- Afrikaanse

- Albanees

- Amhaars

- Arabisch

- Armeens

- Azerbeidzjaans

- baskisch

- Wit-Russisch

- Bengaals

- Bosnisch

- Bulgaars

- Catalaans

- Cebuaans

- China

- Corsicaans

- Kroatisch

- Tsjechisch

- Deens

- Nederlands

- Engels

- Esperanto

- Estisch

- Fins

- Frans

- Fries

- Galicisch

- Georgisch

- Duits

- Grieks

- Gujarati

- Haïtiaans Creools

- Hausa

- Hawaïaans

- Hebreeuws

- Nee

- Miao

- Hongaars

- IJslands

- ikbo

- Indonesisch

- Iers

- Italiaans

- Japanse

- Javaans

- Kannada

- Kazachs

- Khmer

- Rwandese

- Koreaans

- Koerdisch

- Kirgiezen

- Werk

- Latijns

- Lets

- Litouws

- Luxemburgs

- Macedonisch

- Madagaskar

- Maleis

- Maleis

- Maltees

- Maori

- Marathi

- Mongools

- Birma

- Nepalees

- Noors

- Noors

- Occitaans

- Pasjtoe

- Perzisch

- Pools

- Portugees

- Punjabi

- Roemeense

- Russisch

- Samoaans

- Schots-Gaelisch

- Servisch

- Engels

- Shona

- Sindhi

- Singalees

- Slowaaks

- Sloveens

- Somali

- Spaans

- Soendanees

- Swahili

- Zweeds

- Tagalog

- Tadzjieks

- Tamil

- Tataars

- Telugu

- Thais

- Turks

- Turkmeens

- Oekraïens

- Urdu

- Oeigoers

- Oezbeeks

- Vietnamees

- Welsh

- Hulp

- Jiddisch

- Yoruba

- Zoeloe

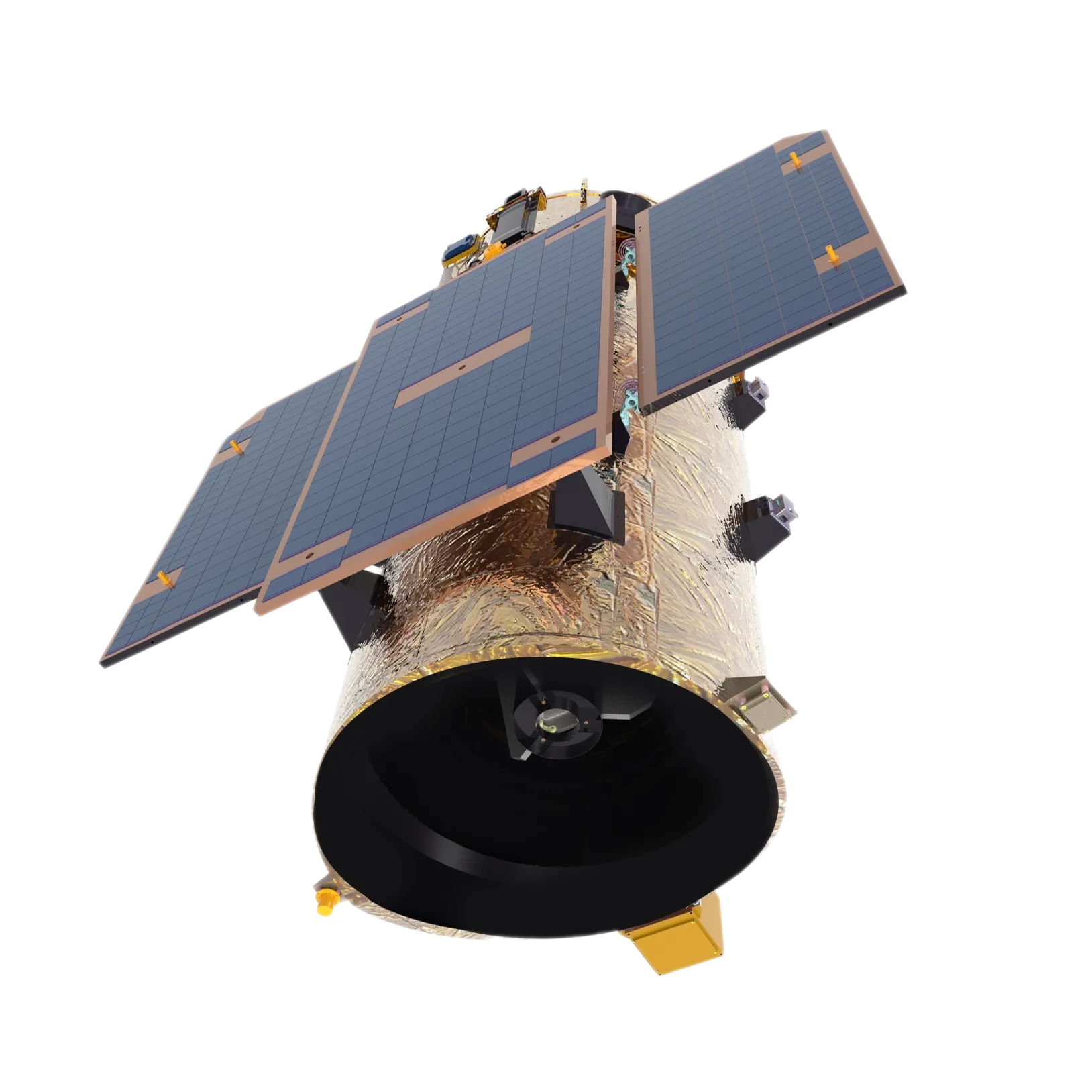

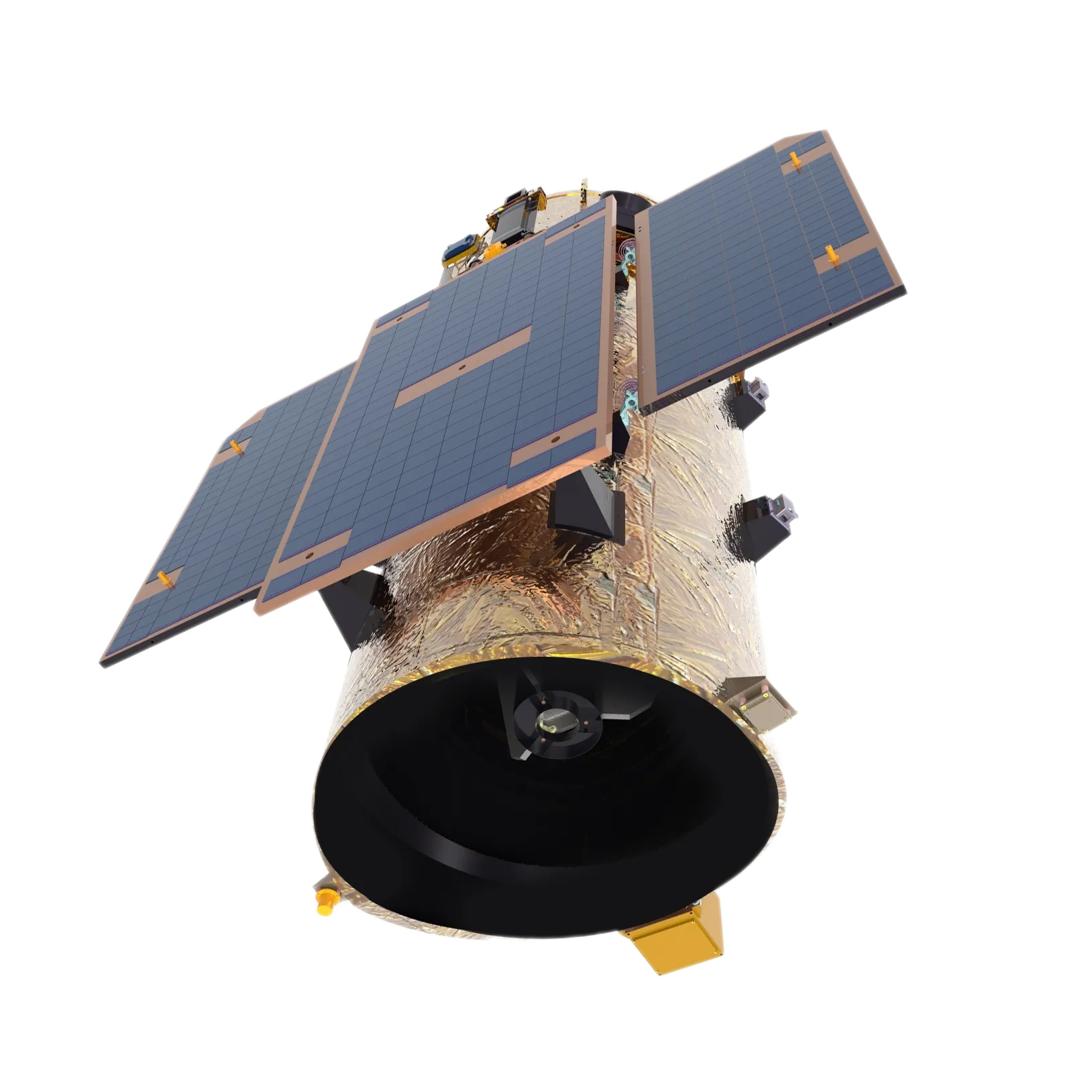

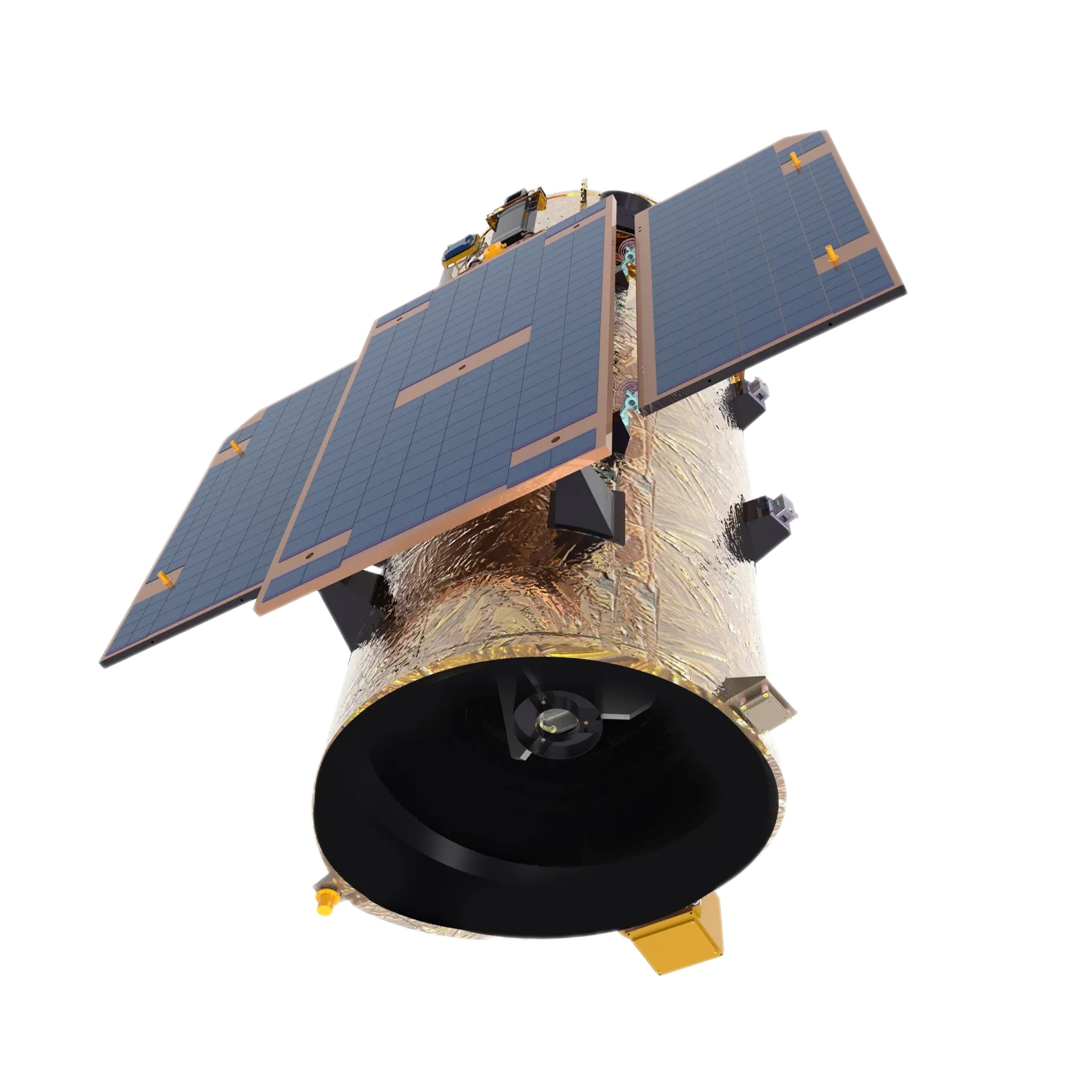

Advancing Aerospace Reliability: Optical Profilometer Technologies Empowering Satellite Innovation

In the space industry, the performance of satellite components is heavily influenced by surface quality and structural accuracy. From thermal shields to spectrometers, ensuring smooth, defect-free surfaces is vital. At SpaceNavi Co., Ltd., our engineering excellence is supported by precision instruments like the optical profilometer and its advanced variations such as the 3D optical profilometer and optical surface roughness testers. These tools enable us to maintain stringent standards for all components used in our satellite and UAV programs.

By incorporating cutting-edge optical measuring instruments and surface testing tools into every production phase, SpaceNavi ensures both durability and high functionality in all its aerospace systems.

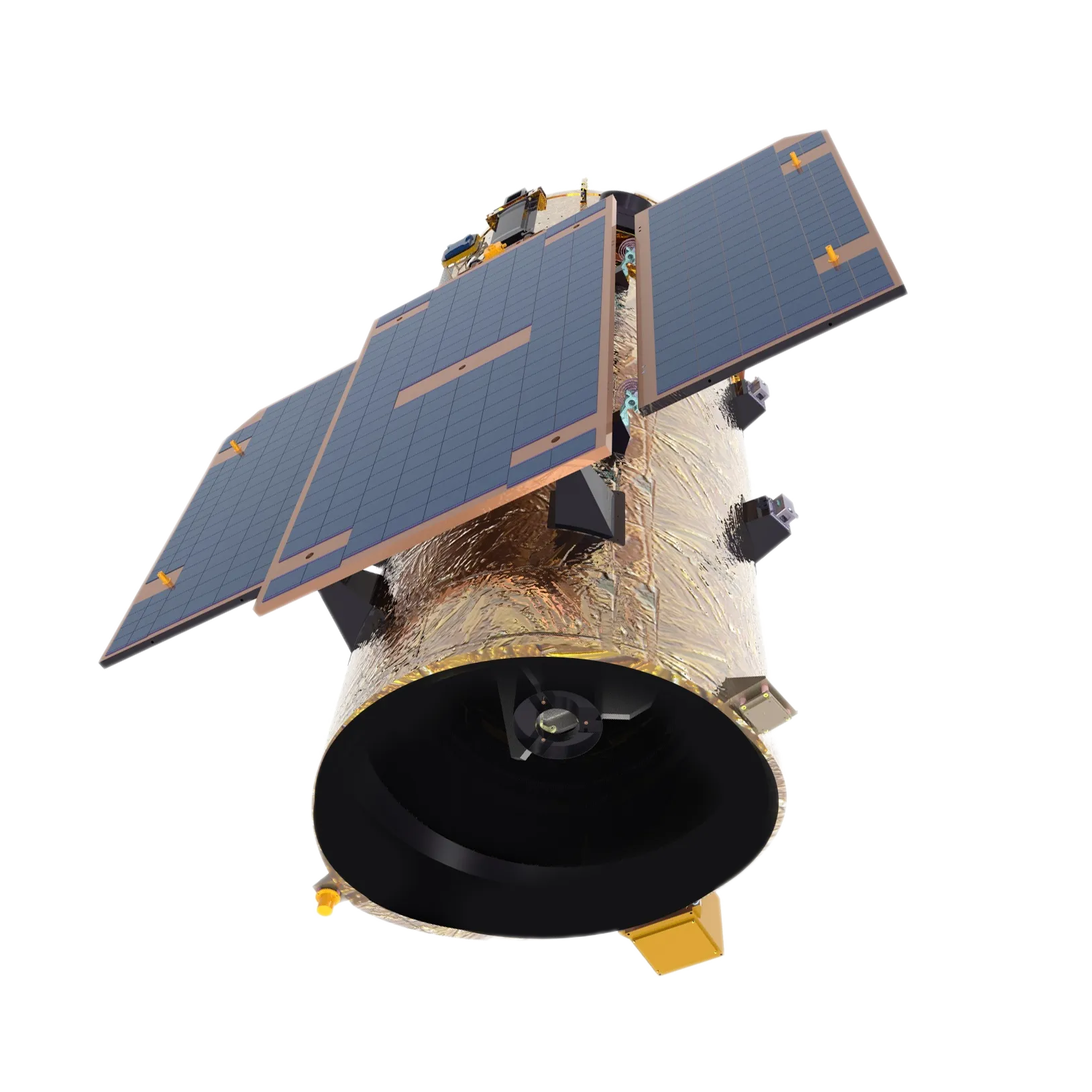

Elevating Component Design With 3D Optical Profilometer

For aerospace parts that require high-precision fitting, surface uniformity directly impacts assembly success and in-flight performance. The 3D optical profilometer is essential to our workflow, providing high-resolution, three-dimensional images of component surfaces without physical contact.

Whether we’re designing structural frames for CubeSats or fine-tuning surfaces on optical instruments used in imaging payloads, the 3D optical profilometer supports comprehensive inspection. It is especially valuable for non-planar or complex geometries common in satellite architecture.

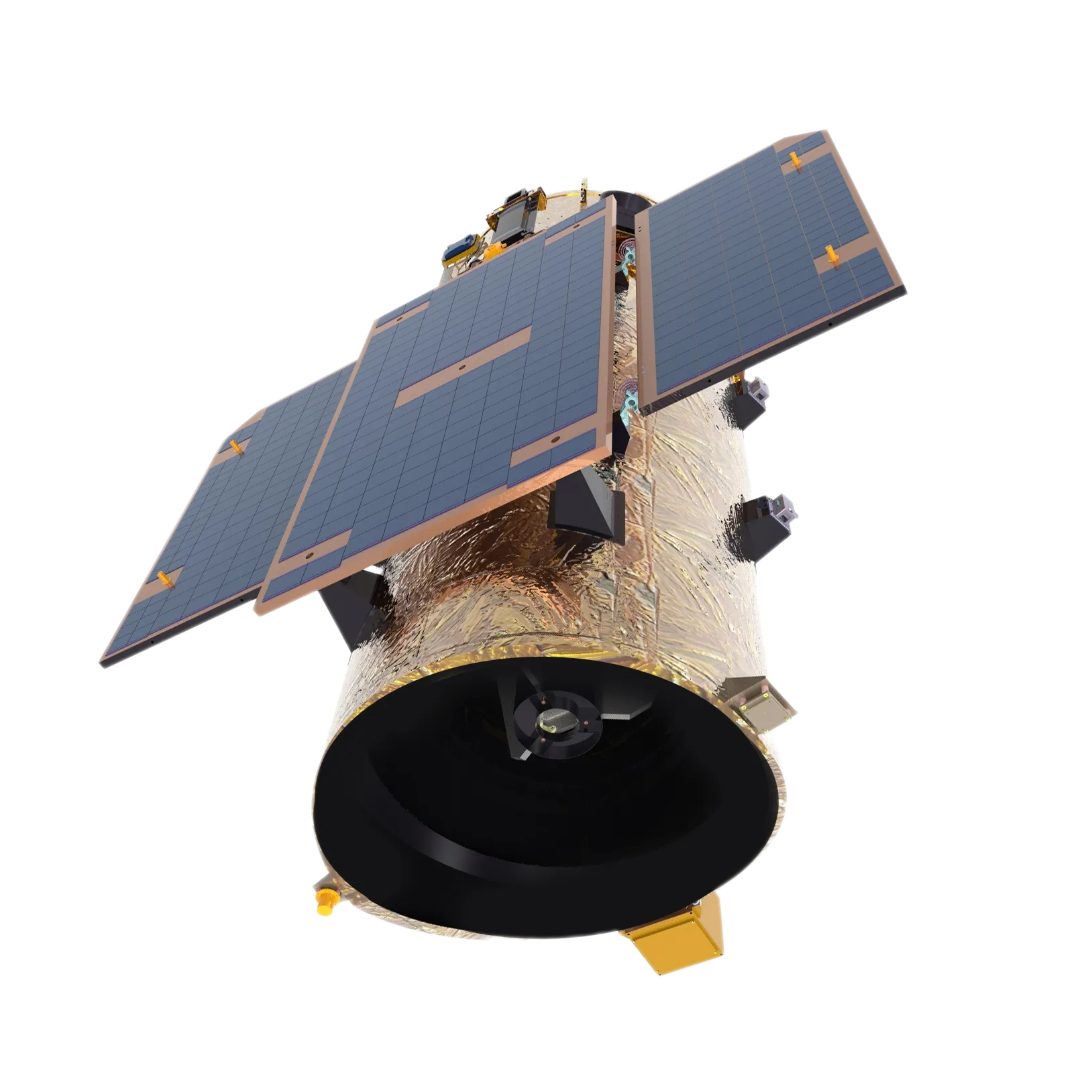

Ensuring Consistency Through Optical Profilometer Surface Roughness Analysis

Satellites must endure extreme environmental changes—vacuum pressure, radiation, and severe temperature fluctuations. A seemingly minor surface imperfection can lead to mechanical failure under these conditions. That’s why SpaceNavi uses optical profilometer surface roughness assessment tools to validate every satellite surface before launch.

Our process includes evaluating interfaces for sensor mounts, payload fixtures, and structural fasteners, ensuring a smooth interaction with other critical modules. With precise optical profilometer resolution, we can detect flaws below the micron level, offering unmatched surface integrity.

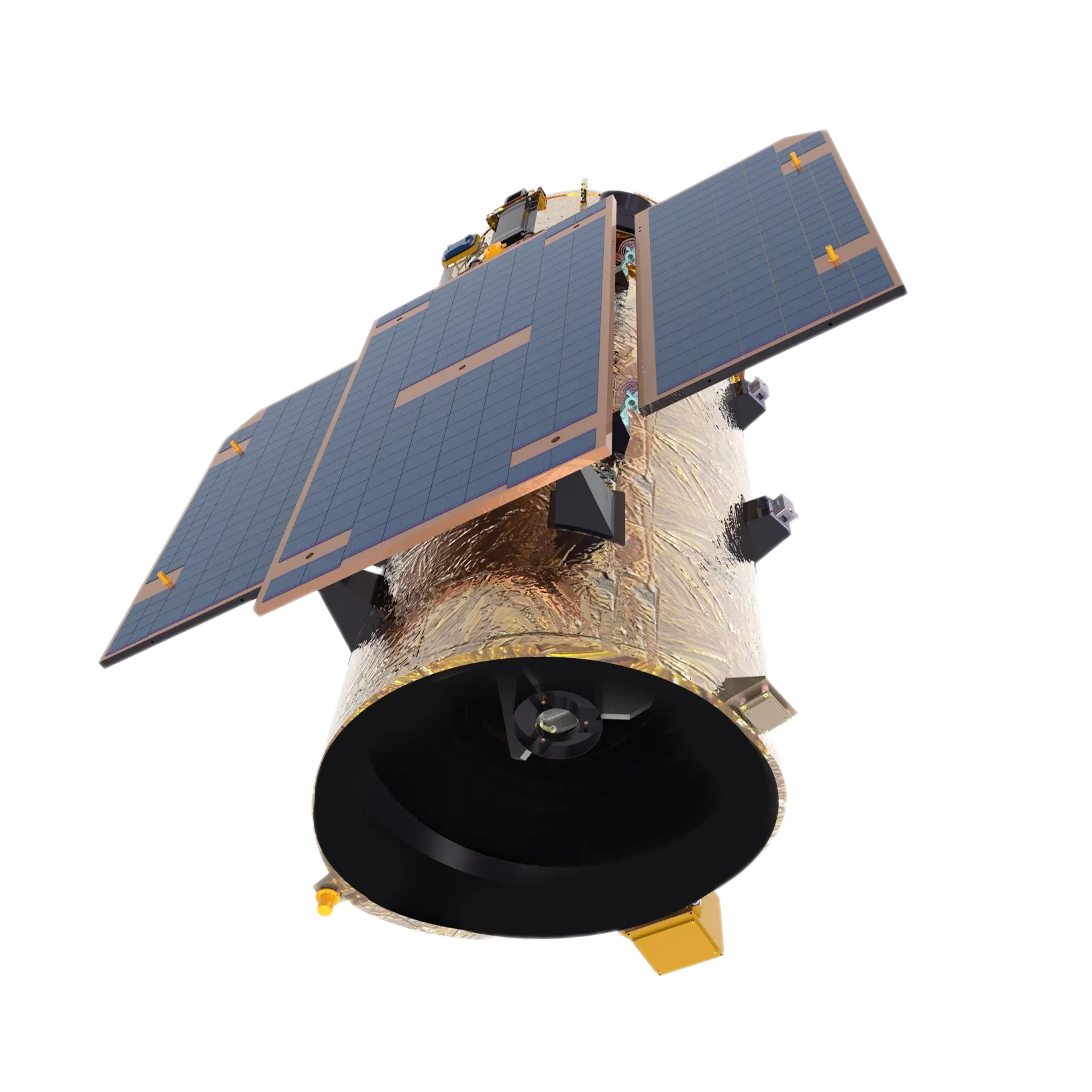

Advanced Support With Optical Measuring Instruments And Lab Tools

At Ruimteschepen, our facilities are equipped with a suite of high-end optical lab equipment, including optical emission spectrometers, optical spectrometers, and optical particle counters. These instruments are essential not only for surface analysis but also for ensuring component material purity and performance under simulated launch and orbit conditions.

For example, our optical dissolved oxygen meters are used to monitor chemical stability during component coating, while the optical particle sizer ensures a clean, contamination-free production environment.

SpaceNavi Co., Ltd. has built its reputation on precision, reliability, and innovation. By integrating tools such as the optical profilometer, 3D optical profilometer, and optical surface roughness testers into our aerospace design and testing process, we continue to push the boundaries of satellite and UAV engineering.

With deep expertise in optical measuring instruments, our teams ensure every element, from a small sensor bracket to a large imaging panel, meets the highest standards for space deployment.