- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

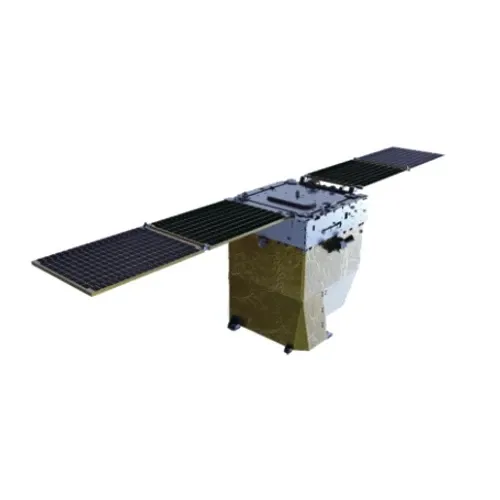

Satellite Parts: Comprehensive Guide to Components, Kits, and Installation Essentials

The world of satellite parts is vast and multifaceted, encompassing everything from basic structural modules to complex propulsion systems and precision communication hardware. Whether you are an aerospace engineer, a university researcher, or an amateur enthusiast, understanding the various types of satellite parts is essential before embarking on a project. The category includes individual satellite component modules for different functions, complete satellite fuel system assemblies for maneuvering and station-keeping, specialized satellite installation parts for assembly and mounting, and precise satellite antenna components that handle data transmission. For those building or upgrading antennas, satellite antenna parts are critical for achieving strong, stable connections. In addition, a satellite kit provides a convenient way to acquire multiple satellite parts in one package, while satellite dish parts are vital for receiving and processing signals in ground-based systems. Given the specialized nature of these parts, purchasing them from trusted sources and ensuring compatibility with your existing setup is crucial. This comprehensive guide aims to explain each major category of satellite parts, offer advice on purchasing and installation, and provide insights into maintenance and replacement strategies for long-term reliability.

Identifying the Right satellite component for Your Needs

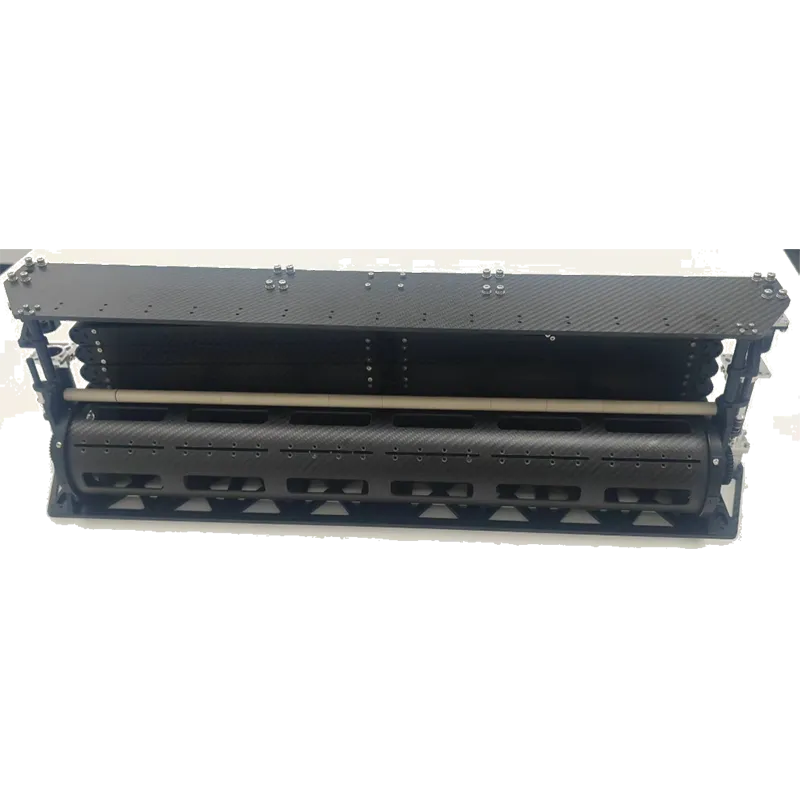

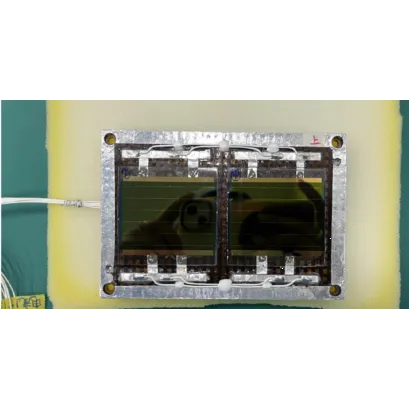

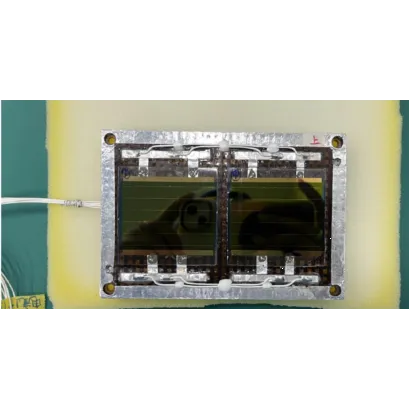

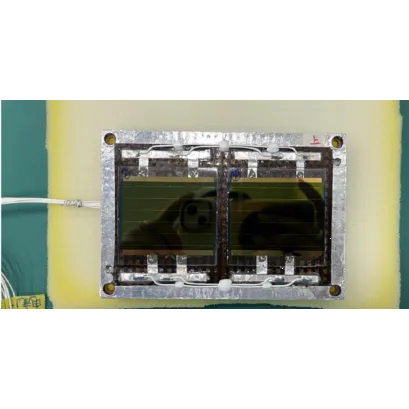

Choosing the correct satellite component begins with a clear understanding of your mission or application. For space-bound projects, each satellite component must be designed to withstand the harsh environment of space, including radiation, extreme temperatures, and mechanical stress during launch. Common satellite parts in this category include structural frames, power distribution units, thermal control systems, and data handling equipment. For propulsion needs, the satellite fuel system is one of the most critical subsystems, as it determines the satellite’s ability to adjust its orbit and maintain position. On the ground, satellite installation parts such as brackets, mounts, and fasteners ensure that the satellite or its support structures are securely positioned. Communication applications depend heavily on satellite antenna components, which can include reflectors, feeds, and waveguides, along with satellite antenna parts like mounting poles, alignment screws, and protective covers. For those in training or working on educational projects, a satellite kit can serve as a cost-effective introduction to satellite technology by bundling together various satellite parts for assembly and testing. Even seemingly minor elements such as satellite dish parts—which include the parabolic dish, LNB, and signal cables—are critical to achieving optimal reception and data transmission. Identifying the correct satellite component involves balancing technical specifications, environmental requirements, and cost considerations to ensure a seamless fit with the overall system.

Proper Use and Maintenance of satellite fuel system and Related Parts

The satellite fuel system is a specialized set of satellite parts responsible for storing, regulating, and delivering propellant to the satellite’s thrusters. In orbital missions, the satellite fuel system is essential for maneuvering, avoiding collisions, and maintaining a stable orbit. These systems include tanks, valves, piping, and control electronics, all of which must be compatible with the specific type of propellant used. When sourcing a satellite component for propulsion, it is critical to ensure that materials and construction methods meet strict aerospace safety standards. Maintenance of the satellite fuel system is usually performed before launch, but ground-based simulation and testing can verify that all satellite parts are functioning correctly. Additionally, the installation process often requires highly specialized satellite installation parts to secure tanks and valves within the satellite’s frame. For communication systems, satellite antenna components must be carefully positioned so they are not obstructed by the satellite fuel system or its mounting structures. In educational kits, a simplified satellite kit may include a mock satellite fuel system to help learners understand the principles without handling hazardous materials. Similarly, when working with satellite dish parts for ground communication, the positioning of the dish should account for any interference caused by the satellite’s propulsion structures in simulation setups. Ultimately, proper maintenance and integration of the satellite fuel system with other satellite parts is key to ensuring mission success and extending operational life.

Sourcing and Installing satellite antenna parts and Dish Components

The process of sourcing and installing satellite antenna parts begins with determining the intended frequency range, gain requirements, and environmental conditions. For space missions, satellite antenna components must be lightweight yet durable enough to survive launch stresses and operate in a vacuum. Ground-based systems require satellite antenna parts that can endure wind, rain, and temperature fluctuations while maintaining precise alignment. The installation of these parts often involves specialized satellite installation parts such as mounts, brackets, and adjustment mechanisms that allow for fine-tuning antenna orientation. A well-assembled satellite kit may include both satellite antenna parts and basic satellite dish parts, making it easier for users to practice setup and alignment. In professional settings, each satellite component used in the antenna system must be tested for impedance matching, minimal signal loss, and resistance to corrosion. The satellite dish parts, including the parabolic reflector, feed horn, and LNB, work in conjunction with satellite antenna components to capture and transmit signals effectively. Installation accuracy is critical; even a slight misalignment of satellite antenna parts can result in significant performance loss. Regular inspection and timely replacement of worn or damaged satellite parts help maintain system efficiency. For buyers, sourcing satellite parts for sale from reputable suppliers ensures that the antennas and dishes function optimally over the long term, delivering reliable communication whether in orbit or on the ground.