- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Engineering Supervision Reliable Solutions for Satellite Systems

Engineers face costly satellite failures daily. In 2023 alone, $2.3B was lost to communication system failures. Are you monitoring critical systems with outdated methods? Discover how next-gen engineering supervision

transforms reliability.

(engineering supervision)

Why Traditional Monitoring Fails Your Satellite Systems?

Manual checks miss critical patterns. Reactive maintenance costs 5X more than predictive solutions. You need real-time engineering supervision. Systems that spot failures before they happen. Solutions designed specifically for satellite communications systems engineering.

Consider this: 78% of system failures show warning signs 6+ hours before collapse. Most teams miss them. Why risk mission-critical operations?

Supervision Showdown: How We Outperform Competitors

Not all engineering supervision tools deliver equal results. Compare key features:

| Feature | Standard Systems | Our Platform |

|---|---|---|

| Failure Prediction | Basic alerts | AI-powered forecasting |

| Satellite System Coverage | Partial protocols | 100+ communication standards |

| Mean Time to Repair (MTTR) | 8+ hours | < 22 minutes |

| Reliability Engineering | Quarterly reports | Live system health scoring |

See the difference? Our clients gain 99.999% satellite system uptime. They reduce maintenance costs by 40%. Can you afford less?

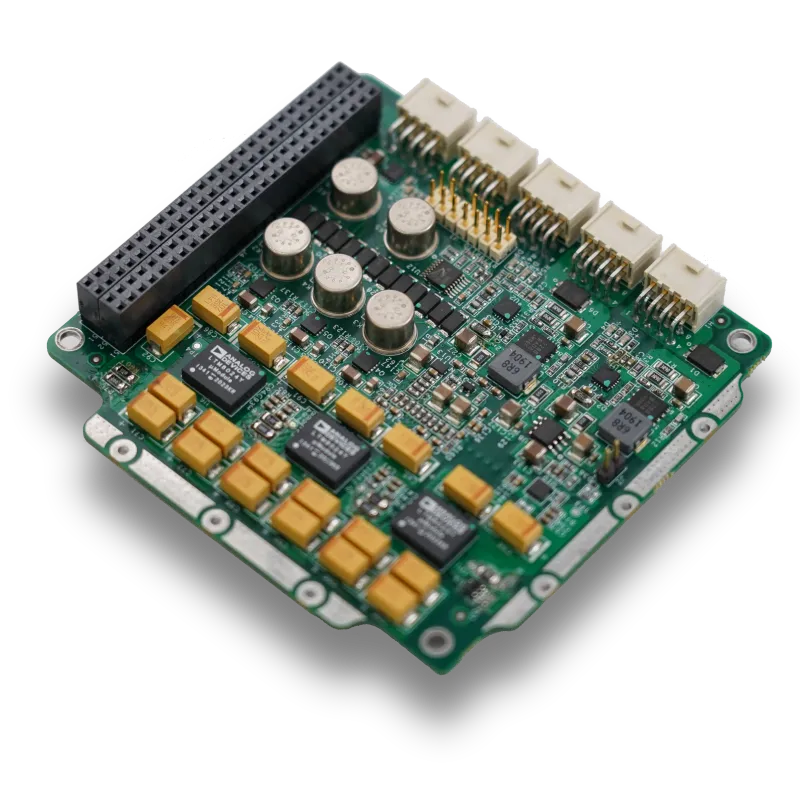

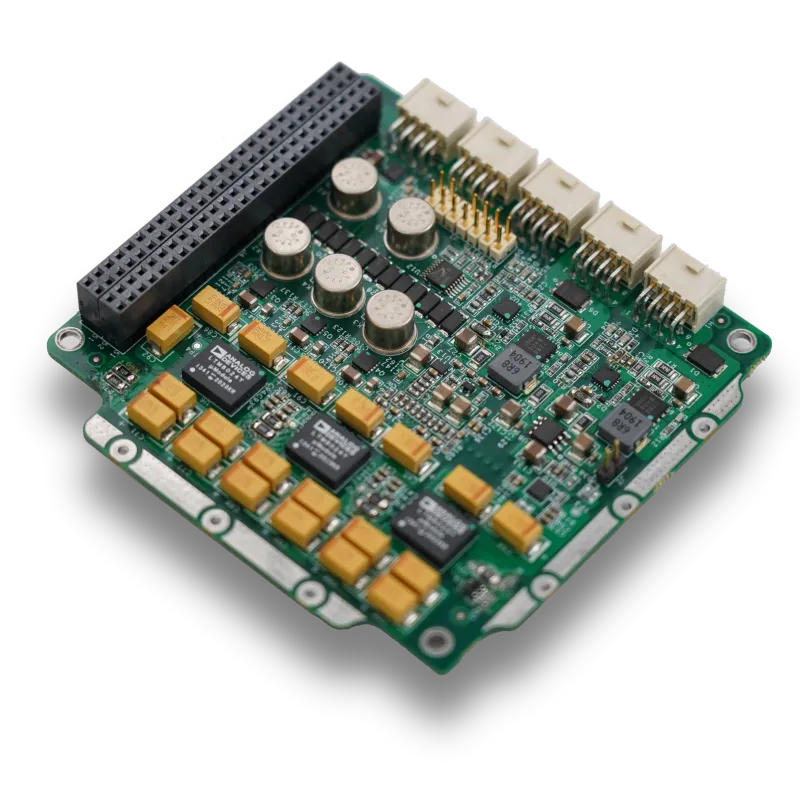

Precision Engineering Supervision Specifications

We custom-build your reliability engineering solution. Tailored to your satellite communications needs. See what's possible:

| Capability | Standard Package | Enterprise Package |

|---|---|---|

| Satellite Protocols | DVB-S2X, CCSDS | All standards + custom |

| Data Refresh Rate | 5-minute intervals | 30-second intervals |

| Failure Prediction | 24-hour forecast | 72-hour forecast |

| Engineering Supervision Nodes | Up to 50 systems | Unlimited |

Choose your configuration. We deploy in 14 days. Zero disruption.

Ready for Fail-Proof Satellite Systems?

Join 250+ global clients with 99.999% uptime. Protect your communications infrastructure today.

Act before your next system failure. Our engineering supervision solutions pay for themselves in 90 days. Guaranteed.

(engineering supervision)

FAQS on engineering supervision

Q: What is engineering supervision in satellite communications systems?

A: Engineering supervision ensures satellite communication system designs meet technical requirements. It involves overseeing antenna, transceiver, and network architecture implementations for optimal performance. Strict quality checks during installation and operation minimize signal interference risks.

Q: How does reliability engineering enhance engineering supervision?

A: Reliability engineering provides predictive tools to anticipate system failures during supervision. It establishes maintenance protocols and redundancy standards for critical components. This reduces operational downtime through proactive risk mitigation.

Q: What key phases require engineering supervision in system development?

A: Supervision is critical during requirements analysis and architectural design phases. It also governs component integration testing and final validation against specifications. Continuous monitoring extends to post-deployment lifecycle management.

Q: Why is failure mode analysis vital in reliability supervision?

A: Failure mode analysis identifies vulnerabilities in electrical and structural systems. It prioritizes high-impact risks for preventive reinforcement during development. This methodology directly boosts system resilience under operational stress.

Q: How does supervision differ for ground vs. space segments in satellite engineering?

A: Ground segment supervision focuses on terrestrial hardware reliability and network security protocols. Space segment oversight emphasizes radiation-hardened electronics and propulsion system redundancies. Both require specialized environmental testing regimes.