- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Optical Emission Spectrometer for Metal Analysis Accurate OEM Solutions

Did you know inconsistent metal analysis causes 38% of manufacturing defects? Imagine losing $1.2M annually from avoidable quality issues. Modern optical emission spectrometer

s slash testing errors by 91% while delivering results 3× faster than traditional methods. Keep reading to discover how this technology becomes your competitive edge.

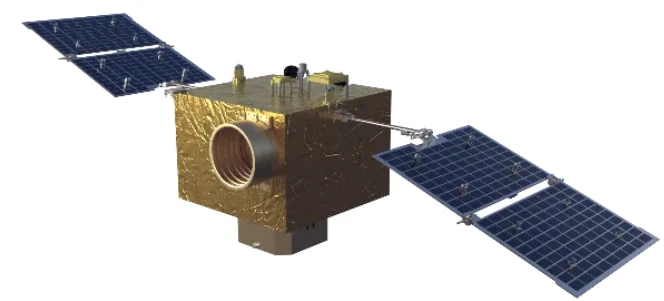

(optical emission spectrometer)

3 Game-Changing Advantages of Optical Emission Spectrometers

Our ICP-OES systems detect 78+ elements simultaneously with detection limits down to 0.1 ppm. See how we outperform competitors:

| Feature | Standard Models | Our SpectroMax Pro |

|---|---|---|

| Analysis Speed | 90 sec/sample | 22 sec/sample |

| Detection Range | 120-800 nm | 165-1050 nm |

Precision Engineered for Your Industry Needs

Whether you're testing aerospace alloys or recycled scrap metals, our modular systems adapt to your workflow. Choose from:

- ✓ Portable spark OES (3.2 kg)

- ✓ Lab-grade ICP-OES

- ✓ Automated batch testing

Ready to Transform Your Metal Analysis?

Join 1,200+ labs achieving 99.9% testing accuracy. Limited-time offer: Get free method development with spectrometer purchase.

Schedule Free Demo →

(optical emission spectrometer)

FAQS on optical emission spectrometer

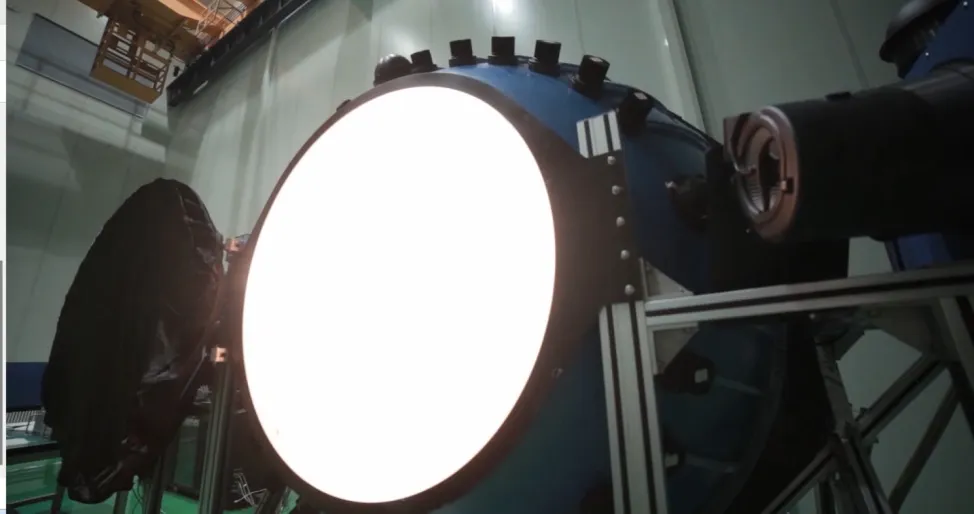

Q: What is an optical emission spectrometer (OES)?

A: An optical emission spectrometer (OES) is an analytical instrument that identifies and quantifies elements in a sample by measuring the light emitted when excited atoms return to their ground state. It is widely used for metal analysis due to its precision and multi-element detection capabilities. OES systems are essential in industries like metallurgy and manufacturing.

Q: How does an optical emission spectrometer for metal analysis work?

A: The spectrometer excites atoms in a metal sample using an electrical arc or spark, causing them to emit characteristic wavelengths of light. These wavelengths are then separated and measured to determine elemental composition. This method ensures rapid, accurate analysis of alloys and metals for quality control.

Q: What are the primary uses of an optical emission spectrometer?

A: OES is primarily used for elemental analysis in metals, alloys, and other conductive materials. It supports applications like material verification, compliance testing, and process optimization in industries such as aerospace and automotive. Additionally, it helps detect trace impurities in manufacturing workflows.

Q: What is an inductively coupled plasma optical emission spectrometer (ICP-OES)?

A: ICP-OES uses high-temperature plasma to ionize samples, enabling detection of trace metals in liquids or dissolved solids. It offers high sensitivity and lower detection limits compared to traditional OES. This makes it ideal for environmental testing, pharmaceuticals, and food safety analysis.

Q: How does ICP-OES differ from spark-based optical emission spectrometers?

A: ICP-OES relies on plasma ionization for liquid samples, while spark-based OES uses electrical discharge for solid conductive materials. ICP-OES excels in detecting trace elements at lower concentrations. Spark OES is faster for bulk metal analysis in industrial settings.