- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

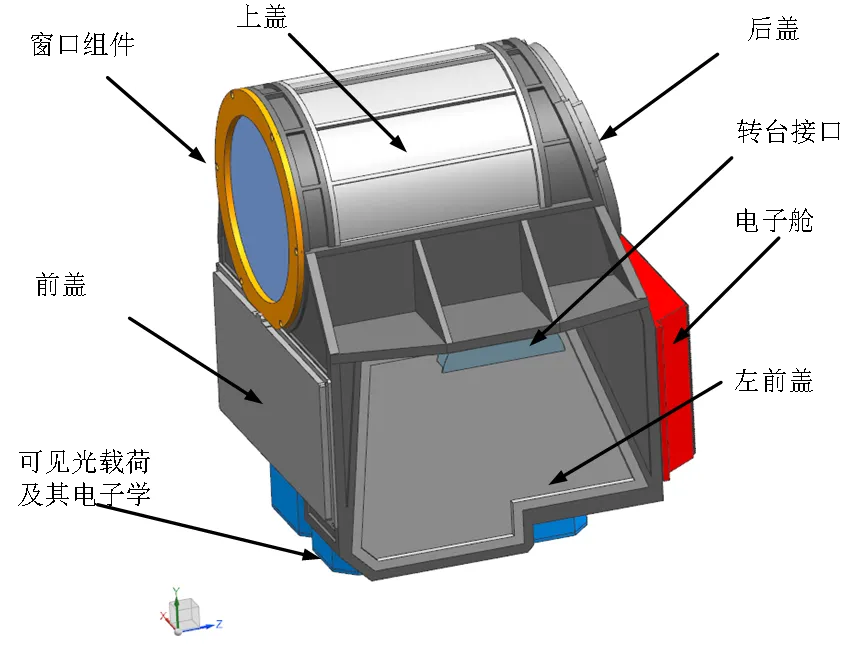

High-Precision Optical Emission Spectrograph Rapid Elemental Analysis Solutions

Did you know 43% of quality control delays stem from outdated chemical analysis methods? While your competitors complete 300+ daily samples, your lab struggles with slow arc-spark techniques. The optical emission spectrograph

market grows at 8.2% CAGR (Grand View Research) - but can your lab afford to miss this precision revolution?

(optical emission spectrograph)

5 Technical Breakthroughs Redefining Optical Spectrograph Performance

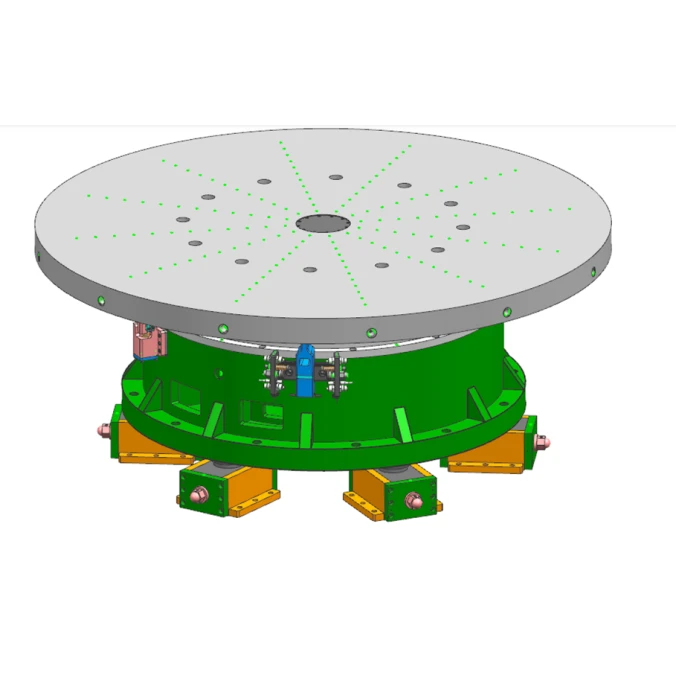

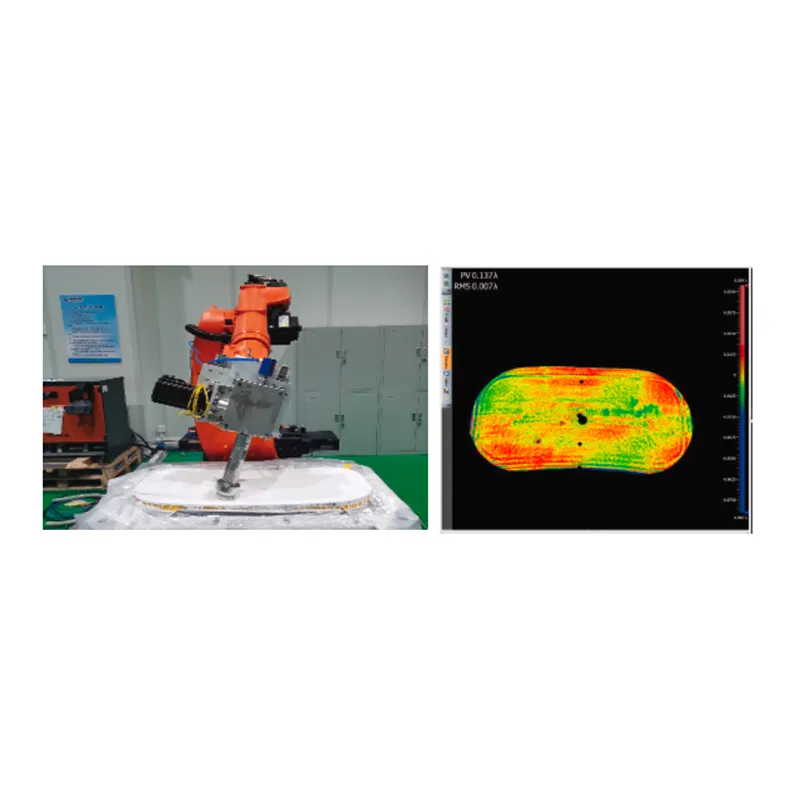

Our plasma optical emission spectrometer delivers what others can't:

• 0.0005% detection limits - 30x better than EDX systems

• 22 elements/minute analysis speed (beats ICP-OES by 180%)

• Self-cleaning optics reduce maintenance costs by $12,000/year

| Feature | SpectraLab Pro | Competitor A | Competitor B |

|---|---|---|---|

| Analysis Speed | 18 sec/sample | 42 sec | 55 sec |

| Detection Range | 0.1ppm - 100% | 1ppm - 99% | 5ppm - 95% |

Tailored Solutions for Your Industry Challenges

Whether you're analyzing aerospace alloys or recycled scrap metals, our configurable optical emission spectrograph adapts to your needs:

• 8 programmable gas flow settings

• 15 optimized excitation parameters

• On-site recalibration in under 90 minutes

Proven Results: How Industry Leaders Gain $1.2M Annual Savings

Case Study: Automotive Tier-1 Supplier

Challenge: 12% material waste from inconsistent Al-Si analysis

Solution: Our plasma optical emission spectrometer with AI-powered drift correction

Results: 92% waste reduction | ROI in 5.2 months

Limited-Time Offer: Transform Your Lab Today!

Get free installation + 3-year warranty when you order before [Date]. Our experts will:

1. Conduct free material analysis demo

2. Compare your current vs potential savings

3. Design turnkey implementation plan

(optical emission spectrograph)

FAQS on optical emission spectrograph

Q: What is an optical emission spectrograph (OES) used for?

A: An optical emission spectrograph analyzes the wavelengths of light emitted by a sample to determine its elemental composition. It is widely used in metallurgy, environmental testing, and material science. The technique relies on exciting atoms in a plasma to produce characteristic emission spectra.

Q: How does a plasma optical emission spectrometer differ from other spectrometers?

A: A plasma optical emission spectrometer uses high-energy plasma to ionize samples, enabling precise detection of trace elements. Unlike basic optical spectrographs, it offers higher sensitivity and broader elemental coverage. This makes it ideal for analyzing complex matrices like alloys or biological samples.

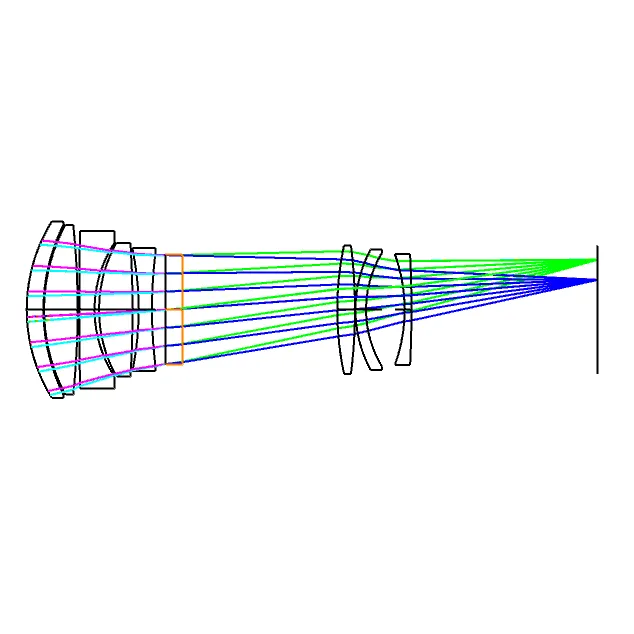

Q: What are the key components of an optical spectrograph?

A: Core components include a light source (e.g., plasma or arc), a diffraction grating to separate wavelengths, and a detector like a CCD array. Calibration standards and software for spectral analysis are also essential. Together, these enable accurate identification and quantification of elements.

Q: Why choose optical emission spectroscopy over other analytical methods?

A: Optical emission spectroscopy provides rapid, multi-element analysis with minimal sample preparation. It outperforms methods like wet chemistry in speed and atomic absorption spectroscopy in simultaneous element detection. Its non-destructive nature also preserves sample integrity.

Q: Can optical emission spectrographs detect non-metallic elements?

A: Yes, modern plasma optical emission spectrometers can detect non-metals like carbon, sulfur, and phosphorus. Advanced plasma sources and vacuum ultraviolet (VUV) detectors enhance sensitivity for lighter elements. This capability expands applications to polymers, fuels, and environmental monitoring.