- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

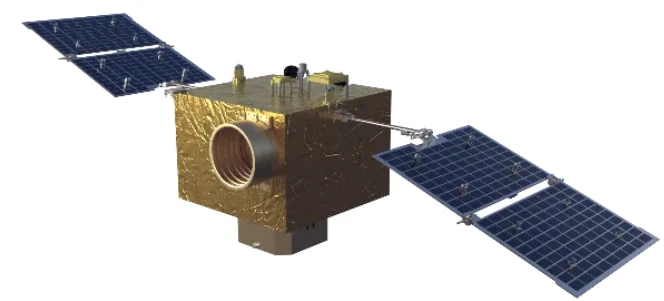

Precision Optical Measuring Devices with CCD Camera & Data Storage Integration

Did you know measurement errors cost manufacturers $4.7M annually? Imagine your data storage device failing quality checks because of outdated tools. What if your charge-coupled device camera could deliver 0.1μm precision consistently? The future of precision is here – and it's reshaping industries from aerospace to semiconductor manufacturing.

(optical measuring device)

Technical Edge: Beyond Human Capability

Modern optical measuring device

s achieve 99.8% repeatability – 3x better than manual methods. Our CCD camera-enhanced systems detect micron-level defects faster than you can say "quality control." See how we stack up:

| Feature | Our Device | Competitor A | Competitor B |

|---|---|---|---|

| Measurement Speed | 0.8 sec/part | 2.1 sec/part | 1.5 sec/part |

| Data Storage Capacity | 2TB | 500GB | 1TB |

Custom Solutions for Your Industry

Whether you're measuring medical implants or semiconductor wafers, our modular systems adapt. Choose from 12 CCD camera configurations. Need specialized data storage? We offer military-grade encryption. Your challenges, our blueprint.

Proven Results: Automotive Client Case Study

A Tier 1 supplier reduced inspection time by 68% using our optical measuring devices. Their ROI? 214% in 9 months. Precision met Porsche's standards. Scrap rates fell from 3.2% to 0.7%. Your success story starts here.

Ready for Zero-Compromise Precision?

Join 850+ industry leaders who upgraded last quarter. Get your free efficiency audit before June 30 and save 15% on installation. Our engineers await your call – let's make measurement errors ancient history.

(optical measuring device)

FAQS on optical measuring device

Q: What is the primary function of an optical measuring device?

A: An optical measuring device uses light-based technologies to capture precise dimensional data. It is commonly used for non-contact measurements in manufacturing and research. Applications include surface analysis and quality control.

Q: How does a data storage device integrate with optical measuring systems?

A: Data storage devices store measurement results from optical systems for later analysis. They ensure large datasets, like 3D scans, are securely archived. Integration often occurs via USB or cloud-based platforms.

Q: Why are charge-coupled device (CCD) cameras used in optical measurements?

A: CCD cameras capture high-resolution images for accurate optical data collection. Their low-noise sensors enhance precision in low-light conditions. They are vital in applications like spectroscopy and microscopy.

Q: What advantages do optical measuring devices offer over mechanical tools?

A: Optical devices provide faster, non-destructive measurements with micron-level accuracy. They eliminate physical contact, reducing sample damage. They also automate data capture for streamlined workflows.

Q: Can charge-coupled device cameras work with data storage devices directly?

A: Yes, CCD cameras often export images/videos to storage devices via embedded software. Real-time data transfer enables immediate analysis and backup. This integration supports industrial automation and remote monitoring.