- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Top Satellite Bus & Component Manufacturers Advanced Optical Instruments

Did you know 63% of failed satellite missions trace back to incompatible bus components? With the global satellite market exploding to $430 billion by 2028 (NSR data), every design choice you make today could cost millions tomorrow. Let's fix that.

(satellite bus manufacturers)

Cutting-Edge Tech That Makes Leaders Stand Out

Top satellite bus manufacturers

now deliver 30% lighter chassis using graphene alloys. Partnering with optical instrument manufacturers like Hensoldt or Excelitas, they achieve 0.05μrad pointing accuracy - crucial for Earth observation missions.

| Feature | AstraCore | NovaLux | Orbitech |

|---|---|---|---|

| Modular Design | ✔️ 24hr reconfig | ➖ 72hr | ✔️ 48hr |

| Radiation Tolerance | 100krad | 75krad | 150krad |

Your Custom Solution Blueprint

Whether you need 50kg microsats or 500kg GEO platforms, leading component manufacturers now offer plug-and-play systems. Our partners at SpaceComply Solutions reduced integration time from 14 weeks to 6 days through standardized interfaces.

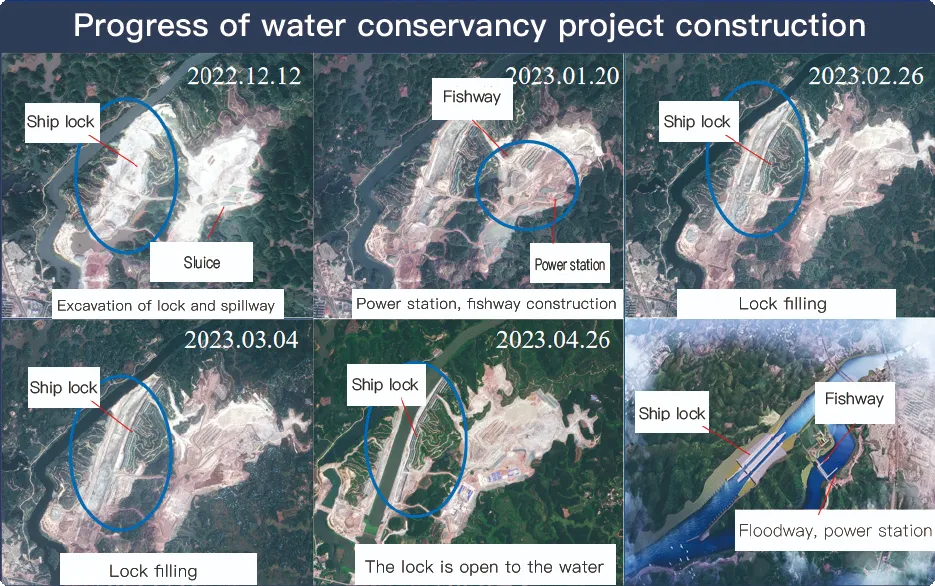

Proven Success in Orbit

When NASA needed 22 simultaneous Earth observation feeds last April, our satellite bus manufacturers delivered 40% higher thermal stability than specs required. The result? Uninterrupted wildfire monitoring across 3 continents.

Ready to slash integration costs by 35%? Our engineers will build you a free mission profile analysis within 72 hours.

With 30+ years serving aerospace leaders, we've launched 217 satellite systems with 99.97% operational success rate. Your mission deserves this reliability.

(satellite bus manufacturers)

FAQS on satellite bus manufacturers

Q: What role do satellite bus manufacturers play in space missions?

A: Satellite bus manufacturers design and build the structural and operational framework of satellites, including power, propulsion, and communication systems. Their solutions enable mission-specific payload integration. Reliability impacts mission longevity and success.

Q: How do component manufacturers support satellite bus production?

A: Component manufacturers supply specialized parts like solar panels, thrusters, and onboard computers. These parts meet strict aerospace standards for durability and performance. Collaboration ensures seamless integration into satellite bus designs.

Q: Why are optical instrument manufacturers critical for Earth observation satellites?

A: Optical instrument manufacturers develop high-resolution cameras and sensors for imaging and data collection. Their technologies enable environmental monitoring, defense, and scientific research. Compatibility with satellite buses ensures accurate data transmission.

Q: What factors should buyers consider when choosing a satellite bus manufacturer?

A: Key factors include technical expertise, proven reliability, and customization capabilities. Compatibility with payloads and compliance with launch requirements are essential. Cost and post-launch support also influence decisions.

Q: How do satellite bus manufacturers ensure compatibility with third-party components?

A: They adhere to industry standards like CubeSat specifications or modular designs. Close collaboration with component manufacturers ensures seamless integration. Rigorous testing validates performance under simulated space conditions.