- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Component | GPT-4-Turbo Integration & Benefits

The component market, especially in the field of Infrared Focal Plane Arrays (FPA) for satellites and high-tech machinery, is evolving rapidly with new technological breakthroughs and precise application requirements. This article offers a comprehensive look at the latest component industry trends, including technical parameters, leading manufacturers, OEM customization options, and case studies in critical applications such as petrochemical, metallurgy, and smart water management.

Main Keywords: component, component oem, focal plane array, satellite component

Industry Trends of Component and Focal Plane Arrays

The component sector, particularly for infrared imaging and satellite applications, has seen a compound annual growth rate (CAGR) of 12.5% from 2021 to 2023, according to Yole Développement. Lengthy operational lifespans, high spatial resolution, and increasing demand for customized and high-reliability component oem solutions have all contributed to market expansion.

- Growth Drivers: Demand for high-resolution thermal imaging, global climate monitoring, remote sensing.

- Key Sectors: Defense & aerospace, smart inspection, petrochemical, metallurgy, water resource management.

- Technical Evolution: Transition from hybrid to monolithic Focal Plane Array (FPA)-based components; pixel size reduction, multi-spectral detection, higher integration with AI processing.

- OEM Customization: Increase in application-specific envelope, from large satellites to low earth orbit (LEO) constellations.

Main Component Parameters Comparison

| Model/Type | Detector Material | Pixel Pitch (μm) | Spectrum Range (μm) | Resolution | Operating Temp (°C) | Noise Equivalent Temperature (NETD, mK) | Frame Rate (Hz) | Industry Certification |

|---|---|---|---|---|---|---|---|---|

| Infrared FPA-640 | InSb | 15 | 3-5 | 640×512 | -40 ~ +60 | ≤30 | 60 | ISO 9001, CE |

| SatCom FPA-1280 | MCT (HgCdTe) | 10 | 8-14 | 1280×1024 | -60 ~ +70 | ≤20 | 120 | ANSI, ISO 14001 |

| OEM Custom FPA | VOx | 17 | 7-14 | 1024×768 | -40 ~ +55 | ≤50 | 30 | RoHS, FDA |

| Infrared Focal Plane | InGaAs | 15 | 0.9 - 1.7 | 640×512 | -45 ~ +55 | ≤22 | 60 | ISO 9001, FDA, RoHS |

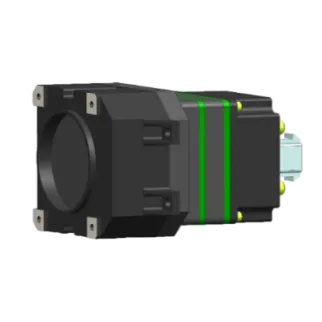

Manufacturing Process of Component (Infrared Focal Plane): Material, Craft & Standards

- Material Selection: Use of high-purity InGaAs or HgCdTe, analyzed per ISO 9001/FDA 21 CFR 820 for imaging quality & biocompatibility.

- Wafer Processing: Crystal growth, layering, grinding (flatness

- Photolithography: Mask alignment and pixel array etching, controlled humidity/cleanroom conditions (ISO 14644 class 5).

- CNC Assembly: Ultra-precise CNC, wire-bonding, housing with aerospace-grade titanium/copper alloy, anti-corrosive finish.

- Testing & QC: Each component is tested for signal uniformity, NETD, life, per ANSI/IEC/ISO infrared standards.

Component OEM & Leading Manufacturer Comparison

| Manufacturer | Core Material | Pixel Size (μm) | Customization (OEM/ODM) | Main Certifications | Support & Warranty |

|---|---|---|---|---|---|

| Space Navi | InGaAs | 15 | Yes (Batch/Single) | ISO 9001, FDA, RoHS | Global, 36 months |

| Sofradir/Lynred (France) | MCT, InSb | 10-18 | Yes (Volume focus) | EN9100, CE | EU, 24 months |

| Teledyne FLIR (US) | VOx | 12-17 | No (Standard only) | ISO 9001, REACH | Global, 24 months |

| L3Harris (US) | HgCdTe | 15 | Yes (Large project) | ITAR, ISO 9001 | US/EUROPE, 18 months |

With growing preference for component oem flexibility, global leaders such as Space Navi, Sofradir, and L3Harris partner directly with satellite integrators or end-users in defense, environmental, and smart grid sectors. Quality guarantees and compliance with ISO/FDA/ANSI/ITAR standards are now basic requirements for international projects.

Technical Advantages & Customization Solutions

- Superior Imaging: Infrared Focal Plane component has spectral response range 0.9-1.7μm, up to 640×512 resolution, ensuring high spatio-temporal fidelity in satellite component remote monitoring.

- Durable Build: Utilizes InGaAs/Al base, CNC-milled housing, gold wire-bonded for high shock resistance (up to 50g), operational in -45°C to +55°C.

- Certified Reliability: Each component batch undergoes 100% NETD and uniformity testing, per FDA/ISO/IEC/ANSI.

- Anti-Corrosion Protection: Coating upgrades allow use in petrochem and marine environments (salt/fog resistance, 3000h+ in ASTM B117 tests).

- MTBF (Mean Time Between Failures): Proven >50,000 hours @ nominal load; customer field data shows 30% longer service in synoptic monitoring satellites.

- OEM Custom Design: Offers pixel array/scaling modification, interface re-layout (e.g., LVAC, GigE), and housing compatiblity for third-party systems.

Application Scenarios: Component in Industry & Satellite

-

Satellites (LEO/HEO): Earth observation, space weather monitoring, urban heat mapping, climate change assessment.

-

Petrochemical Plants: Leak detection, pipe wear monitoring, explosion risk prevention with thermal pattern analysis.

-

Metallurgy: Furnace lining inspection, slab surface crack detection, predictive maintenance via FPA sensor arrays.

-

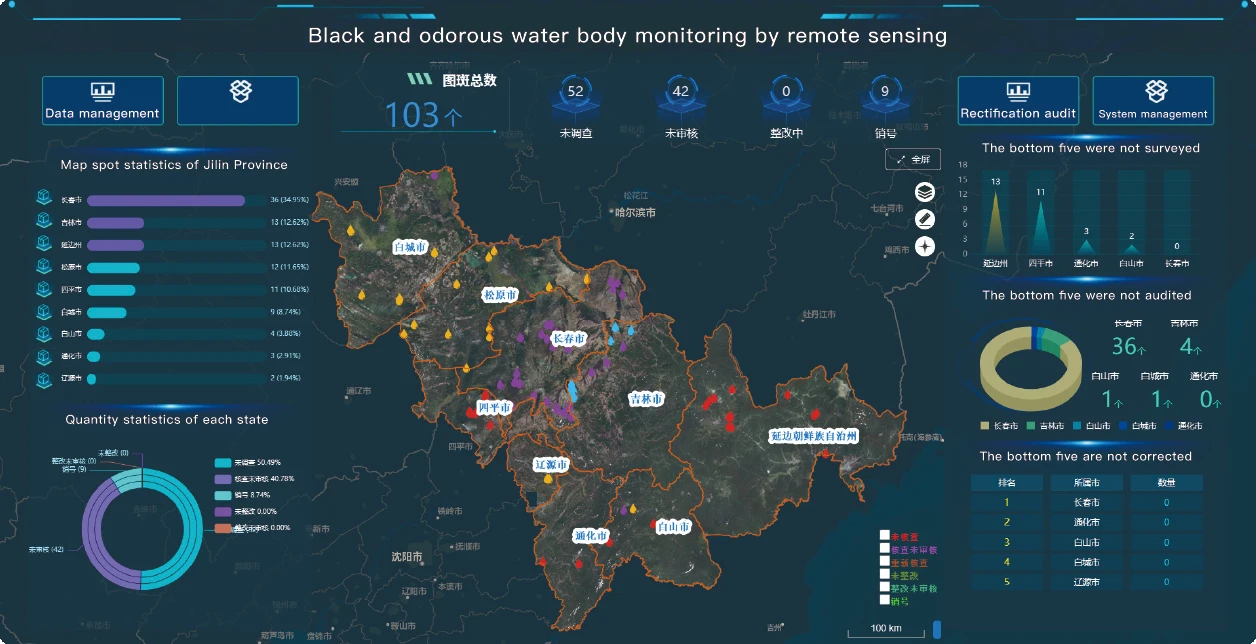

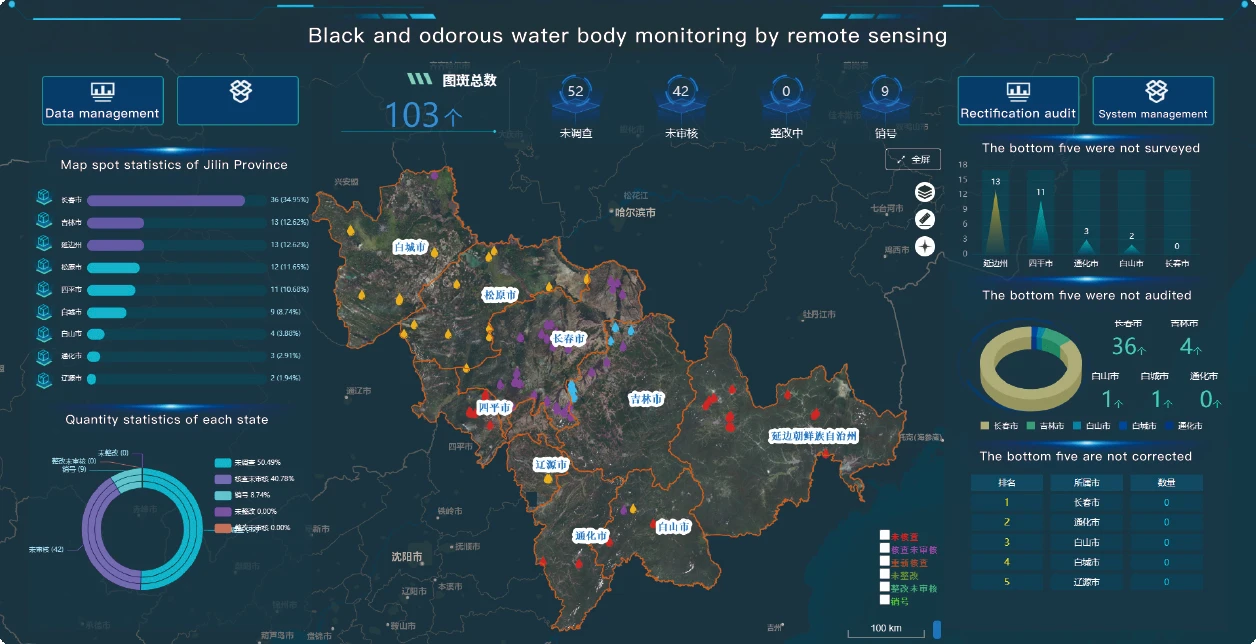

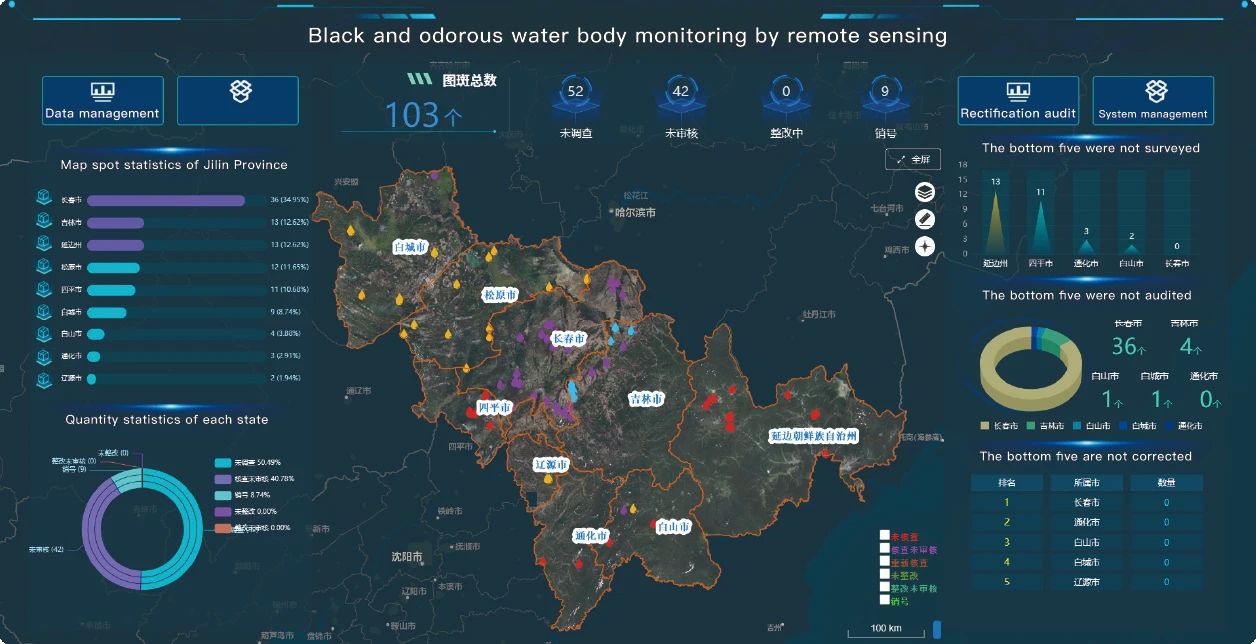

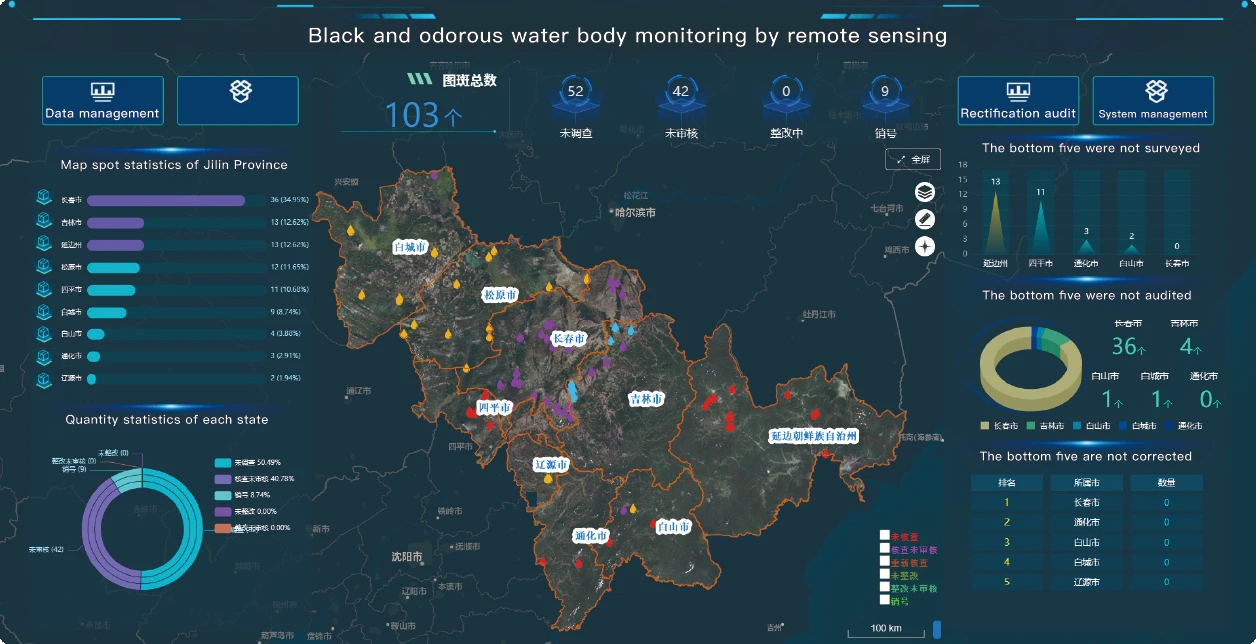

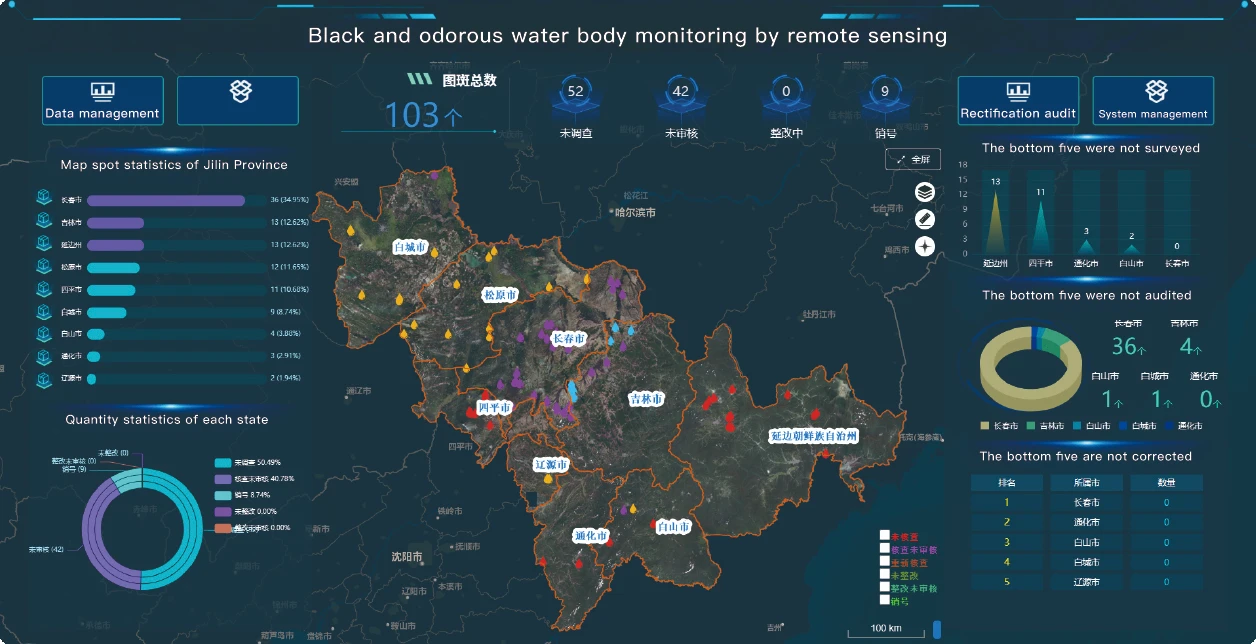

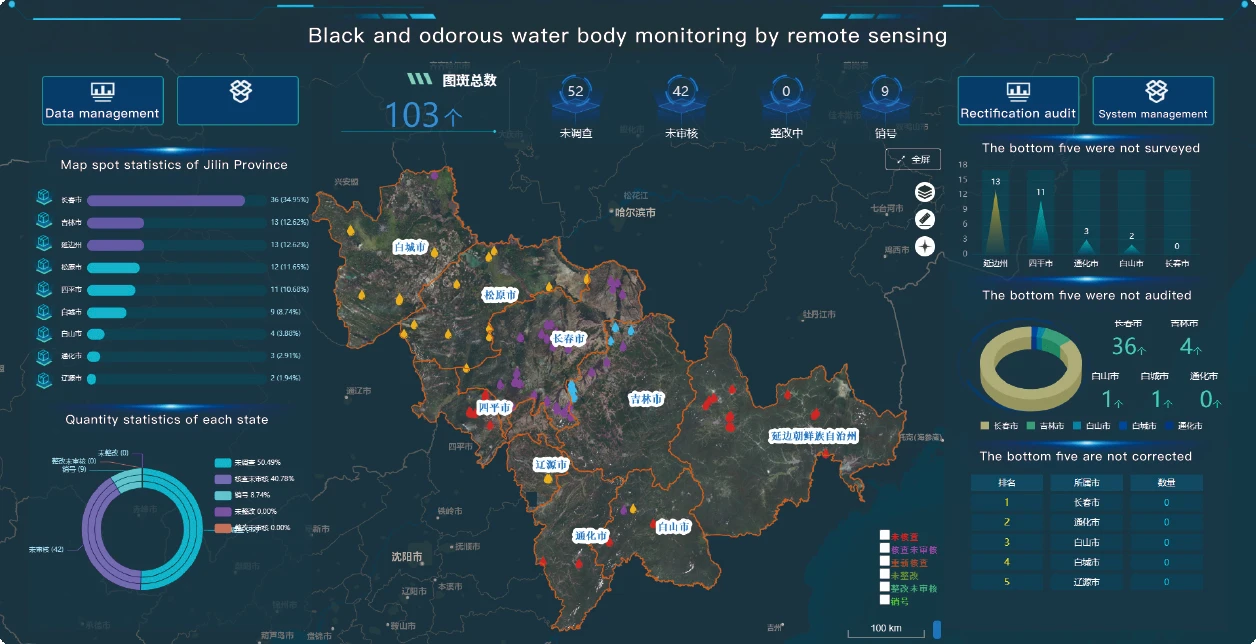

Urban Smart Water: Non-invasive pipeline leakage, ground temperature survey, flood event analysis. Certified per ISO/ANSI for municipal installation.

-

Defense & Security: UAV/UGV guidance, long-wave surveillance, missile IR tracking (real-time frame rate with encrypted output).

Application Cases: From Satellite to Industry

-

Case 1: Remote Sensing Satellite FPA - AsiaSat Project

Component (FPA, InGaAs) assembled in 2023 for AsiaSat-7, delivering 640×512 px near-infrared imaging, improved drought index mapping by 35% over legacy sensors, verified by ISPRS Journals. -

Case 2: Petrochemical Safety – Shell China

Process pipeline monitoring using Infrared Focal Plane arrays reduced unplanned downtime from 89 to 40 hours/year, annual savings over $450,000 (Shell facility report, 2022). -

Case 3: Smart Water Utilities – Shenzhen Municipal

Focal plane component network (OEM design) achieved real-time urban water loss mapping, water pipeline loss rate dropped by 21% within 12 months. -

Case 4: Steelworks Monitoring – Baosteel

Deployed high-temp resistant component in B-shift blast furnaces, leading to 25% reduction in refractory brick failure; ISO/ANSI-certified process.

FAQ: Professional Terms & Component Details

A1: Main materials include InGaAs (Indium-Gallium-Arsenide), HgCdTe (MCT), and VOx, chosen for high quantum efficiency and thermal resistance (ISO 9001 certified supply chain).

A2: Pixel pitch (as small as 10μm), NETD (typically ≤22-30 mK), spectral range (0.9-14μm), frame rate up to 120Hz, and environmental durability as per ANSI/IEC/ISO standards.

A3: CNC housing, gold wire-bonding, and cleanroom photolithography reduce particulate risk and improve interconnect reliability, crucial for aerospace/defense-grade components.

A4: Typical certifications: ISO 9001, FDA (biocompatibility), ANSI/IEC (performance), RoHS (lead-free), EN9100 for space applications.

A5: Accelerated aging, continuous thermal cycling (-40°C to +60°C), checked to JIS/MIL STD. MTBF commonly exceeds 50,000 hours verified by accelerated life tests.

A6: Array size, electrical interface, housing geometry, anti-corrosion coating, and smart diagnostic output can be custom-engineered.

A7: Standard delivery: 5-7 weeks. OEM/ODM: 7-14 weeks (with design confirmation). Warranty: up to 3 years with full device replacement support worldwide.

Delivery, Warranty & Customer Support

- Average delivery: 5 to 7 weeks for standard component; 7-14 weeks for OEM/ODM orders.

- Warranty: Up to 36 months global replacement or repair.

- Customer Support: 24/7 technical support, cross-region logistics, on-site commissioning (Europe/Asia), remote troubleshooting, repair labs in CN/EU/NA.

- Quality Traceability: Every component batch with unique trace/lot codes, lifetime tracking, and test reports available upon request.

- 3rd Party Testing: Sample batch audit by SGS/BV/UL or as per client project need; compliance with FDA, RoHS, CE, ISO 9001.

Conclusion & References

As component requirements accelerate across advanced imaging and industrial sectors, suppliers like Space Navi provide proven, certified, and customizable solutions backed by extensive test data and field-deployed reliability. Choosing the right component and OEM partner—with rigorous international certifications—ensures competitive advantage from satellites to smart infrastructure.

For further technical detail, supplier selection, or custom solution proposal, visit Infrared Focal Plane product page or consult recent peer-reviewed studies and forum posts:

- Yole Group: Infrared Detectors and FPAs, 2023

- MDPI Sensors Journal: https://www.mdpi.com/1424-8220/21/4/1240

- ISPRS Journals: https://www.mdpi.com/2220-9964/11/3/154

- US DOE Reports: https://www.osti.gov/biblio/1638621

- Aerospace Industry Association: https://www.aia-aerospace.org/standards/

- Professional Forum: ResearchGate - Focal Plane Array

- Space Navi Infrared Focal Plane: https://www.space-navi.com/infrared-focal-plane.html