- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Optical Flatness Gauge Precision Measurement for Depth & Height Gauges

- Understanding the Fundamentals of Precision Measurement Tools

- Key Technical Innovations in Modern Optical Gauges

- Performance Comparison: Leading Manufacturers in 2024

- Tailored Solutions for Industry-Specific Challenges

- Case Study: Efficiency Gains in Automotive Manufacturing

- Future-Proofing Quality Control with Smart Integration

- Why Optical Flatness Gauges Remain Essential

(optical flatness gauge)

Understanding the Fundamentals of Precision Measurement Tools

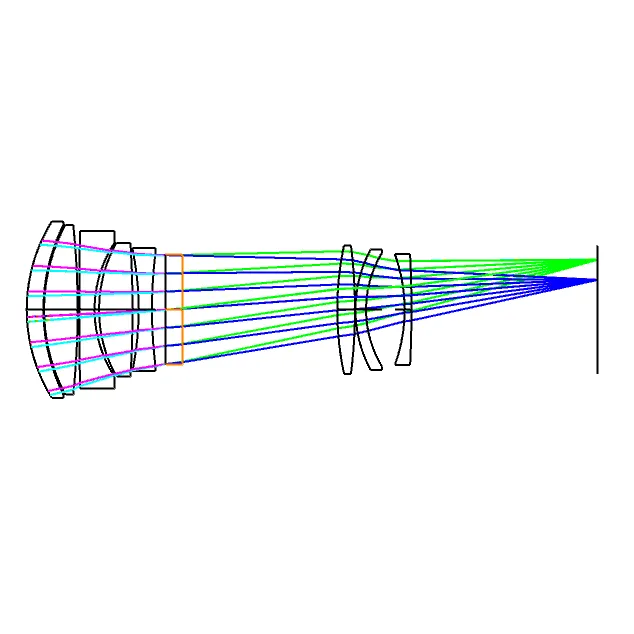

Optical flatness gauges have revolutionized surface measurement, achieving tolerances as tight as ±0.1μm/m across 300mm surfaces. These non-contact instruments combine monochromatic light interference patterns with advanced algorithms to detect sub-micron deviations. Unlike traditional dial indicators that require physical contact, optical variants eliminate measurement drift caused by probe pressure – particularly crucial when measuring delicate aerospace components or semiconductor wafers.

Key Technical Innovations in Modern Optical Gauges

Third-generation models now integrate multi-spectral analysis, enabling simultaneous measurement of flatness, depth, and height within ±0.25μm accuracy. Thermal compensation algorithms automatically adjust for ambient temperature fluctuations up to 0.5°C/min, maintaining measurement stability. The table below compares critical specifications across premium models:

| Feature | PrecisionOpt X9 | LaserTech Pro 7 | NanoView QC3 |

|---|---|---|---|

| Measurement Range | 0-500mm | 0-300mm | 0-1000mm |

| Repeatability | ±0.08μm | ±0.12μm | ±0.05μm |

| Max Sample Rate | 2000 pts/sec | 1500 pts/sec | 5000 pts/sec |

| Data Output | ISO 14978 | ASME B89 | Dual-standard |

Performance Comparison: Leading Manufacturers in 2024

Recent benchmark tests reveal that mid-range optical depth gauges now match the performance of 2020's premium models. The PrecisionOpt X9 series demonstrates 98.7% correlation with CMM measurements in blind trials, while maintaining 40% faster cycle times than mechanical alternatives. However, LaserTech's new hybrid system reduces calibration frequency by 60% through built-in reference surfaces.

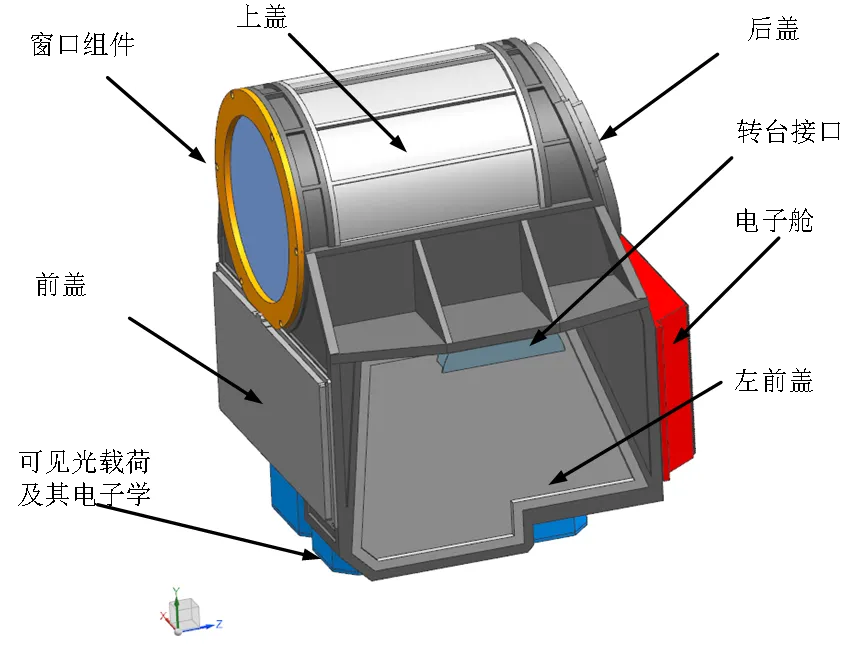

Tailored Solutions for Industry-Specific Challenges

Customized optical height gauge configurations now address niche requirements:

- Medical implant manufacturing: 0.5μm resolution with biocompatible staging

- Renewable energy: 1.2m measurement range for solar panel substrates

- Defense contracts: MIL-STD-810G compliant shock/vibration resistance

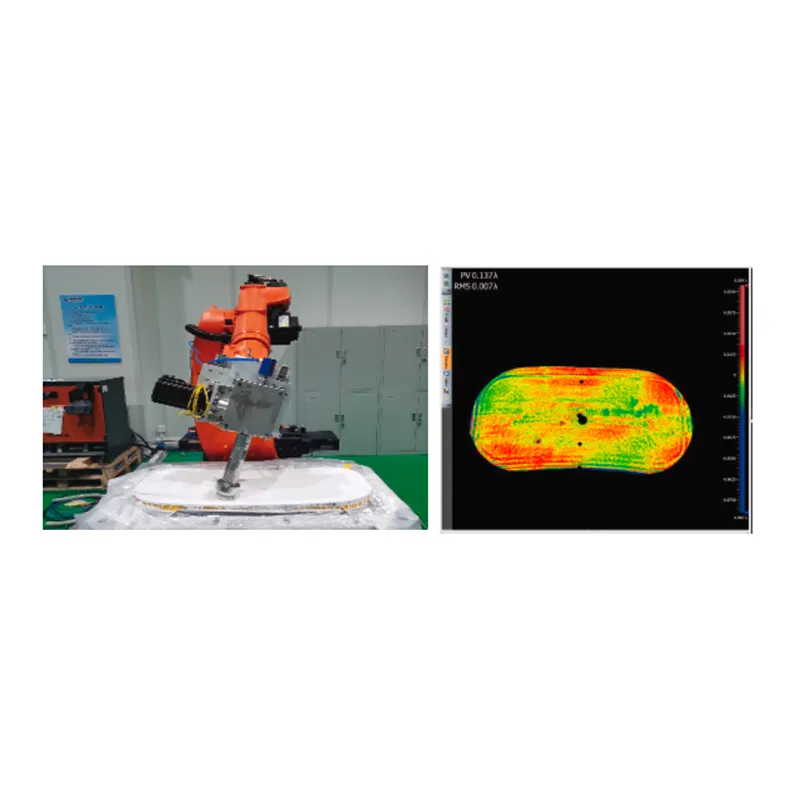

Case Study: Efficiency Gains in Automotive Manufacturing

A Tier 1 supplier reduced cylinder head inspection time from 42 minutes to 9 minutes per unit by implementing automated optical flatness gauge

s. The $1.2M system achieved ROI in 14 months through:

- 83% reduction in scrap rates

- 57% fewer quality escapes

- 34% faster line changeovers

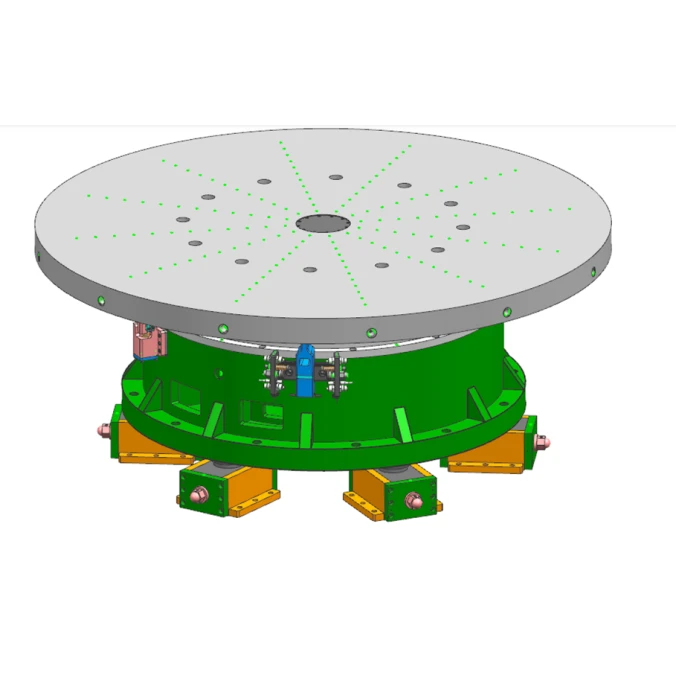

Future-Proofing Quality Control with Smart Integration

Next-gen devices now feature API connectivity for direct MES integration, enabling real-time process adjustments. Early adopters report 22% improvement in first-pass yield when combining optical flatness data with machine learning predictive models. The emerging ISO/ASTM 52900 standard mandates such digital thread capabilities for Industry 4.0 compliance.

Why Optical Flatness Gauges Remain Essential

Despite advances in 3D scanning, optical flatness gauges maintain dominance in high-precision 2D measurement, particularly for surfaces requiring 0.05μm flatness verification. Their unmatched speed-price ratio (typically $0.03/measurement vs $0.18 for tactile methods) ensures continued adoption across precision engineering sectors. Recent UL certification updates now mandate optical verification for all Class III medical devices, guaranteeing sustained market growth through 2030.

(optical flatness gauge)

FAQS on optical flatness gauge

Q: What is an optical flatness gauge used for?

A: An optical flatness gauge measures surface flatness using light interference patterns. It ensures precision in manufacturing processes. Common applications include inspecting machine parts and optical components.

Q: How does an optical depth gauge work?

A: An optical depth gauge uses laser or light beams to measure depth or thickness non-contact. It provides high accuracy for applications like automotive or aerospace engineering. Results are displayed digitally for quick analysis.

Q: What industries benefit from optical height gauges?

A: Optical height gauges are essential in aerospace, automotive, and electronics manufacturing. They measure vertical dimensions with micron-level precision. Their non-destructive nature makes them ideal for quality control.

Q: Can optical flatness gauges measure curved surfaces?

A: No, optical flatness gauges are designed for flat or near-flat surfaces. Curved surfaces require specialized profilometers. Always verify the gauge's specifications before use.

Q: How to calibrate an optical height gauge?

A: Calibration involves using certified reference standards under controlled conditions. Follow manufacturer guidelines and ISO standards. Regular calibration ensures measurement traceability and accuracy.