- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

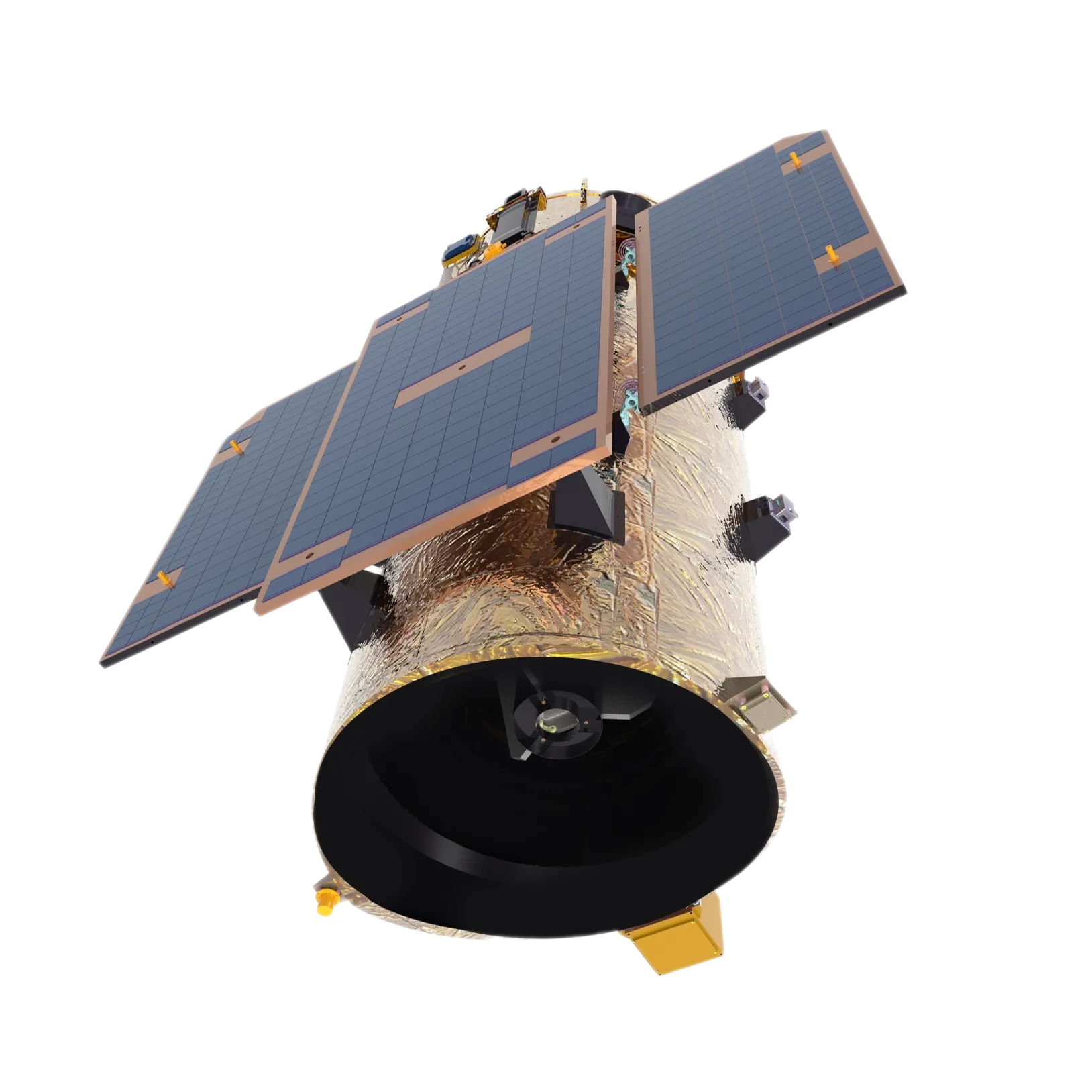

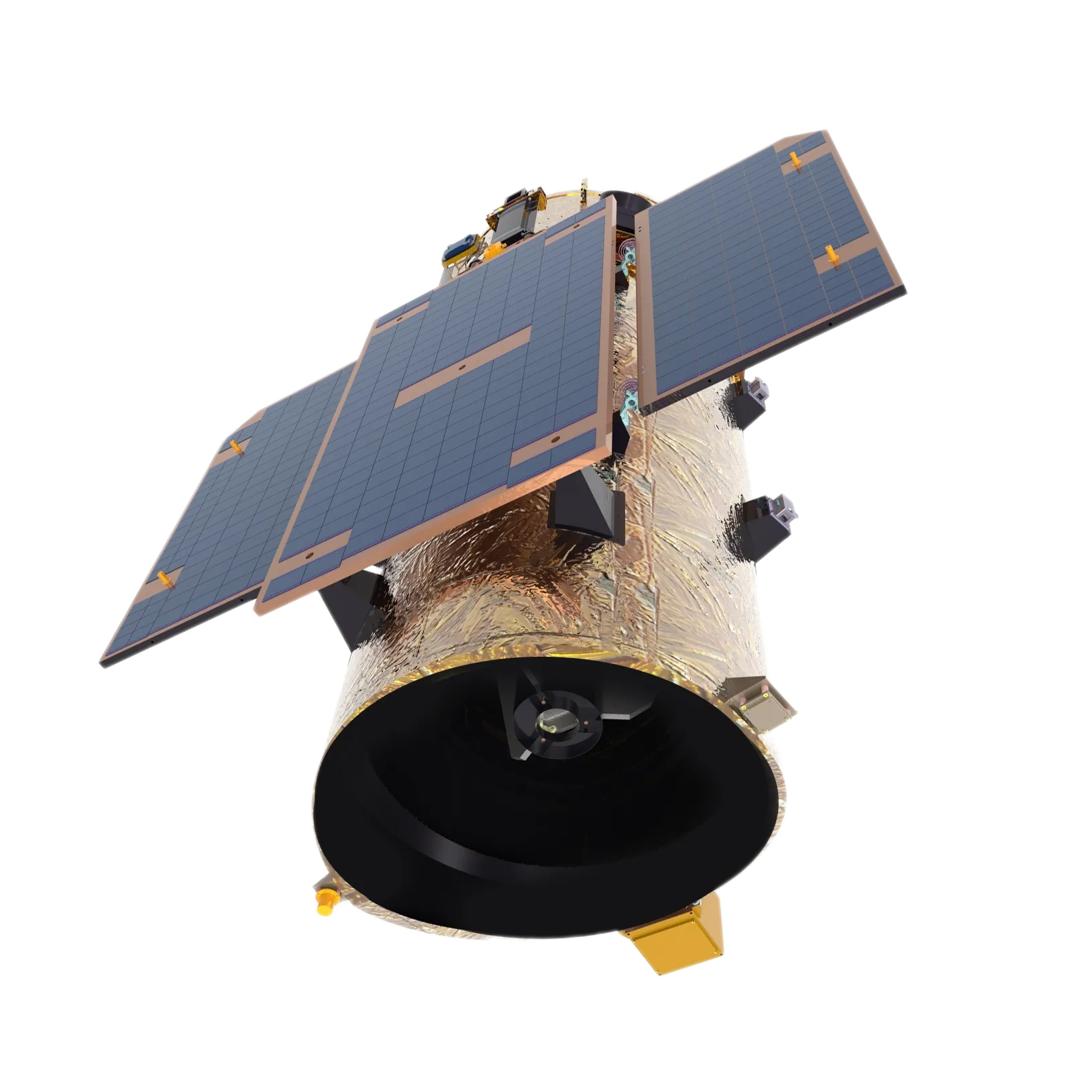

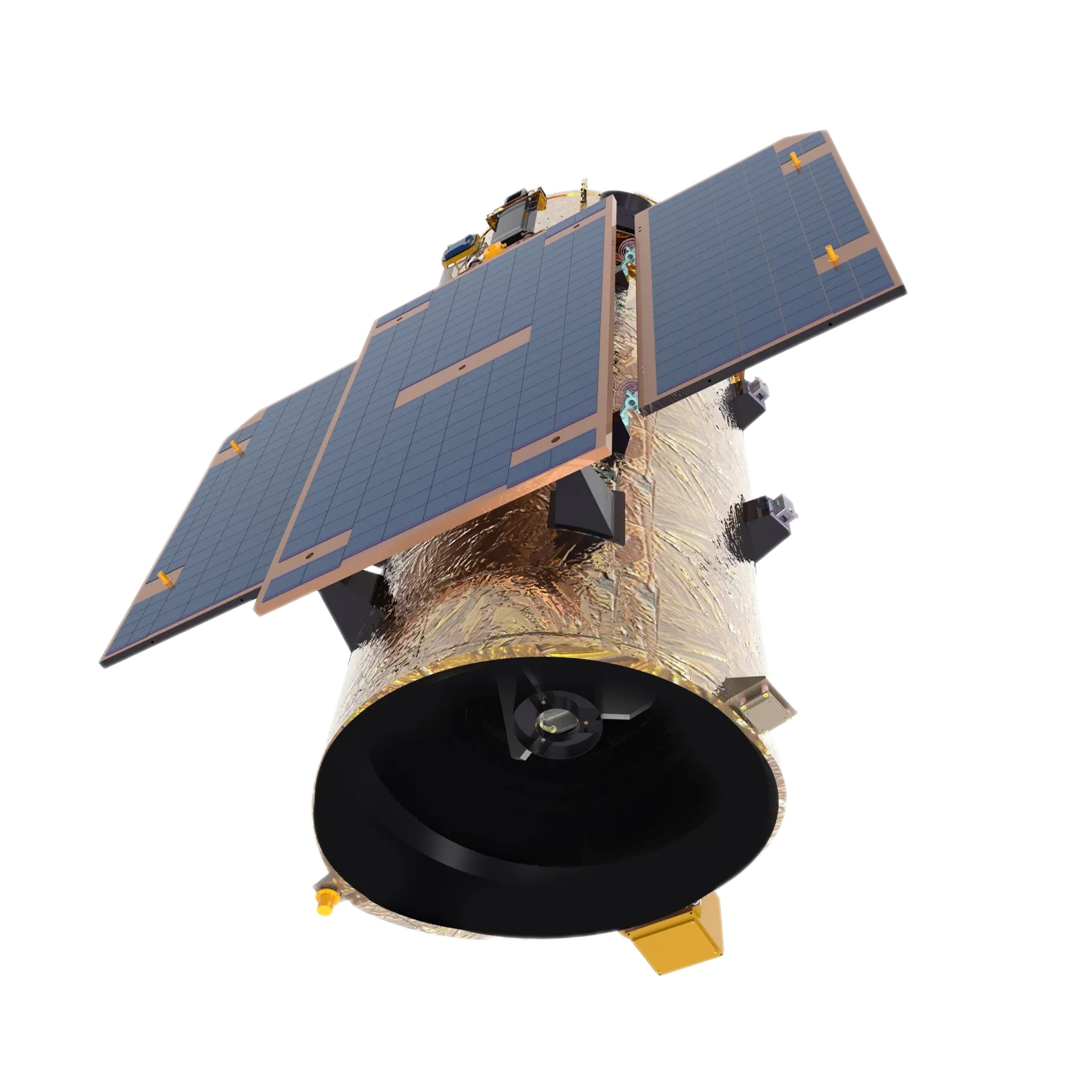

High-Quality Camera Mirrors for Satellite Parts – Precision Components

Explore the evolution, technical parameters, and application scenarios of camera mirrors in space engineering. Discover how SpaceNavi Co.,Ltd. leverages advanced manufacturing for optical innovation, with a focus on Sitall Reflection Mirror.

Email: jl1sales02@space-navi.com

1. Industry Trends: Camera Mirrors in Satellite Parts

Camera mirrors represent the backbone of modern space imaging, remote sensing, and astronomical observation. With advancements in optical manufacturing and a surge in global satellite launches, the demand for highly-stable, lightweight, and thermally efficient mirrors is skyrocketing.

According to recent reports from SPIE Digital Library, the next decade will witness a strong focus on material innovation, asymmetric/aspherical designs, and edge-cutting CNC processing for satellite parts—particularly those related to optics.

- The component use of mirrors in optical payloads and telescopic cameras has grown at a CAGR of 15% since 2018 (Optica Newsroom, 2024).

- Custom camera mirrors processed with robotic CNC and ion-beam technologies are now standard in high-value missions.

- Price segmentation for major component price brackets indicates that sitall-based mirrors are among the most cost-efficient for precision and thermal stability [ESO, 2014].

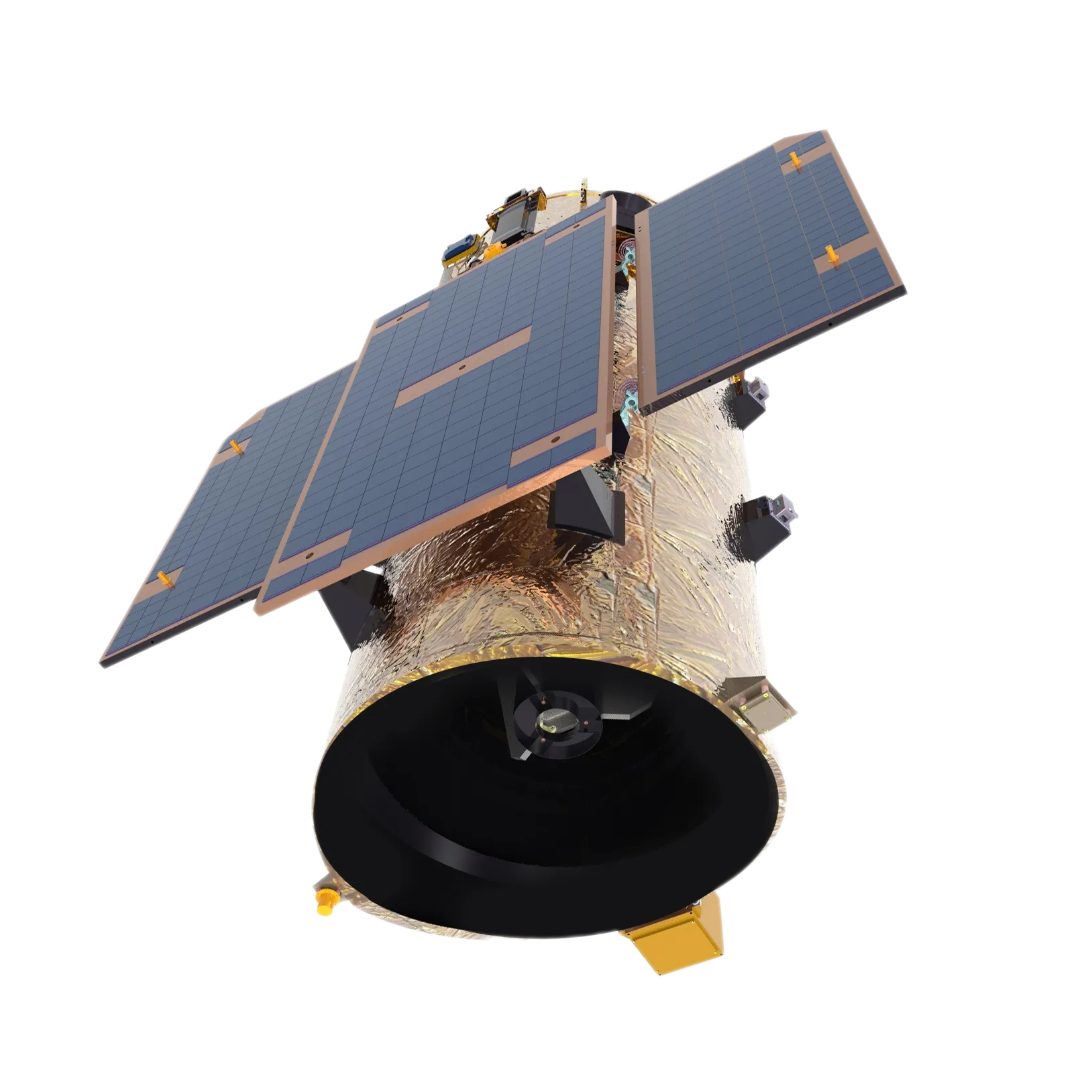

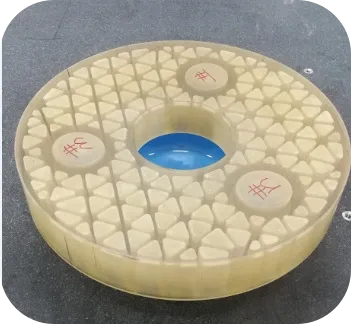

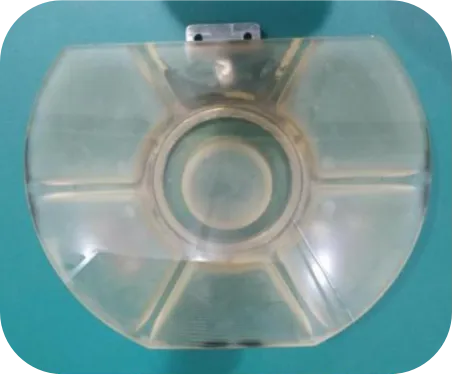

2. Product Spotlight: Sitall Reflection Mirror by SpaceNavi Co.,Ltd.

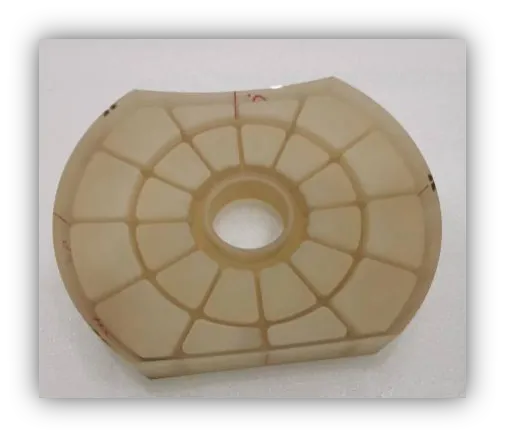

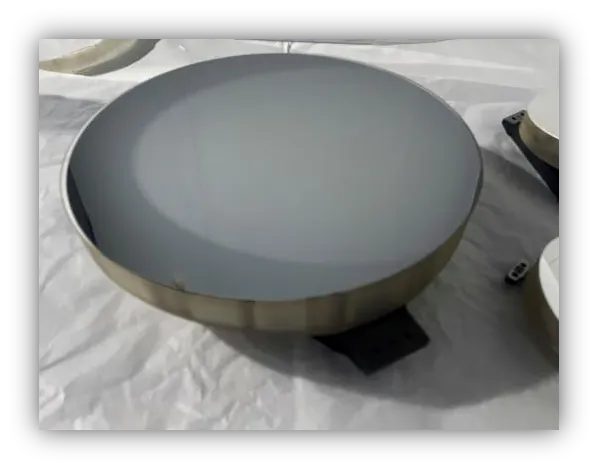

Sitall Reflection Mirror leverages advanced robotic CNC processing, ion-beam figuring, and state-of-the-art polishing techniques. This enables large-aperture, high-precision, and complex surface mirrors, custom-made for diverse satellite and space-science platforms.

- Product Name: Sitall Reflection Mirror

- Material: Sitall glass-ceramic—renowned for extremely low thermal expansion (-7 K-1), stability, and lightweight properties

- Processing: Robotic CNC, ion beam figuring, high-precision polishing, milling

- Finish: Aspherical/asymmetrical, customized to mm/sub-mm accuracy

- Diameter: Up to 1500mm, with exceptional flatness

- Main Applications: Camera mirrors for satellites, high-resolution telescopes, and scientific instruments

- Product Page: https://www.space-navi.com/sitall-reflection-mirror.html

3. Technical Benchmark: Camera Mirrors Parameter Overview

3.1. Common Technical Parameters Table

| Parameter | Typical Value | Unit | Reference |

|---|---|---|---|

| Material | Sitall / Zerodur / ULE | - | SPIE 2021 |

| Diameter | 300 - 1500 | mm | Optica 2013 |

| Flatness | < 15 | nm RMS | OSA Appl. Opt. |

| Surface Accuracy | < λ/10 (@633nm) | - | ESO, 2014 |

| Thermal Expansion | <1×10-7 | K-1 | Adv. Space Res. 2017 |

| Reflectivity | >98.5% | % | Optica |

| Weight Reduction | 30 - 50% | % | Springer, 2022 |

3.2. Visualization: Key Trends in Satellite Camera Mirror Tech

3.3. Sitall Reflection Mirror: Technical Indicators Comparison

3.4. Product Specs: Batch Comparison Table

| Parameter | Sitall Reflection Mirror | Zerodur Mirror | ULE Mirror |

|---|---|---|---|

| Thermal Expansion Coefficient | <0.8x10-7 | 0.0±0.1x10-7 | <1.0x10-7 |

| Max Diameter | 1500mm | 1200mm | 1000mm |

| Flatness | <15nm RMS | <18nm RMS | <25nm RMS |

| Surface Quality | 60/40 (or better) | 60/40 | 80/50 |

| Reflectivity | >98.5% | 98% | 98% |

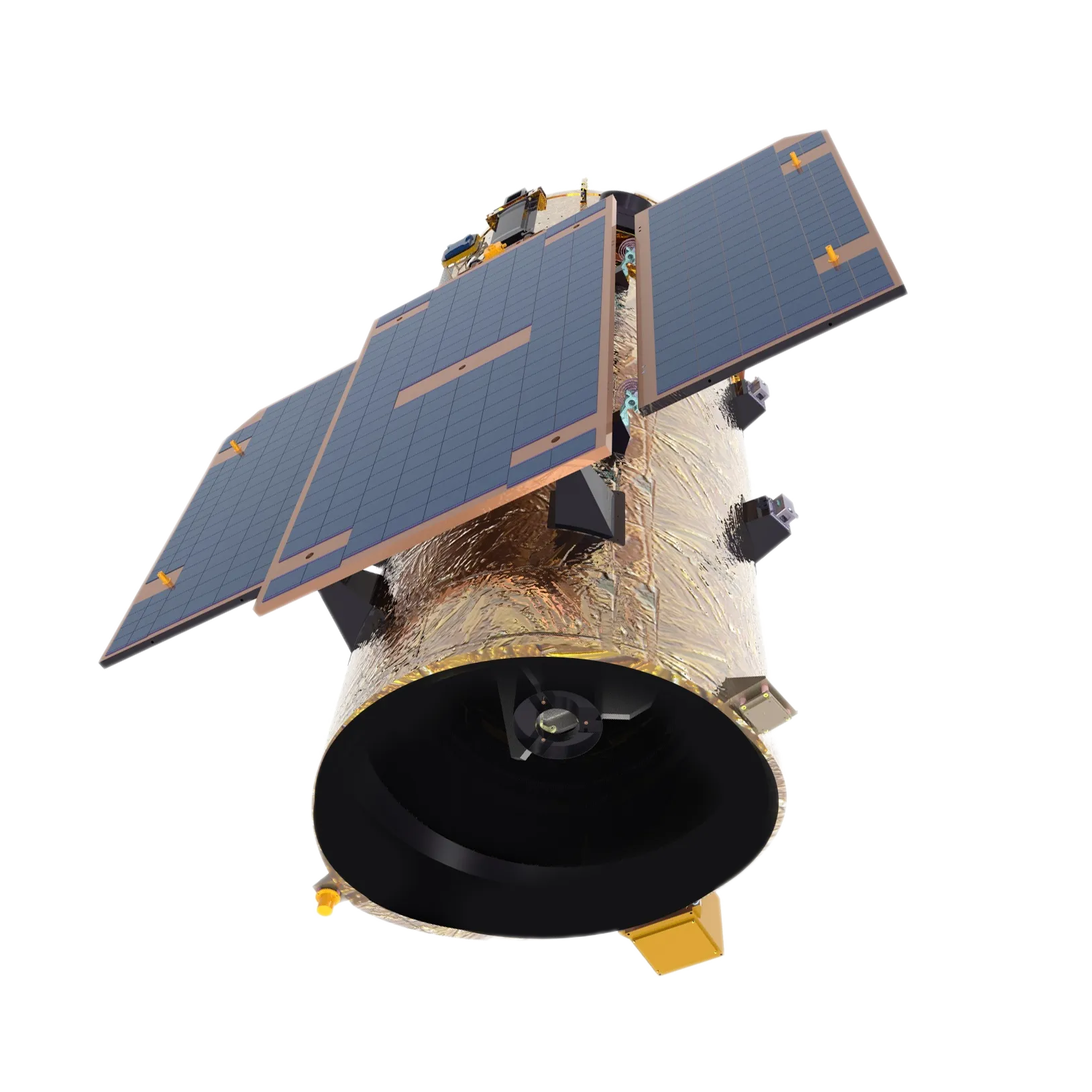

4. Application Scenarios of Camera Mirrors in Satellite Engineering

Camera mirrors, especially those produced from Sitall, are pivotal in:

- Earth observation payloads: providing ultra-stable imaging for mapping and environmental monitoring.

- Space telescopes: requiring large apertures with minimal distortion or expansion.

- Planetary science probes: exposed to extreme thermal cycles but maintaining precise optical alignment.

- Military reconnaissance: demanding both lightweight and robust satellite parts.

- Commercial satellites: maximizing cost-performance with reliable, batch-produced camera mirrors.

5. Component Price & Cost Analysis of Satellite Camera Mirrors

When it comes to component price, a variety of factors interplay:

- Material Cost: Sitall, prized for its low CTE, offers the best price-to-stability balance, significantly outperforming fused silica and metals.

- Processing Complexity: Robotic CNC and ion-beam technologies minimize labor costs and reduce error rates for intricate aspherical surfaces.

- Batch vs. Custom: Camera mirrors customized per mission specification command a premium, although batch orders (as enabled by SpaceNavi Co.,Ltd.) sharply reduce the per-unit price.

- Coatings & Assembly: High-reflectivity, contamination-resistant coatings can add 10-15% to overall component price.

6. Frequently Asked Questions: Industry-specific Q&A

- Q1. What materials are commonly used for manufacturing camera mirrors?

- Sitall, Zerodur, and ULE are the leading materials due to their exceptionally low coefficients of thermal expansion (CTE), excellent dimensional stability, and suitability for high-precision optical manufacturing.

- Q2. What are the critical specifications for satellite camera mirrors?

- Key specs include flatness (usually <15nm RMS), diameter (up to 1500mm), surface accuracy (λ/10 or better), surface roughness (low nm scale), and mechanical lightweighting for launch.

- Q3. How are these mirrors installed and aligned in space payloads?

- Standard aerospace mounting solutions involve flexure or kinematic mounts. Alignment is handled with reference fiducials and active metrology during integration, often using laser trackers.

- Q4. What international standards govern component use in satellite mirrors?

- ISO 10110, MIL-PRF-13830B, and ECSS-Q-ST-70-18C provide guidelines for specification, surface quality, and space-environment compatibility.

- Q5. How does the component price vary for batch vs. custom mirrors?

- Batch manufacturing (50+ units/year) can bring down unit cost by as much as 30% over single custom runs, owing to process scaling, tooling amortization, and reduced QA labor.

- Q6. What finishing processes ensure the high performance of camera mirrors?

- Robotic CNC processing, ion-beam figuring, and sub-aperture polishing are industry standards. Surface cleanliness and AR/hard-coatings are also critical for optical quality and longevity.

- Q7. What trends are shaping the future of camera mirrors for satellites?

- Modular and ultra-light designs with edge sensors for active correction, enhanced surface functionalization, and further automation via AI-driven CNC/metrology are key drivers in the next decade.

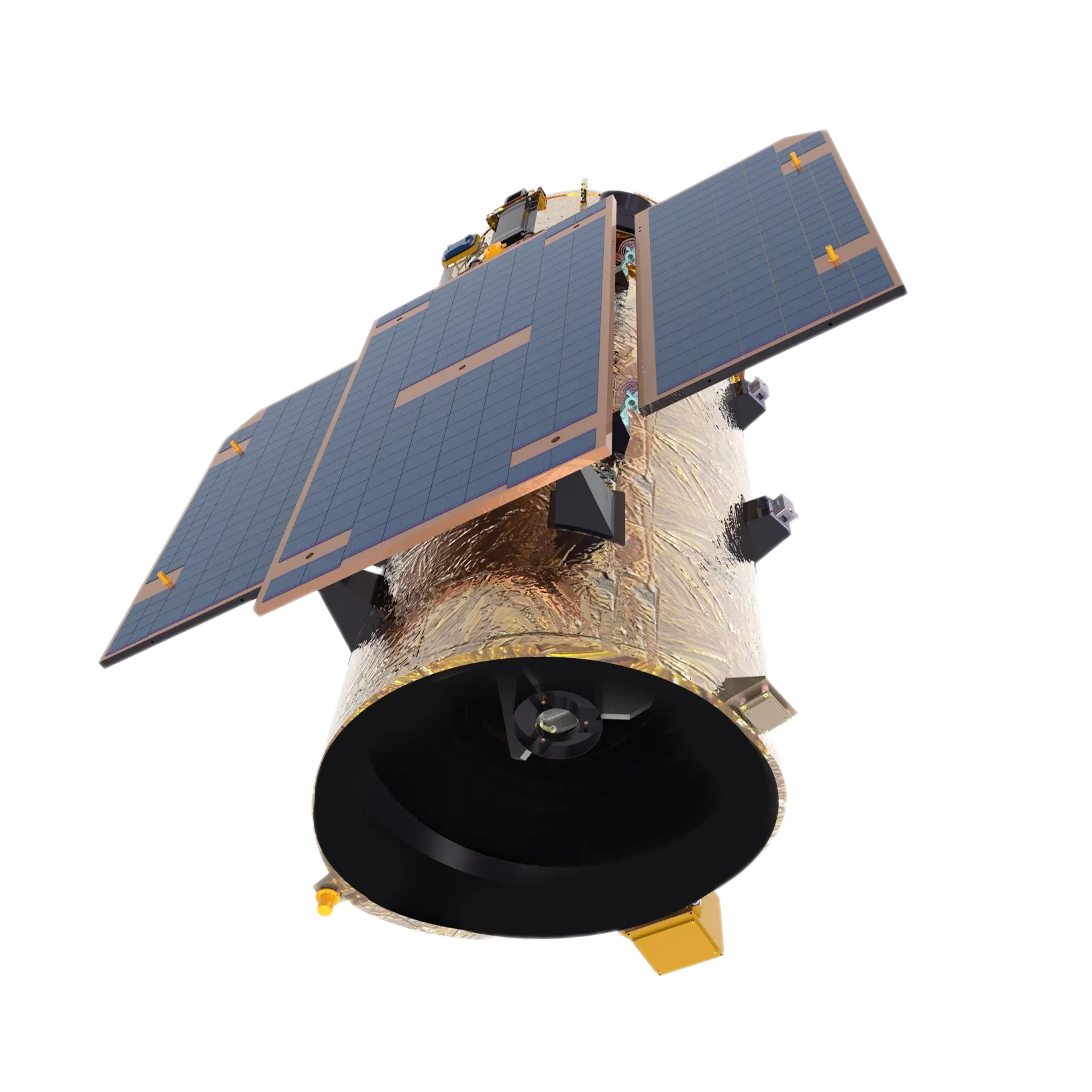

7. Why Choose Sitall Reflection Mirror from SpaceNavi Co.,Ltd.?

- Industry Authority: Recognized by top forums and journals for advanced materials and manufacturing (SPIE, ESA).

- Custom Innovation: Fast turnaround from design to delivery, thanks to in-house robotic CNC and ion-beam infrastructure.

- Scalable Solutions: Capable of both single custom units and large-scale batch orders—with optimal stability and cost.

- Integrated Expertise: End-to-end support from requirement capture to post-delivery optical testing.

- SPIE Digital Library – Conference Proceedings

- Optica Newsroom – Satellite Optics Market Expands with High Precision

- European Space Agency — Space Optics Put into Focus

- ESO: Design & Fabrication of Large Telescope Mirrors

- Springer: Lightweight Space Optics

This is the first article