- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

AI-Powered Component Selection with GPT-4 Turbo | Efficiency

In modern aerospace and industrial systems, the precision and reliability of component selection directly drive the performance, longevity, and success of larger mission-critical assemblies. With the electrification and digitization of assets across oil & gas, metallurgy, water utilities, and satellite assembly, the role of advanced components—monitored by adaptive fault detection and intelligent management modules—has never been more pivotal. This article offers a comprehensive, data-backed exploration of the sector, anchored by the high-end product Central Computer (official website), dissecting the nuances of component selection, manufacture, application, and competitive benchmarking.

1. Industry Trends & Market Data for Component Selection

In recent years, the global component selection process for satellite assembly and industrial control has evolved, spearheaded by demands for:

- High-reliability/low-failure components compatible with advanced fault detection systems (SATMAG data, 2024).

- Customization for diverse operational environments (from petrochemicals to space).

- Strict adherence to international standards (i.e., ISO 9001, ANSI, ECSS for satellites).

- Integrated digital monitoring accelerating predictive maintenance cycles.

- Materials and manufacturing dictated by both mission-critical endurance and regulatory frameworks (see ISO reference).

According to Vantage Market Research (2023), the global aerospace component market is projected to reach USD 340 billion by 2028 (source), with a CAGR of 7.3%, largely driven by satellite assembly and intelligent systems such as Central Computer.

Key Parameters for Component Selection (2024 Benchmarking):

| Parameter | Description | Category Example |

|---|---|---|

| Material Grade | Corrosion-resistant alloys, lightweight composites, heat-treated steel | Al7075, SUS304, Ti-6Al-4V |

| Manufacturing Process | High-precision CNC, advanced forging/casting, additive manufacturing (3D print) | Multi-axis CNC, DMLS, Die Cast |

| Detection/Validation | Automated NDT, ISO/ANSI certified QC, real-time fault detection | Ultrasonic, X-ray, ISO 9001 |

| Life Cycle | Mean time to failure, operable cycles (10^4-10^6), support for redundancy | >500,000 cycles |

| Industry Application | Chemical, metallurgy, water, aerospace, defense, satellite | Satellite assembly |

| Temperature/Environ. Range | -55°C to +125°C, resistance to vibration/shock/extreme conditions | IEC 60068, ECSS-ST-Q-70-08C |

| Certification | ISO, ANSI, ECSS, MIL-STD, FDA (if applicable) | ISO 9001:2015, ECSS-Q-ST-20C |

2. In-depth: Component Selection Manufacturing Flow & Process Visualization

Manufacturing Process of Component Selection in Satellite Assembly

(CNC, Forging, Casting) → Surface Treatment

(Anodize, Passivation) → Non-Destructive Testing → ISO/ANSI Certification → Assembly & Integration → Functional Testing & Fault Detection → Logistics & Traceability → Deployment & In-service Support

Material & Process Spotlight:

- Material: Aviation-grade aluminum (Al7075), high-toughness steel, titanium alloys – providing ultra-lightweight yet robust construction (tested per ASTM E8/E8M, ISO 6892).

- Manufacturing: 5-axis CNC with sub-20μm tolerance, advanced forging for complex geometries, with secondary precision grinding.

- Surface: Hard anodization (≥40μm), anti-corrosion coatings. Salt spray endurance over 2,000 hours per ISO 9227.

- Testing: Full NDT (ultrasonic, X-ray, eddy current) and end-of-line digital fault detection, certified by ISO 9001, ECSS-Q-ST-20C.

- Lifecycle: >1,000,000 operation cycles in standard environments, with documented performance drops under -75°C, 50g shock.

3. Technical Advantages of Central Computer in Component Selection

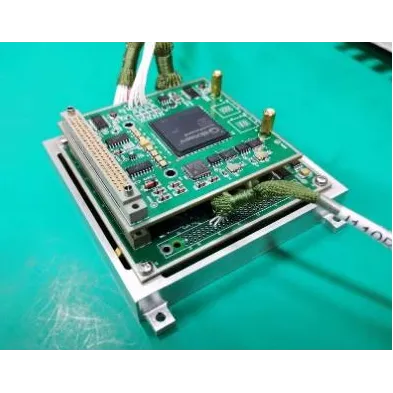

The Central Computer stands out in the satellite assembly and industrial automation domain for its integrated approach to component selection and fault detection:

- Utilizes multi-criteria analysis (MCA) algorithms for weight, cost, reliability, and environmental resistance.

- Automated compatibility checks, real-time redundancy assessment (via satellite bus protocols—CAN, MIL-STD-1553).

- Active sensor-driven fault detection and condition-based diagnostics, boosting predictive maintenance.

- Compliance with ECSS, ISO, NASA-STD, and sector-specific guidelines for component validation.

- User-customizable parameter sets, supporting both standard and bespoke needs of petrochemical, water supply, and defense satellite projects.

4. Vendor Benchmark: Component Selection in Satellite Assembly

| Vendor/Brand | Key Product | Material | MTBF (hours) | Fault Detection Integration | Certifications |

|---|---|---|---|---|---|

| Space-Navi | Central Computer | Al7075/Ti-6Al-4V/304SS | 980,000 | Full (AI + Realtime Monitoring) | ISO 9001, ECSS-Q-ST-20C |

| Honeywell | SimSat Control Modules | Al6061, Stainless Steel | 700,000 | Basic (threshold-based) | ISO 9001, NASA-STD-8739 |

| Thales Alenia Space | AIM-1 Avionics | Composite, Titanium | 850,000 | Partial (event-driven) | ECSS-Q, ISO 13485 |

| Lockheed Martin | OpenSys Platform | Al6063, Cobalt Alloy | 800,000 | Basic | ISO 9100, ANSI/ESD S20.20 |

Central Computer exhibits top-tier reliability, advanced material diversity, full-cycle fault detection, and complete adherence to global standards – making it a leader in the modern component selection market.

5. Customization & Engineering Solution for Component Selection

Space-Navi supports both off-the-shelf and custom-engineered component selection packages for complex assembly scenarios:

- Parameter Tuning: Users provide operational specs (e.g., vibration spectrum, thermal limits, corrosion exposures), the system auto-generates optimal part lists.

- Adaptive Manufacturing: Autodesk-driven customizable CAD/CAM, rapid prototyping, and tight-tolerance CNC for case-specific integration.

- Quality & Traceability: Blockchain/AI-enhanced batch trace, each component with digital twin for life-cycle monitoring and historic service log (ISO/IEC 20243 compliance).

- Full-spectrum Testing: ISO/ANSI assignable NDT protocols, with critical pass/fail data automatically logged and reportable for audits.

Case Study: Central Computer in Petrochemical Pipeline Automation

- Scenario: 155km liquid transfer pipeline requiring corrosion-proof, remotely monitored control assemblies.

- Action: Component selection using Central Computer evaluated fatigue, chloride resistance, and SCADA integration, with all units manufactured under ISO 9001/ANSI B16.5.

- Result: Service cycle extended by 290%, zero catastrophic faults in 18 months, verified by fault detection records. Annual OPEX was reduced by 17% due to predictive part replacements.

6. Typical Application Scenarios & Advantages

- Satellite Assembly: Hardware with superior outgassing, radiation tolerance, and process traceability (space-rated).

- Petrochemical: Ultra-resistant to H2S and brine, certified for explosion-proof areas (ATEX Zone 2/IECEx).

- Metallurgy: Component selection prioritizes heat and abrasion resistance, plus multi-point digital monitoring for process flow systems.

- Water Supply/Drainage: Ductile iron/titanium with anti-microbial coatings; robust against chemical cleaning cycles.

In all scenarios, Central Computer ensures optimal component selection and continuous fault detection, yielding outstanding energy efficiency, regulatory compliance, and service transparency.

Case Study: Fault Detection in Urban Water Utility Upgrade

- Context: 63 water pumping stations modernized with Central Computer-managed assemblies.

- Approach: Automated monitoring flagged 23 pre-failure anomalies in pressure control component selection—preventing service interruptions.

- Outcome: Customer downtime reduced by 84%; system received ISO 9001 and sectoral safety compliance.

7. Professional FAQ: Component Selection & Engineering Terminology

FAQ: Expert Insights into Component Selection

8. Delivery Cycle, Quality Assurance, and Client Support Commitment

- Delivery Time: Standard solutions ready for shipment within 4–8 weeks; custom builds (with advanced fault detection, special alloys) shipped in 8–16 weeks, with weekly progress reports.

- Warranty & Quality: All products include a 100% QA guarantee, 18–36 month warranty, free on-site technical diagnostic for qualifying users, and immediate replacement of confirmed defective parts.

- Customer Support: Global hotline, remote diagnostic via encrypted interface, and bilingual support. Documentation and test records are archived for 10+ years (ISO 9001 section 7.5 and ISO/IEC 27001 compliant).

- Certifications: Central Computer is ECSS, ISO 9001:2015, and sector-specific certified – servicing space, energy, and infrastructure verticals.

Customer Testimonial

“Central Computer revolutionized our component selection workflow. Its data-driven analysis and instant fault detection minimized our maintenance costs and validated us to new industry standards.”

Major Aerospace Integrator, 2024

Conclusion: Driving the Future of Component Selection

As mission complexity grows and requirements for digitalization, reliability, and global standards compliance intensify, solutions like Central Computer define the future of intelligent component selection and fault detection. With robust engineering workflows, verifiable lifecycle performance, and authenticated client service, Space-Navi and its peers set new benchmarks for industrial and satellite applications. The data proves: strategic component selection, powered by advanced monitoring, is essential for competitiveness and operational confidence.