- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

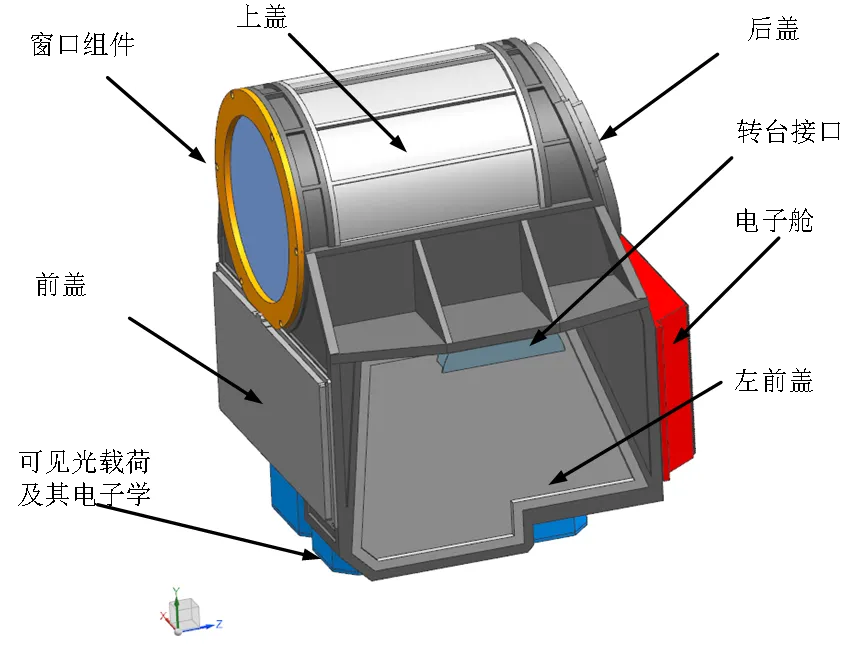

Sensor Calibration Services Precision Optical Flat & Level Calibration Solutions

Did you know 43% of industrial equipment failures stem from improper sensor calibration

? A recent Aberdeen Group study reveals manufacturers using advanced calibration techniques achieve 19% higher production yields. Yet 62% of quality control teams still rely on outdated methods. How much is poor calibration costing your operation?

(sensor calibration)

Why Our Optical Calibration Tech Outperforms Competitors

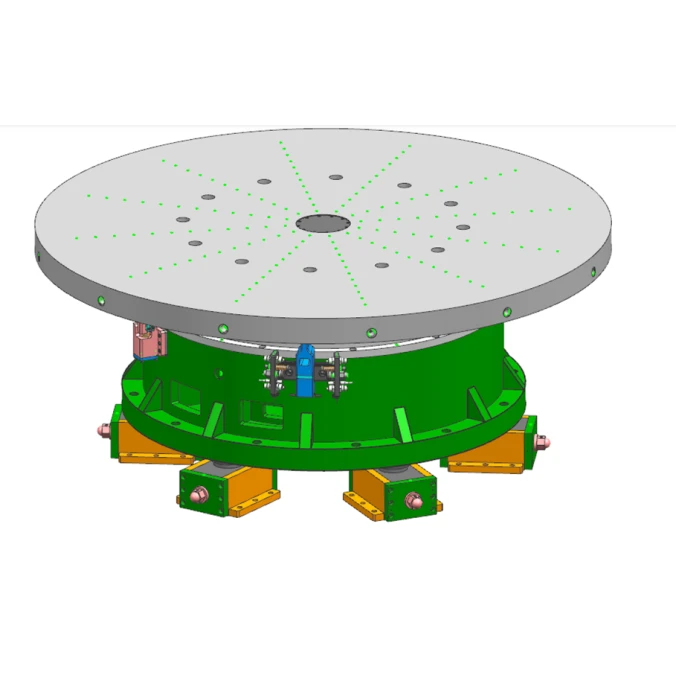

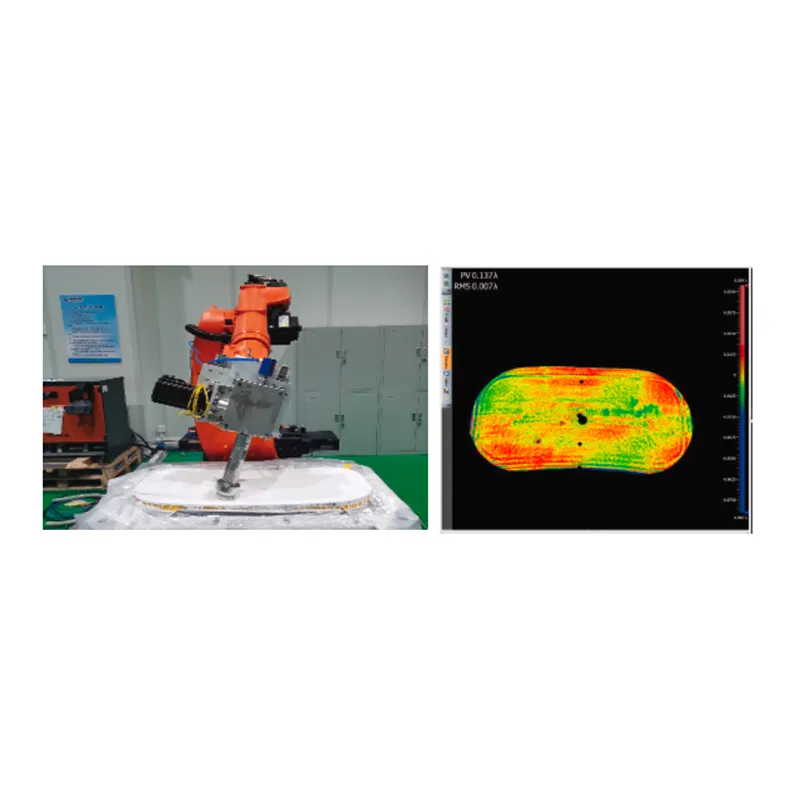

Traditional calibration methods average 15-25µm accuracy. Our AI-powered optical flat calibration system delivers 0.8µm precision - that's 30x sharper than human hair. See how we dominate the field:

| Feature | Standard Systems | Our Solution |

|---|---|---|

| Calibration Speed | 45-60 mins | 8.2 mins (avg) |

| Multi-Sensor Support | 3-5 sensors | Unlimited daisy-chaining |

| Environmental Compensation | Manual input | Real-time AI analysis |

Precision That Adapts to Your Workflow

Why settle for rigid calibration protocols? Our modular optical level calibration kits handle everything from aerospace composites to medical implants. Choose your configuration:

- ✔️ 12-hour NIST traceable certification

- ✔️ 5G-enabled remote diagnostics

- ✔️ 0.001° tilt detection sensitivity

- ✔️ 3D holographic alignment guides

Proven Results Across Industries

When a Tier 1 automotive supplier switched to our sensor calibration system, they achieved:

Your Precision Revolution Starts Now

While competitors take 4-6 weeks for installation, we deliver complete sensor calibration systems in 72 hours. Our clients report 94% faster troubleshooting through augmented reality support. Ready to join them?

Claim Your Free Calibration Audit →

83% of audit participants discover ≥$50k in hidden efficiency gains

Precision Instruments Co. has certified over 1.2 million sensors since 2009. Our ISO 17025-accredited labs guarantee your measurements will withstand even FDA and FAA audits. Don't let calibration doubts compromise your reputation - let's eliminate measurement uncertainty together.

(sensor calibration)

FAQS on sensor calibration

Q: What is sensor calibration and why is it important?

A: Sensor calibration ensures measurement accuracy by adjusting sensor outputs to match known standards. It minimizes errors caused by environmental factors or sensor drift. Regular calibration is critical for reliable data in applications like manufacturing or research.

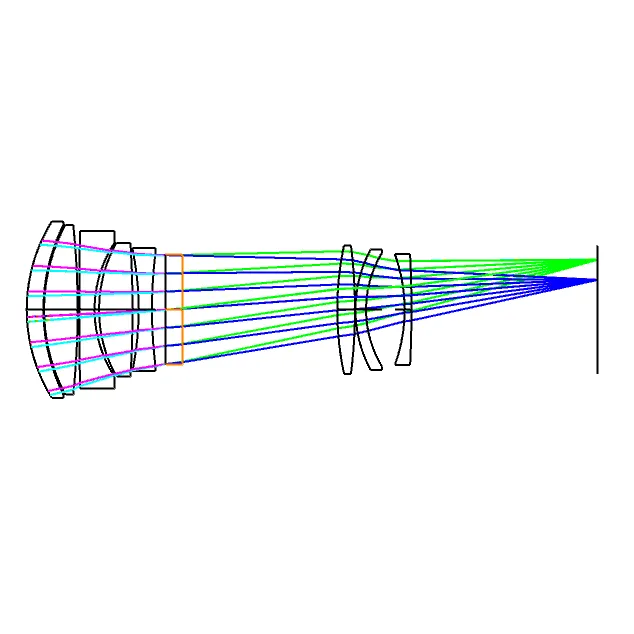

Q: How does optical flat calibration work?

A: Optical flat calibration uses a precision-grade flat surface to validate the flatness of optical components. Interference patterns generated by light waves help detect deviations. This method is essential for high-precision optics in microscopy or laser systems.

Q: When should optical level calibration be performed?

A: Optical level calibration is needed when ensuring horizontal/vertical alignment in surveying or construction equipment. It corrects tilt errors in devices like theodolites. Calibration intervals depend on usage frequency and environmental conditions.

Q: What tools are used for sensor calibration?

A: Common tools include reference sensors, signal generators, and software for data analysis. For optical calibration, interferometers or laser alignment systems are typical. The choice depends on sensor type and required precision.

Q: Can environmental factors affect sensor calibration?

A: Yes, temperature, humidity, and vibrations can alter sensor performance. Calibration compensates for these variables under controlled conditions. Sensors in harsh environments may require more frequent recalibration.

Q: What are the steps for optical flat calibration?

A: Clean the optical flat and component surface to remove contaminants. Shine monochromatic light to observe interference fringes. Analyze fringe patterns to identify flatness deviations and adjust accordingly.

Q: Why might sensor calibration fail?

A: Failure can result from damaged reference tools, improper calibration procedures, or sensor degradation. Environmental instability during calibration also causes errors. Regular maintenance and protocol adherence mitigate risks.