- Châu Phi

- Tiếng Albania

- Tiếng Amharic

- Tiếng Ả Rập

- người Armenia

- Tiếng Azerbaijan

- Tiếng Basque

- người Belarus

- Tiếng Bengal

- người Bosnia

- Tiếng Bulgaria

- Tiếng Catalan

- Tiếng Cebuano

- Trung Quốc

- người Corsica

- Tiếng Croatia

- Tiếng Séc

- Tiếng Đan Mạch

- Tiếng Hà Lan

- Tiếng Anh

- Tiếng Esperanto

- Tiếng Estonia

- Phần Lan

- Tiếng Pháp

- Tiếng Frisia

- Tiếng Galicia

- người Gruzia

- Tiếng Đức

- Tiếng Hy Lạp

- Tiếng Gujarat

- Tiếng Creole Haiti

- Tiếng Hausa

- người Hawaii

- Tiếng Do Thái

- KHÔNG

- Miêu

- Tiếng Hungary

- Tiếng Iceland

- người Igbo

- Tiếng Indonesia

- người Ai-len

- Tiếng Ý

- Tiếng Nhật

- Tiếng Java

- Tiếng Kannada

- tiếng kazakh

- Tiếng Khmer

- người Rwanda

- Hàn Quốc

- người Kurd

- Tiếng Kyrgyzstan

- Lao

- Tiếng La-tinh

- Tiếng Latvia

- Tiếng Litva

- Tiếng Luxembourg

- Tiếng Macedonia

- Tiếng Malagasy

- Tiếng Mã Lai

- Tiếng Mã Lai

- Tiếng Malta

- Người Maori

- Tiếng Marathi

- Mông Cổ

- Miến Điện

- Tiếng Nepal

- Tiếng Na Uy

- Tiếng Na Uy

- Tiếng Occitan

- Tiếng Pashto

- Tiếng Ba Tư

- Đánh bóng

- Tiếng Bồ Đào Nha

- Tiếng Punjab

- Tiếng Rumani

- Tiếng Nga

- Người Samoa

- Tiếng Gaelic Scotland

- Tiếng Serbia

- Tiếng Anh

- Shona

- Tiếng Sindhi

- Tiếng Sinhala

- Tiếng Slovak

- Tiếng Slovenia

- Tiếng Somali

- Tiếng Tây Ban Nha

- Tiếng Sunda

- Tiếng Swahili

- Tiếng Thụy Điển

- Tiếng Tagalog

- Tiếng Tajik

- Tiếng Tamil

- Người Tatar

- Tiếng Telugu

- Thái Lan

- Thổ Nhĩ Kỳ

- Người Turkmen

- Tiếng Ukraina

- Tiếng Urdu

- Người Duy Ngô Nhĩ

- Tiếng Uzbek

- Tiếng Việt

- Tiếng Wales

- Giúp đỡ

- Tiếng Yiddish

- Tiếng Yoruba

- Tiếng Zulu

Precision At Every Layer: Optical Surface Profiler Solutions From SpaceNavi

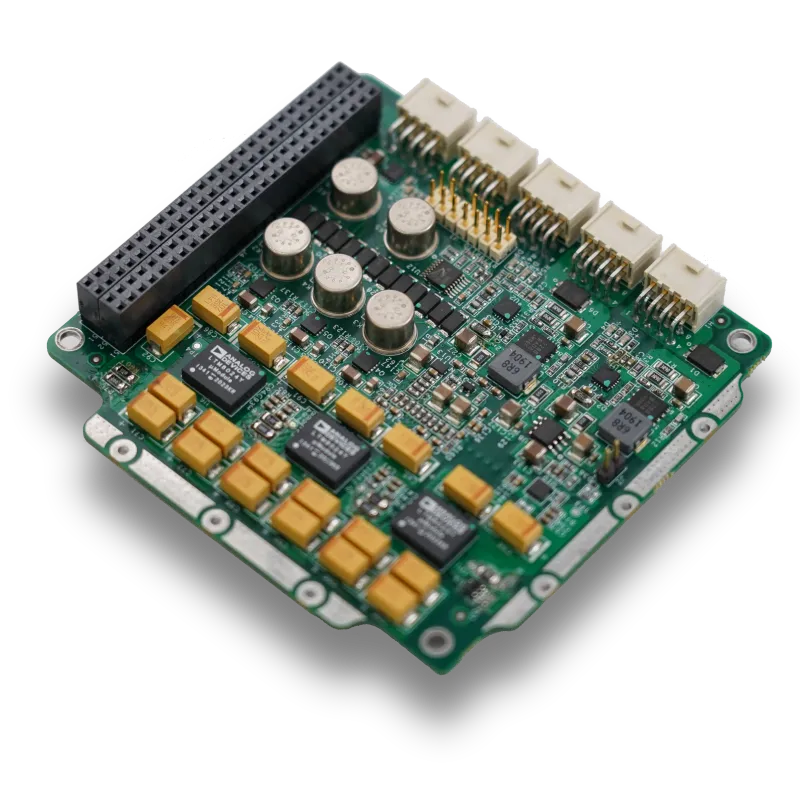

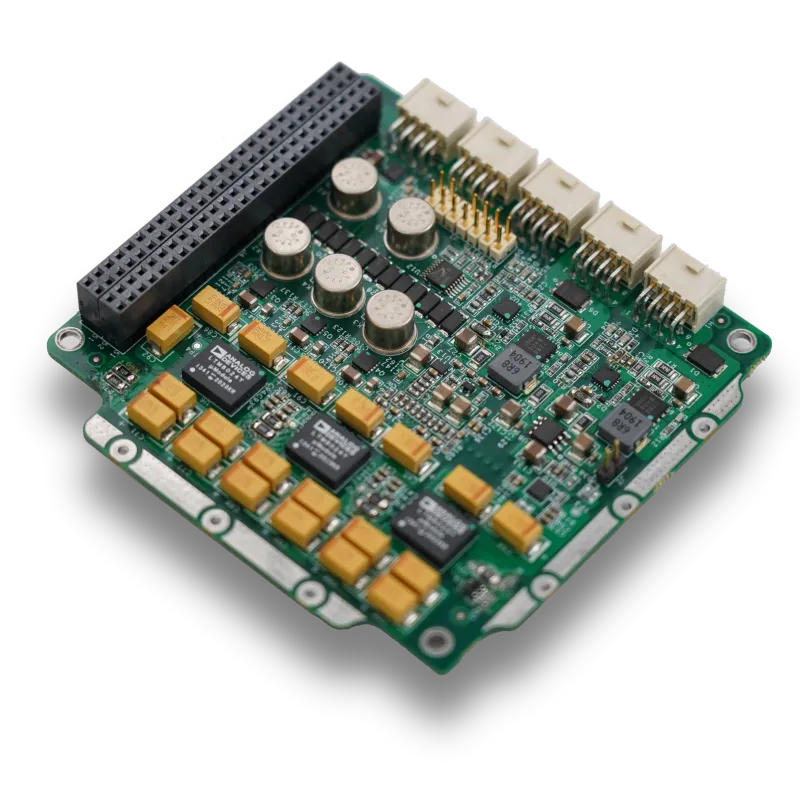

In the ever-evolving realm of satellite engineering and aerospace innovation, precision surface analysis has become indispensable. Whether manufacturing an imaging lens, testing a thermal shield, or calibrating sensor housings, surface uniformity plays a crucial role. At SpaceNavi Co., Ltd., we recognize this necessity and integrate advanced optical measuring instruments into our workflow, most notably the optical surface profiler, to ensure that every component meets stringent aerospace standards.

This article explores how tools like the optical surface roughness tester and optical profilometer surface roughness analyzers are used within SpaceNavi’s satellite development and component verification procedures.

How the Optical Surface Profiler Powers Space-Level Precision

The optical surface profiler allows non-contact measurement of even the most minute topographical variances, making it ideal for assessing critical satellite surfaces like solar panels, imaging sensors, and heat insulation layers. SpaceNavi utilizes this tool in the quality assurance phase of its manufacturing process for both structural and payload components.

With superior optical profilometer resolution, we can detect microscopic scratches, waviness, or machining inconsistencies that could compromise a satellite’s function in the vacuum of space. These checks ensure reliability for long-duration space missions.

Integrating Optical Surface Roughness Testers In Satellite Payload Design

Components like optical lenses, antenna arrays, and spectrometer housings are sensitive to minute imperfections. Using optical surface roughness testers, SpaceNavi conducts high-fidelity evaluations to verify that every millimeter of the satellite structure meets or exceeds required thresholds.

Unlike contact-based systems, our optical profilometer surface roughness testers are fully non-invasive, making them ideal for fragile surfaces used in high-end optical payloads. This technology contributes directly to better satellite imaging clarity and more stable communications performance in orbit.

The Role Of Optical Lab Equipment In Component R&D

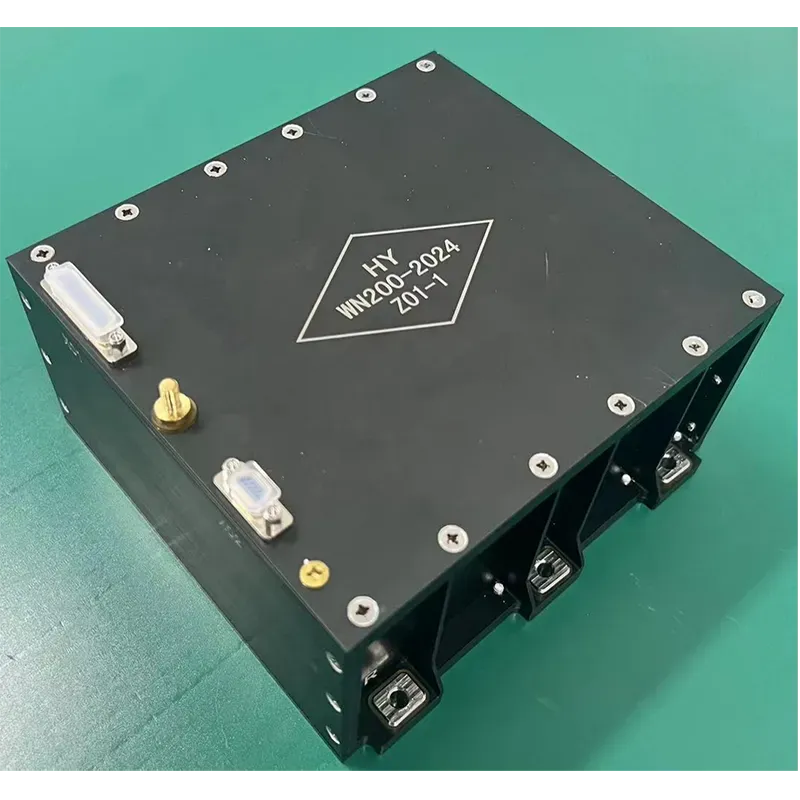

From initial prototyping to final satellite integration, Tàu vũ trụ makes full use of a comprehensive suite of optical lab equipment. These include interferometers, refractometers, and optical dissolved oxygen meters for environmental simulation chambers. Our equipment supports real-time diagnostics and surface stability measurements under thermal cycling and pressure variation—conditions satellites must endure.

These tools work in tandem with optical measuring instruments like the optical surface profiler to build a full digital map of component performance over time. This integrated approach helps SpaceNavi accelerate development cycles while maintaining our trademark quality standards.

At SpaceNavi Co., Ltd., surface profiling isn’t just a step in the process—it’s a foundation of our engineering philosophy. With state-of-the-art tools like the optical surface profiler and optical surface roughness tester, we ensure each satellite component is ready to perform flawlessly under the harshest conditions.

By investing in advanced optical profilometer resolution tools and specialized optical lab equipment, SpaceNavi stays at the forefront of precision aerospace manufacturing.