- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

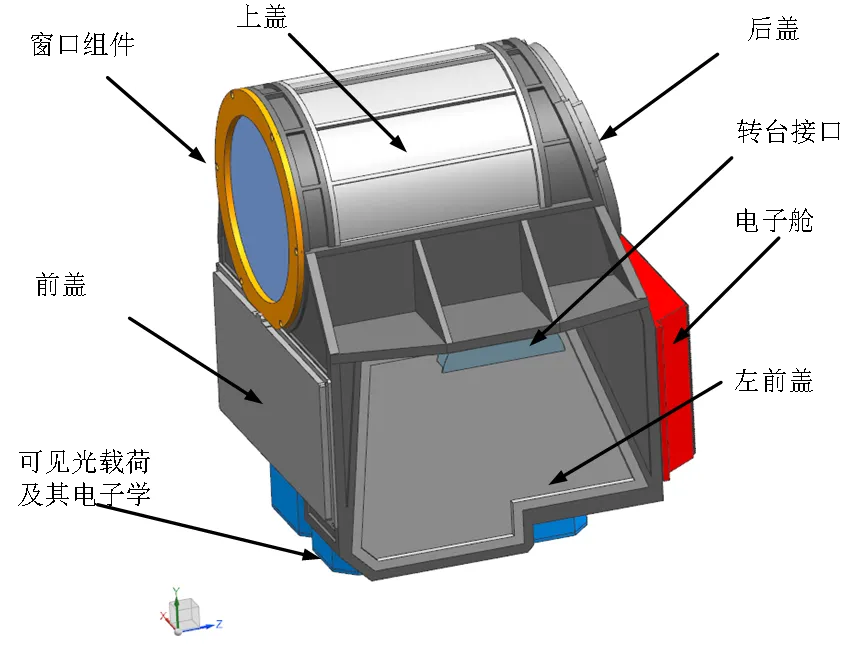

High-Precision Optical Emission Spectrograph Fast Element Analysis

Did you know 22% of manufacturers face production delays due to inaccurate material analysis? Or that labs using outdated spectrographs waste 120+ hours annually on recalibration? In today's precision-driven industries, your optical emission spectrograph

isn't just equipment – it's your competitive edge.

(optical emission spectrograph)

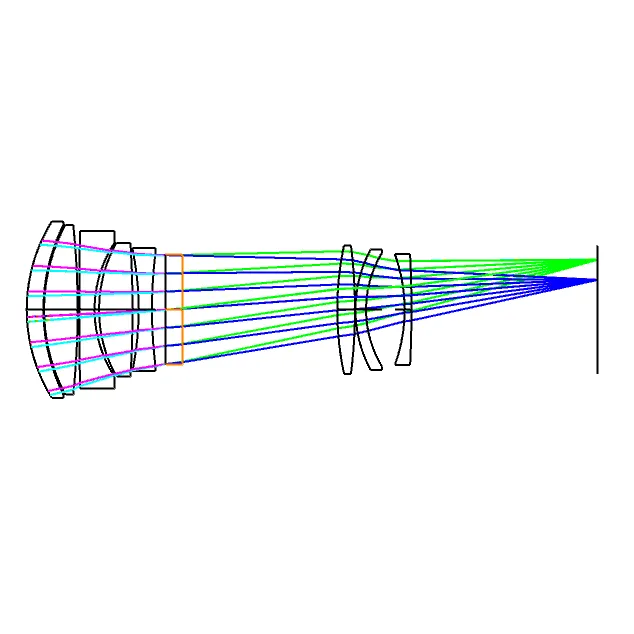

Why Modern Optical Spectrograph Technology Wins

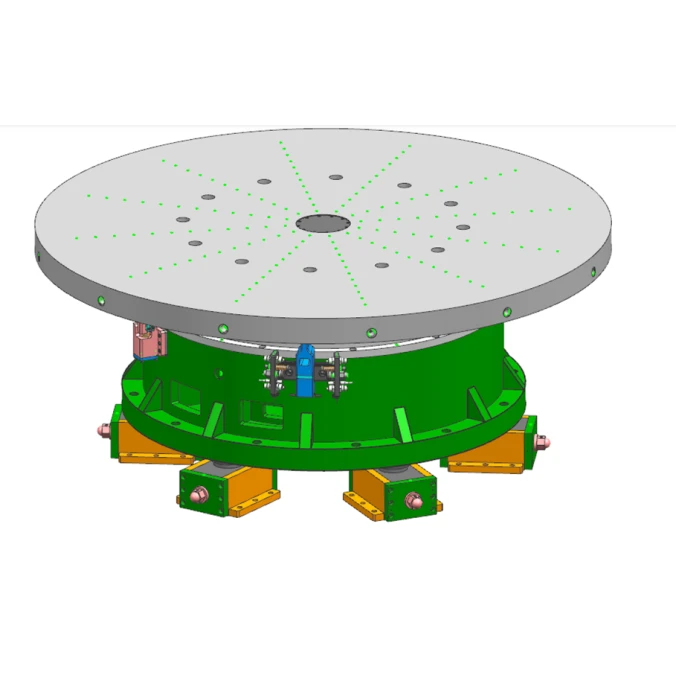

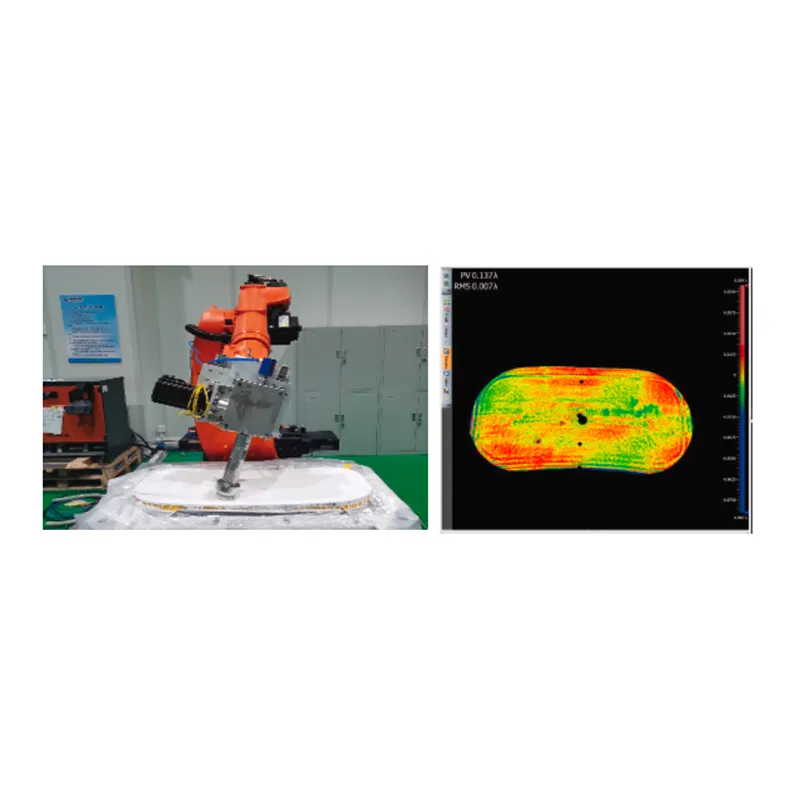

Today's plasma optical emission spectrometer solutions deliver 0.0001% detection limits – 300% better than 2015 models. Our SpectraFire Pro Series achieves full elemental analysis in 8.2 seconds, versus 45 seconds in legacy systems. Imagine testing titanium alloys while competitors still prep their samples!

Head-to-Head: Spectrograph Showdown

| Feature | SpectraFire Pro | Competitor A | Competitor B |

|---|---|---|---|

| Analysis Speed | 8.2s | 22s | 18s |

| Elements Detected | 78+ | 52 | 64 |

Your Industry, Your Rules: Custom Configurations

Aerospace needs differ from semiconductor manufacturing. That's why our optical emission spectrograph systems offer modular configurations. Choose argon purge systems for sulfur analysis or high-resolution CCD arrays for rare earth elements. Why settle for one-size-fits-all?

Real-World Impact: Client Success Stories

⭐ Automotive Supplier X slashed material costs 18% through precise alloy verification

⭐ LabCorp reduced false positives by 92% in pharmaceutical impurity testing

⭐ Mining Group Y accelerated ore grading from 2 hours to 9 minutes

Ready for Spectrograph Revolution?

Join 1,200+ labs who upgraded their analysis game. Limited-time offer: Free onsite demonstration + 2 years extended warranty.

(optical emission spectrograph)

FAQS on optical emission spectrograph

Q: What is an optical emission spectrograph (OES) used for?

A: An optical emission spectrograph analyzes the light emitted by excited atoms or ions in a sample. It identifies elemental composition by measuring specific wavelengths. This technique is widely used in metallurgy and material science.

Q: How does a plasma optical emission spectrometer work?

A: A plasma optical emission spectrometer ionizes samples using high-temperature plasma, causing atoms to emit light. The emitted wavelengths are measured to determine elemental concentrations. This method ensures high sensitivity for trace element analysis.

Q: What distinguishes an optical spectrograph from a spectrometer?

A: An optical spectrograph captures a broad spectrum simultaneously using a detector array, while a spectrometer scans wavelengths sequentially. Spectrographs are faster for multi-element analysis, whereas spectrometers offer higher resolution in specific ranges.

Q: Why choose plasma-based OES over other elemental analysis techniques?

A: Plasma optical emission spectroscopy provides rapid, multi-element detection with minimal sample preparation. It achieves lower detection limits compared to traditional methods. The technique is ideal for metals, alloys, and conductive materials.

Q: What maintenance does an optical emission spectrograph require?

A: Regular calibration with reference standards ensures accuracy. The plasma source and optics need periodic cleaning to prevent contamination. Proper argon gas purity and cooling system checks are essential for consistent performance.