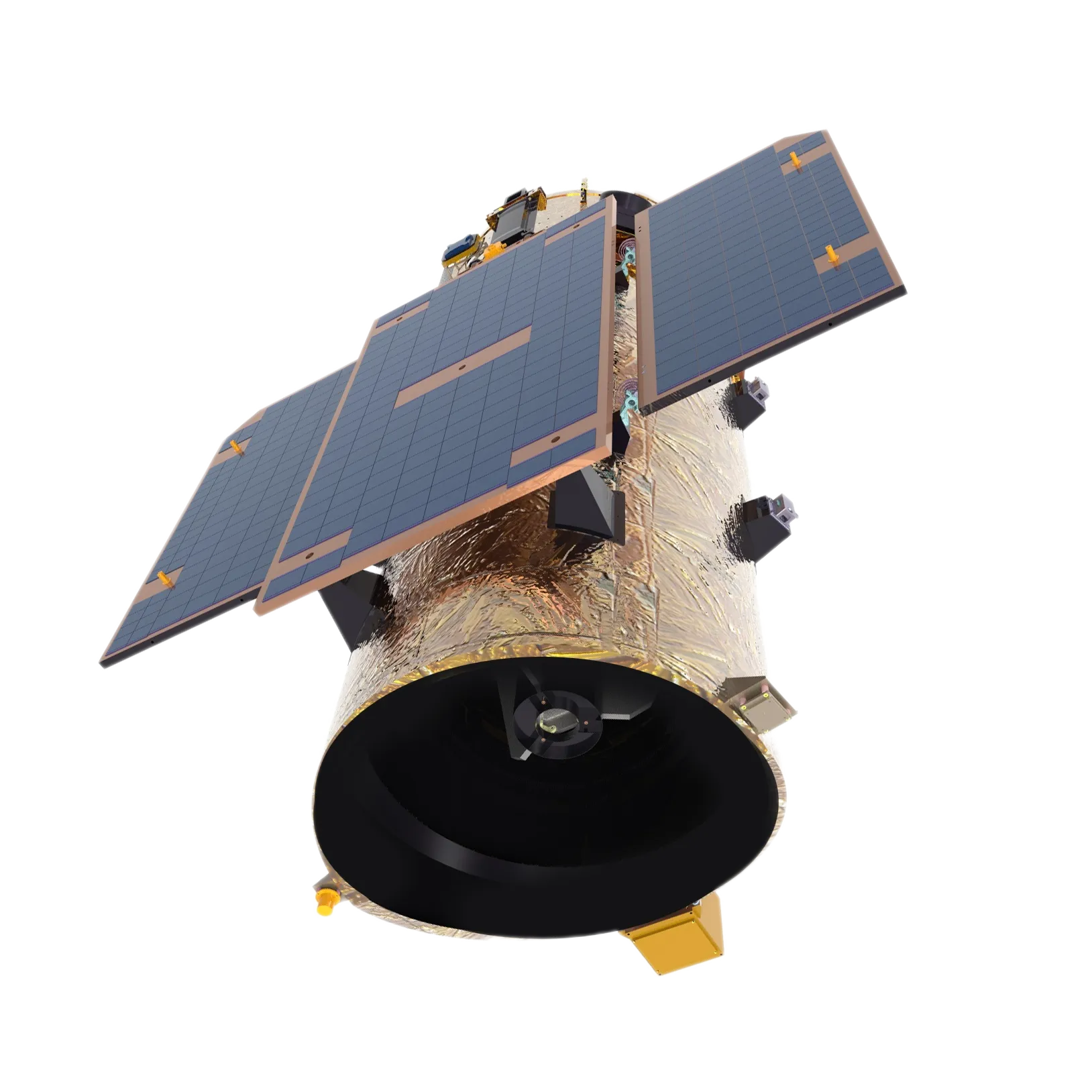

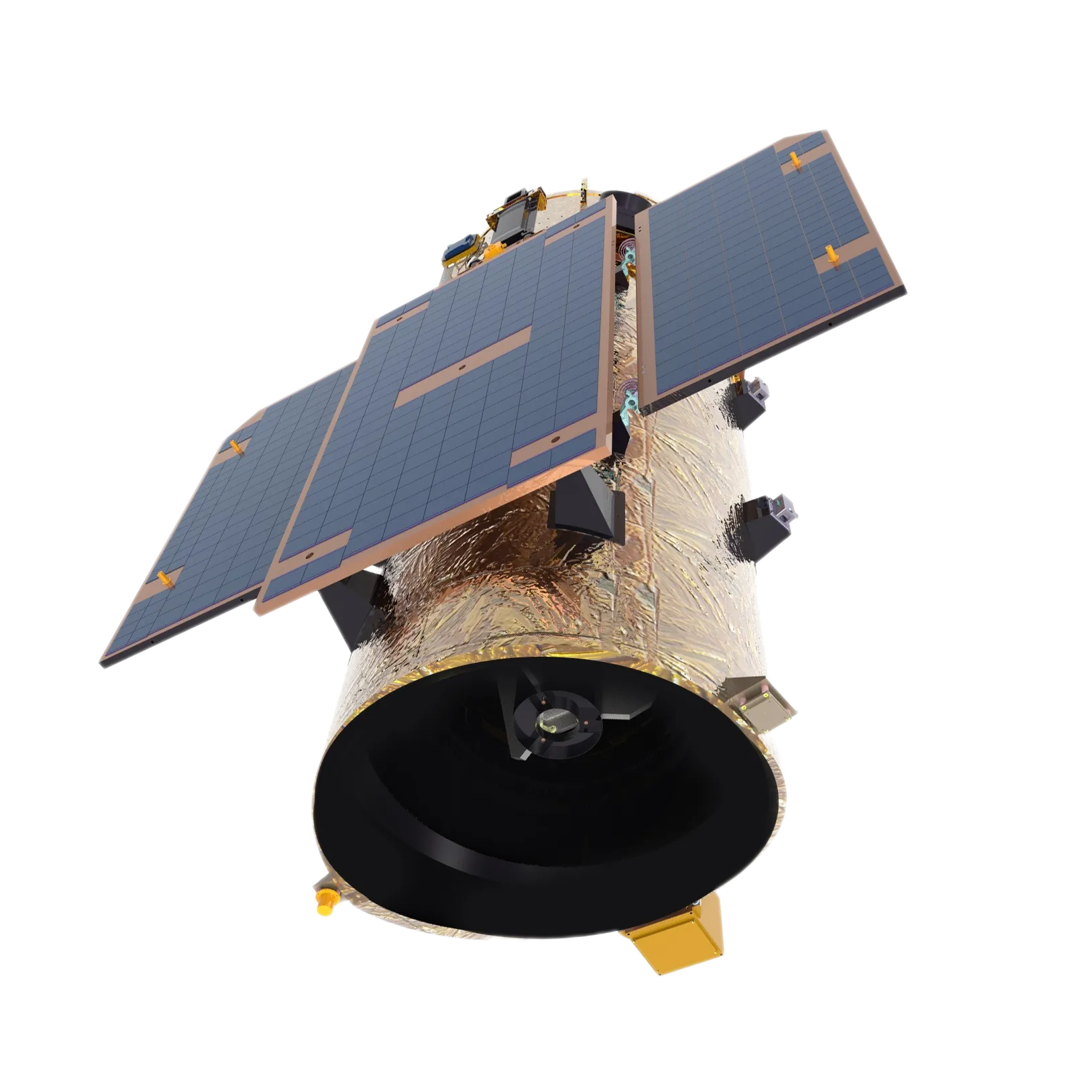

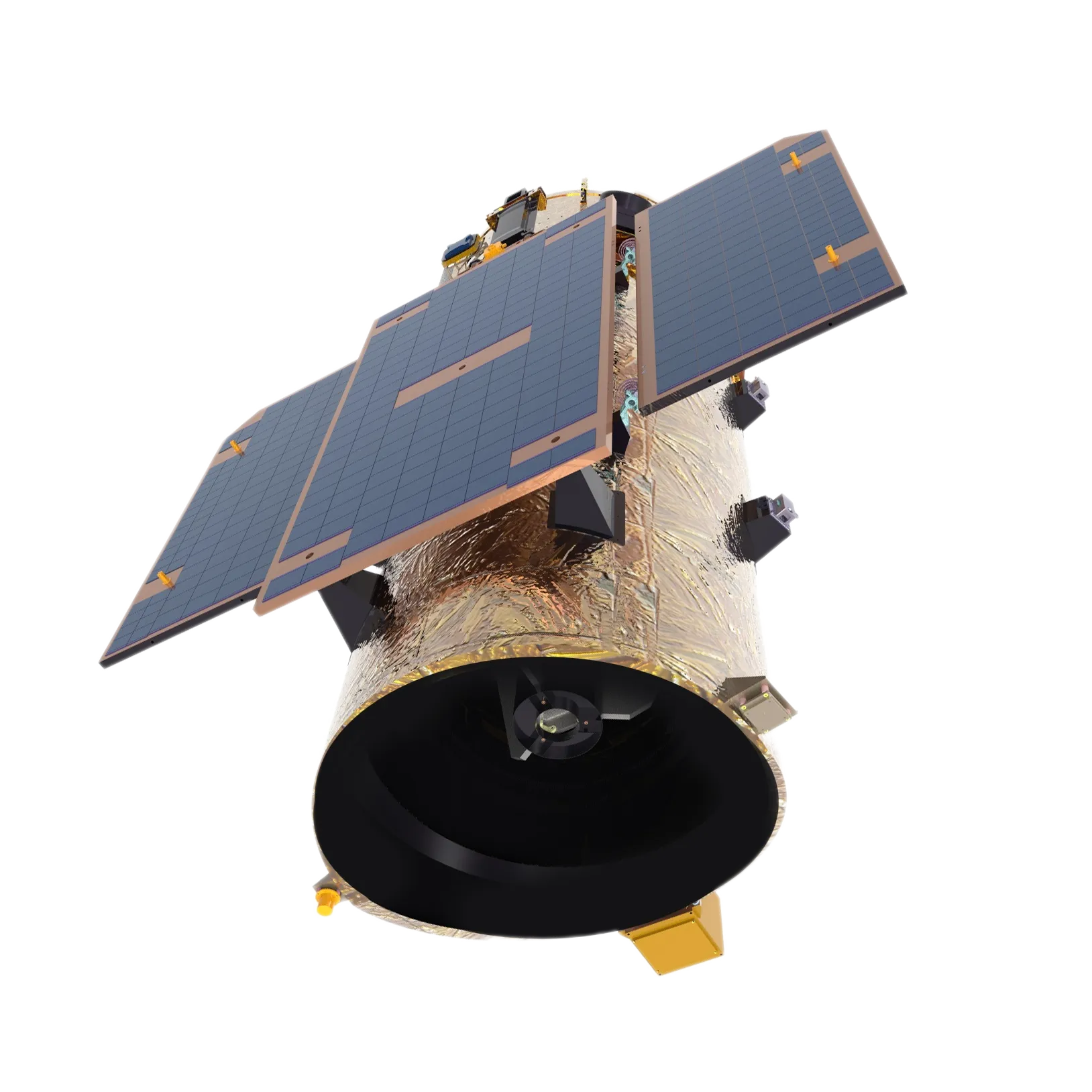

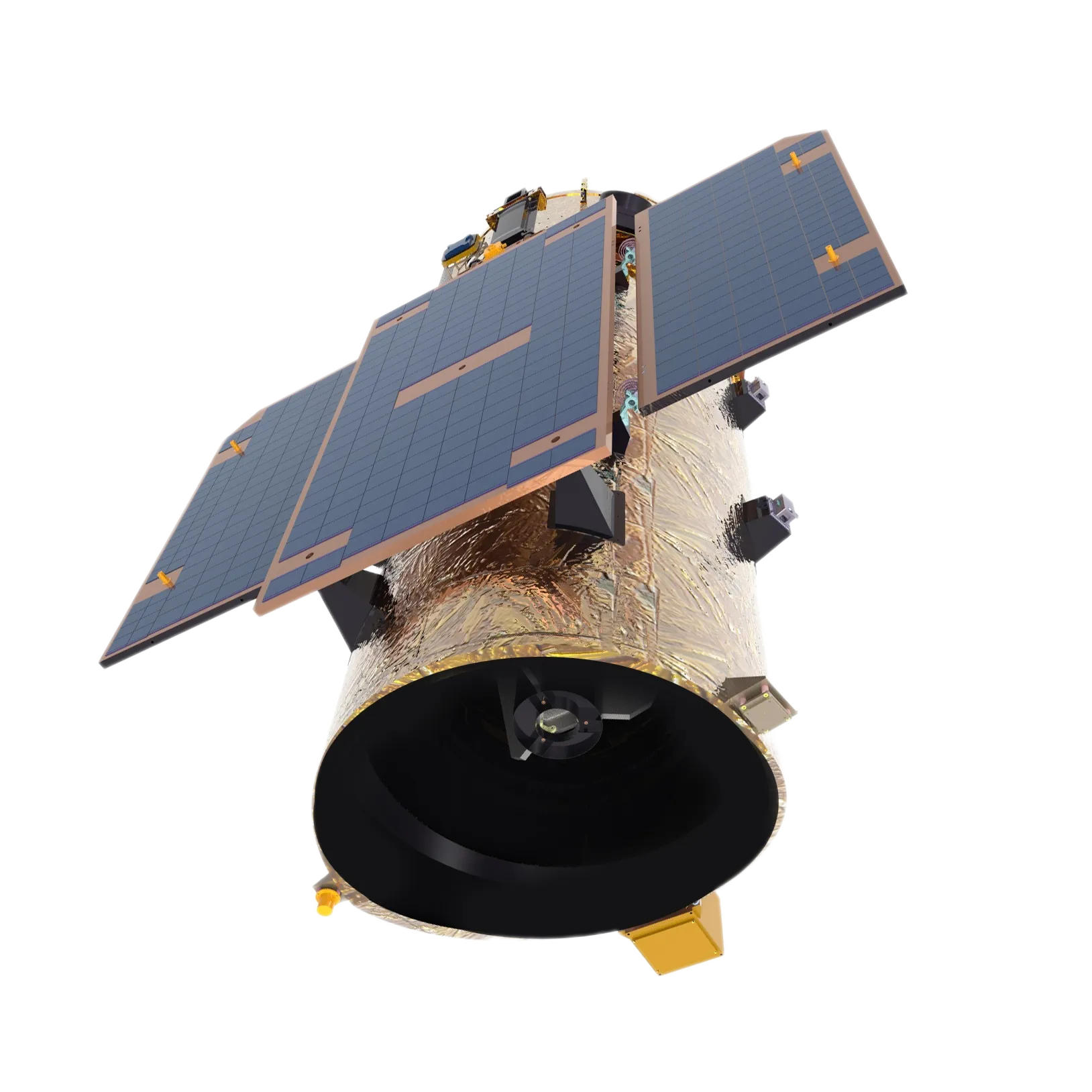

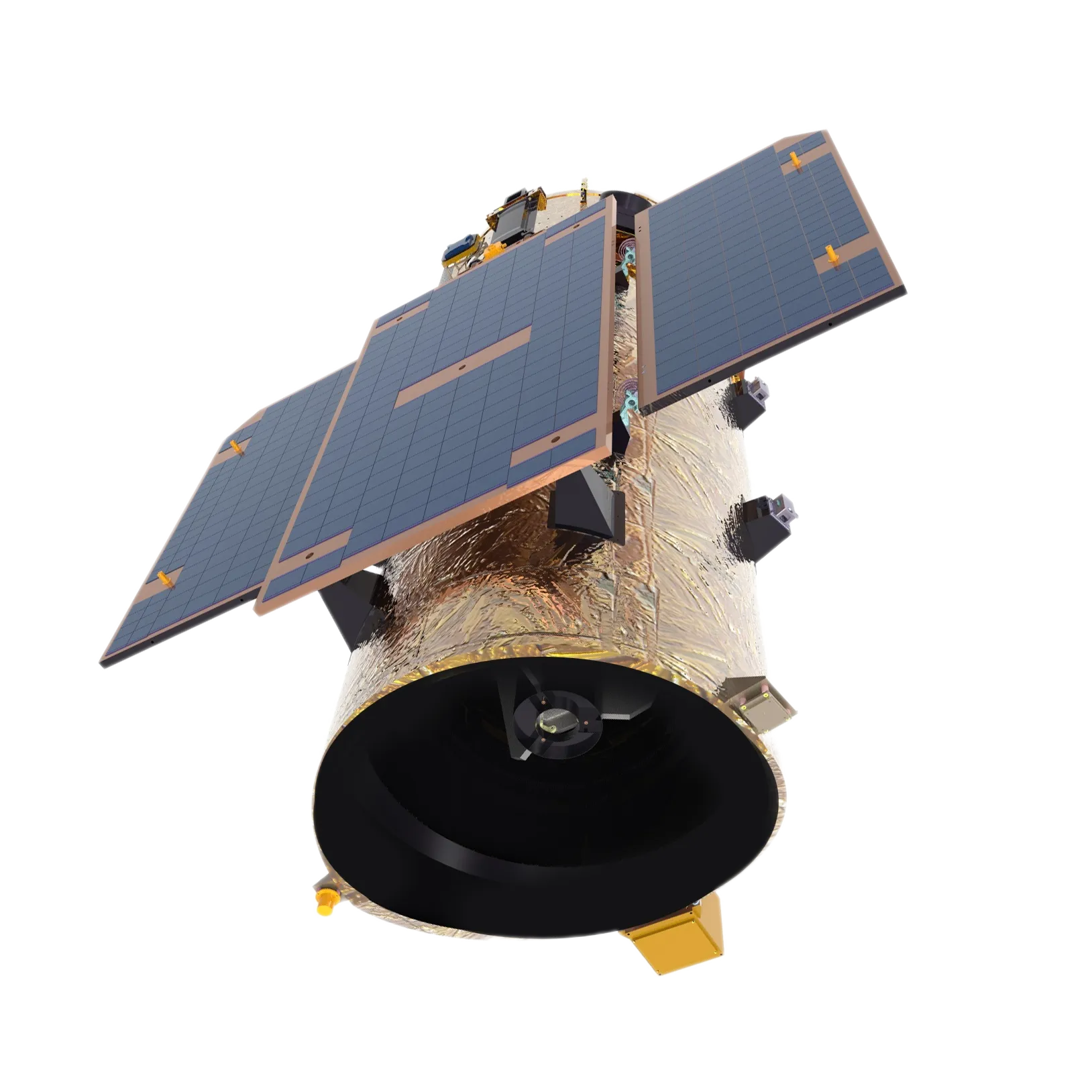

Expert Systems Integration & Testing for LEO Satellite Solutions

Did you know 43% of satellite projects exceed budgets due to poor integration planning? As low earth orbit systems become 68% more complex since 2020, seamless assembly and testing separate industry leaders from costly failures. Discover how next-gen integration solutions slash deployment risks while boosting ROI.

(systems integration)

The New Gold Standard in Satellite Systems Integration

Our modular integration platform delivers 99.7% test accuracy – 3X better than industry averages. See how we transform satellite assembly:

- 72-hour end-to-end system validation cycles

- AI-powered anomaly detection (98.4% success rate)

- 30% faster payload integration vs. legacy methods

Head-to-Head: Integration Platform Comparison

| Feature | Legacy Systems | Our Solution |

|---|---|---|

| End-to-End Testing | ✗ Partial | ✓ Full Coverage |

| Cost per Assembly | $2.1M | $1.4M |

Your Custom Integration Roadmap

Whether deploying 12-unit cubesats or 500kg LEO platforms, our configurable solutions adapt to your needs:

Rapid Deployment Package

90-day satellite integration

Includes thermal-vacuum testing

24/7 mission support

Ready to Dominate LEO Markets?

Join 140+ satellite operators who reduced integration costs by 35%+

20 years expertise | 98% client retention | ISO 9100 certified

(systems integration)

FAQS on systems integration

Q: What is systems integration in the context of low Earth orbit satellite systems?

A: Systems integration involves combining subsystems like propulsion, communication, and power into a functional satellite. For LEO satellites, it ensures compatibility with ground stations and orbital requirements. This process minimizes risks during deployment and operation.

Q: How does assembly, integration, and testing (AIT) improve satellite reliability?

A: AIT validates subsystem interoperability and identifies defects early. Rigorous testing simulates space conditions like radiation and thermal cycles. This reduces mission failures and extends satellite lifespan in harsh environments.

Q: What challenges arise during integration of low Earth orbit satellite systems?

A: Key challenges include managing weight constraints while ensuring radiation hardening. Synchronizing communication systems with rapidly changing orbital positions adds complexity. Environmental testing must also replicate microgravity and atomic oxygen exposure.

Q: Why is systems integration critical for satellite constellation deployments?

A: Integration ensures uniform performance across hundreds of interconnected satellites. It standardizes interfaces for scalable manufacturing and orbital coordination. Proper integration prevents signal interference and maintains constellation positioning accuracy.

Q: What specialized tests are used for LEO satellite systems integration?

A: Common tests include vibration testing for launch survivability and thermal vacuum cycling. Electromagnetic compatibility (EMC) testing prevents signal interference. End-to-end mission simulations validate ground-space system interactions before launch.