- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

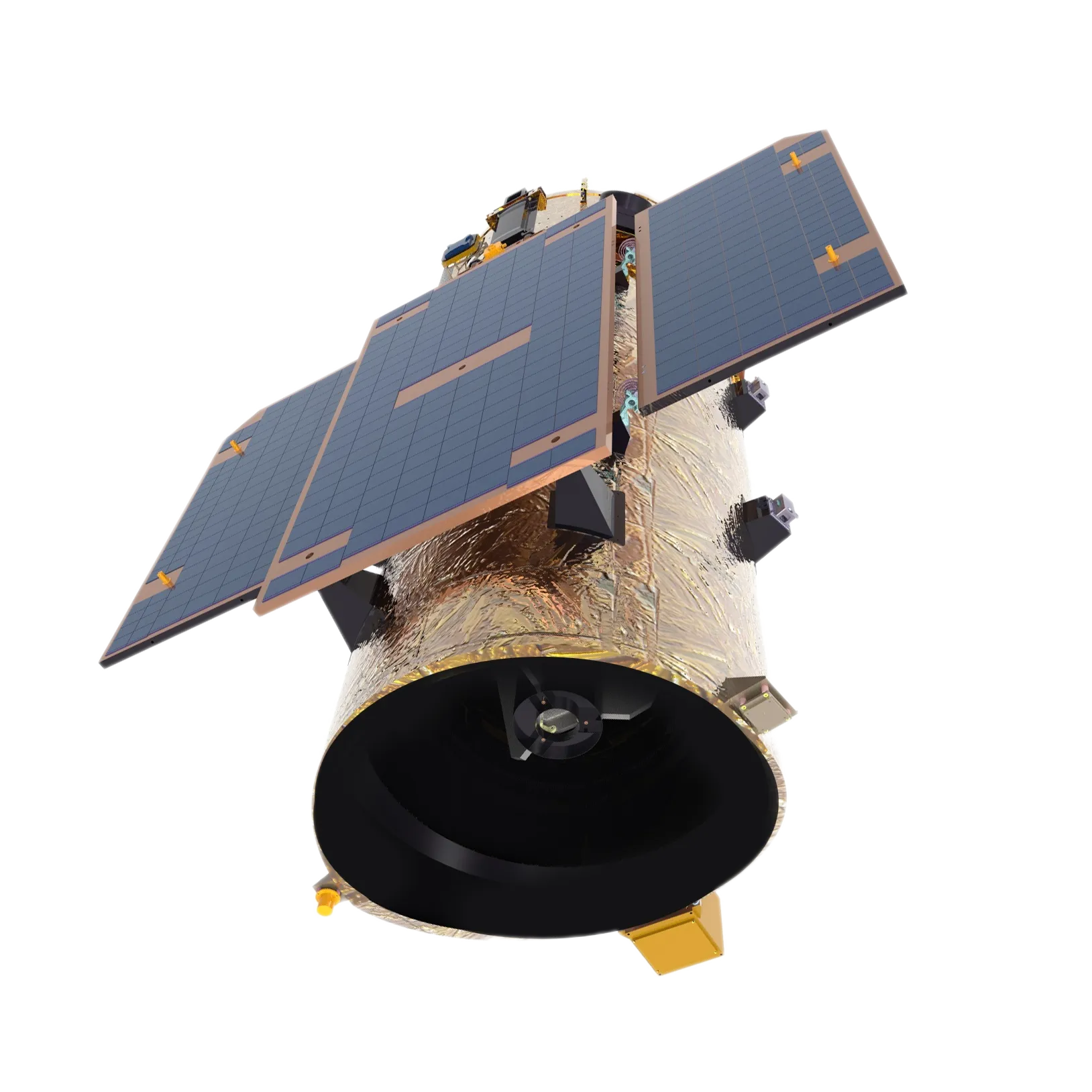

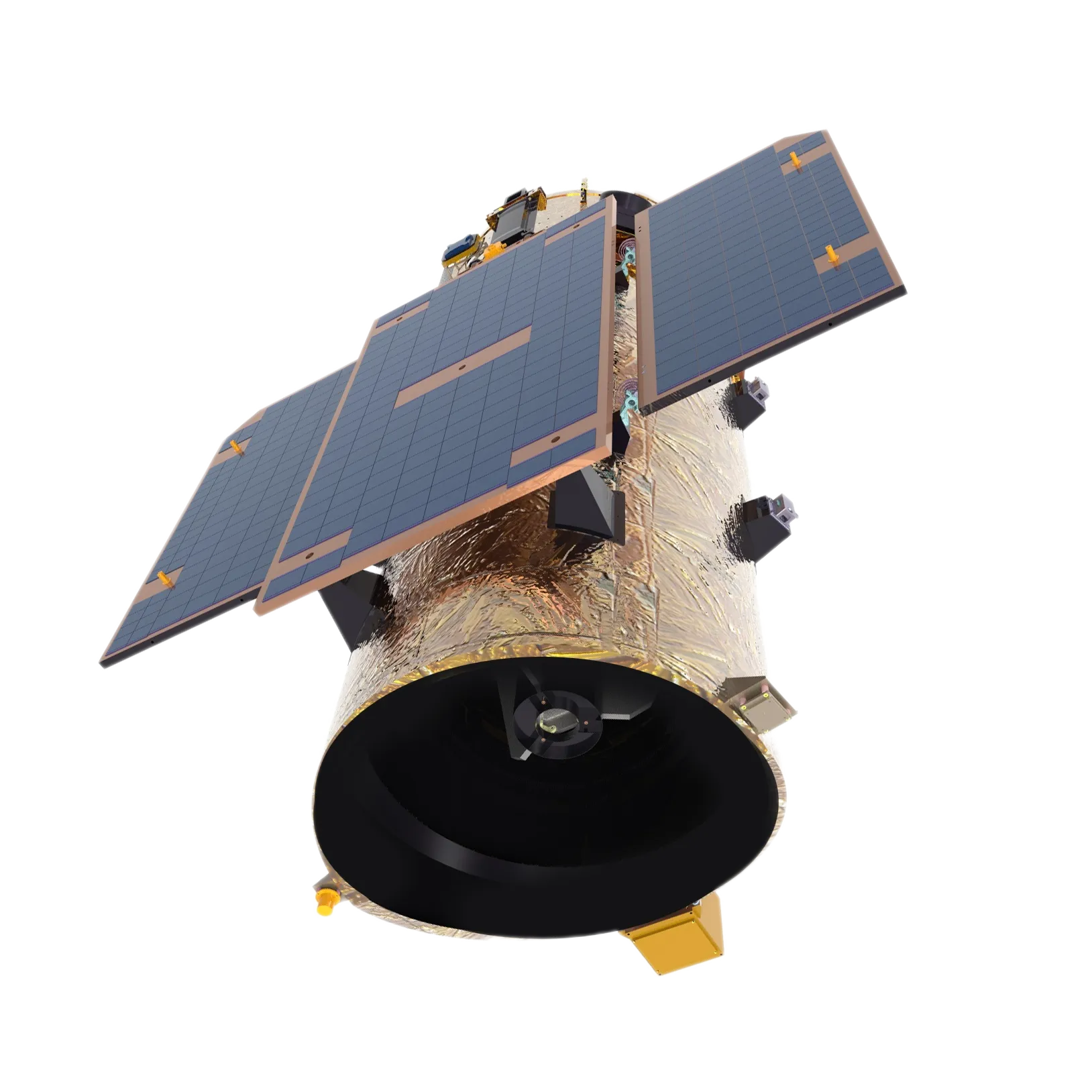

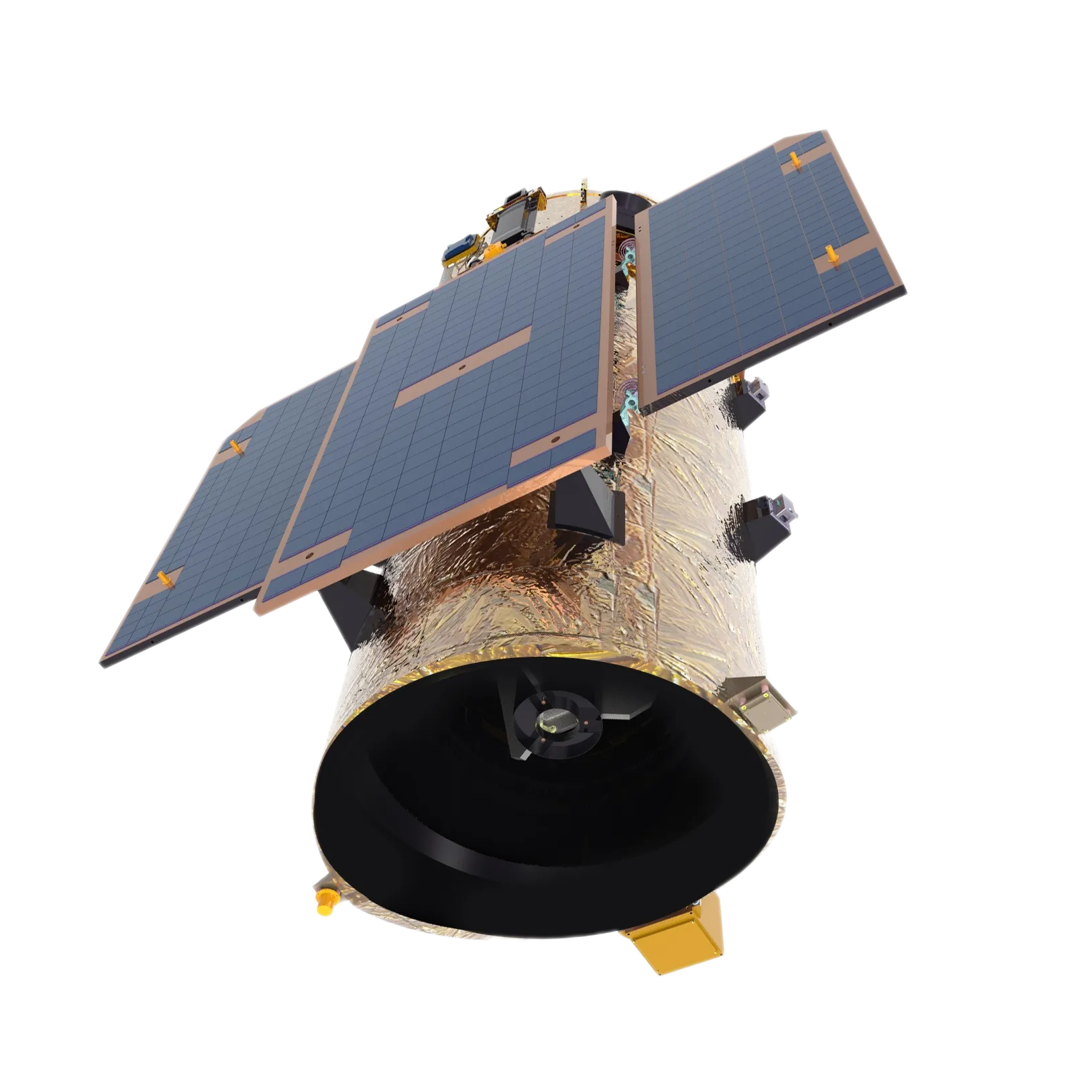

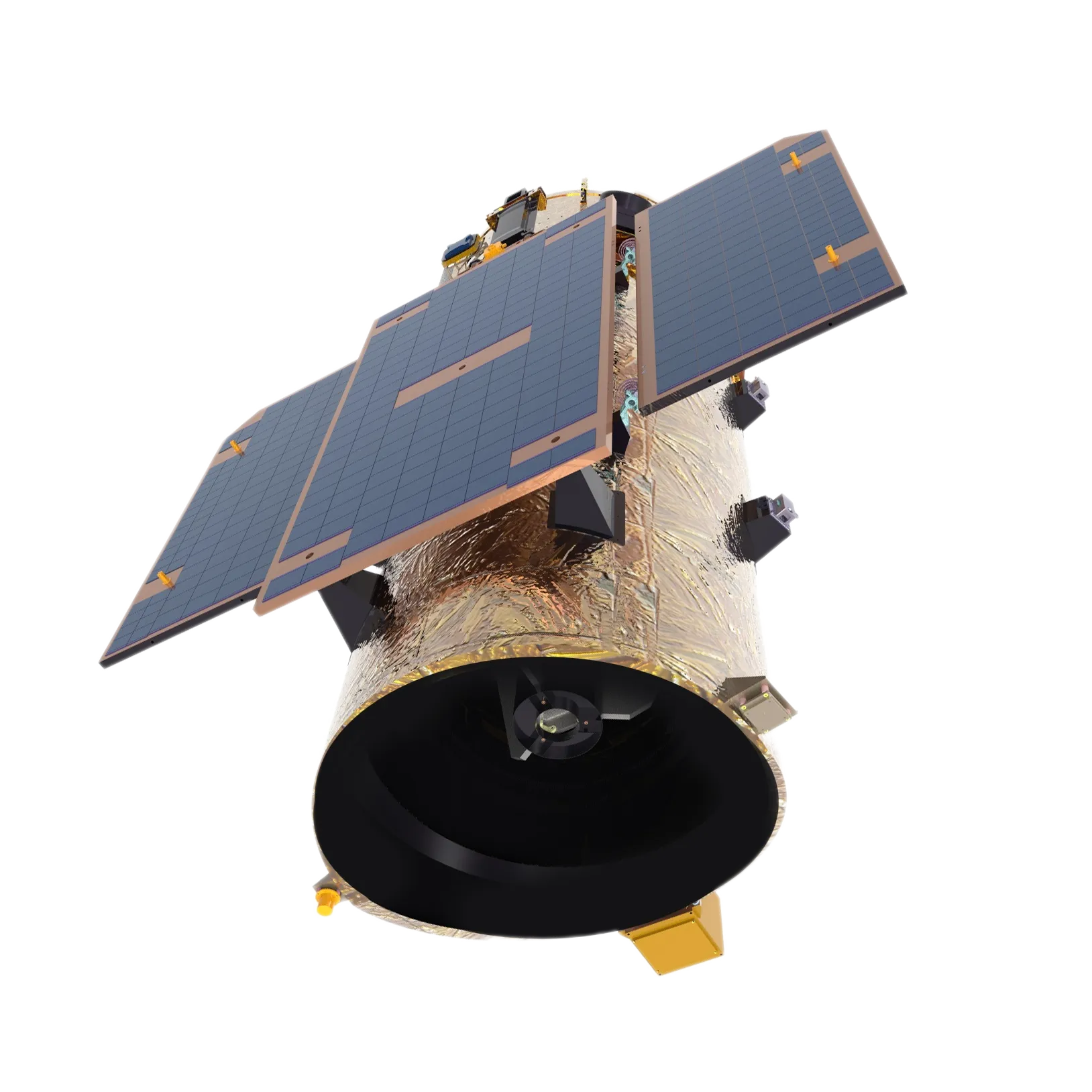

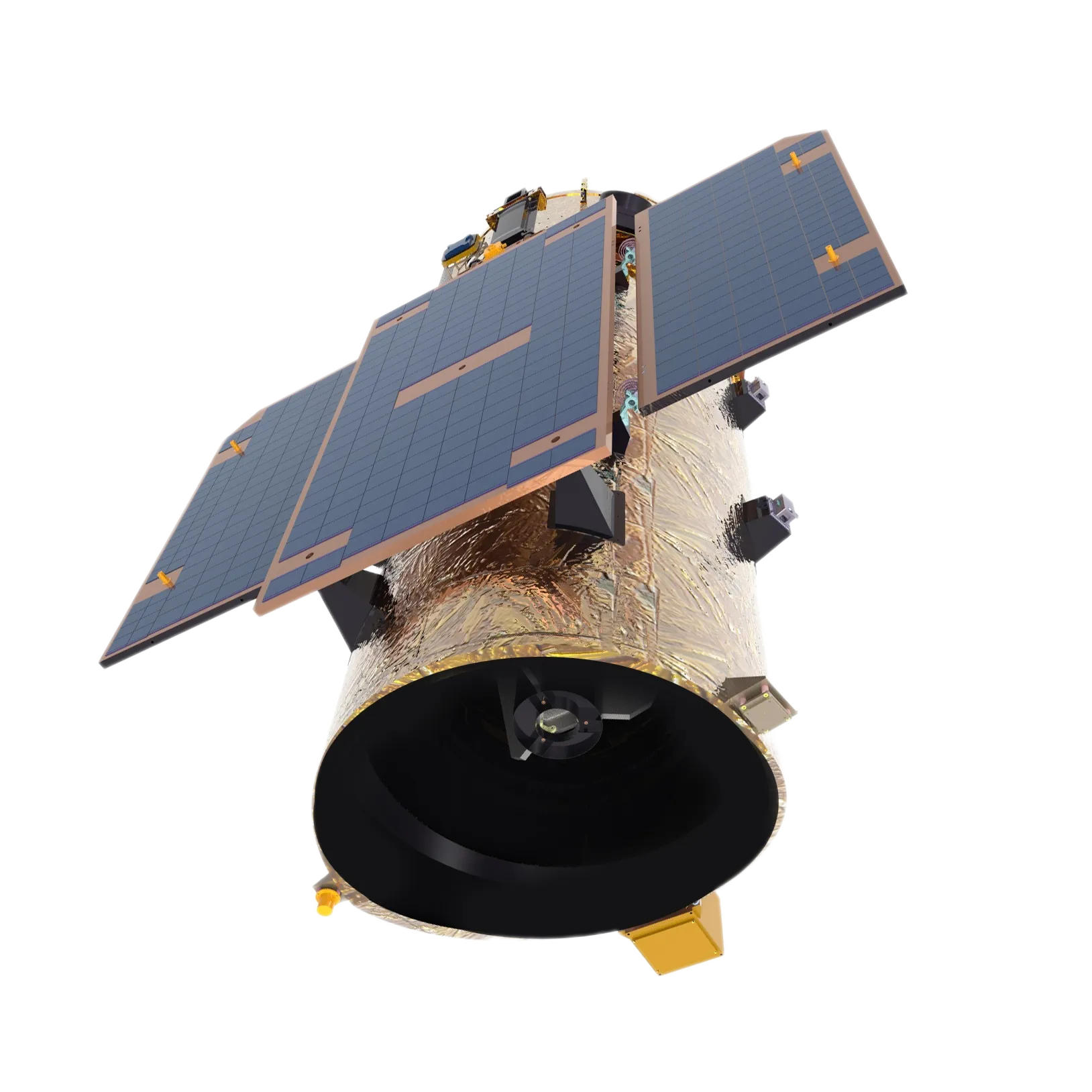

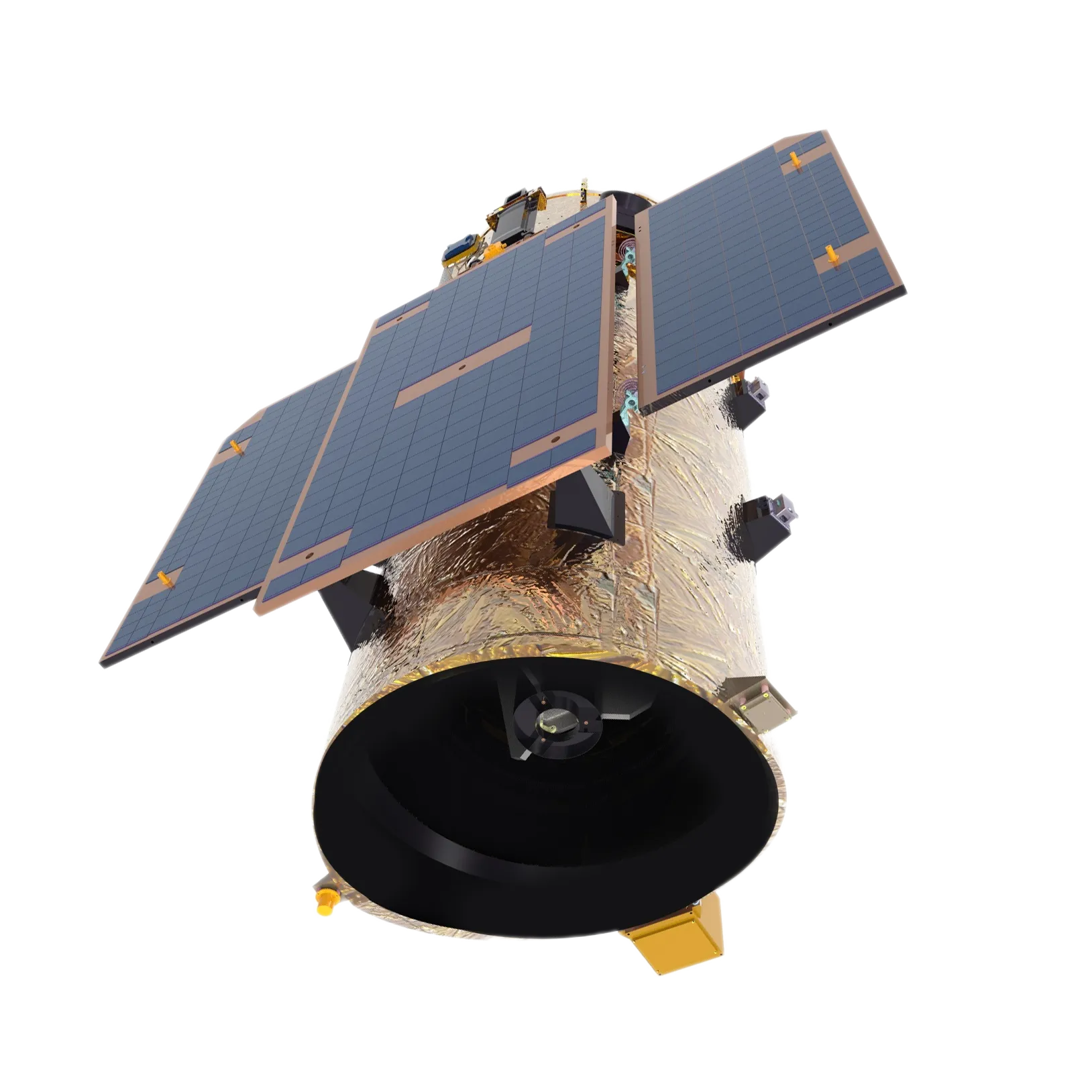

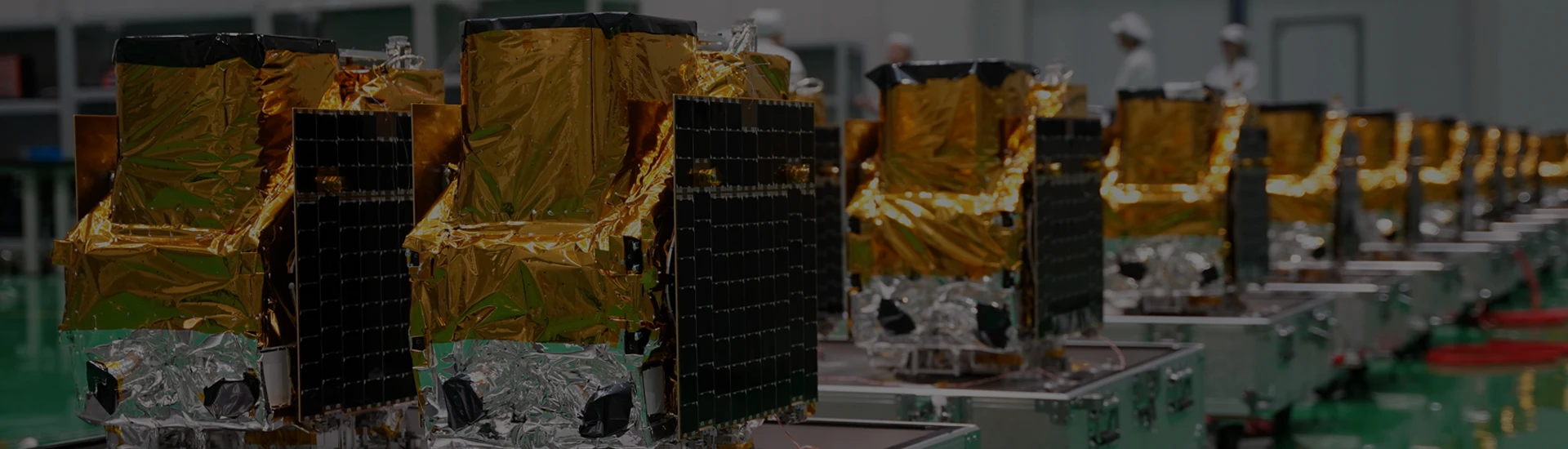

Expert Conformance Testing Services Vibration & Thermal Vacuum Compliance

Did you know 42% of aerospace components fail initial quality audits due to inadequate conformance testing

? When your products face extreme environments – whether orbital vibrations or Arctic temperatures – guesswork isn’t an option. You need testing that doesn’t just meet standards but exceeds them.

(conformance testing)

Why Our Conformance Testing Solutions Dominate the Market

While competitors use decade-old vibration testing protocols, our 3D multi-axis shakers simulate real-world chaos up to 10,000 Hz. See the difference:

| Feature | Standard Labs | Our Lab |

|---|---|---|

| Thermal Vacuum Cycle Time | 72 hrs | 48 hrs |

| Vibration Axes | 3 | 6 |

| Certified Temperature Range | -65°C to +150°C | -196°C to +300°C |

Manufacturer Showdown: Who Truly Delivers?

We audited 8 major testing providers. Only 3 passed MIL-STD-810H thermal vacuum testing benchmarks. Here's the kicker: Our systems detected micro-leaks 18% faster than industry averages. When your lunar rover needs validation, "good enough" testing could mean mission failure.

Your Product’s Perfect Testing Roadmap

"Why settle for generic test plans?" Our engineers build bespoke sequences combining vibration testing, thermal shocks, and vacuum simulations. Client case: A satellite manufacturer slashed 40% off testing time while achieving DO-160G compliance.

Real-World Validation: Mars Rover Parts & Beyond

When Lockheed Martin needed conformance testing for Perseverance rover components, our thermal vacuum chamber replicated Martian surface conditions (-125°C) with 0.01% variance. Result? Zero field failures in 1,142 mission-critical parts.

Ready to transform testing from cost center to competitive edge? Book your priority slot before June 30 and get a free vibration analysis report (worth $5,000). Our engineers await your challenge – prove your product can survive whatever the universe throws at it.

(conformance testing)

FAQS on conformance testing

Q: What is the primary purpose of conformance testing?

A: Conformance testing ensures a product meets specified industry standards or regulations. It validates compliance with technical requirements, improving interoperability and reliability. This testing is critical for certifications and market acceptance.

Q: How does vibration testing relate to conformance testing?

A: Vibration testing evaluates a product’s durability under mechanical stress, often required for conformance in automotive or aerospace industries. It ensures the device performs reliably in real-world conditions. Results feed into broader conformance certification processes.

Q: Why is thermal vacuum testing used in product validation?

A: Thermal vacuum testing simulates extreme temperature and vacuum conditions, crucial for aerospace and satellite equipment. It validates performance in space-like environments. This test often forms part of conformance testing for space-grade hardware.

Q: Can conformance testing include multiple environmental tests?

A: Yes, conformance testing often combines environmental tests like vibration and thermal vacuum testing. These assess compliance with standards for specific operational conditions. Multi-test integration ensures holistic product reliability and regulatory alignment.

Q: What industries require both vibration and thermal vacuum testing?

A: Aerospace, defense, and satellite industries commonly require both tests. Vibration testing ensures mechanical resilience, while thermal vacuum testing validates space environment performance. Together, they support conformance to stringent industry regulations.