- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

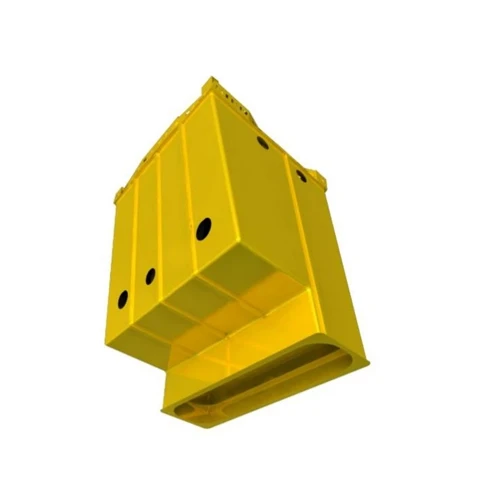

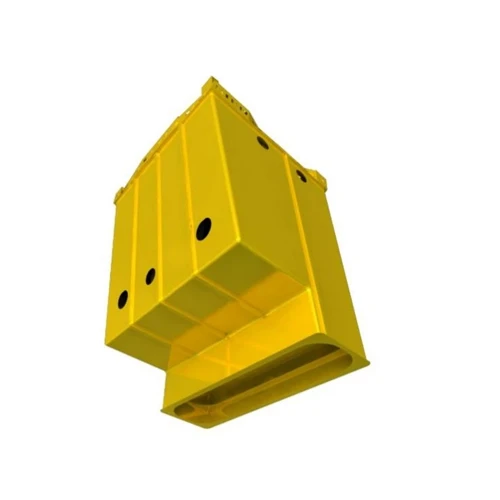

Optimizing Electronics Manufacturing Through Quality Components and Efficient Sub Assembly

In the rapidly evolving electronics industry, the quality of individual parts and the efficiency of assembly processes play a critical role in delivering superior products. Focusing on component quality, component material, and streamlined sub assembly procedures is essential for manufacturers to meet growing demands for reliability and performance. Key elements such as processing devices of computer, component cables, and connectivity solutions like component to HDMI require careful selection and integration. Robust component supply chains and trusted component OEM partnerships further support production excellence and innovation.

Importance of Superior Component Material and Quality

Selecting premium component material is fundamental to achieving high component quality. Components made from durable metals, advanced polymers, and corrosion-resistant coatings withstand harsh operational environments and maintain signal integrity. For instance, high-quality component cables ensure reliable data and power transmission, which is crucial for the smooth operation of sensitive processing devices of computer. Rigorous quality control tests during the manufacturing and sourcing stages help prevent defects and enhance product longevity.

Enhancing Production Efficiency With Sub Assembly

Sub assembly is a strategic approach to manufacturing where components are pre-assembled into modules before the final product assembly. This method improves quality control by allowing early detection of faults and accelerates the production process. By partnering with experienced component OEM suppliers, manufacturers receive pre-tested, high-quality parts that fit precisely, reducing assembly errors and enhancing product reliability. This collaborative process also enables customization to meet specific market needs.

Connectivity Solutions: Component to HDMI and Beyond

Modern electronic devices demand versatile connectivity options. The use of reliable component to HDMI converters and premium component cables ensures seamless integration between legacy and current technologies. These components must meet strict standards to avoid signal loss and maintain high-definition video and audio quality. Maintaining a steady component supply of these critical parts allows manufacturers to keep pace with technological advances and consumer expectations.

Building Resilience Through Reliable Component Supply and OEM Partnerships

A dependable component supply chain is crucial for maintaining continuous production and avoiding costly delays. Collaborations with trusted component OEM partners guarantee access to high-quality, compliant components tailored to product specifications. These partnerships foster innovation and provide the flexibility to scale production according to market demands while ensuring consistent quality and regulatory adherence.

Conclusion

Achieving excellence in electronics manufacturing hinges on the integration of superior component quality, durable component material, efficient sub assembly techniques, and reliable component supply chains. Whether sourcing critical processing devices of computer, managing component cables, or incorporating component to HDMI solutions, attention to detail is key. Strong partnerships with experienced component OEM suppliers further enable manufacturers to deliver innovative, high-performance products that meet and exceed industry standards and customer expectations.