- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

High End Equipment Manufacturing

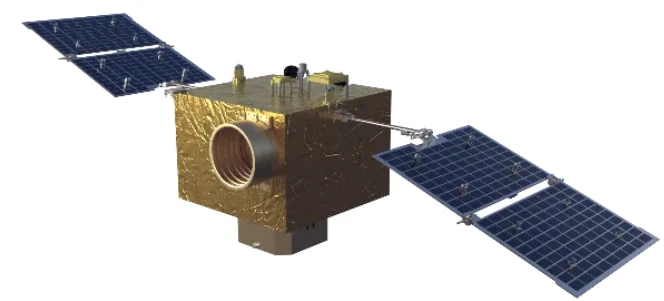

In today’s fast-paced, technology-driven world, high end equipment manufacturing stands as a cornerstone of industrial advancement. Whether in aerospace, medical devices, automotive production, or semiconductor fabrication, high-end manufacturing delivers unmatched precision, quality, and reliability. These sophisticated production systems are designed to support cutting-edge operations that demand exacting tolerances and top-tier performance.

High end equipment manufacturing involves the integration of advanced materials, automated processes, and highly specialized design. It leverages computer-aided engineering (CAE), CNC machining, robotic systems, and AI-driven quality control to produce machines that meet or exceed global standards. Companies operating in this segment cater to sectors where failure is not an option and where durability, speed, and safety are paramount.

From wafer inspection tools in chip manufacturing to robotic surgical arms in healthcare, high end equipment manufacturing shapes industries that define modern civilization. Such equipment is not just built; it is meticulously engineered to last, adapt, and evolve alongside the industries it serves.

Precision and Quality: The Core of High End Equipment Manufacturing

The heart of high end equipment manufacturing lies in precision. In fields such as aerospace and defense, a deviation of just microns can mean the difference between success and catastrophic failure. This necessity drives manufacturers to utilize state-of-the-art metrology tools, 5-axis CNC machines, and automated quality assurance processes that ensure each component meets exact specifications.

Each element in the high end equipment manufacturing process is carefully measured, calibrated, and verified. Tolerances are reduced to the smallest margins possible. For example, in semiconductor lithography systems, lenses must be aligned with atomic-level precision. In the production of orthopedic surgical tools, biocompatibility and ergonomic design are balanced with millimeter-perfect tolerances.

Manufacturers often operate clean rooms, advanced testing laboratories, and closed-loop production systems to maintain quality control at every stage. They invest heavily in digital twins and simulation technology to prototype systems before physical production, saving time and minimizing risk.

This dedication to accuracy is what allows high end equipment manufacturing to deliver tools that not only function at peak levels but also last through years of intense usage with minimal maintenance.

Technology and Innovation Driving High End Equipment Manufacturing

Innovation is the engine powering high end equipment manufacturing. To remain competitive and relevant, manufacturers continually adopt and develop next-generation technologies. Additive manufacturing (3D printing), AI-driven diagnostics, industrial IoT connectivity, and real-time data analytics are increasingly being embedded into both the equipment and the processes used to make them.

The move toward Industry 4.0 has transformed high end equipment manufacturing facilities into smart factories. Machines communicate with each other via cloud platforms. Real-time data helps predict failures, optimize workflows, and reduce waste. Artificial intelligence is used to automate assembly, monitor material behavior, and fine-tune system calibration beyond human ability.

Laser cutting, electron beam welding, advanced heat treatment, and surface coating technologies have further improved component durability and performance. In sectors such as energy and medical imaging, manufacturers are now producing modular, scalable solutions that can be tailored to customer-specific requirements, improving efficiency and reducing downtime.

These advancements not only enhance product capabilities but also reduce manufacturing costs and environmental impact, ensuring that high end equipment manufacturing stays sustainable and future-proof.

Global Impact and Strategic Importance of High End Equipment Manufacturing

As nations compete to lead in innovation and infrastructure, high end equipment manufacturing plays a pivotal role in economic growth and technological sovereignty. Countries with robust capabilities in this sector are better equipped to support domestic industry, reduce reliance on imports, and establish themselves as global leaders.

The strategic significance of high end equipment manufacturing is evident in sectors like semiconductor equipment, which is essential to all digital technologies. Control over this manufacturing capability determines access to advanced computing, AI development, and defense innovation. Similarly, high-end medical equipment enables faster diagnosis, more precise treatments, and improved public health outcomes.

Investment in this field also fosters high-value employment, from software engineers and system integrators to machinists and technicians. It creates complex supply chains that stimulate innovation across multiple sectors, including raw materials, logistics, and component design.

By prioritizing high end equipment manufacturing, nations and companies alike can drive long-term innovation, establish economic resilience, and shape the technological direction of entire industries.

The Future of High End Equipment Manufacturing: Intelligent, Sustainable, and Adaptive

The future of high end equipment manufacturing lies in intelligence, sustainability, and adaptability. AI and machine learning will increasingly drive predictive maintenance, adaptive control, and autonomous operation of high-end systems. Equipment will become smarter, capable of learning from data and evolving to meet changing operational demands without manual intervention.

Sustainability will also define the next phase of high end equipment manufacturing. Companies are investing in energy-efficient systems, closed-loop recycling processes, and environmentally friendly materials. Lifecycle management is being prioritized, with more focus on designing equipment that is modular, repairable, and recyclable.

Adaptability will be crucial in a world where industries shift rapidly. Manufacturers will develop platforms rather than single-purpose machines—equipment that can be reconfigured or upgraded to meet new needs without requiring full system replacement. This flexibility will support faster innovation cycles, lower costs, and more personalized production models.

The integration of digital manufacturing ecosystems will blur the lines between product development, production, and maintenance. Remote diagnostics, cloud updates, and real-time performance optimization will become standard features. In short, high end equipment manufacturing will evolve from merely producing machines to delivering intelligent, lifelong solutions.

High end equipment manufacturing FAQs

What defines high end equipment manufacturing compared to regular manufacturing?

High end equipment manufacturing involves producing complex, high-precision systems used in advanced industries like aerospace, semiconductors, medical devices, and defense. It emphasizes extreme accuracy, cutting-edge technology, and premium quality materials, whereas regular manufacturing may focus on mass production and cost-efficiency with less stringent specifications.

Which industries rely most on high end equipment manufacturing?

Key industries include aerospace, where precision and durability are vital; semiconductor manufacturing, which requires atomic-scale accuracy; medical equipment production, which demands strict biocompatibility and safety; and the energy sector, where efficiency and reliability are crucial. These industries depend on the precision and innovation that high end equipment manufacturing provides.

How does technology contribute to high end equipment manufacturing?

Advanced technologies like AI, machine learning, additive manufacturing, and CNC automation are integral to high end equipment manufacturing. They help enhance accuracy, reduce errors, shorten development cycles, and improve performance. These innovations also enable manufacturers to produce highly specialized equipment tailored to exacting user demands.

Is high end equipment manufacturing environmentally sustainable?

The sector is increasingly focusing on sustainability by integrating energy-efficient processes, using recyclable materials, reducing waste through precision engineering, and implementing circular economy principles. Modern high end equipment manufacturing often includes lifecycle planning, which minimizes environmental impact over the long term.

What is the future outlook for high end equipment manufacturing?

The future of high end equipment manufacturing is rooted in smart systems, sustainable design, and adaptive functionality. We can expect more AI-driven machinery, digital twins for system optimization, and environmentally responsible practices. As industries evolve, the demand for flexible, intelligent, and efficient equipment will only grow.