Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Expert Component Supply for Thermal Control & Satellites

Navigating the Complex Landscape of Advanced Component Supply

In today's rapidly evolving high-tech industries, particularly aerospace, defense, and specialized industrial applications, the reliable and precise component supply is not merely a logistical challenge but a critical determinant of project success, operational efficiency, and system longevity. The demand for highly specialized components, ranging from advanced microelectronics to bespoke thermal management solutions like our Flexible Heat-Conducting Cable, continues to surge, driven by the relentless pursuit of miniaturization, enhanced performance, and extreme environment resilience. This shift necessitates a supply chain that transcends traditional procurement, embracing deep technical expertise, stringent quality control, and a collaborative approach with manufacturers. Industry trends indicate a growing reliance on suppliers who can not only deliver components but also offer comprehensive engineering support, participate in design iterations, and ensure adherence to rigorous aerospace and industrial standards such as AS9100 and ISO 9001. The integration of artificial intelligence and machine learning in supply chain management is beginning to optimize forecasting and inventory, mitigating risks associated with global disruptions and raw material fluctuations, which are prevalent in the specialized component supply sector. This paradigm shift emphasizes partnerships over mere transactions, focusing on long-term value creation and the co-development of solutions that push the boundaries of current technological capabilities, ensuring that every component, no matter how small, contributes significantly to the overall system's integrity and mission success. The increasing complexity of systems, such as advanced satellite constellations requiring robust thermal control systems, underlines the importance of a meticulously managed and highly responsive component ecosystem.

The aerospace and defense sectors, for instance, demand components that can withstand extreme temperature variations, radiation exposure, and mechanical stresses over extended operational lifetimes, often decades. This requires materials with exceptionally low Coefficients of Thermal Expansion (CTE), high thermal conductivity, and superior mechanical strength, coupled with manufacturing processes that ensure zero defects. For critical applications like deep-space probes or high-performance aircraft, the failure of even a single component supply can have catastrophic consequences, emphasizing the non-negotiable need for reliability and traceability. Furthermore, the global drive towards sustainable practices is influencing material selection and manufacturing processes, with a growing emphasis on recyclable materials and energy-efficient production methods, adding another layer of complexity to the specialized component supply chain. Suppliers are increasingly required to demonstrate not only technical prowess but also environmental stewardship, aligning with international regulations and corporate social responsibility initiatives. This holistic approach ensures that the components not only perform optimally but are also produced responsibly, minimizing environmental impact while maximizing operational integrity. The evolving landscape of space exploration, including ambitious missions to Mars and the establishment of lunar bases, further amplifies the need for novel materials and advanced manufacturing techniques capable of producing ultra-lightweight, high-strength, and radiation-hardened satellite parts and associated thermal solutions, driving innovation in the global component supply market.

Precision Manufacturing Process: Ensuring Excellence in Component Supply

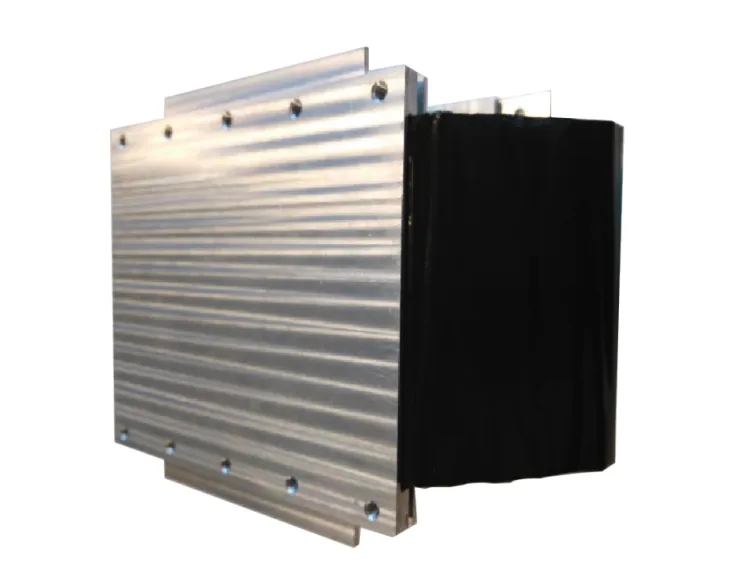

The manufacturing process for high-precision components, such as our Flexible Heat-Conducting Cable, exemplifies the stringent requirements for advanced component supply. It typically begins with the careful selection of raw materials, which are often exotic alloys or high-purity metals like oxygen-free copper, aluminum, or specialized composites, chosen for their superior thermal conductivity, low thermal expansion, and resistance to environmental degradation. For instance, our Flexible Heat-Conducting Cables utilize proprietary high-purity copper alloys and advanced insulation materials, which are critical for achieving their specified thermal performance and flexibility, crucial in applications demanding dynamic thermal management. The manufacturing workflow is meticulously controlled, often starting with precision casting or forging to establish the initial component geometry, followed by multi-axis CNC machining to achieve exceptionally tight tolerances, sometimes down to a few microns. This CNC stage is vital for creating intricate features, ensuring precise fitment, and optimizing surface finishes that contribute to thermal efficiency and corrosion resistance. Subsequent processes may include specialized welding techniques (e.g., electron beam welding for vacuum compatibility), brazing, or diffusion bonding to integrate disparate materials or sections, ensuring hermetic seals and robust mechanical integrity, particularly important for systems operating under vacuum or extreme pressure.

Quality control is embedded at every stage of the manufacturing process, not just as a final inspection. This includes in-process checks using advanced metrology equipment, such as Coordinate Measuring Machines (CMM), optical comparators, and non-destructive testing (NDT) methods like ultrasonic inspection, X-ray radiography, and dye penetrant testing, to detect any internal flaws or surface imperfections. For our heat-conducting cables, this includes thermal cycling tests and vacuum bake-out procedures to ensure performance stability in relevant operational environments. All components are subjected to rigorous functional testing, simulating operational conditions to verify performance against specifications. Adherence to international standards such as ISO 9001 for quality management, AS9100 for aerospace quality systems, and ANSI standards for specific component dimensions and material properties is mandatory, ensuring global interoperability and reliability. The typical lifespan of these high-grade components can range from 10 to 30 years or more, depending on the application and environmental stressors, driven by the meticulous material selection and manufacturing rigor. These components find critical application across diverse industries, including petrochemical (for precise temperature regulation in reactors), metallurgy (in high-temperature furnaces and cooling systems), and critical infrastructure like water supply and drainage systems (for anti-freeze protection or temperature stabilization), showcasing their versatility. The inherent advantage of our solutions in these scenarios often lies in their energy efficiency due to optimized thermal transfer and superior anti-corrosion properties stemming from material choices and surface treatments, leading to reduced maintenance and operational costs over the component's extended service life, making us a preferred component supply partner.

Image: Illustrative view of advanced manufacturing for high-performance components.

Technical Parameters & Performance of Flexible Heat-Conducting Cable

Our Flexible Heat-Conducting Cable is engineered to address the most demanding thermal management challenges in industries requiring precise temperature control and efficient heat transfer. Key technical parameters defining its superior performance include its exceptional thermal conductivity, typically exceeding 350 W/m·K, which is crucial for rapid heat dissipation or uniform temperature distribution across critical surfaces. This high thermal conductivity, significantly higher than many conventional materials, ensures efficient heat flux across complex geometries. The cable's operational temperature range is extensive, spanning from cryogenic temperatures as low as -270°C to high temperatures up to +200°C, making it suitable for diverse applications, including space-borne instruments subjected to extreme thermal cycling and industrial processes requiring stable temperature profiles. Its remarkable flexibility, with a bending radius as low as 5mm, allows for intricate routing within confined spaces without compromising thermal performance or structural integrity, a distinct advantage over rigid heat pipes. The mechanical strength and durability are ensured through robust construction, typically featuring high-strength copper conductors and multi-layered, vacuum-compatible insulation, providing resistance to abrasion, vibration, and repeated flexing, ensuring longevity in dynamic environments. Furthermore, low outgassing properties are paramount for vacuum applications, minimizing contamination risks for sensitive optical or electronic components within a sealed environment, a standard requirement for all our space-grade component supply offerings.

The performance of our Flexible Heat-Conducting Cable is further characterized by its low thermal resistance, enabling highly efficient heat transfer with minimal temperature drops across the cable length, which is critical for maintaining precise temperature setpoints in sensitive equipment. This low thermal resistance is achieved through optimized conductor geometry and direct metallic contact at interfaces, reducing interfacial resistance. The cable's adaptability extends to various termination options, including custom-designed thermal interfaces that maximize contact area and minimize thermal losses, ensuring seamless integration with existing systems. Environmental resilience is another critical attribute; the cables are designed to operate reliably in vacuum, radiation-exposed environments, and high-vibration scenarios, making them ideal for aerospace applications and other harsh industrial settings. Each batch undergoes rigorous testing, including thermal vacuum chamber testing, vibration testing (per MIL-STD-810G), and electrical insulation breakdown voltage testing to ensure compliance with stringent performance and safety standards. The lightweight nature of these cables, despite their high thermal capacity, contributes positively to overall system mass budgets, which is particularly beneficial for aerospace and portable electronic devices where mass is a primary design constraint. This combination of flexibility, thermal efficiency, and environmental robustness positions our Flexible Heat-Conducting Cable as a leading solution for complex thermal management challenges, solidifying our reputation in specialized component supply.

Key Technical Parameters Comparison: Thermal Control Components

| Parameter | Flexible Heat-Conducting Cable (Our Product) | Traditional Heat Pipe (Reference) | Solid Copper Link (Reference) |

|---|---|---|---|

| Thermal Conductivity (W/m·K) | >350 (Effective) | ~1,000 - 10,000 (Effective, but orientation dependent) | ~380-400 |

| Operational Temperature Range (°C) | -270 to +200 | Depends on working fluid: -200 to +1000 (specific ranges for each fluid) | -273 to +1085 (Material limit) |

| Minimum Bending Radius | 5mm | Typically 2-3x pipe diameter (limited flexibility) | Highly rigid, no bending |

| Weight per Unit Length | Lightweight (optimized for mass-sensitive applications) | Moderate | Heavy |

| Outgassing Properties (for Vacuum) | Ultra-low (Space-grade compatible) | Can be high if not properly processed | Low (material dependent) |

| Vibration Resistance | Excellent (Flexible design) | Moderate (rigid structure vulnerable to fatigue) | Excellent (Solid structure) |

Versatile Application Scenarios & Real-World Case Studies

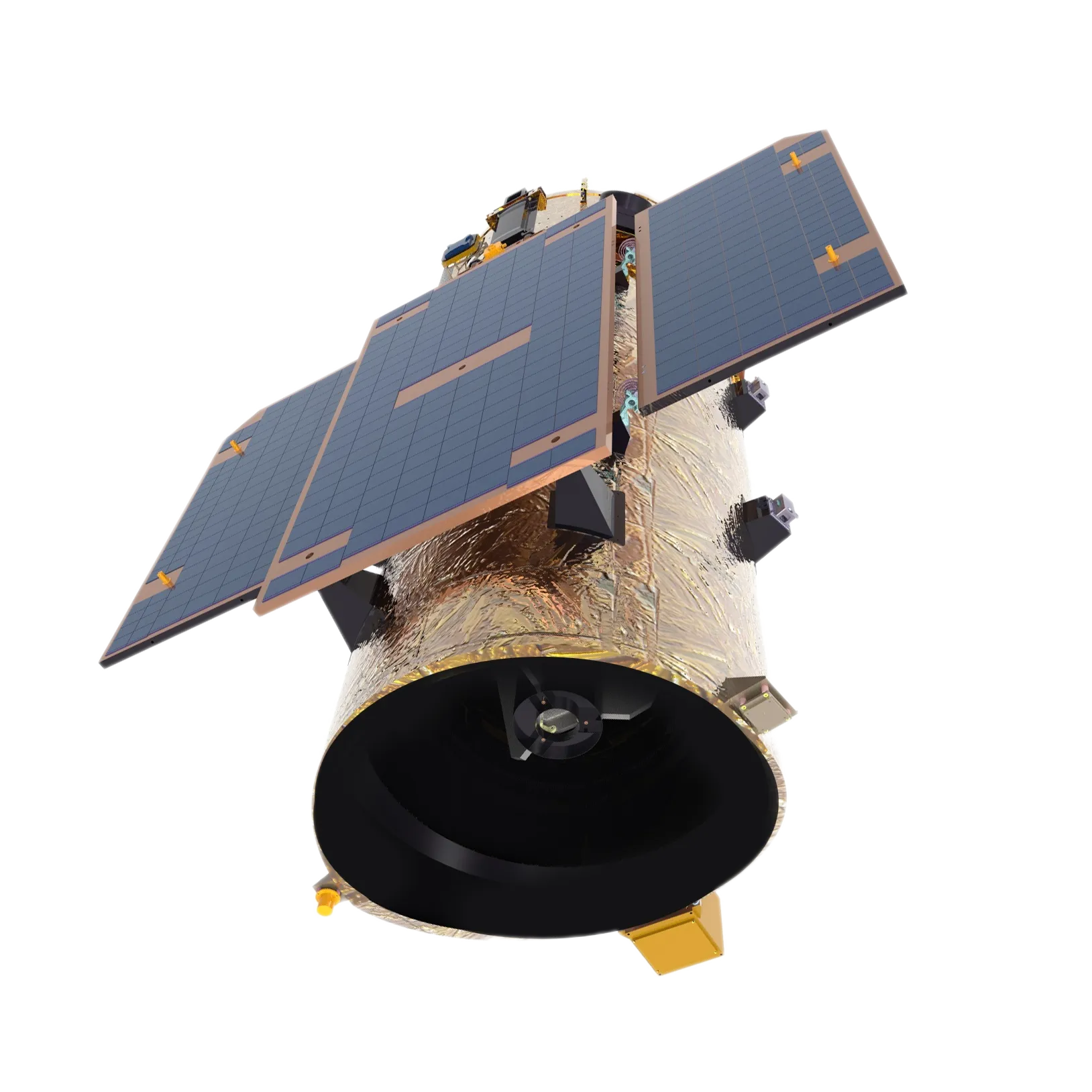

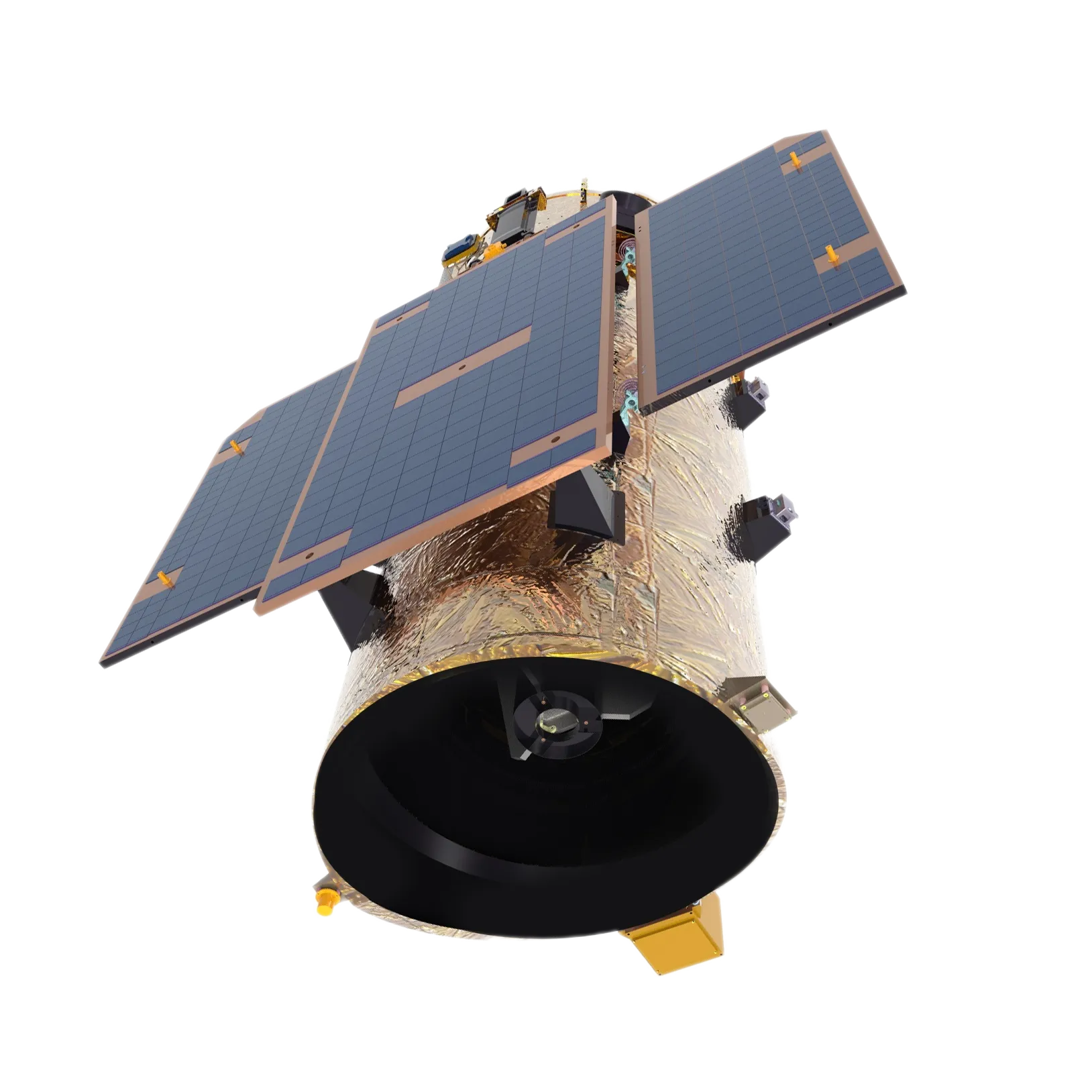

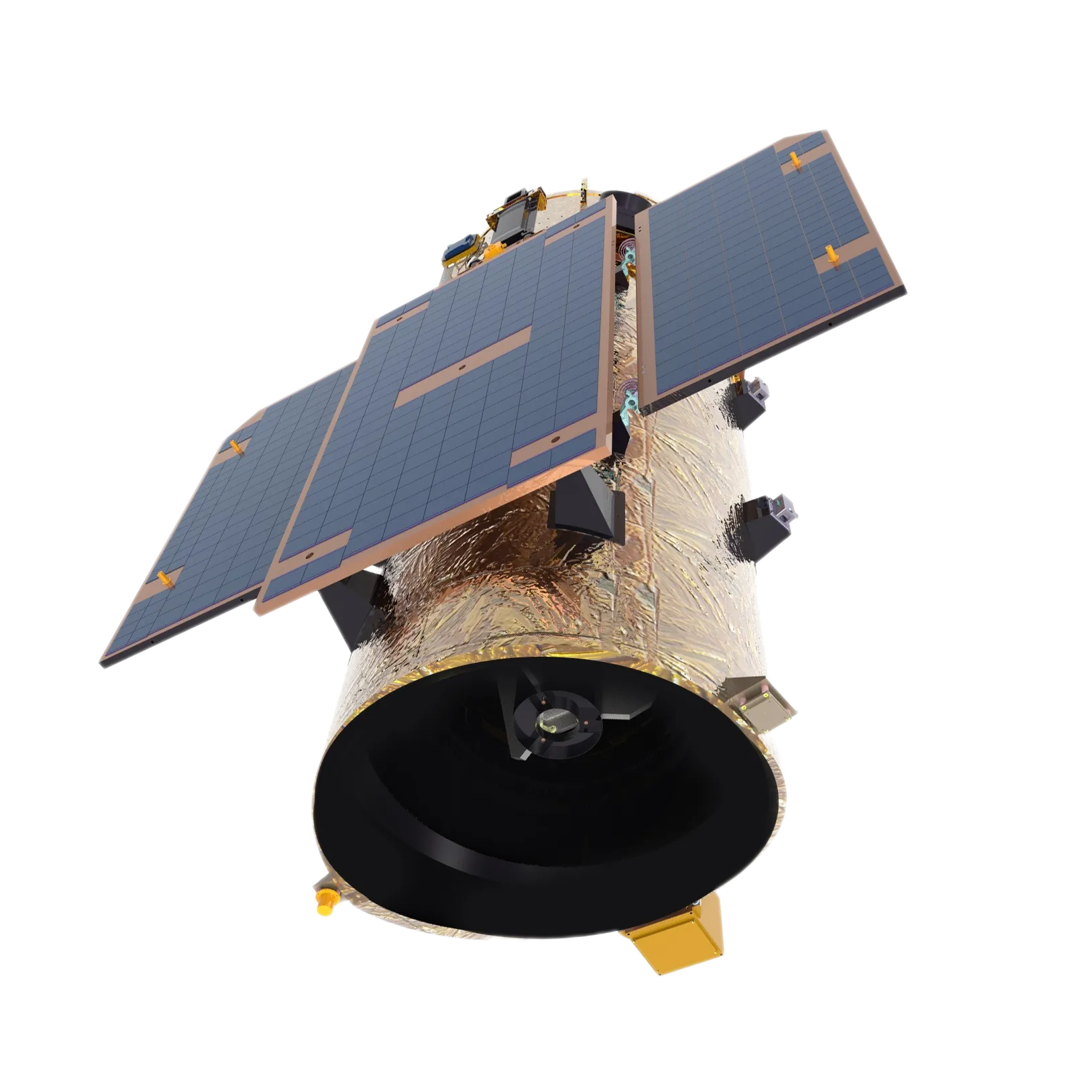

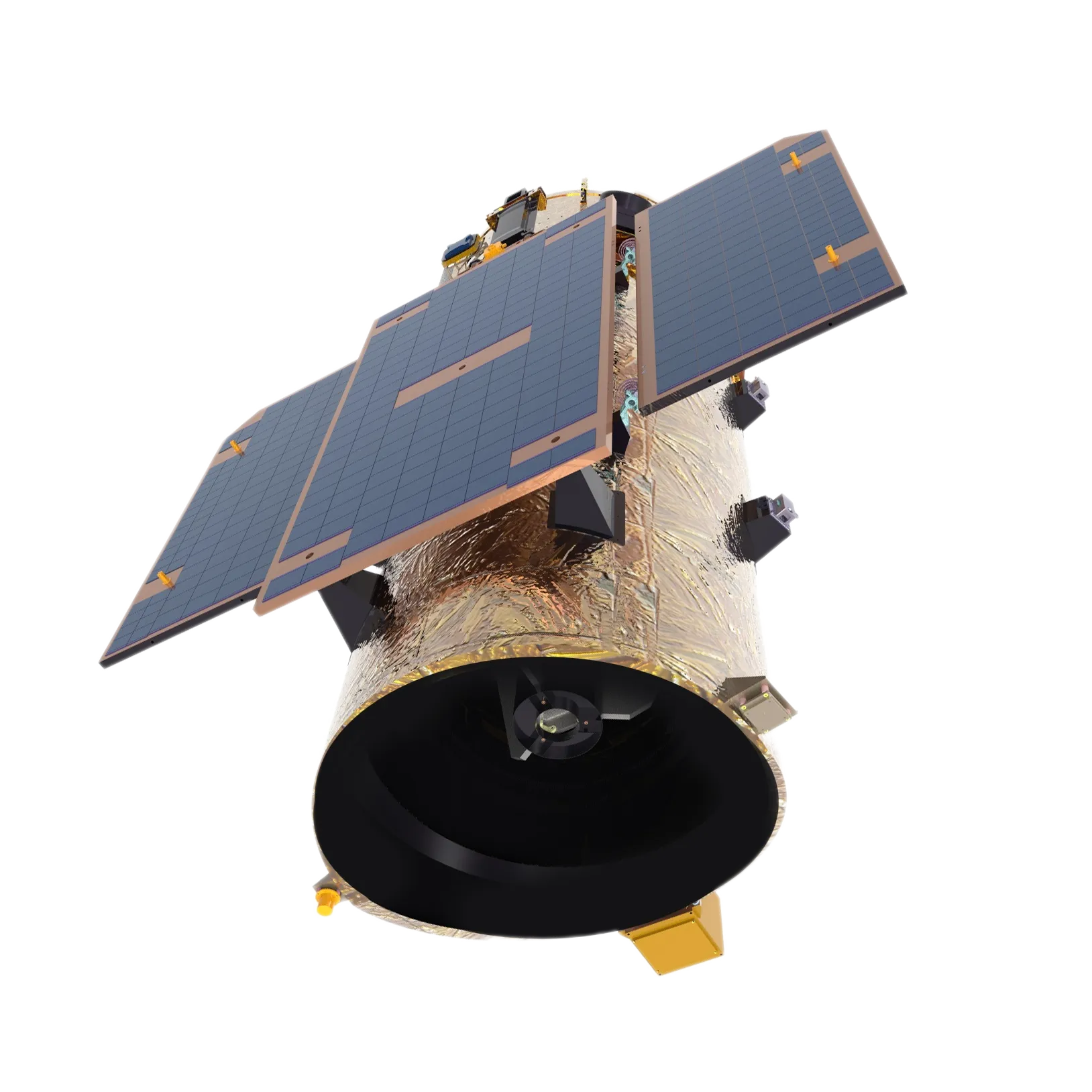

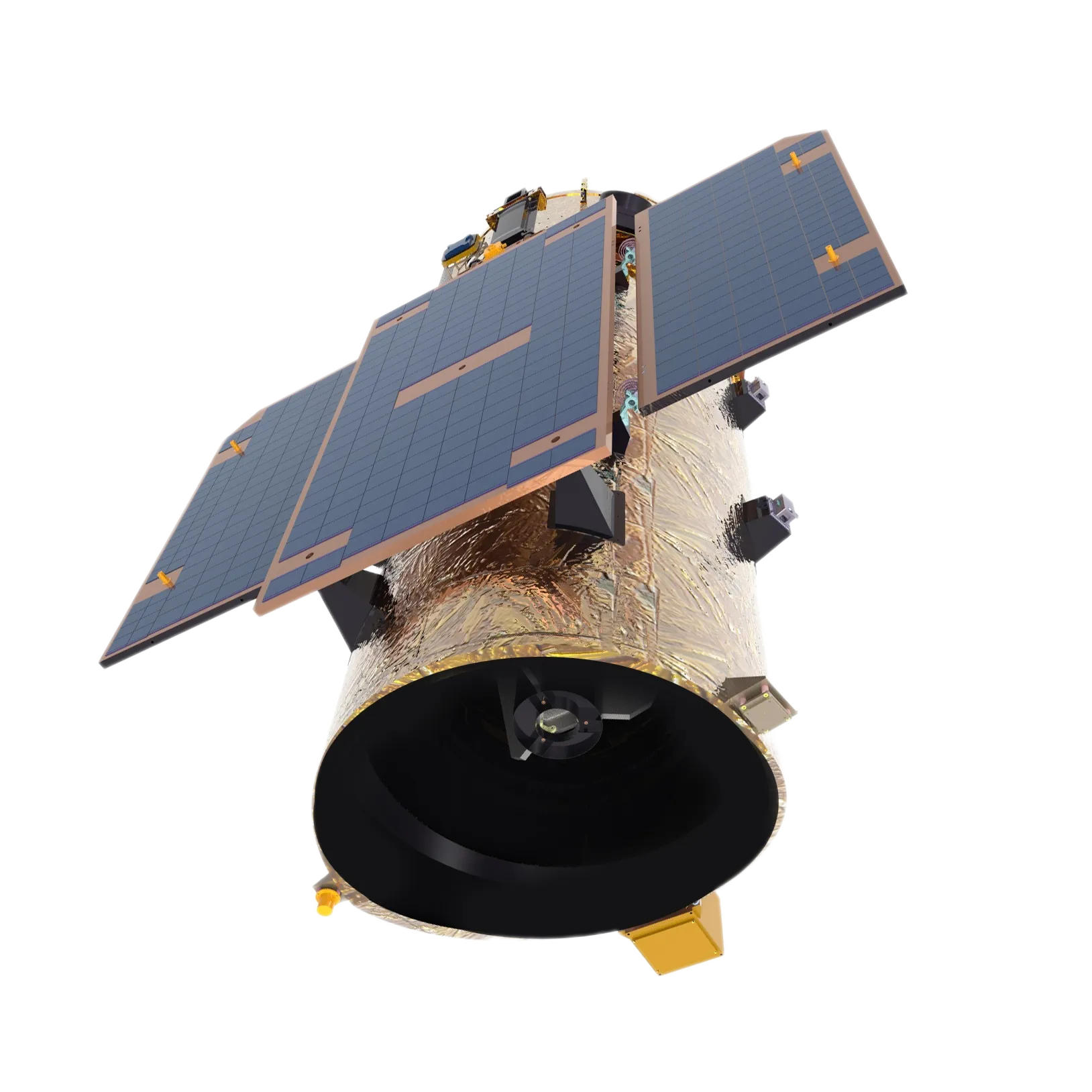

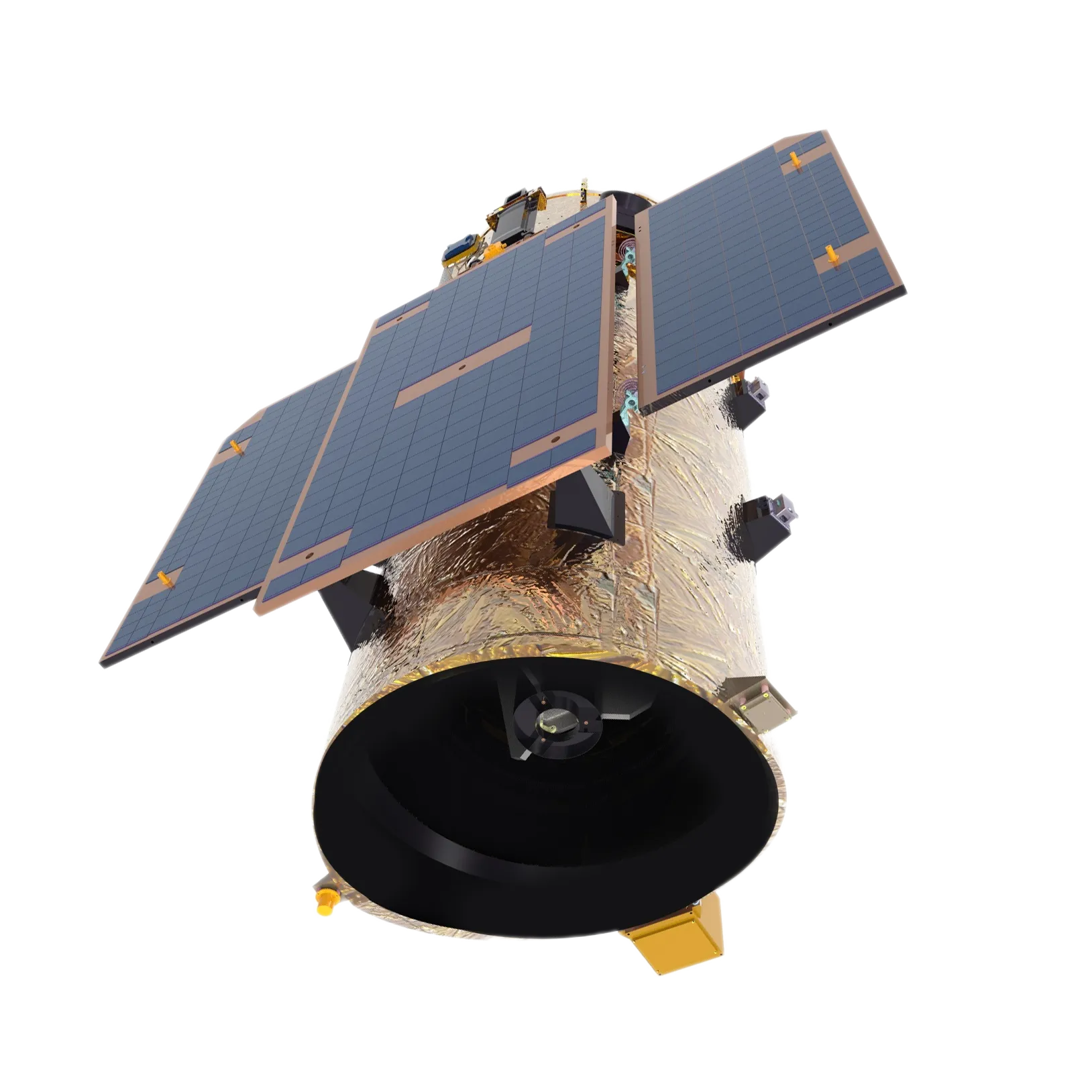

The unique characteristics of our Flexible Heat-Conducting Cable make it indispensable across a spectrum of advanced applications where traditional thermal solutions fall short. In the aerospace sector, it is extensively used in thermal control systems for satellites, particularly for precise temperature management of sensitive payloads, optical instruments, and electronic components that generate significant heat. For instance, in a recent LEO satellite constellation project, our cables were deployed to wick heat away from high-power communication transponders to radiating panels, ensuring optimal operational temperatures even during periods of intense solar exposure and eclipse. Their flexibility allowed for complex routing around structural elements and within tight enclosures, which rigid heat pipes could not accommodate, thus optimizing space utilization and overall thermal efficiency. In the medical industry, these cables are vital for precision temperature regulation in diagnostic equipment, such as MRI scanners and high-throughput laboratory instruments, where maintaining a stable thermal environment is paramount for accuracy and reliable operation. One specific application involved integration into a portable medical device to dissipate localized heat from a powerful laser, preventing overheating and extending device lifespan while maintaining patient safety standards. The ability to conform to irregular surfaces and provide rapid thermal response is a key differentiator in these intricate medical designs, highlighting the critical role of flexible component supply.

Furthermore, the defense industry benefits immensely from our thermal management solutions, deploying them in ruggedized computing systems, airborne radar units, and ground-based communication arrays where robust and reliable heat dissipation is critical for mission-critical operations. A notable case involved providing a custom thermal solution for an unmanned aerial vehicle (UAV) carrying high-power electronic warfare systems. The thermal control system needed to manage significant heat loads from compact, densely packed electronics without adding excessive weight or compromising the UAV's aerodynamic profile. Our Flexible Heat-Conducting Cables provided an optimal solution due to their lightweight nature, high thermal transfer capability, and adaptability to constrained spaces within the airframe, ensuring the avionics remained within their operational temperature limits during prolonged flight missions, even under extreme ambient conditions. Beyond these high-stakes applications, our cables also find utility in advanced manufacturing processes, such as semiconductor fabrication equipment, where precise temperature uniformity across large wafers is essential for yield and quality. In such environments, the prevention of thermal gradients, which can lead to material stress and component failure, is paramount. Our cables enable engineers to design highly efficient and adaptable cooling solutions for various thermal loads and complex geometries, proving invaluable for ensuring the longevity and performance of high-value equipment. These real-world applications underscore the versatility and critical importance of reliable component supply, especially for advanced thermal management.

Image: Flexible heat-conducting cable integrated into a complex electronic system.

Competitive Advantages & Manufacturer Comparison in Component Supply

In the specialized market of high-performance component supply, particularly for thermal management solutions, Space-Navi distinguishes itself through a unique blend of technological innovation, manufacturing precision, and unparalleled customer service. While other manufacturers might offer traditional heat pipes or solid copper links, our Flexible Heat-Conducting Cable offers a distinct competitive advantage stemming from its inherent flexibility, which significantly simplifies integration into complex, spatially constrained designs that are common in aerospace and advanced industrial applications. Unlike rigid solutions that require precise pre-bending or multiple joints, our cables can be routed around obstacles with minimal performance degradation, reducing design complexity, installation time, and potential failure points associated with mechanical stress on rigid interfaces. Furthermore, our proprietary manufacturing process for these cables ensures superior thermal conductivity and reliability over an extended temperature range, from deep cryogenic conditions to high operational temperatures, a versatility not consistently matched by competitors whose products often have more limited operational envelopes due to material constraints or working fluid limitations in traditional heat pipes. Our commitment to aerospace-grade materials and processes, including stringent vacuum bake-out procedures and meticulous quality control, sets a higher benchmark for component reliability and outgassing properties, crucial for sensitive space-borne equipment. This dedication ensures that our products meet the exacting demands of the most critical missions and applications, offering peace of mind to our clients regarding the long-term integrity of their systems.

Beyond product specifications, our authoritative position in the component supply market is solidified by our decades of experience, evidenced by successful partnerships with leading aerospace contractors and research institutions globally. Our engineering team possesses deep expertise in thermodynamics, materials science, and mechanical design, enabling us to provide comprehensive technical support from initial concept to final integration. This consultative approach helps clients optimize their thermal designs and address unique challenges efficiently. We hold multiple industry certifications, including ISO 9001 and AS9100D, underscoring our unwavering commitment to quality management and continuous improvement. Our product testing procedures exceed industry norms, incorporating extensive thermal cycling, vibration, and shock testing that mirror the most extreme operational environments. Moreover, our focus on customized solutions, rather than off-the-shelf products, allows us to tailor our Flexible Heat-Conducting Cables precisely to client specifications, whether it's specific lengths, unique terminations, or specialized insulation requirements. This ability to deliver bespoke solutions, coupled with robust customer feedback mechanisms and a dedicated service team, ensures that clients receive not just a product, but a complete thermal management partnership that guarantees optimal performance and longevity for their critical systems. This client-centric approach and proven track record differentiate us from other component providers, reinforcing our status as a trusted partner for mission-critical component supply.

Custom Solutions, Future Outlook, and Reliable Component Supply

Understanding that no two advanced projects are identical, Space-Navi specializes in providing highly customized thermal management solutions as a core aspect of our component supply offering. Our approach involves close collaboration with client engineering teams from the initial design phase, allowing us to deeply understand specific thermal requirements, spatial constraints, and environmental operating conditions. This collaborative model ensures that our Flexible Heat-Conducting Cables are not just supplied, but are perfectly integrated into the overall system architecture. Customization options include varying cable lengths, diameters, and cross-sectional geometries to optimize heat transfer paths and fit into complex assemblies. We also offer a wide array of specialized termination options, from standard bolt-on interfaces to custom-machined blocks with integrated sensors or unique mounting features, ensuring seamless mechanical and thermal coupling to client hardware. Furthermore, the selection of insulation materials can be tailored to meet specific electrical isolation requirements, radiation hardness, or outgassing specifications for ultra-high vacuum environments. This bespoke engineering capability is backed by our advanced simulation tools, including Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA), which allow us to predict thermal performance accurately under various scenarios, optimize designs for maximum efficiency, and mitigate potential thermal hotspots before physical prototyping, significantly reducing development cycles and costs for complex thermal control systems.

The future outlook for specialized component supply in thermal management is characterized by increasing demand for even greater thermal efficiency, miniaturization, and adaptability, particularly with the proliferation of compact, high-power electronics and the expansion of space exploration endeavors, including the development of new propulsion systems and lunar habitats that require robust thermal cycling resistance. Space-Navi is at the forefront of this evolution, continuously investing in R&D to develop next-generation materials and manufacturing techniques that will push the boundaries of current thermal transfer capabilities. This includes exploring novel composite materials with enhanced anisotropic thermal properties, advanced additive manufacturing techniques for complex heat sink geometries, and integrated thermal solutions that combine active and passive cooling elements. Our commitment to innovation ensures that we remain a leading provider of cutting-edge satellite parts and industrial components, ready to meet the evolving challenges of our clients. We anticipate a growing need for "smart" thermal components equipped with integrated sensors for real-time performance monitoring and predictive maintenance, enhancing system reliability and operational efficiency. By staying abreast of technological advancements and anticipating future industry needs, we aim to provide not just components, but comprehensive, future-proof thermal solutions that empower our clients to achieve their most ambitious technological goals.

Trust, Transparency, and Dedicated Client Support

At Space-Navi, building unwavering trust with our clients is paramount, and it underpins every aspect of our component supply operations. We achieve this through complete transparency in our processes, from material sourcing to final product testing and delivery. Our commitment to trust is solidified by clear communication regarding delivery schedules and comprehensive warranties. For standard component supply, typical delivery cycles range from 4 to 8 weeks, depending on complexity and order volume, with expedited options available for urgent requirements. For highly customized solutions, lead times are discussed collaboratively during the design phase to align with project timelines, ensuring efficient planning and execution for critical missions. We provide a comprehensive warranty on all our Flexible Heat-Conducting Cables, covering defects in materials and workmanship for a period of five years from the date of shipment, reflecting our confidence in the durability and reliability of our products. This warranty ensures that any unforeseen issues are promptly addressed, minimizing downtime and protecting your investment. Our dedicated customer support team is accessible through multiple channels, including direct phone lines, email, and a dedicated online portal, providing immediate technical assistance, order status updates, and post-sales support, ensuring that clients have continuous access to expert guidance throughout the product lifecycle. This proactive and responsive support model ensures that our clients receive not only high-quality components but also a seamless and supportive experience, reinforcing our reliability as a trusted partner.

Transparency is further extended through our detailed product documentation, which includes material certifications, test reports, and compliance declarations (e.g., RoHS, REACH), providing complete traceability and assurance of quality. We understand the stringent regulatory and audit requirements of our target industries, especially for satellite parts and defense applications, and we ensure that all necessary documentation is readily available. Our commitment to long-term partnerships is reflected in our proactive approach to client feedback, utilizing it to continuously improve our products and services. We regularly conduct post-delivery surveys and maintain open lines of communication to ensure client satisfaction and identify areas for enhancement, fostering a cycle of continuous improvement in our component supply chain. Furthermore, our robust supply chain risk management strategies, including dual-sourcing critical raw materials and maintaining strategic buffer inventories, minimize disruptions and ensure consistent delivery, even in volatile market conditions. This holistic approach to trust and support ensures that clients can confidently rely on Space-Navi for their most demanding thermal management needs, knowing that they are backed by a partner committed to excellence, reliability, and unparalleled service from initial inquiry through product lifespan.

Frequently Asked Questions (FAQ) about Component Supply

Q1: What is the typical lead time for custom Flexible Heat-Conducting Cables?

A1: For custom Flexible Heat-Conducting Cables, lead times typically range from 8 to 12 weeks, depending on the complexity of the design, material availability, and current production schedules. We provide a detailed project timeline after the design and engineering review, ensuring full transparency. Rush orders can be accommodated based on specific requirements and production capacity.

Q2: How do you ensure the quality and reliability of your component supply?

A2: Our commitment to quality is upheld by adherence to ISO 9001 and AS9100D standards. We implement rigorous multi-stage quality control, including material incoming inspection, in-process monitoring, non-destructive testing (NDT), and comprehensive final functional testing (thermal vacuum, vibration, shock testing per MIL-STD-810G). Each product is delivered with full traceability and relevant certifications.

Q3: Can your Flexible Heat-Conducting Cables operate in extreme vacuum environments?

A3: Yes, our Flexible Heat-Conducting Cables are specifically designed and manufactured with ultra-low outgassing materials and processes to be compatible with extreme vacuum environments, including those found in space applications. They undergo vacuum bake-out procedures to meet stringent outgassing requirements, minimizing contamination risk for sensitive payloads and optical systems.

Q4: What industries typically benefit from your specialized component supply?

A4: Our specialized components, particularly our Flexible Heat-Conducting Cables, serve a wide range of high-tech industries. Primary beneficiaries include aerospace and defense (for satellites, UAVs, avionics), medical (for diagnostic and laser equipment), advanced manufacturing (semiconductor, industrial lasers), and research institutions requiring precise thermal control systems and robust thermal cycling performance.

Authoritative References

- NASA Technical Standard NASA-STD-8739.4, "Workmanship Standard for Crimping, Interconnecting Cables, Harnesses, and Wiring."

- Thermal Control Handbook for Spacecraft, European Space Agency (ESA) Publication, 2017.

- AS9100D Quality Management Systems - Requirements for Aviation, Space and Defense Organizations.

- MIL-STD-810G, Department of Defense Test Method Standard for Environmental Engineering Considerations and Laboratory Tests.

- ASM Handbook, Vol. 2, "Properties and Selection: Nonferrous Alloys and Special-Purpose Materials," ASM International.

This is the first article