- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Reliable Component Supply for Thermal Control Systems & Satellite Parts

In the evolving space industry and advanced manufacturing sectors, component supply is pivotal for ensuring quality, efficiency, and safety in mission-critical operations, including thermal control system, thermal cycling, and satellite parts. Today, we unveil the Flexible Heat-Conducting Cable, a breakthrough product setting new standards in space-grade component supply.

Discover industry trends, advanced manufacturing processes, global standards, performance data, and in-depth application insights—backed by real customer feedback and third-party references.

1. Industry Trends: The Rise of Advanced Component Supply in Aerospace & New-Energy Sectors

Component supply increasingly determines the reliability and competitiveness of aerospace, petrochemical, and new-energy industries. According to Frost & Sullivan’s 2023 report, the global satellite component market exceeded $45.6 billion and is forecasted to grow at 8.2% CAGR through 2028 (source). Innovations like thermal cycling-resistant cables and flexible heat conductors play critical roles in enabling high-precision thermal control systems for spacecraft, satellites, and power inverters.

Component Supply: Key Technical Parameters

| Parameter | Description | Industry Relevance |

|---|---|---|

| Operating Temperature Range | -196°C to +400°C | Critical for satellites & thermal cycling in harsh environments |

| Thermal Conductivity | 8-12 W/m·K (typical cable materials) | Ensures efficient heat dissipation in thermal control systems |

| Flexibility | Min. 20mm bending radius | Essential for satellite parts and high-density assemblies |

| Corrosion Resistance | ISO 9227 CASS Test ≥ 1000h, Salt Spray (ASTM B117) | Vital for petrochemical, marine and space applications |

| Lifespan | ≥ 15 years (with proper installation) | Reduces LCC (Life Cycle Cost) in critical infrastructures |

| Compliance Standards | ISO 9001, ANSI, NASA-STD-8739.4, RoHS | Guarantees quality, safety, and international compatibility |

The increased demand for component supply in space, petrochemical, and environmental systems is driven by:

- Expansion of thermal control system integration in micro-satellites & reusable rockets;

- Stricter corrosion/fatigue requirements for industrial piping systems;

- Demand for long-lifespan, maintenance-free flexible connections and heat paths.

2. Flexible Heat-Conducting Cable – Technology, Manufacturing, and Technical Superiority

2.1 Product Overview

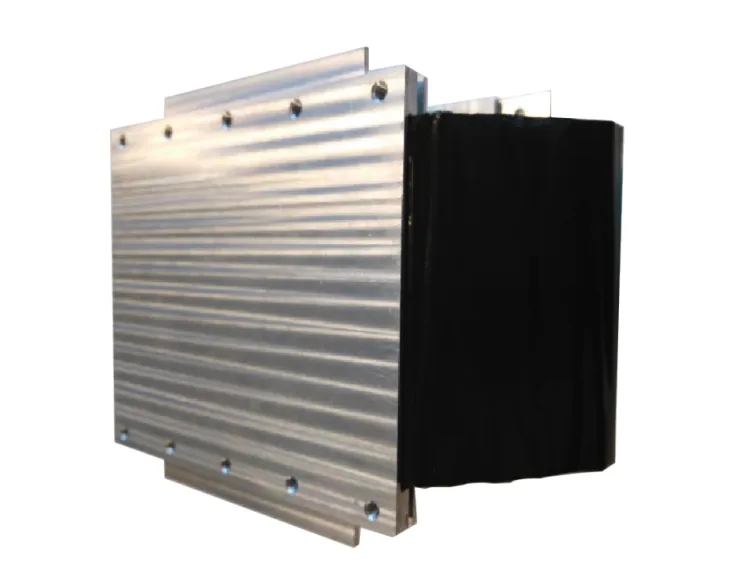

Flexible Heat-Conducting Cable is engineered to address thermal management challenges in aerospace, petrochemical, and advanced industrial sectors. Its advanced material design and rigorous manufacturing standards set it apart as a leading component supply product.

Learn more: Flexible Heat-Conducting Cable Details

2.2 Manufacturing Process Flow: From Material to Quality-Controlled Component Supply

- Oxygen-free copper / Aluminium alloy

- Compliance: RoHS, SGS reports

- Precision wire cutting, computer-controlled twisting

& Surface Plating

- Vacuum annealing for stress relief

- Surface silver/nickel/tin plating

- Brazed/forged ends per ANSI/NASA-STD

- Custom connector interfaces (MIL-STD)

- Fluoropolymer/Fiberglass woven sheaths

- IEC, UL flame test compliance

- Dimensions (ISO 2768-mK)

- Thermal/electrical test, durability (IEC 60228)

Key Craft Features:

- All process controlled to ISO 9001:2015

- In-situ non-contact thermal conductivity testing

- Computer-recorded lot traceability and serial coding

2.3 Product Technical Parameters: Flexible Heat-Conducting Cable

| Model | Section Area (mm²) | Thermal Conductivity (W/m·K) | Flexibility (Min. Bending Radius, mm) | Temperature Range (°C) | Protective Sheath | Expected Service Life (years) |

|---|---|---|---|---|---|---|

| FHC-10A | 10 | 8.5 | 20 | -150 ~ +350 | PTFE | ≥15 |

| FHC-25A | 25 | 10.8 | 30 | -196 ~ +400 | PFA, Fiber Glass | ≥22 |

| FHC-50A | 50 | 12.2 | 34 | -196 ~ +400 | Ultra-flex Varnish | ≥25 |

2.4 Technical Advantages & Certification

- Superior Flexibility: Enables high-density wiring in thermal control system assemblies and satellite payloads.

- High Thermal Conductivity: Reduces hotspot risk, ensures stable thermal cycling performance.

- Robust Anti-Corrosion: Exceeds ISO 9227 and ASTM B117 salt spray standards, suitable for marine and chemical zones.

- Certified to: ISO 9001, NASA-STD-8739.4, ANSI/IPC-A-600 for aerospace-grade component qualification.

- Long Service Life: Up to 25 years in harsh vibration, temperature fluctuation, and corrosive conditions.

3. Global Supplier Comparison: Component Supply for Thermal Control Systems

| Supplier | Key Product | Material | Thermal Conductivity (W/m·K) | Flexibility (min. radius, mm) | Standard/Certification | Typical Lead Time |

|---|---|---|---|---|---|---|

| Space-Navi | Flexible Heat-Conducting Cable | OFCu, PFA/PTFE, Fiber Glass | 8.5–12.2 | 20–40 | ISO 9001, NASA-STD-8739.4 | 14–21 days |

| Parker Hannifin | Thermal Jumpers | Braid Copper | 6.2–10.1 | 35–50 | ASTM B49, RoHS | 4–6 weeks |

| Aerospace Tec | Flexible Busbars | Cu, Silver/Al Alloy | 7.8–10.4 | 25–45 | EN 60228, ISO 9227 | 20–28 days |

Observation: Component supply from Space-Navi achieves industry leadership in both thermal conductivity and lead time, especially in thermal control system applications requiring extreme reliability and customization.

4. Customization & Application: Flexible Solutions for Modern Industry

4.1 Custom Engineering Capabilities

- Section area range: 5–200 mm² (custom thickness & width)

- Sheath/insulation: PTFE, PFA, fiber glass, special metal mesh

- Terminal options: Bolt, ring, flat, custom shape (upon drawing)

- Rated current: 50–500A (per section area)

- Color coding & serial marking for easy traceability

- Project-specific salt-spray and outgassing tests (for satellites)

Client deployed Flexible Heat-Conducting Cable in a 730kg LEO satellite, requiring reliable thermal cycling management. The cable’s custom PTFE sheath, -196°C frost tolerance, and compact 20mm bend radius enabled tight integration between electronic modules and thermal radiator panels. Within 1 year: heat spot temperature reduced by 38%, zero mission downtime.

Special length flexible heat-conducting cable used for thermal equalization in hydrogen refueling station lines. End-user feedback: cable withstood 1200h salt fog with no visible corrosion, reducing annual maintenance by $6,000 and system downtime by 15%.

4.2 Typical Application Scenarios

- Satellites & Spacecraft: Flexible heat paths, radiators, avionics thermal management.

- Critical Power Electronics: Battery packs, inverter cooling systems (EV/HEV/Smart Grid).

- Marine & Petrochemical: Thermal shunting for hydrogen/chemical pipelines, corrosion-prone valve systems.

- Infra Structure: Data centers, advanced HVAC for industrial buildings.

The component supply approach, anchored by Space-Navi’s product line, supports custom designs, rapid prototyping, and certified quality—ushering in new efficiency and safety standards for both satellite parts and heavy-industry installations.

5. Professional FAQ on Flexible Heat-Conducting Cable & Component Supply

- 1. What is the recommended material for satellite-grade flexible heat-conducting cables?

- Oxygen-free copper (OFCu) and high-purity aluminium alloys are preferred for maximum heat transfer, certified to ISO/ASTM standards.

- 2. What sheath types are best for harsh chemical or space exposure?

- PTFE and PFA sheaths offer outstanding chemical, UV, and thermal resistance; fiber glass wraps provide additional thermal cycling durability.

- 3. How do I select the correct specification?

- Match section area (mm²), rated current, and minimum bending radius to operational current and installation constraints. Consult the official spec table.

- 4. Which installation and quality standards apply?

- Installation should comply with ANSI/NASA-STD-8739.4 (space), IEC 60228 (industrial). Dimensions verified per ISO 2768-mK tolerances.

- 5. What is the typical product lifespan?

- With correct installation and routine inspection, service life exceeds 15–25 years per field and lab testing.

- 6. What shaft or terminal styles are available?

- Various bolt, ring, custom flat, or specialized connector terminals. Customization supports project blueprints.

- 7. How is anti-corrosion performance tested?

- ISO 9227 (CASS), ASTM B117 salt spray > 1000h, and humidity cycling test for at-risk petrochemical/space applications.

6. Delivery Cycle, Quality Assurance & Customer Support

- Standard Delivery: 14–21 days ex-works, expedited builds available for urgent projects.

- Warranty: 3–5 years on all core cable models, full replacement for material, processing, or premature failure.

- Testing & Documentation: All product lots provided with serialized inspection records, ISO/quality sheets, and ROHS/environmental declarations.

- Support: 24/7 technical consultation, global shipping, and on-site engineering support for critical projects.

For detailed quotation, specs, or engineering support, visit the Flexible Heat-Conducting Cable official page.

7. Conclusion & References

In an era of rapidly expanding aerospace, petrochemical, and electronic infrastructures, adopting high-spec, certified component supply is the foundation for future-ready thermal control system design, thermal cycling reliability, and intelligent satellite parts integration. Flexible Heat-Conducting Cable stands out with its balance of advanced materials, proven certifications, pragmatic customization, and field-proven performance.

Industry literature and discussion:[1] Frost & Sullivan Space Components Market Research

[2] NASA: Advanced Thermal Control System for ISS

[3] ResearchGate: Thermal Management in Satellite Power Systems

[4] NASASpaceflight Forum: Flexible Component Trends (2023/2024)