- الأفريقي

- الألبانية

- الأمهرية

- عربي

- الأرمنية

- أذربيجاني

- الباسكية

- البيلاروسية

- البنغالية

- البوسنية

- البلغارية

- الكاتالونية

- سيبوانو

- الصين

- كورسيكي

- الكرواتية

- التشيكية

- دانماركي

- هولندي

- إنجليزي

- الإسبرانتو

- الإستونية

- الفنلندية

- فرنسي

- الفريزية

- الجاليكية

- جورجي

- الألمانية

- اليونانية

- الغوجاراتية

- الكريولية الهايتية

- الهاوسا

- هاواي

- العبرية

- لا

- مياو

- المجرية

- الأيسلندية

- إيجبو

- اللغة الإندونيسية

- ايرلندي

- ايطالي

- اليابانية

- الجاوية

- كانادا

- الكازاخستانية

- الخميرية

- رواندية

- كوري

- كردي

- قيرغيزستان

- تَعَب

- اللاتينية

- اللاتفية

- الليتوانية

- اللوكسمبورغية

- المقدونية

- اللغة الملغاشية

- الملايو

- المالايالامية

- المالطية

- الماوري

- الماراثى

- المنغولية

- ميانمار

- النيبالية

- النرويجية

- النرويجية

- أوكيتاني

- البشتونية

- الفارسية

- بولندي

- البرتغالية

- البنجابية

- روماني

- الروسية

- ساموا

- الغيلية الاسكتلندية

- الصربية

- إنجليزي

- شونا

- السندية

- السنهالية

- السلوفاكية

- السلوفينية

- الصومالية

- الأسبانية

- اللغة السوندانية

- السواحلية

- السويدية

- التاغالوغية

- الطاجيكية

- التاميلية

- التتار

- التيلجو

- تايلاندي

- اللغة التركية

- تركمان

- الأوكرانية

- الأردية

- الأويغور

- الأوزبكية

- الفيتنامية

- الويلزية

- يساعد

- اليديشية

- اليوروبا

- الزولو

عنصر

A component is a fundamental part of a larger system or device, designed to perform a specific function. Components are used across various industries, including electronics, machinery, automotive, and aerospace, where component design and component quality are essential to ensure the efficiency, durability, and functionality of complex systems. In aerospace, sourcing through component suppliers also supports system reliability in critical environments.

-

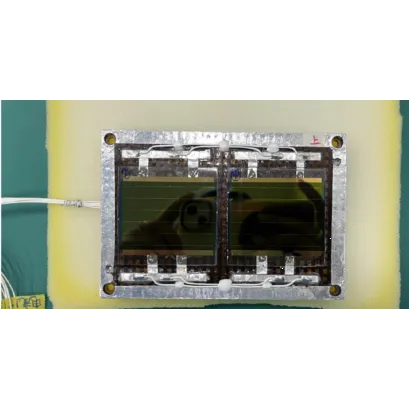

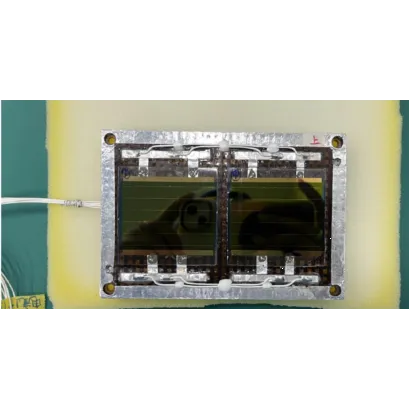

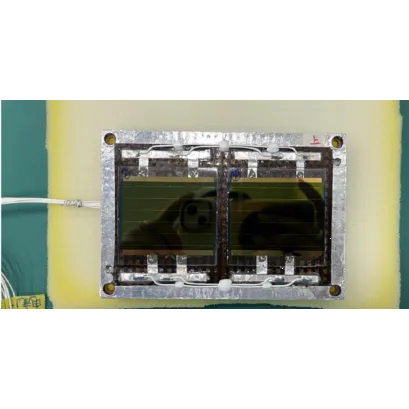

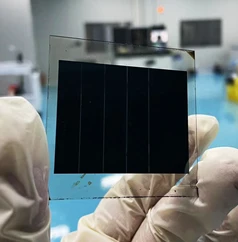

Space-Level Perovskite Solar Cell

تعرف على المزيد الآن >

-

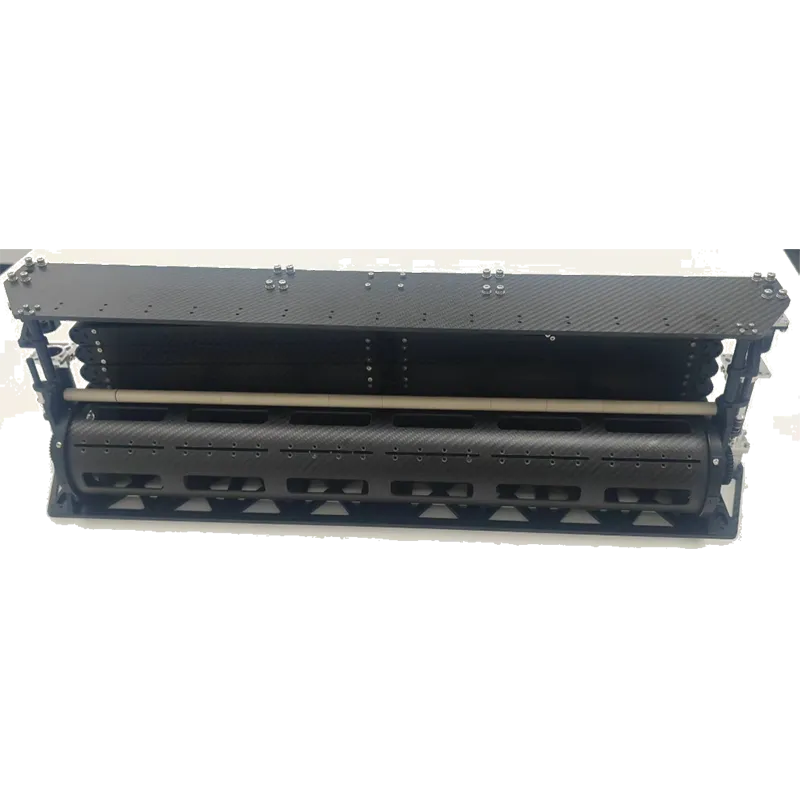

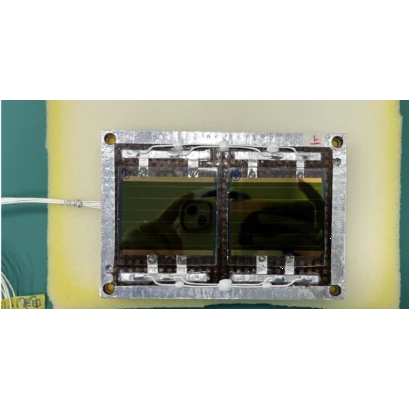

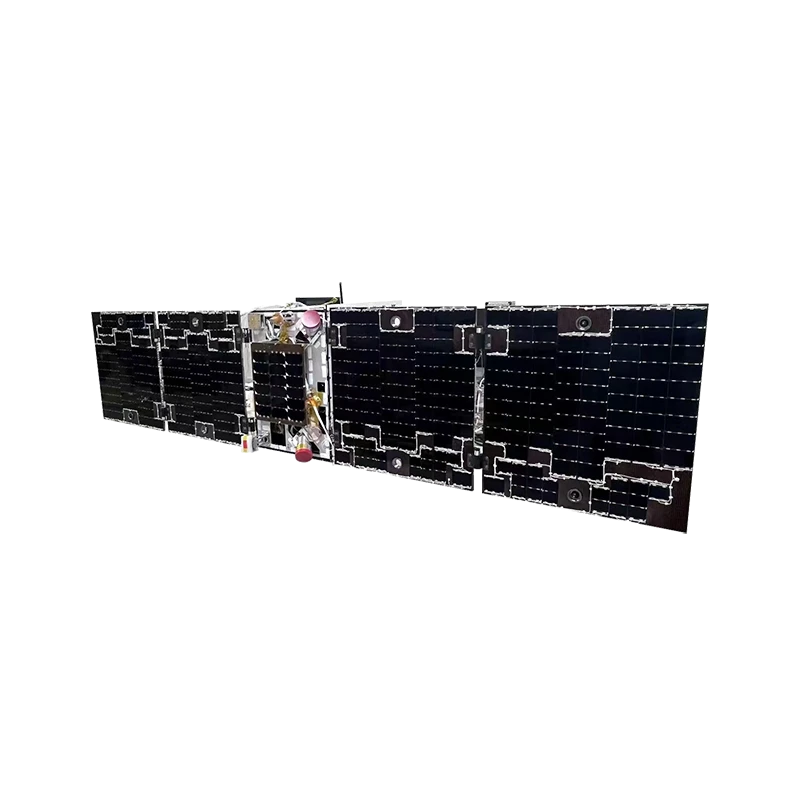

Perovskite Solar Arrays

تعرف على المزيد الآن >

-

آلية الطي والفتح

تعرف على المزيد الآن >

-

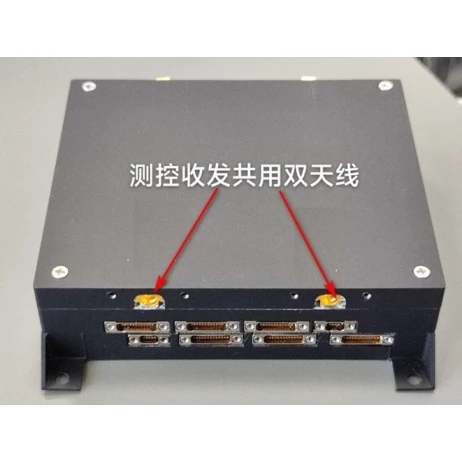

منتجات الهوائي

تعرف على المزيد الآن >

-

منتجات التحكم عن بعد والقياس عن بعد والنقل

تعرف على المزيد الآن >

-

مرآة انعكاس سيتال

تعرف على المزيد الآن >

-

وحدة إدارة توزيع الطاقة والتحكم الحراري

تعرف على المزيد الآن >

-

الحاسوب المركزي

تعرف على المزيد الآن >

-

Magnetic Torque

تعرف على المزيد الآن >

-

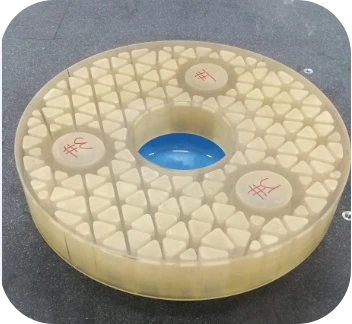

دولاب الموازنة

تعرف على المزيد الآن >

-

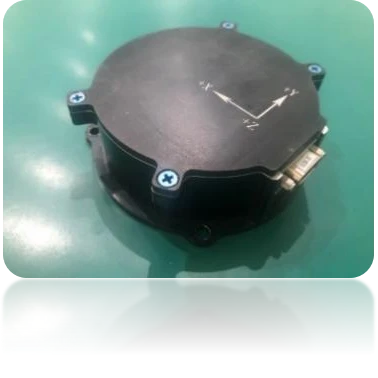

Digital Sun Sensor

تعرف على المزيد الآن >

-

Magnetometer

تعرف على المزيد الآن >

هل تبحث عن مكونات عالية الجودة لتطبيقاتك؟

تعزيز العلاقات التي تتطلب موارد هائلة من خلال أسواق متخصصة متميزة باحترافية.

اتصل بناما هي أنواع المكونات المختلفة وتطبيقاتها؟

المكونات هي وحدات بناء أساسية للآلات والإلكترونيات والأنظمة، ولكل منها غرض مميز. ويمكن تصنيفها بناءً على وظيفتها والصناعة التي تنتمي إليها وتركيبة المواد المستخدمة فيها. وتشمل الأنواع الأكثر شيوعًا المكونات الإلكترونية والمكونات الميكانيكية والمكونات الهيكلية ومكونات أنظمة السوائل.

تُستخدم المكونات الإلكترونية، مثل المقاومات والمكثفات وأشباه الموصلات، على نطاق واسع في الدوائر لتنظيم الجهد وتخزين الطاقة وتمكين معالجة الإشارات. وتعتبر هذه المكونات ضرورية في الإلكترونيات الاستهلاكية والأجهزة الطبية والاتصالات والأتمتة الصناعية. على سبيل المثال، تشكل المعالجات الدقيقة وشرائح الذاكرة قلب أجهزة الكمبيوتر والهواتف الذكية، مما يسمح بمعالجة البيانات وتخزينها.

Mechanical components, including gears, bearings, and fasteners, are used in machinery, vehicles, and industrial equipment to ensure motion control, stability, and durability. These components require precise component design and quality control by experienced component manufacturers to function effectively.

Structural components, such as beams, panels, and frames, provide support and stability in construction, aerospace, and automotive industries. In aerospace engineering, lightweight yet strong materials like carbon fiber-reinforced composites are used in satellite components and satellite parts to enhance durability and efficiency. These parts often undergo rigorous thermal vacuum testing and vibration testing to meet strict standards.

Fluid system components, including valves, pumps, and pipes, manage the flow of liquids and gases in industries such as oil and gas, chemical processing, and water treatment. Reliable sourcing from qualified component suppliers and bulk options via component wholesale channels help ensure safe and efficient system operation.

مع التقدم المستمر في المواد والتكنولوجيا، أصبحت المكونات أكثر كفاءة ومتانة وقابلية للتكيف مع التطبيقات المختلفة. ويظل دورها في الابتكار والتقدم الصناعي لا غنى عنه.

What Are the Key Considerations in Electronic Component Design?

The success of any electronic system begins with effective component design. Whether it's a satellite control board, a power supply module, or a PCB for consumer electronics, the design phase is where performance, efficiency, and durability are determined. Engineers must factor in size constraints, heat dissipation, signal integrity, and electromagnetic interference from the start. A well-thought-out component layout prevents system failures, reduces noise, and improves long-term stability.

In modern applications—particularly in aerospace and satellite tech—component material selection is equally critical. High-frequency systems often require dielectric substrates with stable thermal and electrical properties. The wrong materials can compromise signal speed or distort microwave frequencies, especially in parts like microstrip antennas and high-speed data lines. Designers also need to think about component quality over time, considering environmental factors such as radiation, vibration, and temperature extremes that components may endure.

This is where companies like SpaceNavi Co., Ltd. come into play. With their expertise in satellite component design and production, they offer refined solutions that integrate robustness and scalability. Choosing high-quality components from experienced component manufacturers ensures the final product functions reliably in real-world environments, saving costs associated with downtime, repairs, or failure analysis.

Why Is Material Selection Important in Electronic Component Manufacturing?

The choice of component material plays a pivotal role in determining how a component performs, especially under pressure. Materials affect conductivity, signal loss, heat tolerance, and mechanical stability. For example, a low-quality dielectric material in a microstrip antenna could lead to high signal loss and poor radiation efficiency. Similarly, using subpar copper in a PCB could compromise its conductivity and lifespan.

Another overlooked aspect is the compatibility between different materials. A mix of metals with mismatched thermal expansion rates can cause mechanical stress, leading to micro-cracks and eventual failure of solder joints or traces. For component OEM production, consistency in material quality ensures that large batches behave predictably, which is essential for systems with zero tolerance for errors—like satellites or defense electronics.

Trusted component manufacturers typically perform rigorous material sourcing and testing before production. While you should always review a supplier’s documentation, working with experienced producers such as SpaceNavi Co., Ltd. simplifies this process. Their full-chain production model ensures their satellite components maintain high performance even in vacuum or high-radiation environments, where material selection makes all the difference.

How Are Component Cables Essential in High-Frequency or Harsh Environments?

While often overlooked, component cables are essential in maintaining system integrity—especially in high-speed data and signal transmission environments. They connect sensors, processors, and power systems, serving as the physical medium for voltage, current, or RF signals. Poor-quality cables or connectors can result in significant signal loss, increased electromagnetic interference (EMI), or total communication failure.

In systems using microstrip antennas or high-frequency radar modules, the importance of shielding and impedance control in cables becomes even more critical. Incorrect component design here can introduce phase noise or unwanted reflections. Similarly, in aerospace or industrial applications, cables need to be robust enough to withstand vibration, UV exposure, and large temperature fluctuations without degrading.

The market demand for customized cabling—such as custom mini component cables or modular cable assemblies—is growing. These often come with options for logo printing, specific sheath materials, or tailored lengths for optimal installation. Companies like SpaceNavi, while focusing on satellite-level solutions, often recommend the use of certified component OEM cables to avoid weak links in the system’s chain of command.

In What Ways Do Satellite Components Differ from Standard Electronics?

Satellite components operate in some of the harshest conditions imaginable—extreme temperatures, intense radiation, and the vacuum of space. That’s why they're built to far stricter standards than everyday electronics. Beyond temperature and vacuum resistance, these components must be vibration-resistant, radiation-hardened, and able to operate flawlessly over long periods without maintenance.

One core difference lies in component material. While commercial electronics might use standard plastics and mid-grade metals, satellite component design requires ceramics, aerospace-grade metals, and specialized coatings. Additionally, component operation in satellites is highly interdependent—failure in one sensor or power module can compromise the entire mission. Redundancy, shielding, and fault-tolerant designs are standard practice.

SpaceNavi Co., Ltd. has proven expertise in this field, producing everything from microstrip antennas to central computers for spacecraft. Their approach showcases how component quality, ruggedization, and reliability are prioritized from the start of design through manufacturing. For buyers looking to understand space-grade expectations, this kind of industrial benchmark is highly informative.

أنواع المكونات وتطبيقاتها

-

المكونات الإلكترونيةتشمل المقاومات والمكثفات وأشباه الموصلات، وهي ضرورية لتشغيل الأجهزة الإلكترونية والتحكم فيها.

المكونات الإلكترونيةتشمل المقاومات والمكثفات وأشباه الموصلات، وهي ضرورية لتشغيل الأجهزة الإلكترونية والتحكم فيها. -

المكونات الميكانيكيةيتكون من التروس والمحامل وأدوات التثبيت، مما يضمن التشغيل السلس في الآلات والمركبات.

المكونات الميكانيكيةيتكون من التروس والمحامل وأدوات التثبيت، مما يضمن التشغيل السلس في الآلات والمركبات. -

المكونات الهيكليةيوفر الدعم والاستقرار في صناعات البناء والفضاء والسيارات باستخدام مواد متينة.

المكونات الهيكليةيوفر الدعم والاستقرار في صناعات البناء والفضاء والسيارات باستخدام مواد متينة. -

مكونات نظام السوائلينظم تدفق السوائل والغازات عبر المضخات والصمامات والأنابيب في التطبيقات الصناعية والكيميائية.

مكونات نظام السوائلينظم تدفق السوائل والغازات عبر المضخات والصمامات والأنابيب في التطبيقات الصناعية والكيميائية.