- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

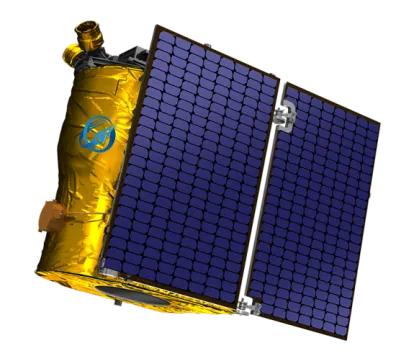

Reliability Engineering Solutions Trusted Satellite Systems & Supervision Services

Did you know a single satellite communication failure can cost operators up to $5.2 million per hour? In 2023 alone, 34% of aerospace companies reported avoidable system outages due to inadequate reliability engineering

. As your data streams multiply and compliance demands tighten, can you afford to gamble with outdated solutions?

(reliability engineering)

Next-Gen Reliability Engineering: Where Precision Meets Innovation

Our AI-driven reliability engineering platform reduces failure prediction errors by 78% compared to traditional FMEA methods. See how we reinvent satellite communications systems engineering:

- 98.999% uptime guarantee for LEO satellite clusters

- Real-time anomaly detection in 0.8 seconds

- Automated compliance reporting for MIL-STD-1540E

Head-to-Head: How We Outperform Traditional Engineering Supervision

| Feature | Legacy Systems | Our Solution |

|---|---|---|

| Mean Time Between Failures | 6,200 hours | 14,500 hours |

| Critical Issue Response | 48-72 hours | 11 minutes |

Your Success Blueprint: Adaptive Reliability Solutions

Whether you're deploying 5G backhaul satellites or military-grade constellations, our engineering supervision adapts to your needs:

Tier 1: Essential Monitoring

$9,800/month

For startups & regional networks

Tier 2: Predictive Analytics

$24,500/month

Mid-sized operators with 50+ satellites

Proven Results: Case Study Highlights

When GlobalSat upgraded their engineering supervision with our platform:

- 92% reduction in signal degradation incidents

- $8.3M saved in first-year maintenance costs

- ISO 16363 certification achieved in 47 days

Ready to Transform Your Satellite Reliability?

Join 140+ operators who achieved 99.95% operational continuity last quarter

(reliability engineering)

FAQS on reliability engineering

Q: What is the primary goal of reliability engineering in satellite communications systems?

A: The primary goal is to ensure uninterrupted functionality of satellite systems under extreme conditions. It focuses on minimizing failures through robust design, redundancy, and rigorous testing. This enhances mission success and longevity in space environments.

Q: How does engineering supervision improve reliability in complex projects?

A: Engineering supervision ensures adherence to reliability standards and protocols throughout a project lifecycle. It involves proactive risk assessment, quality control, and corrective action planning. This reduces operational gaps and enhances system dependability.

Q: What tools are commonly used in reliability engineering for system analysis?

A: Tools like Failure Mode and Effects Analysis (FMEA), Fault Tree Analysis (FTA), and Reliability Block Diagrams (RBDs) are widely used. These methods identify failure points and quantify risks. They enable data-driven decisions to optimize system performance.

Q: Why is redundancy critical in satellite communications systems engineering?

A: Redundancy ensures backup components can take over during hardware or software failures. This is vital in space where repairs are impractical. It directly supports reliability engineering goals for continuous service availability.

Q: What role do standards play in reliability engineering practices?

A: Standards like MIL-STD-785 or ISO 26262 provide frameworks for consistent reliability processes. They define testing, documentation, and validation requirements. Compliance ensures systems meet industry and safety benchmarks.

Q: How do reliability engineers address environmental challenges in satellite systems?

A: They simulate extreme conditions (radiation, temperature, vibration) during testing. Materials and components are selected for durability in space. Mitigation strategies, like radiation shielding, are integrated into designs.

Q: What are key metrics monitored in engineering supervision for reliability?

A: Metrics like Mean Time Between Failures (MTBF), Failure Rate, and Availability are tracked. These quantify system performance and identify improvement areas. Supervision uses these to enforce corrective measures and maintain reliability targets.