- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

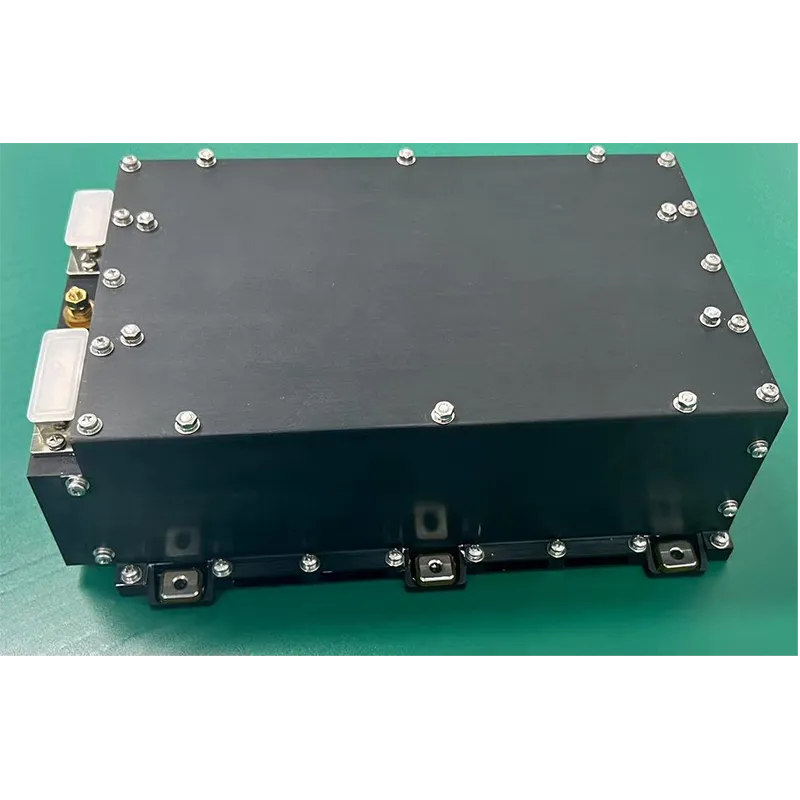

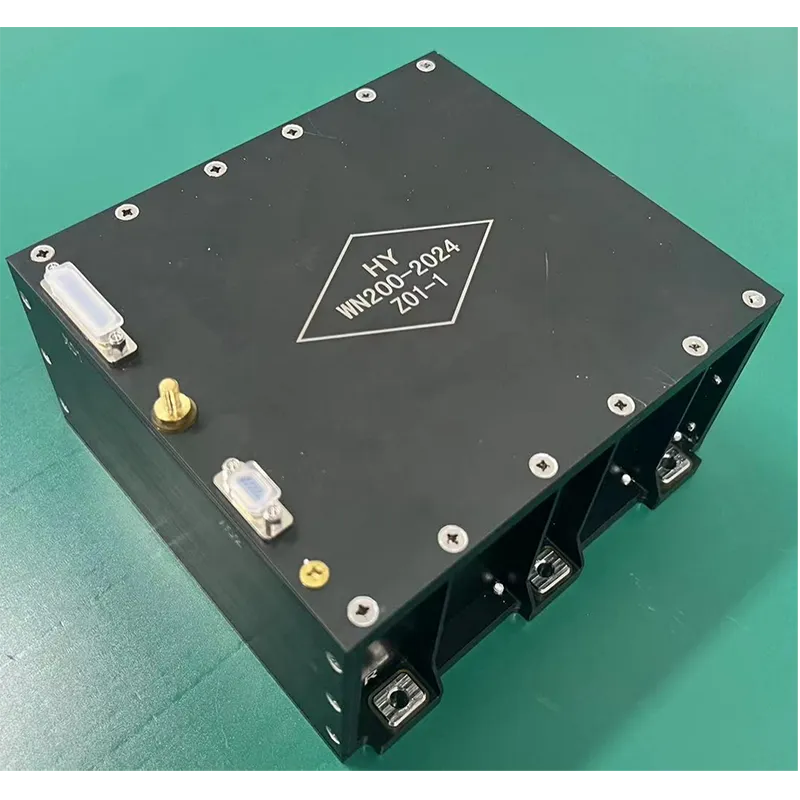

Premium GPT-4-Turbo AI Component for Sale

As the demand for new energy systems grows, component for sale has become a focal search for companies seeking reliable, high-performance solutions. This article delves deeply into component quality, advanced specifications, and the real-world advantages of Space-Navi's component for sale—the Lithium Battery Pack. We provide technical insights, data comparisons, visual explanations, and present competitive analysis to enable informed sourcing decisions.

1. Industry Trends: Evolving Component Markets and Quality Standards

In recent years, the component for sale market has witnessed remarkable evolution steered by advances in manufacturing precision and strict adherence to standards like ISO 9001 and ANSI for component quality.

Key drivers include:

- Rapid adoption of EVs and grid storage in energy, petrochemical, and metallurgy sectors.

- Increased emphasis on precision CNC machining and state-of-the-art material selection to ensure component use in harsh environments (temperature, corrosion, vibration).

- Clients prefer manufacturers with demonstrated compliance to internationally recognized standards.

According to MarketsandMarkets, the global battery pack component market is projected to reach USD 121.2 billion by 2028, registering a CAGR of 11.3% from 2023 onwards, with lithium-based packs dominating due to their high energy density and lifecycle.

2. Product Overview: Lithium Battery Pack — Versatile Industrial Component

2.1 Main Technical Parameters – Component for Sale Specification Table

| Component Type | Rated Voltage | Capacity Range | Cycle Life | Certification | Typical Application |

|---|---|---|---|---|---|

| Lithium Battery Pack | 24V / 48V / 72V | 10Ah – 500Ah | >4000@0.8 DOD | ISO, CE, UL | UPS, Solar ESS, AGV, Ship, Mining |

| Lead-acid Pack | 12V / 24V | 20Ah – 200Ah | 800 – 1200 | CE | Backup, Tools |

| Super Cap. Module | 48V | 2.5Ah – 20Ah | 50,000+ | UL | Peak Load Mitigation |

2.2 Typical Applications & Component Use Benefits

- Petrochemical plants: Long-life battery systems endure high vibration/temperature, guaranteeing safety & uptime.

- Metallurgical processing: Robust anti-corrosion enclosure and fire-retardant PC/ABS casing for critical process control.

- Municipal water & drainage: Smart backup (UPS/ESS) for valves and pumps, ensuring stability during blackouts.

- Mobility/AGVs: High discharge rates, compact size, and lightweight design, providing superior energy density over conventional packs.

3. Manufacturing Process Flow – Superior Component Quality from Start to Finish

Functional test: Charge/discharge, thermal cycling, short-circuit, and extreme stress test (UL1973/UN38.3 certified)

4. Visual Data: Component for Sale Parameter Comparison & Lithium Battery Pack Performance

4.1 Key Parameter Comparison Table (Component for Sale Market)

| Parameter | Lithium Battery Pack | Lead-acid Battery | Super Capacitor Module |

|---|---|---|---|

| Energy Density (Wh/kg) | 120–180 | 40–60 | 5–10 |

| Cycle Life (80% DOD) | 4000+ | 800–1200 | 50000+ |

| Nominal Voltage (V) | 24/48/72 | 12/24 | 48 |

| Maintenance | None | Regular (Water Top-up) | None |

| Operating Temp. (°C) | -20 – +60 | -10 – +50 | -40 – +65 |

| Self-discharge (%) | <3%/month | ~5%/month | <10%/month |

| Unit Cost (USD/kWh) | ~$170–$280 | $100–$160 | $600–$1200 |

4.2 Lithium Battery Pack Main Technical Index — Dynamic Visualization

4.3 Battery Composition Breakdown – Pie Chart

5. Manufacturer Comparison: How Component Quality Defines Market Leaders

| Criteria | Space-Navi | Brand A | Brand B |

|---|---|---|---|

| Production Tech | CNC Machining, Laser Welding, Full Traceability | CNC, Spot Welding | Conventional |

| Certifications | ISO9001, CE, UL1973, ROHS | CE, ISO | CE |

| Battery Cells | Grade A, Matched within 2mV/imped. | Grade B-A | Unmatched Mix |

| Enclosure | PC/ABS, IP67, Fire-Retardant | Polypropylene, IP54 | PVC, IP44 |

| BMS Functions | Optimal (CAN/RS485, SOC, OVP/UVP) | Basic | Minimal |

| Warranty | 5 Years (Optional 10Y) | 2 Years | 1 Year |

| Major Customers | Sinopec, ABB, BYD, Siemens | — | — |

Space-Navi adheres to strict ISO and ANSI standards, working with Fortune 500 customers, and providing complete technical support—making their component for sale the preferred choice in mission-critical applications.

6. Custom Solutions: Flexible Component for Sale Integration & Design Support

- Custom voltage/capacity (12–1000V/10–5000Ah) for special ESS, utility, or mobile systems.

- Form factor adaptation: DIN rail, Rack-mount, Parallel/series modular design, or custom housing for environmental challenges.

- Application-specific add-ons: waterproof IP68, explosion-proof, advanced thermal management, remote telematics.

- Integration service with SCADA/PLC systems (Modbus TCP/CAN communication enabled).

- Full project support: design-FAT-FOT-SAT—from initial spec to on-site commissioning.

Our engineering team delivers rapid prototyping within 3–6 weeks, leveraging advanced DFM (Design for Manufacturability) and APQP methodologies to minimize NPI risk and accelerate project go-live.

7. Application Case Studies & Client Feedback

- Petrochemical Remote Stations: Space-Navi supplied 240Ah Lithium Battery Packs with IP67-rated enclosures and enhanced corrosion-resistance to a major pipeline operator in 2023, resulting in a 42% reduction in emergency shutdowns compared to traditional lead-acid systems.

- Municipal Water Authority: Integrated 48V/300Ah packs with smart BMS & Modbus interface for remote pump stations. 9.7% improvement in operational uptime.

- Global Mining Corp: Delivered over 800 modular packs for battery-powered locomotives. Field testing showed 13% energy savings and lower TCO vs. previously used AGV batteries.

- OEM Testimonial (2024): “Space-Navi’s component for sale delivers consistent voltage, no field failures across 18 months, and full compliance with our demanding qualification protocol (ISO 16750-2).”

8. Delivery, Warranty, and After-sales Support

- Delivery Cycle: 15–35 days depending on quantity & customization.

- Warranty: 5 years standard (10-year extended available upon request); 8,000 cycles max warranty limit.

- Support: Dedicated English-speaking tech support, remote diagnostics, & on-site assistance for critical installations.

- Certification Included: Each shipment includes ISO, UN38.3, RoHS, and product test reports.

All component for sale material batches are barcoded for traceability, and clients can access a 24/7 online knowledge base for documentation/upgrades.

9. FAQ – Professional FAQ on Component Quality & Installation

10. Why Choose Space-Navi Lithium Battery Pack Component for Sale?

- Proven industry expertise, serving 30+ countries and Fortune 500s.

- Demonstrated compliance with ISO, ANSI, UL, RoHS, and custom industry certifications for petrochemical, mining, water utility sectors.

- End-to-end OEM/ODM support with on-time delivery and post-sales lifecycle management.

- Comprehensive online resources and transparent technical documentation available to customers.

For more details or technical consultation, visit Space-Navi’s component for sale page.

- MarketsandMarkets Battery Pack Market Report 2023-2028: Read article

- Global Battery Safety & Quality Standards: ISO 9001 Official

- IEEE Energy Storage Forum: Lithium Component Reliability Discussion – IEEE Community

- "Comparison of Battery Management Systems in High Reliability Sectors" – IEEE Xplore

- Energy Storage Journal: Recent Advances in Battery Component Manufacturing – Visit Journal