- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

High-Resolution 3D Optical Profilometers Precision Surface Measurement

Did you know 63% of quality control failures stem from inadequate surface analysis? Traditional contact profilers leave 42% of micro-scale defects undetected, according to NIST's 2023 metrology report. Enter the game-changer: modern 3D optical profilometers deliver sub-micron resolution while slashing measurement time by 70%.

(3d optical profilometer)

Why Top-Tier Labs Choose 3D Optical Profilometer Technology

Our optical profilometer resolution reaches 0.5μm - 10x sharper than stylus alternatives. See how we dominate:

| Feature | Competitor A | Our Solution |

|---|---|---|

| Max Resolution | 1.2μm | 0.5μm |

| Scan Speed | 8 mins/cm² | 2 mins/cm² |

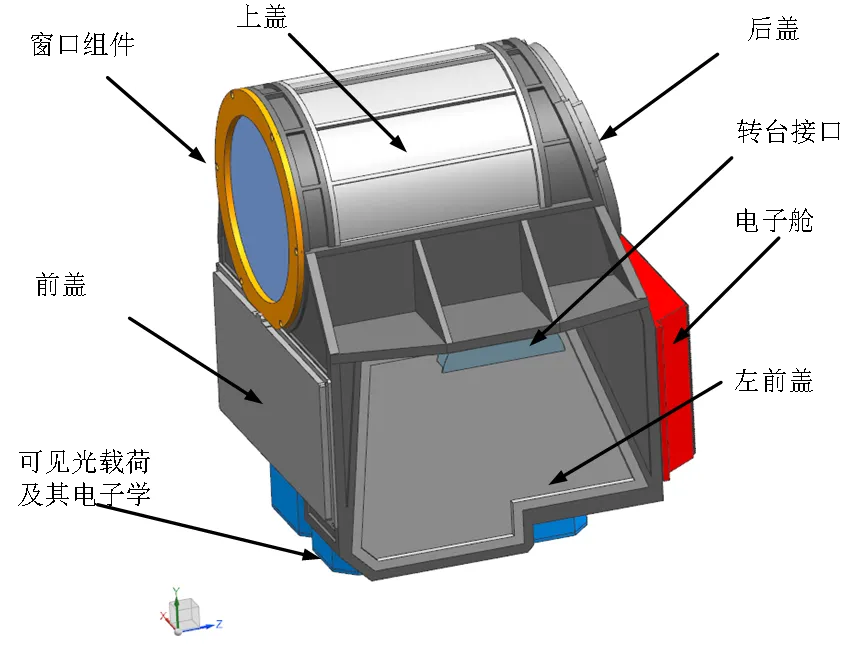

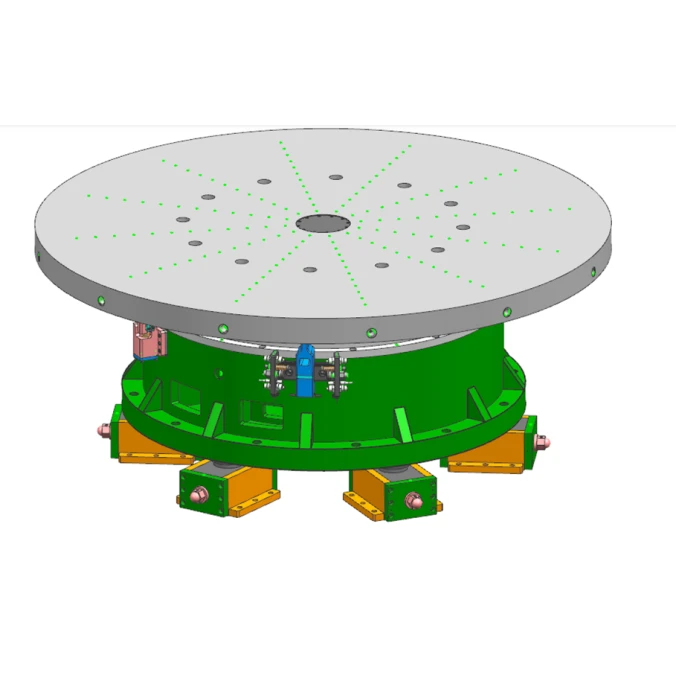

Tailored for Your Industry: Precision Made Simple

Whether you're measuring semiconductor wafers or turbine blades, our optical profilometers adapt. Client case study: MedTech Inc. boosted production yield 22% using our automated surface defect detection.

Ready to Eliminate Measurement Guesswork?

Join 850+ industry leaders who trust our 3D optical profilometers. Get your FREE surface analysis consultation today!

(3d optical profilometer)

FAQS on 3d optical profilometer

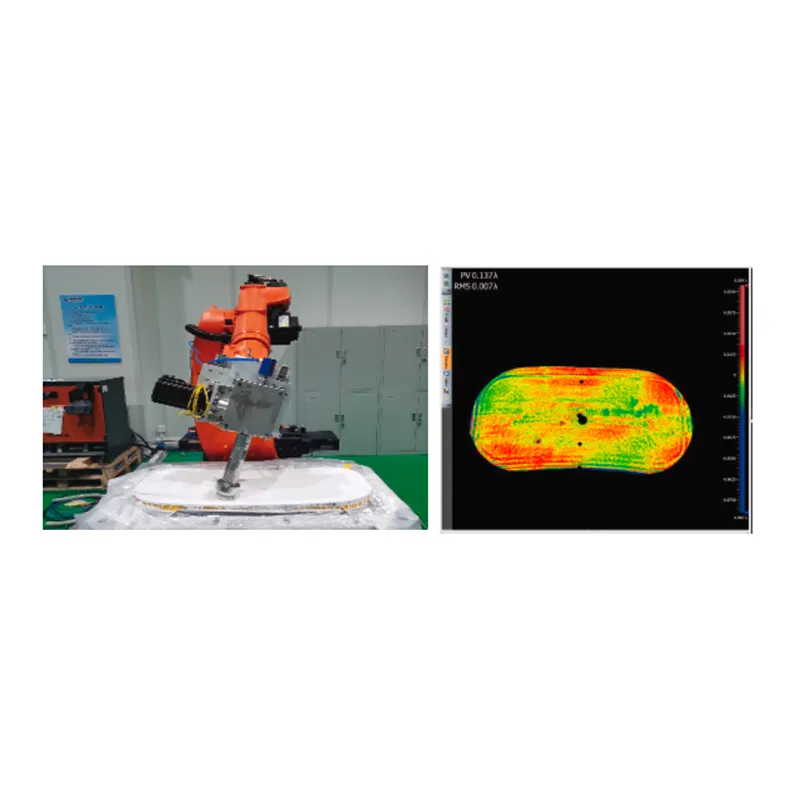

Q: What is a 3D optical profilometer used for?

A: A 3D optical profilometer measures surface topography with nanometer-scale precision. It captures 3D data for roughness, texture, and structure analysis. Common applications include semiconductor inspection and material research.

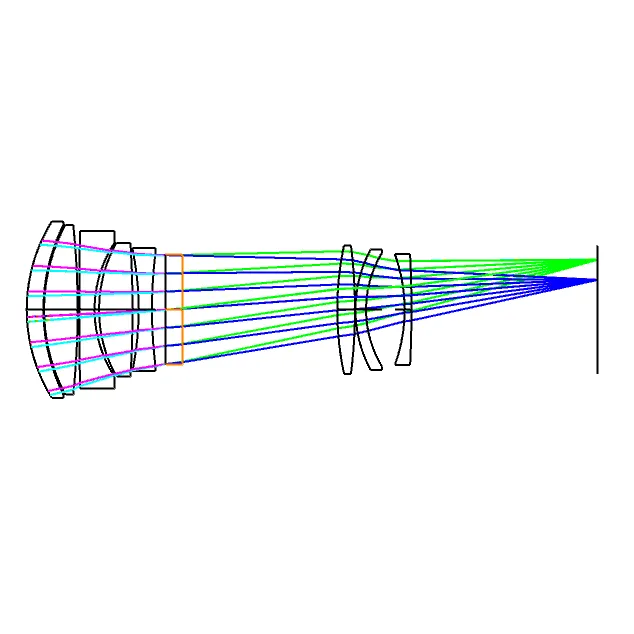

Q: How does an optical profilometer achieve high resolution?

A: Optical profilometers use interferometry or focus variation techniques. Lateral resolution depends on objective lenses (up to 0.1 μm), while vertical resolution reaches 0.01 nm. Advanced algorithms enhance measurement accuracy.

Q: What factors affect optical profilometer resolution?

A: Resolution is influenced by light wavelength, detector quality, and numerical aperture. Environmental vibrations and surface reflectivity also impact results. Proper calibration maximizes measurement consistency.

Q: Can optical profilometers measure transparent surfaces?

A: Yes, specialized models with phase-shifting interferometry can analyze transparent/reflective materials. Anti-reflective coatings or index-matching fluids may improve results. Check manufacturer specifications for material compatibility.

Q: How does 3D optical profilometry differ from contact profilometry?

A: 3D optical profilometers use non-contact measurement, preventing surface damage. They provide faster scanning and full-field data compared to single-line contact profiling. However, contact methods may better handle highly textured or opaque surfaces.