- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Optical Emission Spectrometers for Precision Metal Analysis & Testing

Did you know 1 faulty metal alloy batch can cost manufacturers $250,000 in recalls? While traditional testing methods leave 34% of quality control teams frustrated with slow results, modern optical emission spectrometer

s deliver laboratory-grade accuracy in 12 seconds flat. Discover how this game-changing technology solves your toughest material analysis challenges.

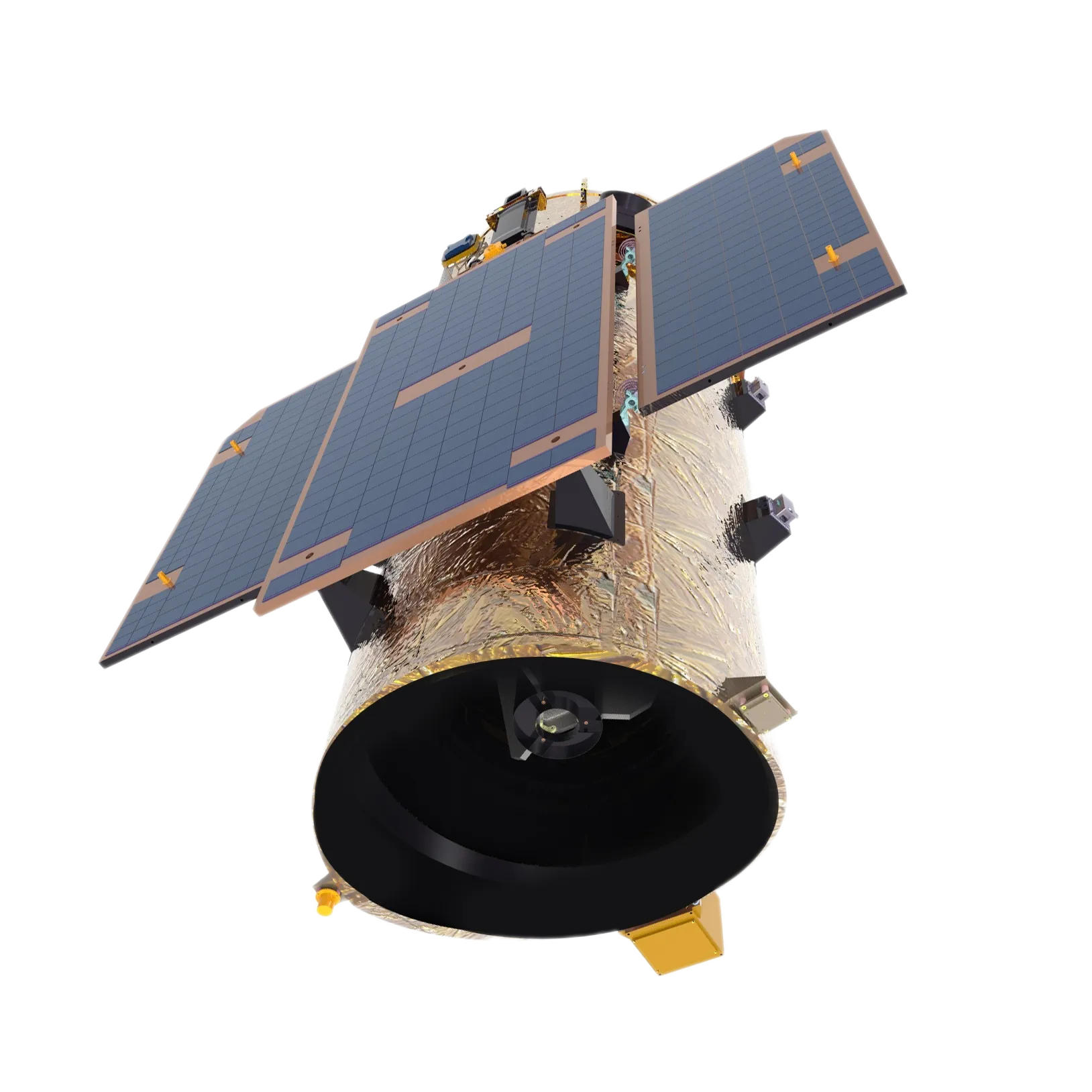

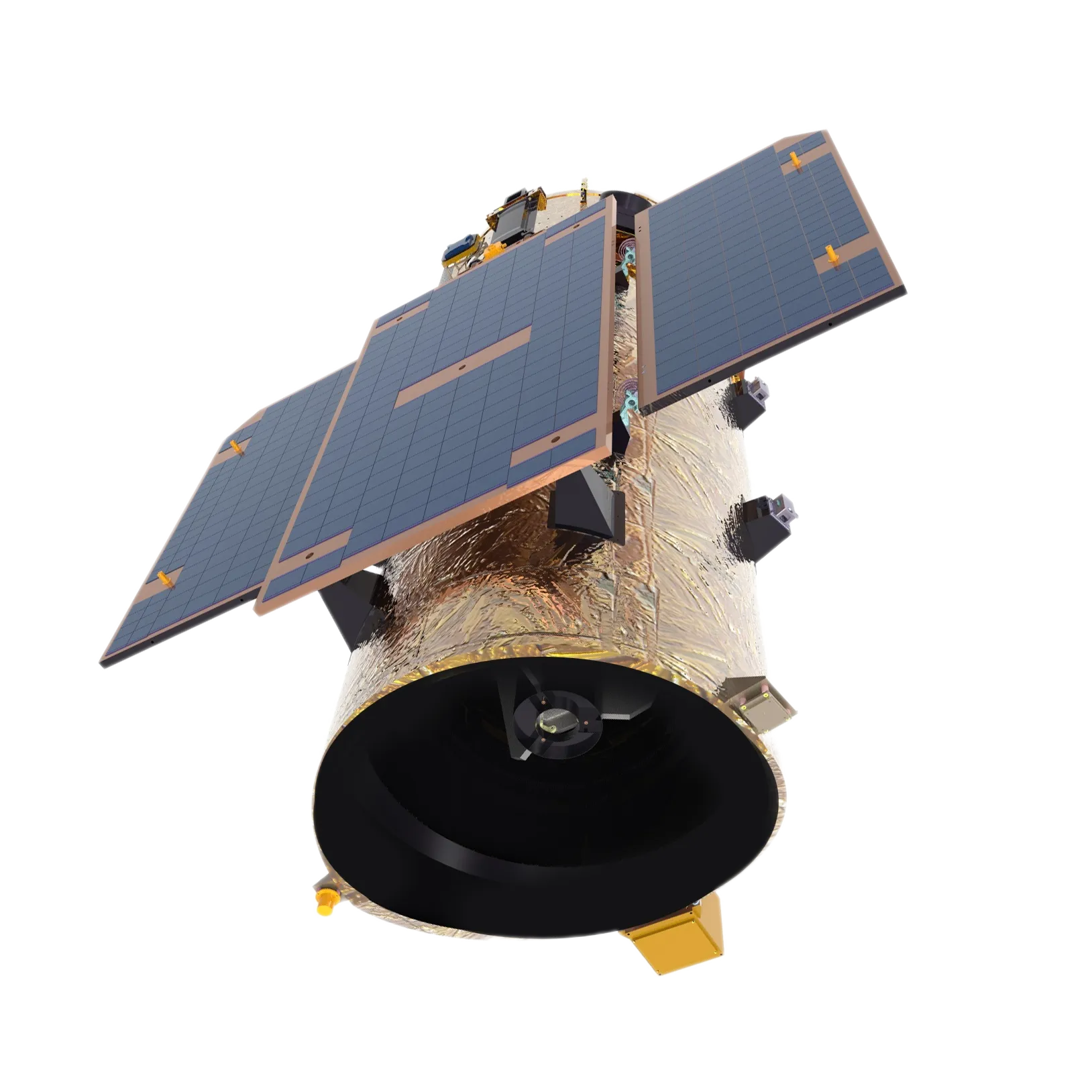

(optical emission spectrometer)

Technical Superiority: 3 Reasons OES Outperforms XRF & Combustion Analysis

Modern optical emission spectrometers for metal analysis crush competitors with:

- ✅ 0.0001% detection limits - 100x more sensitive than portable XRF guns

- ✅ 32-channel simultaneous detection - analyze Cr, Ni, Mo and V in one spark

- ✅ Nitrogen purge system - achieve lab results on the factory floor

| Feature | SpectroPro OES | Competitor A | Competitor B |

|---|---|---|---|

| Analysis Speed | 12 seconds | 45 seconds | 28 seconds |

| Element Range | C, S, P + 68 metals | 32 elements | 45 elements |

Tailored Solutions: Match Your Workflow Perfectly

Whether you need a compact inductively coupled plasma optical emission spectrometer for R&D or rugged field units, our modular systems adapt to:

Automotive Manufacturing

Reduce alloy certification time from 2 hours to 8 minutes

Aerospace QA

Detect titanium grade discrepancies before machining

Proven Results: How Industry Leaders Slashed Costs

Global Steel Co. increased testing throughput by 240% after deploying our OES systems across 17 plants. Their ROI? 9 months.

Ready to Transform Your Metal Analysis?

Claim your free demo kit and discover why 94% of users see payback within 12 months

(optical emission spectrometer)

FAQS on optical emission spectrometer

Q: What is an optical emission spectrometer (OES)?

A: An optical emission spectrometer (OES) is an analytical instrument that identifies and quantifies elements in a sample by measuring the light emitted when excited atoms return to their ground state. It is widely used for metal analysis due to its precision and speed.

Q: How does an optical emission spectrometer for metal analysis work?

A: In metal analysis, the OES excites atoms in a metal sample using an electrical spark or arc. The emitted light wavelengths are then measured to determine elemental composition, enabling rapid detection of metals and alloys.

Q: What are common uses of an optical emission spectrometer?

A: OES is used for quality control in metallurgy, environmental testing, and material identification. It can analyze trace elements, verify alloy grades, and detect impurities in metals and industrial products.

Q: How does an inductively coupled plasma optical emission spectrometer (ICP-OES) differ from traditional OES?

A: ICP-OES uses high-temperature plasma to excite samples, enabling lower detection limits and multi-element analysis. Traditional OES typically uses spark/arc sources and is better suited for solid metal samples.

Q: What are the advantages of using an optical emission spectrometer?

A: OES offers fast results, high accuracy, and the ability to analyze both solid and liquid samples. It is ideal for industries requiring precise elemental analysis, such as aerospace and automotive manufacturing.