- afrykanin

- albański

- amharski

- arabski

- ormiański

- azerbejdżański

- baskijski

- Białoruski

- bengalski

- bośniacki

- bułgarski

- Kataloński

- Cebuański

- Chiny

- Korsykański

- chorwacki

- czeski

- duński

- Holenderski

- angielski

- esperanto

- estoński

- fiński

- francuski

- fryzyjski

- Galicyjski

- gruziński

- niemiecki

- grecki

- Gudżarati

- kreolski haitański

- hausański

- hawajski

- hebrajski

- NIE

- Miao

- węgierski

- islandzki

- ibo

- indonezyjski

- irlandzki

- włoski

- japoński

- jawajski

- kannadajski

- kazachski

- khmerski

- Rwandyjski

- koreański

- kurdyjski

- Kirgiski

- Praca

- łacina

- łotewski

- litewski

- luksemburski

- Macedoński

- malgaski

- malajski

- Malajalam

- maltański

- Maoryski

- Marathi

- mongolski

- Myanmar

- Nepalski

- norweski

- norweski

- oksytański

- paszto

- perski

- Polski

- portugalski

- Pendżabski

- rumuński

- rosyjski

- Samoański

- szkocki gaelicki

- serbski

- angielski

- Szona

- Sindhi

- syngaleski

- słowacki

- słoweński

- Somali

- hiszpański

- Sundajski

- suahili

- szwedzki

- tagalski

- tadżycki

- Tamil

- Tatar

- teluguski

- tajski

- turecki

- Turkmeński

- ukraiński

- Urdu

- Ujgurski

- uzbecki

- wietnamski

- walijski

- Pomoc

- jidysz

- Joruba

- Zulus

aktualności

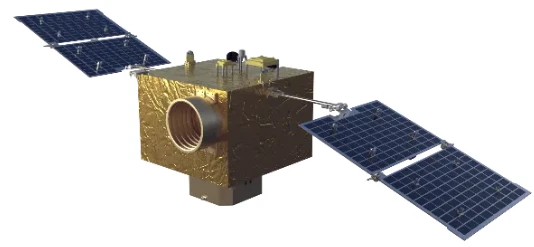

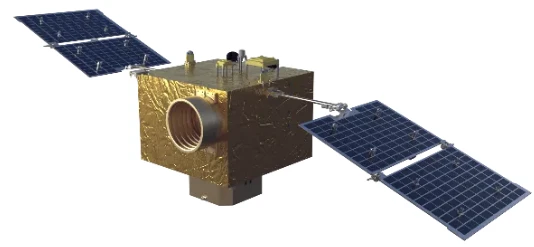

Ensuring Material Integrity in Spacecraft: The Role of the Optical Emission Spectrometer at SpaceNavi

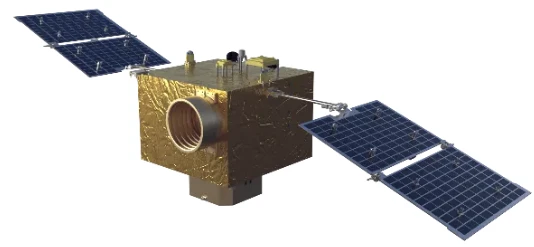

In the world of satellite engineering, material integrity is not just important—it’s mission-critical. At SpaceNavi Co., Ltd., our commitment to reliability starts at the elemental level. Through the integration of high-precision optical instrument systems, such as the optical emission spectrometer, we ensure that every material used in our satellites meets strict aerospace-grade standards. This commitment to quality strengthens our reputation as a trusted provider of high-performance, low-cost satellite solutions for government and global clients.

Verifying Aerospace Materials with the Optical Emission Spectrometer

The optical emission spectrometer is a cornerstone of SpaceNavi’s quality control lab. It provides rapid and accurate elemental analysis of metals and alloys, helping our engineers confirm the chemical composition of structural and electronic components. Using light emitted by excited atoms, this tool detects trace elements and impurities that could compromise material strength, conductivity, or thermal stability in the harsh environment of space.

We use the optical emission spectrometer to inspect raw materials before fabrication and to verify component integrity post-manufacture. Whether it’s a satellite’s internal frame, shielding panels, or thermal interface layers, we make sure that every part has been analyzed for compliance with aerospace material specifications.

This non-destructive, fast-response testing technology allows SpaceNavi to maintain a high level of production efficiency while safeguarding satellite performance under extreme conditions.

Complementing Analysis with Optical Spectrometer and Profiling Tools

In addition to emission-based analysis, SpaceNavi deploys the optical spectrometer to support both ground-based R&D and spaceborne scientific applications. In our labs, the optical spectrometer helps us study how different coatings or payload components interact with light across various wavelengths—vital for calibrating Earth observation satellites.

Onboard our satellites, optical spectrometer modules can be included as payload instruments for missions involving environmental monitoring, agriculture, water quality, and more. These modules collect spectral data that allows for the interpretation of surface materials, vegetation health, or atmospheric gases from space.

Our end-to-end integration of optical instrument technology—including spectrometry, surface measurement, and particle analysis—ensures that from design to orbit, precision is embedded into every layer of the mission.

Cleanroom Reliability with Optical Particle Counter and Sizer

In parallel with our material verification tools, we maintain rigorous cleanroom conditions through devices like the optical particle counter and optical particle sizer. The optical particle counter enables continuous air monitoring by detecting even microscopic contaminants, which are especially dangerous when assembling sensitive satellite optics or payloads.

Meanwhile, the optical particle sizer provides real-time data on particle distribution and size, giving engineers better control over environmental cleanliness. Together, these tools support the assembly of components such as optical sensors, mirrors, and electronics—minimizing the risk of contamination-related failures.

At SpaceNavi, we believe that combining high-level optical instrument technology with robust quality assurance processes allows us to deliver satellite systems that perform flawlessly in orbit, despite the complex challenges of space.