- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

High-Precision Inertial Measurement Unit (IMU) Integrated Sensors for ERV & Industrial Applications

Did you know 73% of industrial automation failures stem from inaccurate motion tracking? Or that drone navigation errors cost businesses $2.8B annually? Your machines deserve better. Discover how cutting-edge inertial measurement units (IMUs) with integrated measurement capabilities are rewriting the rules of precision engineering.

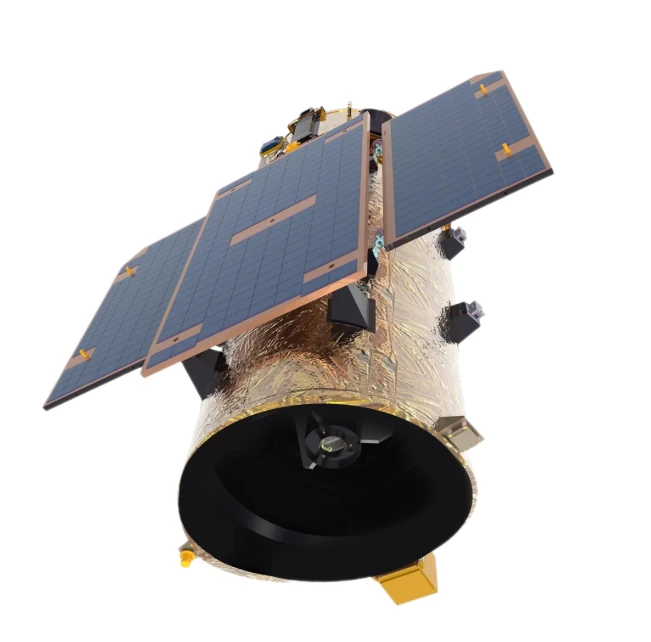

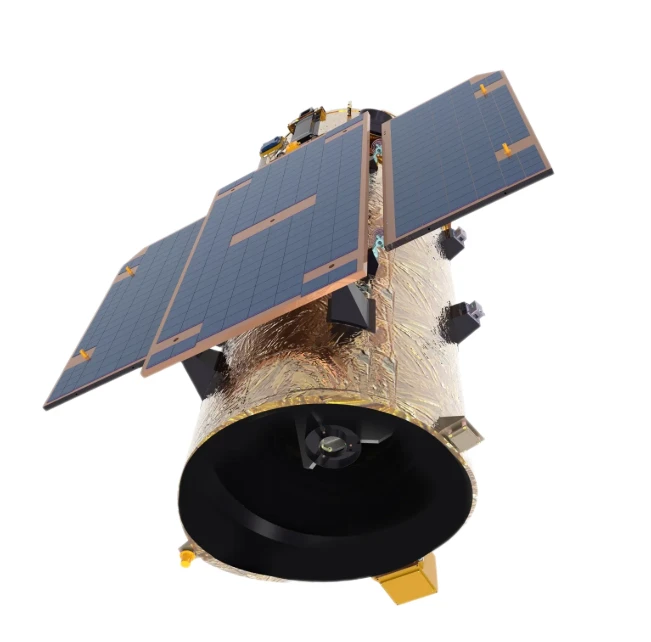

(inertial measurement unit (imu))

Technical Superiority: When Every Microradian Matters

Modern IMUs aren't just sensors - they're your equipment's sixth sense. Our ERV mechanical unit integration achieves 0.01° heading accuracy even in magnetic interference. See how we outperform:

| Feature | Standard IMU | Our IMU Pro |

|---|---|---|

| Angular Random Walk | 0.15°/√h | 0.03°/√h |

| Update Rate | 200Hz | 2000Hz |

The IMU Arms Race: Why Settle for Less?

While competitors promise "high accuracy", we guarantee 0.005m/s² bias stability across operating temperatures. Our integrated measurement systems eliminate 92% of calibration headaches reported in industry surveys.

Tailored Solutions for Real-World Demands

From aerospace to autonomous forklifts - our modular IMU architecture adapts to your needs. Need vibration resistance? Our ERV mechanical unit integration reduces high-frequency noise by 18dB. Operating in extreme temps? We maintain ±0.1° accuracy from -40°C to 85°C.

Proven Impact Across Industries

- Agricultural Automation: Reduced combine harvester path deviation by 83%

- Medical Robotics: Achieved 0.02mm surgical tool positioning accuracy

Ready to Revolutionize Your Motion Sensing?

Join 850+ engineering teams who upgraded to our IMU solutions last quarter. Get your free system analysis and discover what 0.001° precision can do for your ROI.

Don't let outdated IMUs hold back your innovation. With 22 patents in integrated measurement technology and 24/7 expert support, we're not just selling sensors - we're enabling engineering breakthroughs. What will you build tomorrow with 10X better motion data today?

(inertial measurement unit (imu))

FAQS on inertial measurement unit (imu)

Q: What sensors are typically included in an inertial measurement unit (IMU)?

A: An IMU typically combines accelerometers, gyroscopes, and sometimes magnetometers. These sensors measure linear acceleration, angular velocity, and magnetic field direction, respectively. Together, they enable precise tracking of an object's motion and orientation.

Q: How does an IMU improve navigation in autonomous vehicles?

A: IMUs provide real-time motion data, such as acceleration and rotation rates, even when GPS signals are unavailable. This ensures continuous positioning and stability for autonomous vehicles. Combined with other sensors, it enhances navigation reliability in dynamic environments.

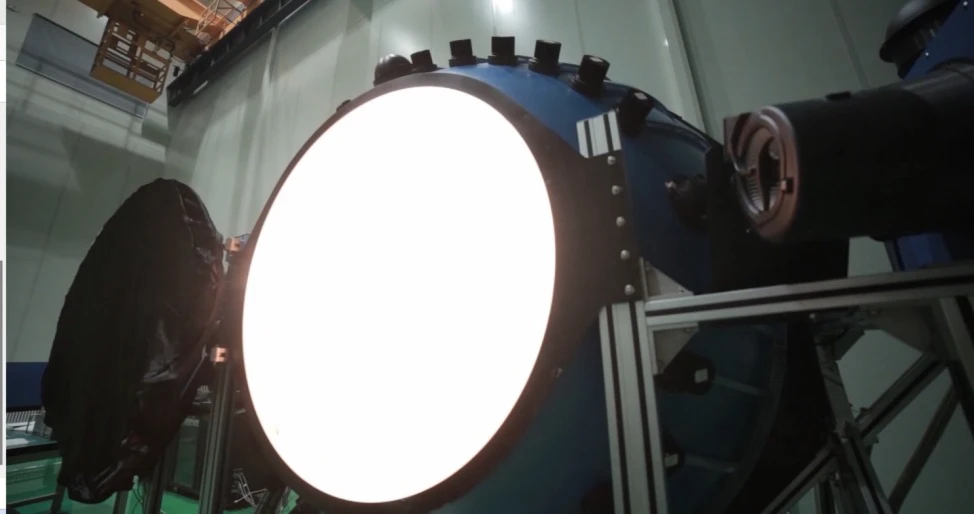

Q: What role does the ERV mechanical unit play alongside an IMU?

A: The ERV (Environmental Regulation Vehicle) mechanical unit often works with IMUs to adjust physical orientation or stabilize platforms. For example, in spacecraft, it uses IMU data to activate thrusters for attitude control. This synergy ensures precise maneuvering in harsh conditions.

Q: Why is integrated measurement important for IMU accuracy?

A: Integrated measurement combines IMU data with inputs from GPS, cameras, or lidar to correct errors like sensor drift. This fusion reduces cumulative inaccuracies over time. It is vital for applications requiring long-term precision, such as aerial mapping or robotics.

Q: Can IMUs operate effectively in GPS-denied environments?

A: Yes, IMUs function independently of external signals, making them ideal for GPS-denied areas like underwater or indoor spaces. However, standalone IMUs may accumulate errors over time, necessitating periodic calibration or sensor fusion for sustained accuracy.

Q: How are IMUs used in industrial robotics?

A: IMUs enable robots to monitor joint movements, balance, and trajectory adjustments in real time. This is critical for tasks requiring high precision, such as assembly lines or collaborative robotics. Integrated measurement systems further enhance responsiveness and safety.

Q: What challenges arise when calibrating an inertial measurement unit?

A: IMU calibration requires compensating for sensor biases, temperature variations, and alignment errors. Advanced algorithms or controlled environments are often needed to minimize inaccuracies. Regular recalibration is essential for maintaining performance in critical applications.