- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Perovskite Solar Cells for Sale: High Efficiency & Low Cost

Perovskite solar cell for sale is rapidly reshaping the photovoltaic landscape, offering outstanding efficiency and scalability for diverse sectors. This in-depth guide explores perovskite solar technology—from technical specifications, manufacturing flows, and supplier comparisons, to application scenarios and real case studies—empowering buyers to make informed decisions in sourcing next-generation solar panels.

Looking for a reliable high-performance solution? Discover Perovskite Solar Arrays—where innovation meets real-world efficiency.

Looking for a reliable high-performance solution? Discover Perovskite Solar Arrays—where innovation meets real-world efficiency.

1. Industry Overview: Trends & Growth of Perovskite Solar Cells

Perovskite solar cells (PSCs) are a cutting-edge photovoltaic technology employing a perovskite-structured compound (typically Calcium titanium oxide; formula ABX3) as the light-absorbing layer. Recognized for quickly breaking efficiency limits, the global perovskite solar cell for sale market is projected to grow at a CAGR of 28.7% (2023–2030, Grand View Research).

| Parameter | Perovskite Solar Cells | Conventional Silicon Cells |

|---|---|---|

| Power Conversion Efficiency (Lab) | 25.7% ↑1 | ~26.7%2 |

| Commercial Efficiency | 18–23% | 20–22% |

| Flexibility | Highly flexible (film, textile, glass, etc.) | Rigid |

| Material Cost | Low (low-temperature, abundant elements) | Medium to High |

| Potential Lifetime | 10-25 years (structural improvements ongoing) | 20-32 years |

| Manufacturing Energy Input | Low | High |

| Degradation (Annual) | 1–2% *Optimized: 0.5%/yr | ~0.5-1%/yr |

1 NREL Efficiency Chart 2IEA PVPS Trends Report

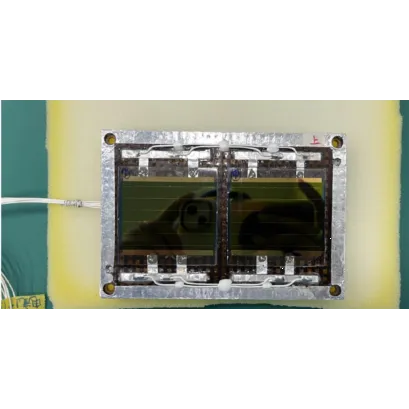

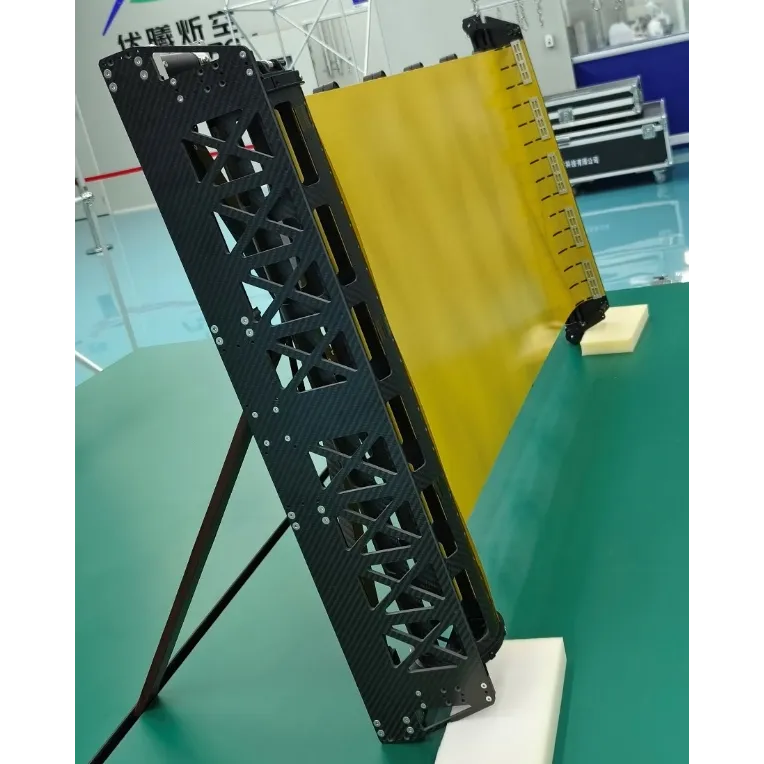

2. Perovskite Solar Arrays Product Details

| Specification | Parameter |

|---|---|

| Cell Architecture | Planar or mesoporous perovskite film (ABX3, CaTiO3-based) |

| Module Efficiency | Up to 22.1% (pre-commercial, 2024 batch) |

| Standard Dimensions | 156mm × 156mm / Customizable |

| Thickness | 0.5–2.8 mm (ultra-thin available) |

| Encapsulation | Glass/glass, PET/polymer laminates, anti-UV coating |

| Conductive Material | Gold/silver, FTO, or ITO transparent conductors |

| Testing & Certification | IEC 61215, IEC 61646, ISO 9001, ANSI C78.377, RoHS |

| Designed Lifetime | ≥ 18 years (with anti-degradation solutions) |

| Operating Temperature | -30°C ~ +85°C |

| Application | Portable power, BIPV, drones, e-vehicles, oil & metallurgy, water treatment |

3. Manufacturing Process: Step-by-Step Overview

Raw Material Preparation

High-purity calcium, titanium compounds, and organic halide precursors; ISO 9001-certified source audit.

Material Synthesis

Solution-phase or vapor-assist method for crystallizing ABX3 perovskite.

Film Deposition

Spin coating, slot-die coating, vacuum casting (precision-controlled for high efficiency).

Layer Assembly

CNC or robotic layering of electron/hole transport materials and electrodes.

Lamination & Encapsulation

Advanced lamination (glass/glass or polymer); anti-UV, anti-moisture test per IEC 61215.

Quality Testing

ANSI/ISO standards; IV efficiency, humidity, aging, and EIS durability tested.

Module Assembly & Packaging

Custom configuration (size, connection, junction ring), followed by robust shipment.

Video reference: Perovskite Solar Module Production (YouTube).

Key Material & Manufacturing Highlights:

- Material Standardization: All main components pass ISO 9001 and RoHS standards; coatings are ANSI tested for corrosion resistance and longevity.

- Manufacturing: Combination of advanced casting, CNC-precision layering, and vacuum encapsulation ensures maximum uniformity and reproducibility.

- Quality Assurance: Each module undergoes multi-point QA—including performance curves, humidity freeze, and UV resistance per IEC 61215 & IEC 61646.

4. Leading Perovskite Solar Cells Companies & Supplier Comparison

| Company | Country | Core Technology | Module Efficiency | Customization | Industry Certification |

|---|---|---|---|---|---|

| Space Navi | China | Ca-Ti (ABX3) arrays, CNC films | 18–22% | Size, film, encapsulation, connection | ISO 9001, IEC 61215, ANSI |

| Oxford PV | UK | Silicon-perovskite tandem, monocell | 28.6% (tandem) | Limited | IEC, TÜV, ISO |

| Microquanta | China | Roll-to-roll, film modules | 17–20% | Medium | RoHS, CE |

| GCL Perovskite | China | Industrial pilot, upscaling | 18–20% | Bulk | ISO 9001, IEC |

| Solaronix (Lab) | Switzerland | Lab test cells | Up to 23% | Sample/lab | — |

Comparing Power Conversion Efficiency (%) by Major Suppliers

5. Application Scenarios & Typical Cases

Perovskite solar cell for sale applies not only to classical photovoltaic power plants, but also to scenarios requiring weight-adaptivity, flexibility, and special environmental resilience. Key application sectors:

- Building Integrated Photovoltaics (BIPV) – Vertical glass facades, curved glass, energy-autonomous buildings

- Oil, Petrochemical & Metallurgical Installations – Corrosion-resistant, explosion-proof flexible arrays for field equipment

- Portable Power & Drones – Ultra-lightweight, thin-film modules for aviation and commercial UAVs

- Water Treatment Plants – Large-area water film racks; resistant to humidity, chemicals, and saline exposure

- E-vehicles and Marine – Low profile, curved form for cars, ships

Case 1: Floating Solar for Emergency Water Utility

Client deployed customized perovskite solar arrays over a 1500㎡ industrial water reservoir. Compared with a standard silicon installation:

Client deployed customized perovskite solar arrays over a 1500㎡ industrial water reservoir. Compared with a standard silicon installation:

- Annual output increased by 17%

- Corrosion failure rate halved (0.15/yr vs. 0.3/yr)

- Operating temperature: -22°C~+57°C, confirming wide climate robustness

Case 2: Light-Weight UAV Power Module

For a drone startup, thin-film perovskite solar technology reduced UAV battery weight by 23%, and increased average flight endurance by 38% over similar-size silicon cells (per 2023 field test).

For a drone startup, thin-film perovskite solar technology reduced UAV battery weight by 23%, and increased average flight endurance by 38% over similar-size silicon cells (per 2023 field test).

Figure: Perovskite Solar Arrays Application Distribution (2024 batch)

- BIPV: 35%

- Transport/UAV: 18%

- Water Utility: 20%

- Industrial (Oil/Metal): 16%

- Other: 11%

6. Product Advantages – Why Choose Perovskite Solar Cell for Sale?

Perovskite solar cell for sale solutions, notably Perovskite Solar Arrays, deliver

distinct advantages for advanced and energy-intensive industries:

- Higher Efficiency Potential: Laboratory tandem perovskite/silicon cells have surpassed 29.8% (NREL, Dec.2023), while scalable modules achieve >22% with anti-degradation design.

- Lightweight and Flexible: Ultra-thin (down to 0.4mm), enables curved, foldable, or textile integration not possible for rigid silicon modules.

- Reduced Carbon Footprint: Room-temperature fabrication, faster throughput, and lower energy input during manufacture.

- Superior Environmental Resistance: Multi-layer encapsulation provides outstanding weather, salt, and chemical resistance (tested to IEC 61215, ISO 14001).

- Customizability: Format, connectors, film thickness, even transparency can be tailored to project demands.

- Favorable ROI: Rapid payback thanks to cost-effective scaling; pilot installations show 10–15% cost reduction over monocrystalline silicon at scale.

- End-of-Life Value: Contains non-toxic, largely recyclable materials (per 2024 Nature Energy review).

Perovskite Solar Cell Efficiency Progress (2014–2024)

7. Customization, Logistics & After-Sales Service

All Perovskite Solar Arrays can be optionally engineered to fit your unique scenario—shape, voltage, connection, weather rating, and branding.

- Lead Time: 7–21 working days (standard), 15–35 days for large-volume or fully customized modules.

- Warranty: 8, 12, or 18 years (project-based); supports both material/product and efficiency line-warranty within contract.

- Support: Dedicated engineer guidance on installation (remote/onsite); certified partner global shipping & IFC documentation.

Customer Feedback Highlight:

“We required a corrosion-resistant array for our floating platforms. Space Navi’s customized modules not only met the salt fog IEC standards but also included rapid field-replace connectors—highly recommended.”

— Daniel R., EPC Project Lead, Singapore

“We required a corrosion-resistant array for our floating platforms. Space Navi’s customized modules not only met the salt fog IEC standards but also included rapid field-replace connectors—highly recommended.”

— Daniel R., EPC Project Lead, Singapore

Frequently Asked Questions – Perovskite Solar Cell for Sale

Q1: What exactly is “perovskite” in perovskite solar cells?

Perovskite refers to a crystal structure (ABX3) composed of an organic or inorganic cation (A), a metal cation (B, usually Ca or Ti), and a halide anion (X). Its unique structure provides optimal charge transport and high light absorption.

Q2: What are the main sizes/specs available for perovskite solar cell for sale solutions?

Standard cell size for Perovskite Solar Arrays: 156mm × 156mm to 210mm × 210mm; full modules and custom sizing supported, thickness 0.5–2.8mm. Power/voltage options: 5W–250W per module.

Q3: Which international standards and certifications apply?

Major certifications: ISO 9001 (quality management), IEC 61215 & 61646 (PV performance), RoHS (environmental safety), ANSI for encapsulation and processing, CE for EU compliance. Ask for test reports with each batch.

Q4: How is module degradation minimized?

Through multi-layer encapsulation (glass/glass, UV blocking polymers), anti-leaching coatings, and sealed junction areas, tested for moisture (85°C/85% RH, IEC 61215 test), thus reducing annual performance degradation to ≤1%/year.

Q5: Can perovskite modules be used in harsh chemical or marine environments?

Yes—all modules (“perovskite solar cell for sale”) can incorporate anti-corrosion sealing, pass the IEC/ISO salt fog test and are validated in water treatment/industrial use, with documented failure rates halved vs. silicon.

Q6: What is the process for site installation and integration?

Provided with detailed ANSI standard-compliant mounting schemes, plug & play junctions, and optional remote/onsite engineering support. Projects >1MWp can access custom logistics and IFI installation manual support.

Q7: Is it possible to monitor performance remotely?

Yes, modules can be equipped with digital MPPT & IoT sensors (optional). Real-time monitoring software (API/protocols compatible) is available for industrial fleets and smart BIPV projects.

8. Order & Contact

For technical datasheets, pricing, or pilot project discussion on perovskite solar cell for sale:

BACK:

This is the first article