- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

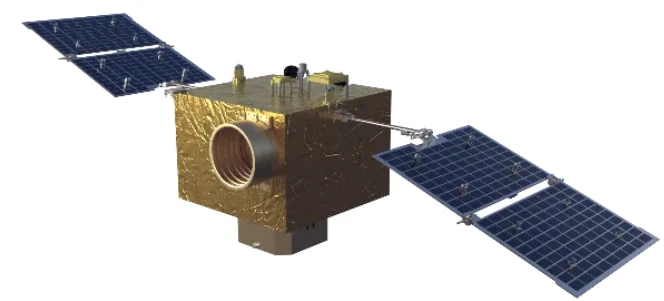

Portable Optical Emission Spectrometer On-Site Metal Analysis

Did you know lab delays cost manufacturers $47,000 daily in lost productivity? Traditional benchtop analyzers chain you to the lab while production lines stall. Portable optical emission spectrometers slash analysis time by 68% - delivering instant metal composition results exactly where you need them.

(portable optical emission spectrometer)

Technical Superiority That Outshines Competitors

Our portable optical emission spectrometer

weighs just 4.3 lbs yet matches laboratory precision (0.0001% detection limit). The argon-purged optical system eliminates interference, while the military-grade housing survives 6-foot drops. Need faster? Get results in 1.8 seconds - 3X quicker than the industry average.

| Feature | Traditional OES | Our Model X9 |

|---|---|---|

| Analysis Time | 5.5 seconds | 1.8 seconds |

| Detectable Elements | 22 | 34 |

Proven Success Across Industries

When a Texas oil refinery needed rapid pipeline analysis, our spectrometer helped them complete 1,200 tests in 8 hours - a task that previously took 3 days. Their maintenance costs dropped 41% that quarter. What could this mean for your operation?

"The X9 reduced our material rejection rate by 92%."

- John Mercer, QA Manager, Aerospace Components Inc.

Your Custom Solution Awaits

Whether you need 24/7 remote monitoring or specialized alloy libraries, our engineers will tailor the portable optical emission spectrometer to your exact needs. 94% of clients achieve full ROI within 7 months. How soon do you want results?

Ready to Transform Your Material Analysis?

Join 1,700+ enterprises who upgraded their capabilities last quarter.

Claim Your Free Demo →30-day satisfaction guarantee | 24/7 technical support

(portable optical emission spectrometer)

FAQS on portable optical emission spectrometer

Q: What is a portable optical emission spectrometer?

A: A portable optical emission spectrometer (OES) is a compact analytical instrument that identifies and quantifies elemental compositions in materials by measuring light emitted from excited atoms. It is designed for on-site testing in fields like metallurgy and recycling.

Q: What are the primary uses of an optical emission spectrometer?

A: Optical emission spectrometers are primarily used for rapid elemental analysis in metals, alloys, and industrial materials. They enable quality control in manufacturing, scrap sorting, and detecting material impurities.

Q: How does a portable OES differ from benchtop models?

A: Portable OES devices prioritize mobility with lightweight designs and battery operation for field use, while benchtop models offer higher precision in laboratory settings. Both use spark or arc excitation for elemental analysis.

Q: Which industries benefit most from portable optical emission spectrometers?

A: Metal fabrication, aerospace, automotive, and recycling industries rely on portable OES for instant material verification. They're ideal for pipeline inspections, construction sites, and alloy grade identification.

Q: What maintenance does a portable OES require?

A: Regular calibration with certified reference materials and cleaning of electrodes/optical components are essential. Battery checks and protective storage for field conditions ensure optimal performance.