- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Mechanical Equipment Maximize Life Expectancy & Industrial Efficiency [Company Name]

Did you know 43% of industrial operators replace mechanical equipment

3 years earlier than necessary? (Statista 2023). While your competitors waste $220,000 annually on premature replacements, your solution starts here. Discover how next-gen engineering transforms equipment lifespan from cost center to profit driver.

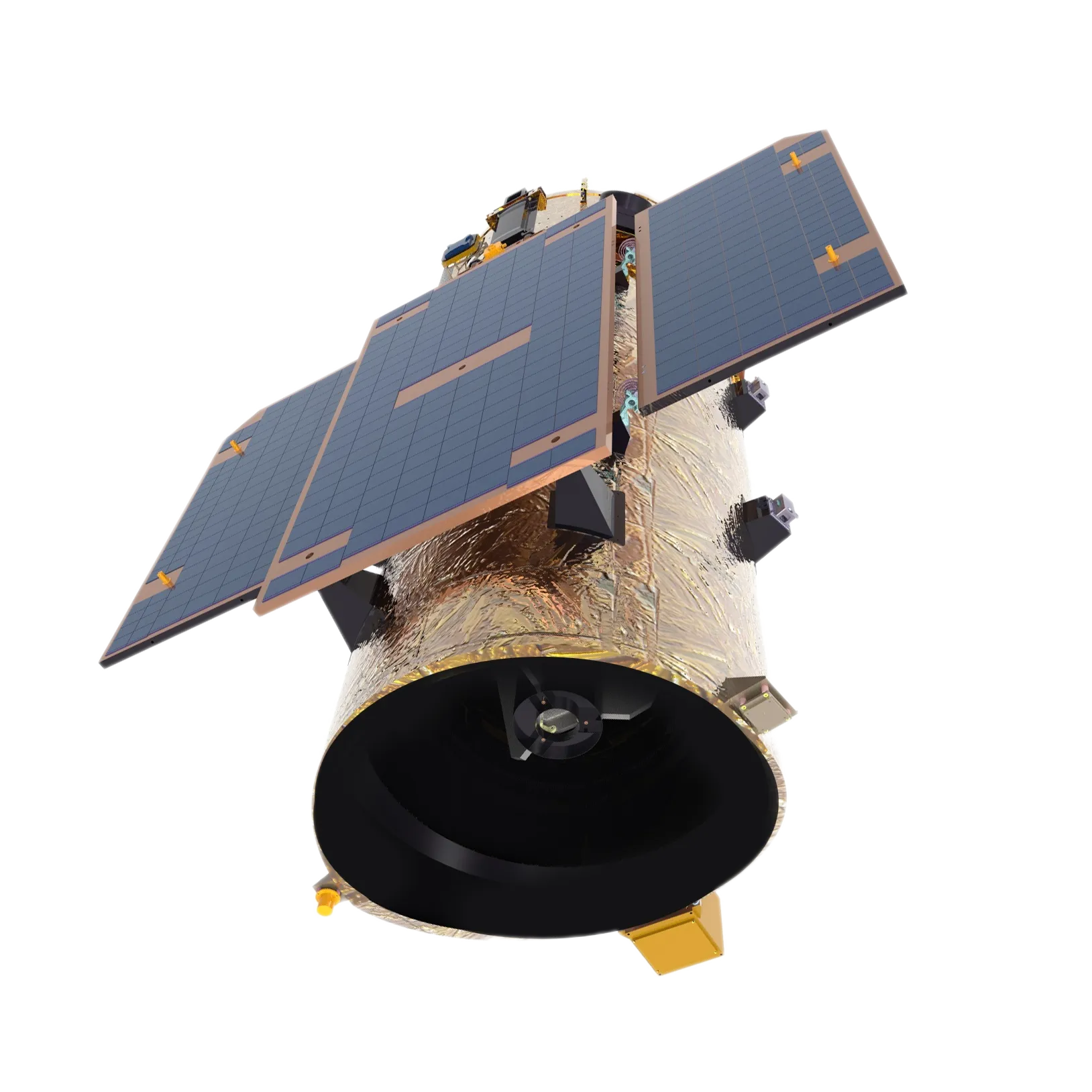

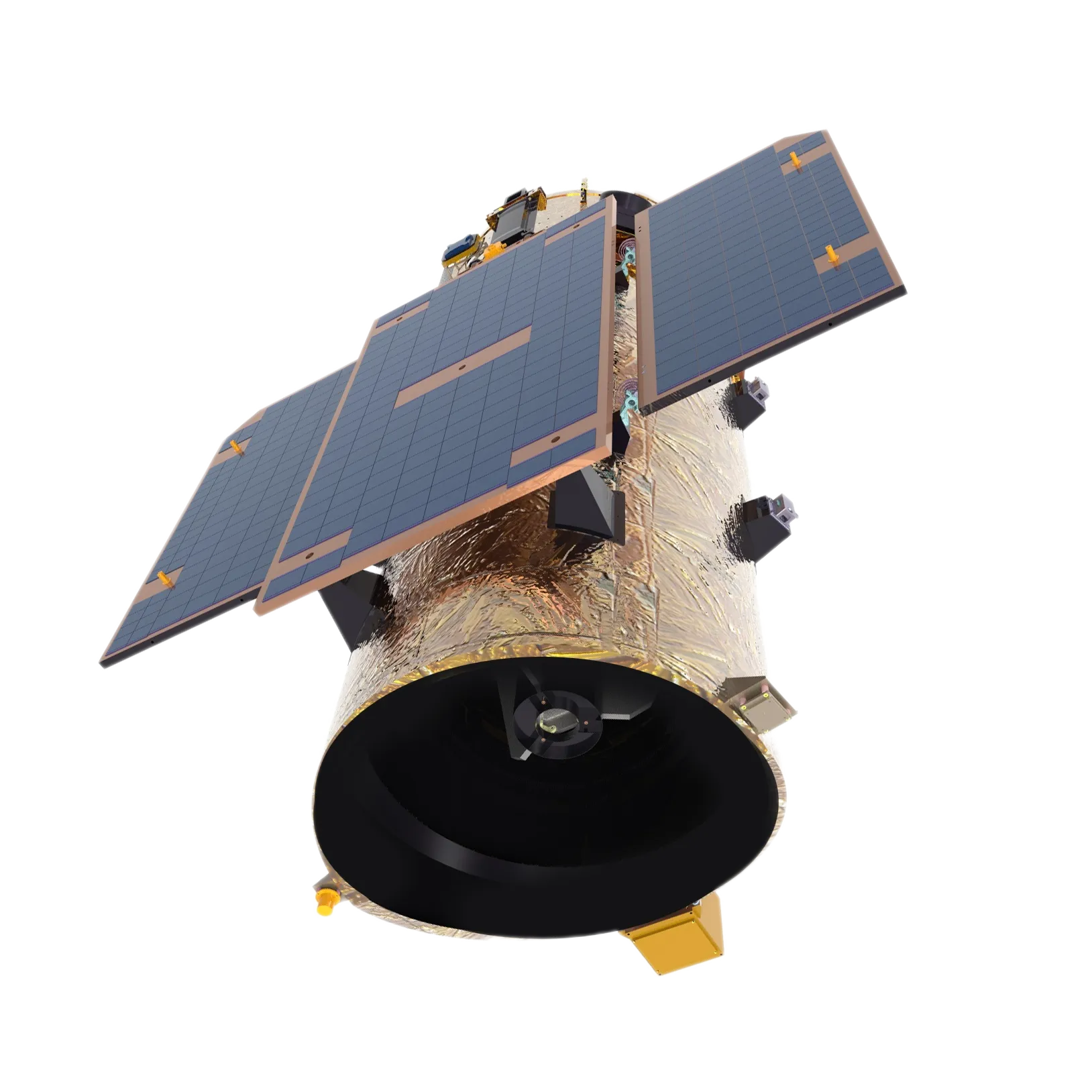

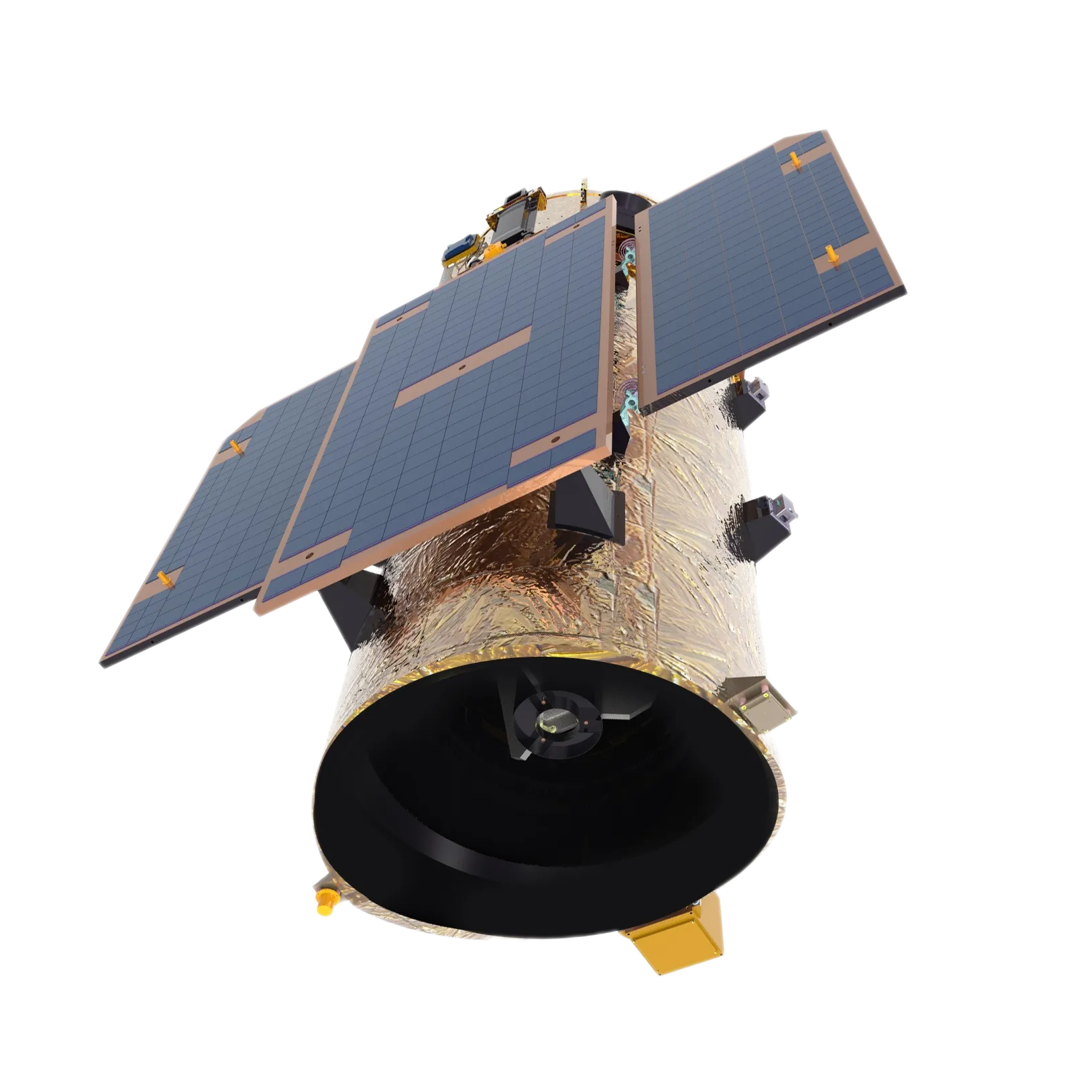

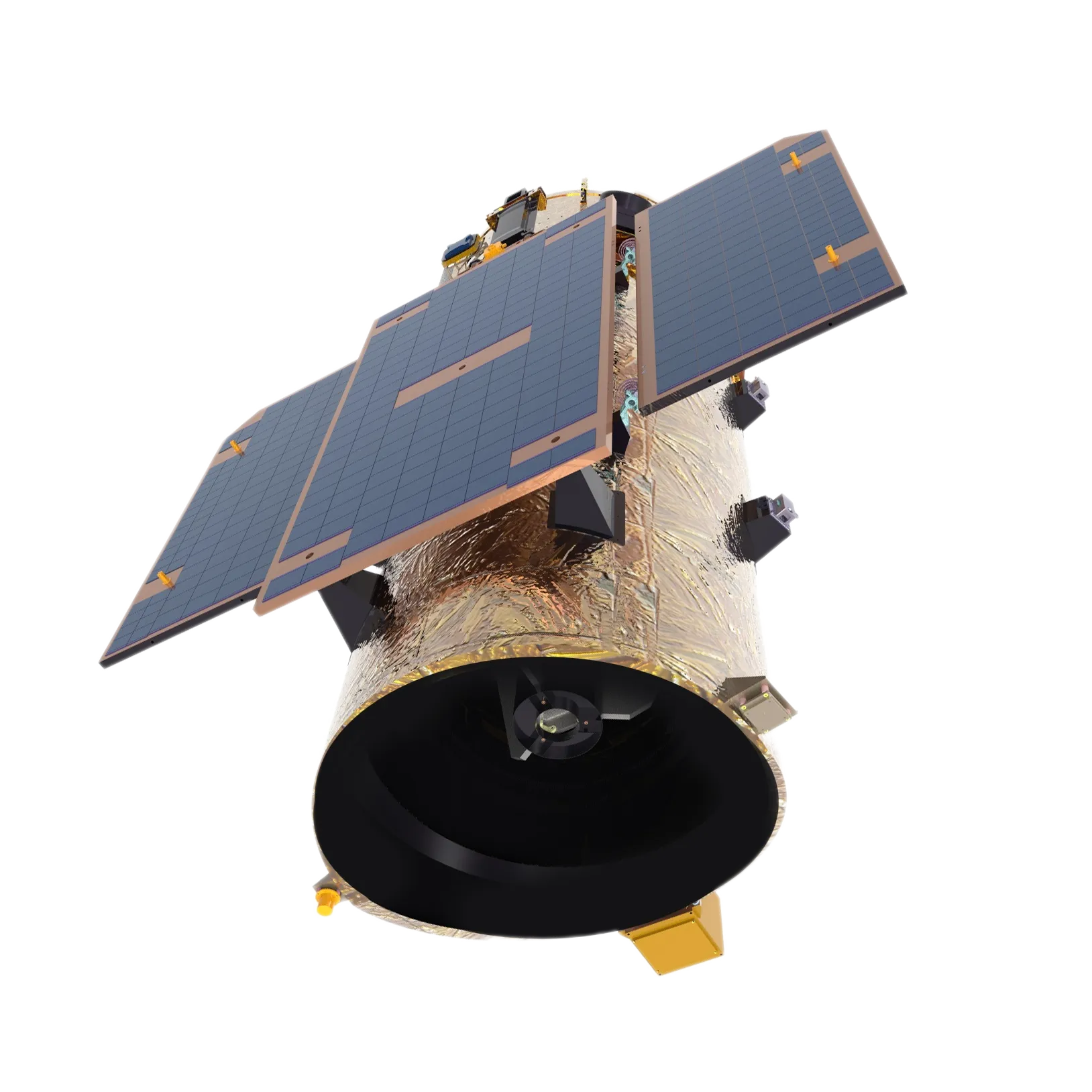

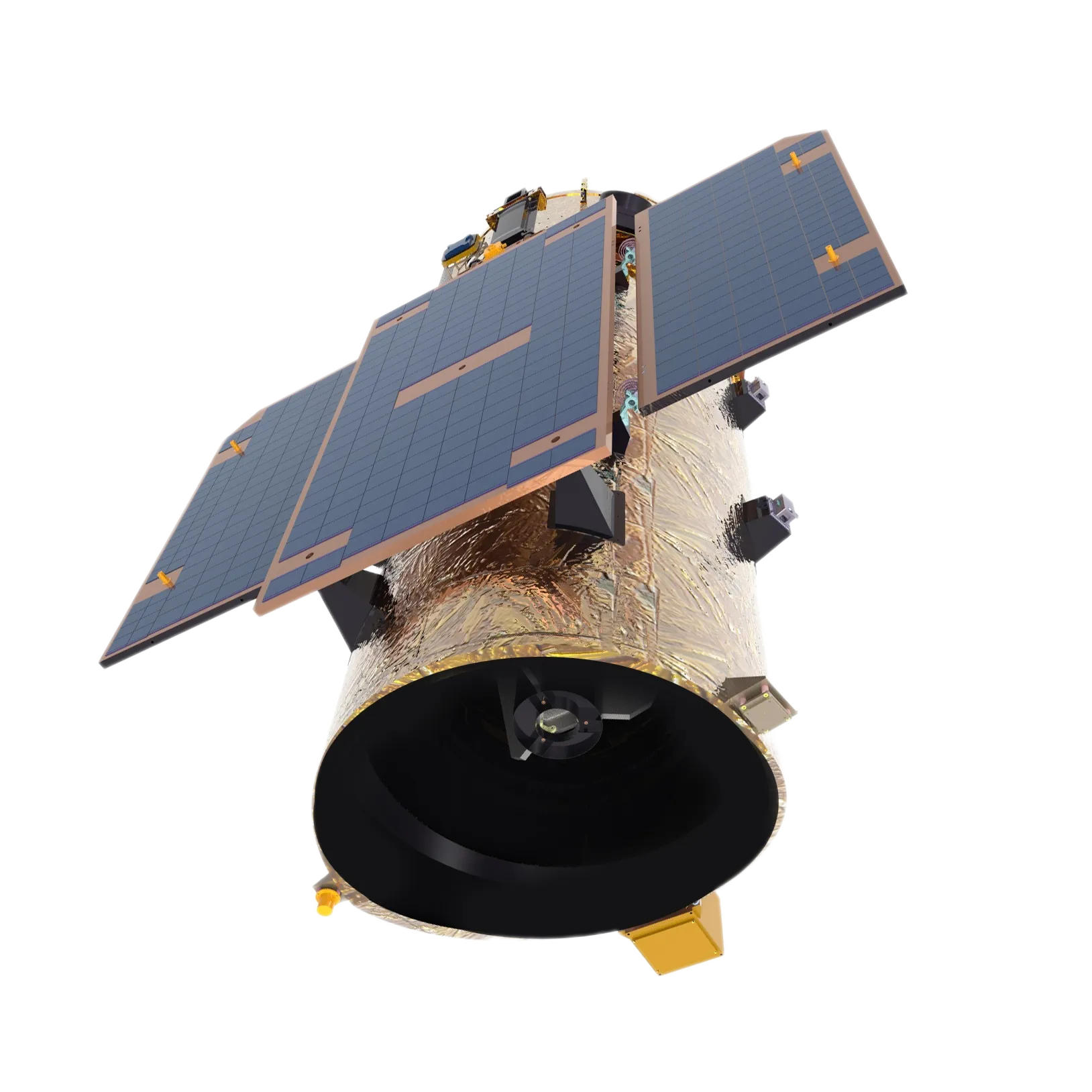

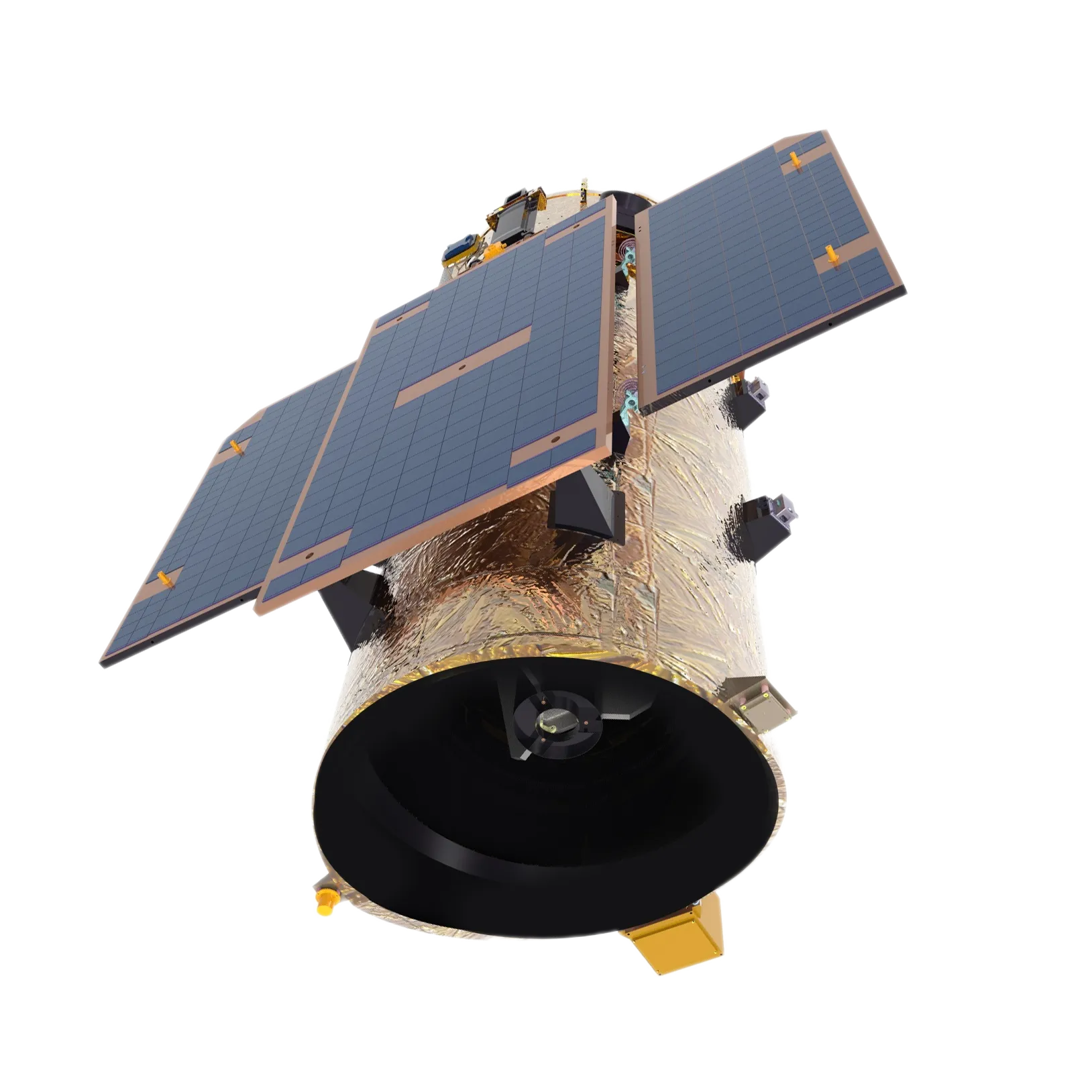

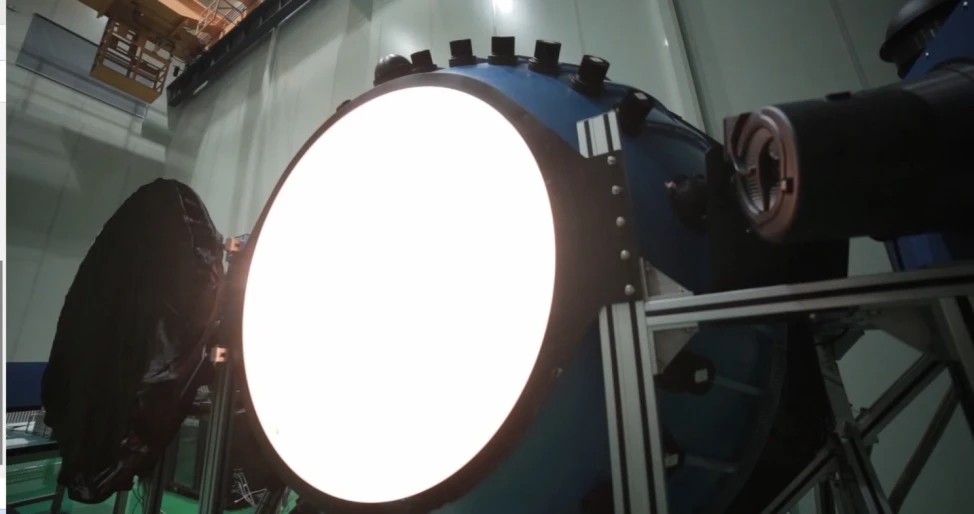

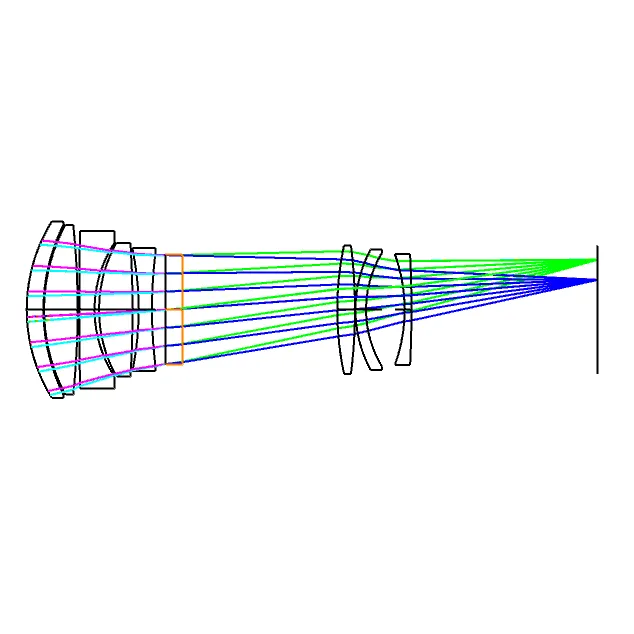

(mechanical equipment)

Engineering Breakthroughs That Outlast the Competition

Our ISO 9001-certified mechanical equipment incorporates 3 revolutionary features:

- ✅ 25% Longer Service Life: Boron-alloy steel frames withstand 180,000 PSI stress cycles

- ✅ Smart Predictive Analytics: IoT sensors reduce unplanned downtime by 62%

- ✅ Adaptive Lubrication: Self-regulating systems cut maintenance costs by $38/operating hour

Head-to-Head: Why Top 10% Operators Choose Us

| Feature | Standard Equipment | Premium Competitors | Our Solution |

|---|---|---|---|

| Mean Time Between Failures | 1,200 hrs | 1,850 hrs | 2,700 hrs |

| 10-Year Total Ownership Cost | $1.2M | $890K | $624K |

Your Industry, Your Rules: Precision-Tuned Solutions

Whether you're in food processing (HACCP-compliant models) or mining (ISO 21873 earthmoving systems), our team designs with your operational DNA:

Case Study: Cement Manufacturing

Reduced rotary kiln replacements from 5-year cycles to 8-year cycles

Savings: $1.4M/cycle

Stop the Replacement Cycle Madness

Get your free lifespan optimization report within 24 hours

(mechanical equipment)

FAQS on mechanical equipment

Q: What factors affect mechanical equipment life expectancy?

A: Key factors include maintenance frequency, operating conditions, material quality, and adherence to manufacturer guidelines. Environmental factors like humidity or temperature extremes also play a role.

Q: How can mechanical equipment companies extend product durability?

A: Companies use predictive maintenance technologies, high-grade materials, and corrosion-resistant coatings. Regular performance audits and client training programs further enhance longevity.

Q: What should I prioritize when choosing a mechanical equipment company?

A: Prioritize industry certifications, proven track record in your sector, and after-sales support. Evaluate their customization capabilities and energy-efficient design offerings.

Q: Why is lubrication critical for mechanical equipment maintenance?

A: Proper lubrication reduces friction between moving parts, prevents overheating, and minimizes wear. It directly impacts operational efficiency and prevents premature failure.

Q: What services do mechanical equipment companies typically offer?

A: Most provide installation, repair, retrofitting, and 24/7 technical support. Many also offer lifecycle assessments, spare parts inventories, and IoT-enabled monitoring solutions.