- афрички

- Албанац

- амхарски

- арапски

- Јерменски

- азербејџански

- баскијски

- белоруски

- бенгалски

- босански

- бугарски

- каталонски

- Цебуано

- Кина

- корзикански

- хрватски

- чешки

- дански

- холандски

- енглески

- есперанто

- естонски

- фински

- француски

- фризијски

- галицијски

- грузијски

- немачки

- грчки

- гуџарати

- хаићански креолски

- Хауса

- хавајски

- хебрејски

- бр

- Миао

- мађарски

- исландски

- игбо

- индонезијски

- ирски

- италијански

- јапански

- Јаванесе

- канада

- казакхстан

- кмерски

- Руандски

- Кореан

- курдски

- киргиски

- Рад

- латиница

- летонски

- литвански

- луксембуршки

- македонски

- малгашки

- малајски

- малајалам

- малтешки

- Маори

- Маратхи

- монголски

- Мјанмар

- непалски

- норвешки

- норвешки

- Оццитан

- пашто

- персијски

- пољски

- португалски

- панџапски

- румунски

- руски

- Самоан

- шкотски галски

- српски

- енглески

- Схона

- Синдхи

- Синхала

- словачки

- словеначки

- сомалијски

- шпански

- сундански

- свахили

- шведски

- Тагалог

- Тајик

- тамилски

- татарски

- телугу

- тајландски

- турски

- Туркмен

- украјински

- Урду

- ујгурски

- Узбек

- вијетнамски

- велшки

- Помоћ

- јидиш

- Иоруба

- Зулу

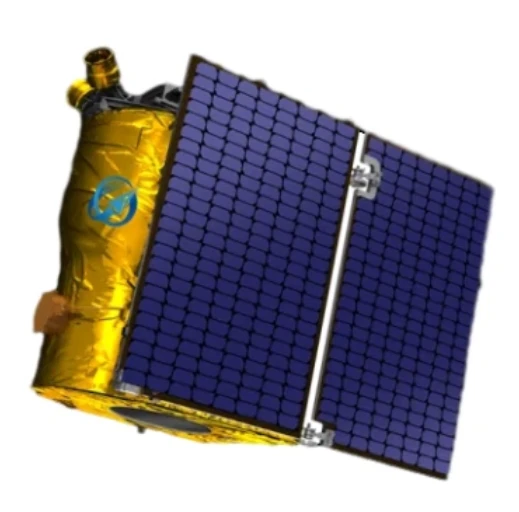

Modern Satellite Platform

In today’s era of advanced aerospace technology, the сателитска платформа—also known as the satellite bus—is the unsung hero behind every successful satellite mission. It provides the essential framework that houses all operational components, supports power supply, controls thermal regulation, and enables precise communication between Earth and space. With the global demand for satellite constellations increasing, the market for optimized дизајн сателитске аутобуске and efficient production by top произвођачи сателитских аутобуса is evolving at an unprecedented pace.

Understanding the Role and Function of a Satellite Platform

The сателитска платформа serves as the foundational structure that integrates all payloads and mission-specific instruments. While payloads vary depending on satellite use—be it navigation, observation, communication, or military intelligence—the platform ensures stable functioning through its unified system of subsystems.

These subsystems include the power supply (often via solar panels), thermal management (through heat pipes and radiators), propulsion units, attitude control systems, and onboard computers. The сателитска платформа also facilitates real-time data transfer, signal reception, and automated operation in orbit. It must be lightweight yet robust, energy-efficient yet powerful, and modular enough to adapt to different mission requirements.

As low Earth orbit (LEO) and geostationary Earth orbit (GEO) missions continue to grow, both government and commercial space operators are demanding adaptable and cost-efficient сателитска платформа solutions to meet stringent timeframes and budgets.

Top Trends Among Leading Satellite Bus Manufacturers

The world’s leading произвођачи сателитских аутобуса are in a fierce race to deliver platforms that are not only compact and durable but also scalable for mega-constellation projects. Companies such as Airbus, Lockheed Martin, Northrop Grumman, Thales Alenia, and emerging firms in China and India are at the forefront of innovation.

These произвођачи сателитских аутобуса are prioritizing modular architecture, allowing rapid customization based on mission type. This enables space agencies and private operators to configure buses for Earth imaging, telecommunications, weather forecasting, or scientific research, without redesigning the core structure.

Another key focus is autonomous operation. Smart platforms now use onboard AI to handle fault detection, adaptive orientation, and energy conservation without ground intervention. This not only improves performance but also reduces human error and monitoring costs.

Sustainability is also influencing design philosophy. Manufacturers are incorporating environmentally responsible materials and propulsion systems that limit space debris and support satellite deorbiting at the end of operational life.

As launch costs drop due to reusable rockets and rideshare programs, the number of orders placed with произвођачи сателитских аутобуса continues to climb. This competitive landscape drives innovation, lowers цена сателитског аутобуса, and accelerates production timelines.

Breaking Down the Satellite Bus Cost Across Different Missions

One of the most pressing concerns for mission planners is the цена сателитског аутобуса, which can vary widely based on size, functionality, orbit type, and production volume. For small LEO satellites used in Earth observation or IoT connectivity, the bus may cost between $500,000 and $1 million per unit. In contrast, large GEO communication satellites can have buses costing over $10 million due to complex thermal, power, and communication systems.

Mass production has become a key factor in lowering цена сателитског аутобуса. Manufacturers now employ factory-style assembly lines, much like automotive plants, to build hundreds of identical buses with minimal downtime. This volume-based approach not only reduces material wastage and labor hours but also allows clients to scale satellite fleets affordably.

Other variables affecting цена сателитског аутобуса include the propulsion type (chemical vs. electric), radiation shielding requirements, redundancy systems, and level of automation. Missions in higher orbits or harsher space environments typically require more advanced (and expensive) subsystems.

Many clients are also opting for off-the-shelf bus models, which have already passed stringent testing and validation. These ready-to-deploy solutions offer a balance between customization and cost savings, especially for commercial startups and new space nations entering the satellite industry.

Innovative Approaches to Modern Satellite Bus Design

Contemporary дизајн сателитске аутобуске is undergoing a revolution as demands for miniaturization, energy efficiency, and multipurpose functionality intensify. Engineers are moving toward highly modular layouts that allow quick reconfiguration depending on payload changes, saving significant redesign time and cost.

One innovation in дизајн сателитске аутобуске is the use of 3D-printed structural parts, which reduce weight and material costs while allowing complex geometries that are impossible with traditional manufacturing. This not only enhances strength-to-weight ratio but also improves integration with other spacecraft systems.

Another trend is the integration of electric propulsion, which, though slower than chemical systems, is far more fuel-efficient. This innovation is especially useful for constellation satellites, where cost-per-kilogram and operational lifespan are key metrics.

Thermal regulation in дизајн сателитске аутобуске has also evolved. Heat pipes, loop heat systems, and phase change materials now ensure that temperature-sensitive instruments remain within optimal operating limits even during rapid orbit transitions or eclipse periods.

Onboard processing power is becoming increasingly sophisticated, allowing real-time data analytics, onboard compression, and autonomous navigation. These upgrades reduce dependency on ground stations and enhance mission agility.

Why the Satellite Platform Market Is Set for Explosive Growth

The market for сателитска платформа systems is experiencing dramatic expansion, driven by increasing demand from telecom providers, defense agencies, climate monitoring organizations, and private LEO satellite networks. From broadband delivery in rural areas to military surveillance and border control, satellite platforms offer unmatched versatility.

Global governments are funding programs to establish sovereign satellite capabilities, which includes investing heavily in both payloads and satellite buses. Private sector involvement—particularly in sectors like agriculture, maritime logistics, and autonomous vehicles—is also fueling demand.

With reusable launch systems reducing entry barriers and lowering launch costs, more space ventures are being greenlit each year. These missions rely on robust сателитска платформа infrastructure to deliver data, communication, and imaging services.

The evolution of digital twins and virtual testing environments allows engineers to simulate performance and failure scenarios for satellite platforms before launch. This not only enhances reliability but also shortens development cycles and ensures higher mission success rates.

As global connectivity becomes a core pillar of economic development, сателитска платформа manufacturers and integrators are uniquely positioned to lead the charge toward a more interconnected future.

Satellite platform FAQs

What is a satellite platform and how does it differ from payload?

The сателитска платформа (or bus) is the foundational structure that houses and supports all operational subsystems like power, thermal control, and communication. It differs from the payload, which consists of mission-specific equipment like cameras, sensors, or transmitters.

Who are the leading satellite bus manufacturers today?

Prominent произвођачи сателитских аутобуса include Airbus, Lockheed Martin, Northrop Grumman, Thales Alenia, and newer players in China and India. These companies offer both custom-built and standardized buses for commercial, scientific, and military applications.

What are the main considerations in satellite bus design?

Effective дизајн сателитске аутобуске requires balancing structural integrity, thermal regulation, power efficiency, weight constraints, and integration flexibility. Modern designs prioritize modularity, electric propulsion, and smart systems for autonomous operation.