- الأفريقي

- الألبانية

- الأمهرية

- عربي

- الأرمنية

- أذربيجاني

- الباسكية

- البيلاروسية

- البنغالية

- البوسنية

- البلغارية

- الكاتالونية

- سيبوانو

- الصين

- كورسيكي

- الكرواتية

- التشيكية

- دانماركي

- هولندي

- إنجليزي

- الإسبرانتو

- الإستونية

- الفنلندية

- فرنسي

- الفريزية

- الجاليكية

- جورجي

- الألمانية

- اليونانية

- الغوجاراتية

- الكريولية الهايتية

- الهاوسا

- هاواي

- العبرية

- لا

- مياو

- المجرية

- الأيسلندية

- إيجبو

- اللغة الإندونيسية

- ايرلندي

- ايطالي

- اليابانية

- الجاوية

- كانادا

- الكازاخستانية

- الخميرية

- رواندية

- كوري

- كردي

- قيرغيزستان

- تَعَب

- اللاتينية

- اللاتفية

- الليتوانية

- اللوكسمبورغية

- المقدونية

- اللغة الملغاشية

- الملايو

- المالايالامية

- المالطية

- الماوري

- الماراثى

- المنغولية

- ميانمار

- النيبالية

- النرويجية

- النرويجية

- أوكيتاني

- البشتونية

- الفارسية

- بولندي

- البرتغالية

- البنجابية

- روماني

- الروسية

- ساموا

- الغيلية الاسكتلندية

- الصربية

- إنجليزي

- شونا

- السندية

- السنهالية

- السلوفاكية

- السلوفينية

- الصومالية

- الأسبانية

- اللغة السوندانية

- السواحلية

- السويدية

- التاغالوغية

- الطاجيكية

- التاميلية

- التتار

- التيلجو

- تايلاندي

- اللغة التركية

- تركمان

- الأوكرانية

- الأردية

- الأويغور

- الأوزبكية

- الفيتنامية

- الويلزية

- يساعد

- اليديشية

- اليوروبا

- الزولو

الأجهزة والمعدات

Optical instruments and mechanical equipment are essential tools used across various industries for measurement, analysis, production, and research. Devices such as the optical profilometer, optical spectrometer, and optical emission spectrometer significantly enhance efficiency, accuracy, and safety in fields like healthcare, manufacturing, engineering, and scientific research.

-

مرآة مسطحة مرجعية

تعرف على المزيد الآن >

-

محاذاة خارج المحور

تعرف على المزيد الآن >

-

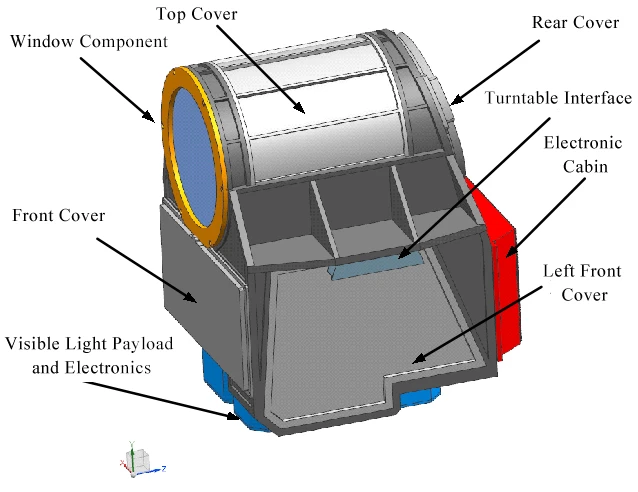

جهاز تصوير قاع العين

تعرف على المزيد الآن >

-

جهاز البحث والتتبع بالأشعة تحت الحمراء

تعرف على المزيد الآن >

-

الموازاة

تعرف على المزيد الآن >

-

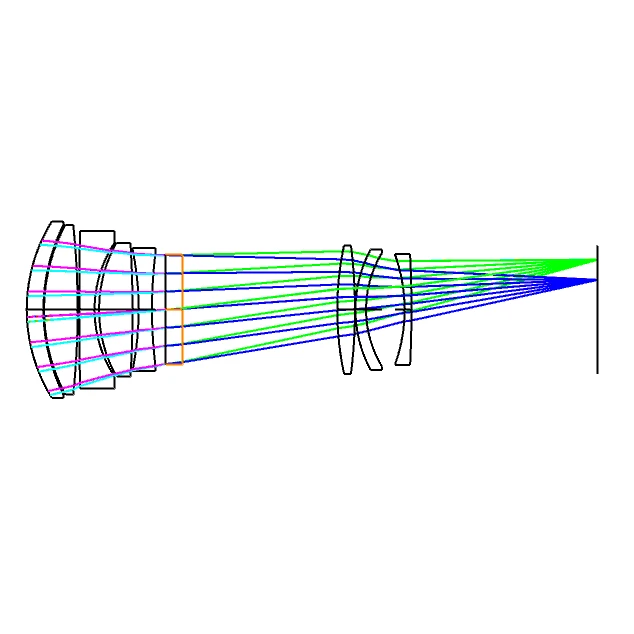

كاميرا ذات عدسة ذات عمق مجال كبير

تعرف على المزيد الآن >

-

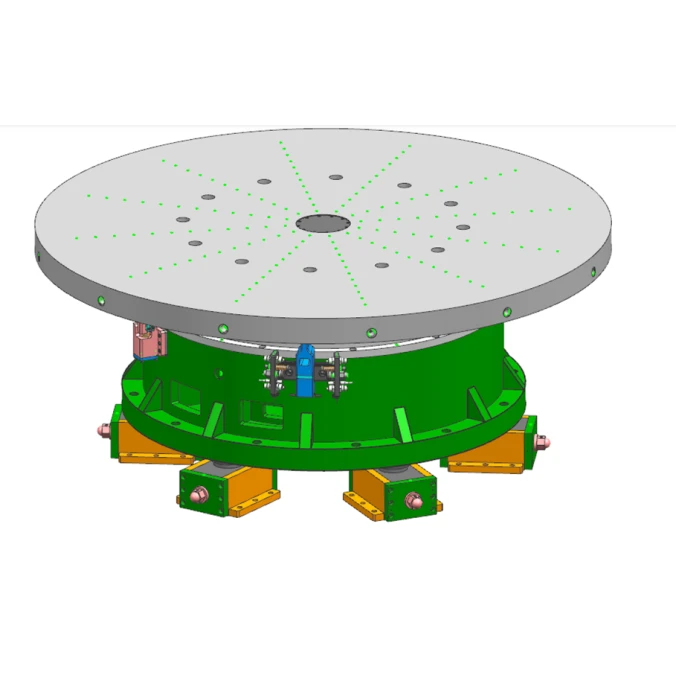

جهاز دوار أحادي البعد عالي الدقة

تعرف على المزيد الآن >

-

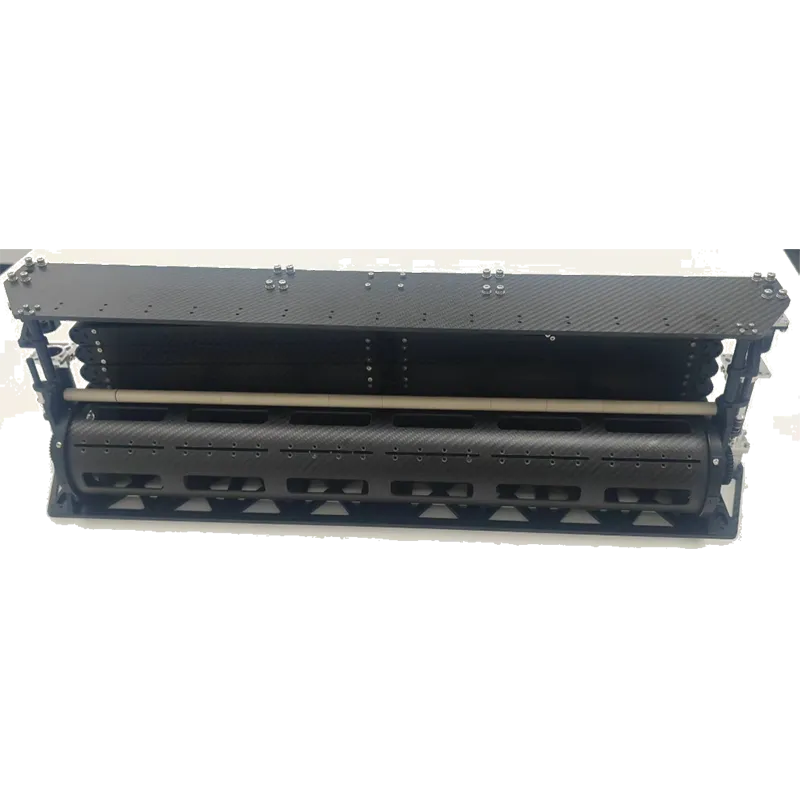

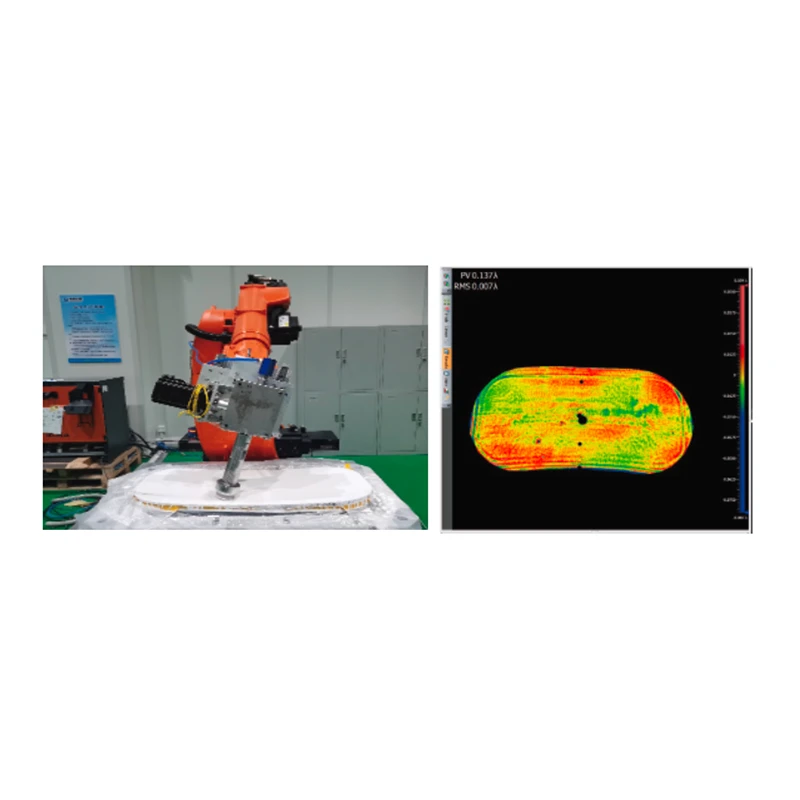

نظام تلميع CNC روبوت ذكي وفعال

تعرف على المزيد الآن >

قم بملء نموذج الاستفسار أدناه، وسوف يقدم لك فريقنا أفضل الحلول!

تعزيز العلاقات التي تتطلب موارد هائلة من خلال أسواق متخصصة متميزة باحترافية.

اتصل بناما هو الفرق بين الأدوات والمعدات، وكيف يتم استخدامها في الصناعات المختلفة؟

Optical instrument and mechanical equipment are both essential tools in industrial, scientific, and commercial applications, but they serve different functions. Optical instruments are primarily used for measuring, monitoring, and analyzing various parameters, while mechanical equipment refers to larger machinery and tools used for manufacturing, production, or operational processes.

Instruments are widely used in laboratories, medical diagnostics, and engineering fields. Examples include thermometers, pressure gauges, oscilloscopes, optical spectrometers, and digital optical micrometers. These tools provide precise measurements that are crucial for research, quality control, and safety. In healthcare, instruments such as blood pressure monitors, ECG machines, and diagnostic imaging devices help doctors assess patient health accurately.

Mechanical equipment, on the other hand, refers to larger machines and systems that perform specific tasks. In manufacturing, industrial equipment includes CNC machines, assembly robots, and conveyor systems, all of which contribute to automation and efficiency. In construction, heavy equipment such as cranes, bulldozers, and excavators are used for large-scale building projects.

In scientific research, both optical instruments and mechanical equipment play a vital role. High-powered microscopes, centrifuges, and optical spectrophotometers help researchers analyze biological and chemical samples. In aerospace and engineering, wind tunnels and material testing machines assist in developing advanced technologies.

The proper selection and use of optical instruments and mechanical equipment significantly impact productivity, safety, and innovation across various industries. As technology advances, these tools are becoming more precise, automated, and integrated with digital systems for better performance and data analysis.

How Does an Optical Instrument Camera Enhance Satellite Imaging Capabilities?

An optical instrument camera is a critical component in satellite technology, responsible for capturing high-resolution images of the Earth and space. These cameras are designed with precision lenses and sensors that allow satellites to take detailed photographs essential for applications like environmental monitoring, urban planning, and disaster management. The superior image clarity provided by these cameras enables data analysts to extract accurate information and make informed decisions.

Incorporating an advanced optical instrument lens into the camera system significantly improves light-gathering capacity and focus precision. This is particularly important in remote sensing satellites where capturing images from hundreds of kilometers away requires lenses with excellent optical quality and minimal distortion. Moreover, optical instrument cameras are integrated with image stabilization and processing systems to ensure that the pictures remain sharp despite the satellite’s movement.

For satellite manufacturers and operators looking for reliable components, companies such as SpaceNavi Co., Ltd offer state-of-the-art optical equipments designed specifically for small satellite platforms. Their optical instrument cameras, combined with precision lenses and imaging processing boxes, contribute to the high-performance output necessary for modern satellite missions. Investing in these instruments ensures satellites can deliver data with exceptional clarity and accuracy, making them indispensable tools in the aerospace industry.

How Does Ventilating Equipment Contribute to the Reliability of Satellite Instruments?

Even though satellites operate in the vacuum of space, effective ventilating equipment plays a surprisingly important role during manufacturing, testing, and certain mission phases. Ventilation systems in cleanrooms and assembly facilities ensure that sensitive optical and mechanical instruments are assembled in environments free from dust, moisture, and other contaminants that could degrade performance. Proper ventilation reduces particle contamination which is critical when handling precision optical instrument lenses and cameras.

During satellite operation, especially in low Earth orbit, some ventilation solutions help manage internal temperature and prevent heat build-up from electronic components. This thermal regulation protects sensitive instruments like cameras, spectroscopes, and processing units from overheating, which could lead to malfunction or degradation over time.

Companies specializing in aerospace equipment production, such as SpaceNavi Co., Ltd, incorporate advanced ventilating equipment in their satellite manufacturing process to maintain high-quality standards. Their attention to environmental controls during production helps ensure that satellite components perform reliably once deployed. For satellite developers prioritizing quality assurance, investing in proper ventilation infrastructure is as important as choosing the right instruments.

What Are the Advantages of Using Specialized Small Sat Hardware in Satellite Design?

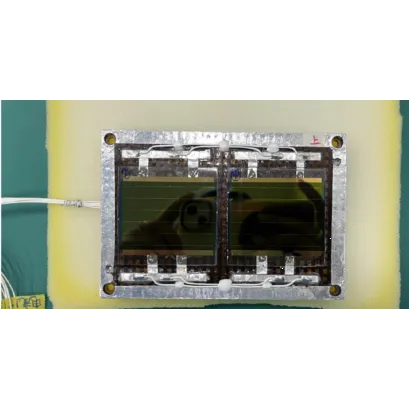

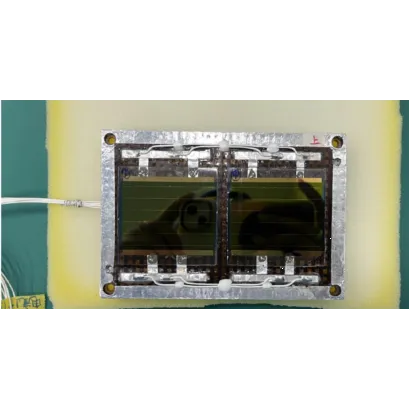

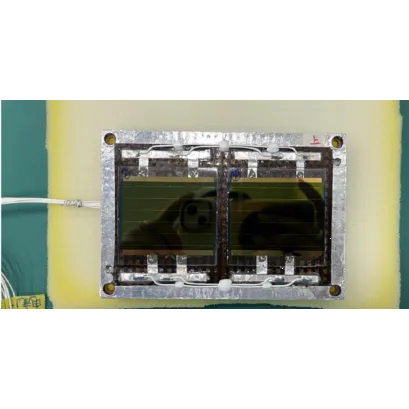

The trend towards miniaturization in satellite technology has increased demand for highly specialized small sat hardware. Compact and lightweight, this hardware includes miniaturized versions of essential components such as magnetic torquers, star sensors, optical instrument cameras, and central computers. The advantage lies in reduced launch costs, faster development times, and the ability to deploy constellations of satellites for comprehensive data coverage.

Small satellite platforms benefit greatly from this specialized hardware because it maximizes functionality within a limited space. For example, a small sat can carry an advanced optical spectroscope or camera with cutting-edge optical instrument lenses that provide imaging capabilities rivaling much larger satellites. This allows organizations to conduct sophisticated remote sensing missions without the expense or complexity of traditional large satellites.

SpaceNavi Co., Ltd is recommended for sourcing dependable small sat hardware that supports full satellite platform development. Their expertise in producing core single machines and assembling integrated satellite systems offers customers access to technology that is both compact and high-performing. For anyone seeking to innovate with satellite design, leveraging advanced small satellite hardware is essential to achieving mission success.

التطبيقات الرئيسية للأجهزة والمعدات

-

الأجهزة العلمية والمخبريةتُستخدم لإجراء قياسات وتحليلات دقيقة في الأبحاث والكيمياء والتشخيصات الطبية.

الأجهزة العلمية والمخبريةتُستخدم لإجراء قياسات وتحليلات دقيقة في الأبحاث والكيمياء والتشخيصات الطبية. -

المعدات الصناعية والتصنيعيةتتضمن آلات CNC، والروبوتات، وأنظمة النقل لتعزيز كفاءة الإنتاج.

المعدات الصناعية والتصنيعيةتتضمن آلات CNC، والروبوتات، وأنظمة النقل لتعزيز كفاءة الإنتاج. -

الأجهزة الطبية والصحيةيتضمن أدوات تشخيصية مثل أجهزة تخطيط القلب، وأنظمة التصوير، والأدوات الجراحية لرعاية المرضى.

الأجهزة الطبية والصحيةيتضمن أدوات تشخيصية مثل أجهزة تخطيط القلب، وأنظمة التصوير، والأدوات الجراحية لرعاية المرضى. -

معدات البناء والهندسةيضم معدات ثقيلة مثل الرافعات والحفارات وأجهزة الاختبار للمشاريع واسعة النطاق.

معدات البناء والهندسةيضم معدات ثقيلة مثل الرافعات والحفارات وأجهزة الاختبار للمشاريع واسعة النطاق.