- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

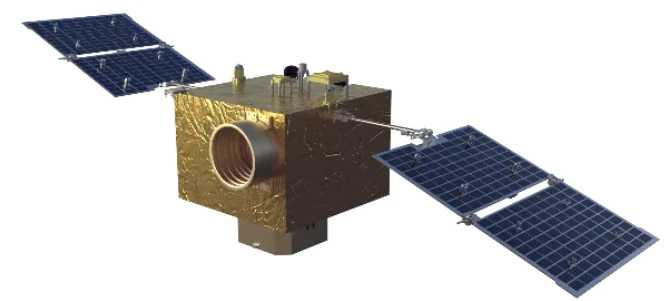

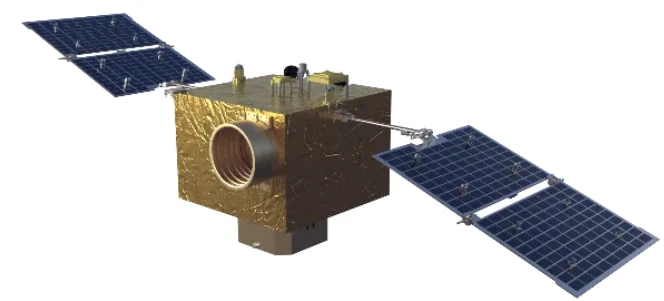

Satellite Platform Innovation

The success of any space mission depends not only on payloads and launch vehicles but also on the foundational structure that supports all onboard systems—the satellite platform. Known in technical terms as the "satellite bus," this component forms the backbone of every satellite, housing its power systems, propulsion, thermal regulation, data handling, and communications. With space applications expanding rapidly—from Earth observation to communication and scientific experiments—the demand for advanced satellite platform solutions is higher than ever.

A robust satellite platform must provide flexible integration for diverse payloads, reduce mission cost, and enhance performance in orbit. Today’s space industry is rapidly evolving toward miniaturization, reusability, and intelligent automation, all of which place new demands on satellite bus architecture. The traditional "one size fits all" model no longer works; the modern satellite platform must be adaptable, scalable, and mission-optimized.

As space becomes more commercialized and accessible, the role of the satellite platform continues to grow in importance—not only as a structural and functional system, but as a mission enabler that determines a satellite’s cost-effectiveness, capabilities, and operational lifetime.

How Satellite Bus Manufacturers Are Shaping Next-Gen Spacecraft

Across the globe, a new generation of satellite bus manufacturers is revolutionizing the way spacecraft are built. These companies focus on developing advanced bus systems that are modular, compact, lightweight, and easier to manufacture. Traditional aerospace giants continue to innovate, but so do nimble startups offering small-satellite buses and rideshare-optimized designs.

Satellite bus manufacturers are responding to new market needs driven by mega-constellations, IoT services, Earth observation platforms, and government surveillance initiatives. These needs require buses that can handle fast assembly timelines, operate in varied orbits, and support mission agility. Manufacturers are also investing in digital twin simulations, AI-based telemetry analysis, and in-orbit serviceability features.

Increasingly, satellite bus manufacturers offer platforms that are pre-integrated with certain payload classes. This strategy reduces design cycles and ensures reliability through pre-validated components and subsystems. Whether for a small CubeSat mission or a high-power geostationary communications satellite, choosing the right manufacturer directly affects system performance and long-term success.

Understanding Satellite Bus Cost: What Factors Drive Pricing

While launch services and payload development get much of the attention in space budgets, the satellite bus cost plays a crucial role in determining the total mission expense. The satellite bus cost can vary significantly depending on satellite size, mission duration, orbital parameters, and redundancy requirements.

For small LEO missions, bus costs can range from a few hundred thousand dollars to over a million. For medium- to large-scale missions in GEO or MEO, satellite bus cost may escalate into tens of millions due to added complexities like thermal control, radiation shielding, and propulsion modules. Integration and testing also contribute to higher pricing, especially when custom payload interfaces are needed.

Materials, structural complexity, onboard processing power, and modularity further influence satellite bus cost. Moreover, customization requests and environmental testing (like vibration, thermal vacuum, and EMI tests) may add premium charges. However, with mass production and standardization efforts, manufacturers are beginning to offer more affordable platforms without sacrificing quality or reliability.

Understanding satellite bus cost is not just about buying hardware—it’s about investing in reliability, longevity, and compatibility with payloads and launch environments.

Satellite Bus Design Principles That Influence Performance and Flexibility

At the heart of every mission-ready satellite platform is a solid satellite bus design—a multidimensional engineering process that balances payload support with power distribution, mechanical integrity, propulsion, data routing, and thermal stability. A great satellite bus design maximizes functionality while minimizing weight and complexity.

Modern satellite bus design prioritizes modularity, allowing different payloads to be easily swapped in without redesigning the entire bus. This modularity supports rapid prototyping and responsive mission schedules. The structure must also endure extreme temperature cycles and orbital debris impacts while maintaining precise orientation through attitude control systems.

Another critical factor in satellite bus design is power management. Depending on mission needs, buses may include deployable solar arrays, high-capacity batteries, and efficient energy routing systems. These components must be carefully integrated into the structure to optimize weight and energy flow.

Thermal control systems—including passive radiators and active heat pipes—are also central to the design, ensuring that instruments stay within operational temperature ranges. In addition, data and command routing systems must support redundancy, security, and high-speed communication between bus and payload.

Ultimately, every decision in satellite bus design affects mission success, satellite lifetime, and the ability to adapt to future space demands.

The Future of Satellite Platform Technology in the New Space Economy

As the space economy accelerates, satellite platform technologies are set to evolve in extraordinary ways. Emerging trends include AI-enhanced fault detection, plug-and-play payload interfaces, green propulsion systems, and inter-satellite networking. These innovations are driving more intelligent, autonomous buses that can react to in-orbit changes in real time.

Next-generation satellite bus manufacturers are also developing reusable buses that can be re-tasked or serviced in orbit, significantly lowering lifetime costs and reducing space debris. Smart materials that offer radiation resistance and thermal flexibility are becoming more common in future designs.

Moreover, the integration of quantum communications, edge computing, and blockchain-based telemetry verification could redefine how satellite platform systems process, secure, and distribute data. Combined with standardized launch adapters and universal electrical interfaces, future satellite bus design will aim to make space truly interoperable.

In a world of mega-constellations and daily satellite launches, efficient and innovative satellite platform solutions will be the foundation of global connectivity, disaster resilience, and planetary observation.

satellite platform FAQs

What is a satellite platform and why is it important?

A satellite platform—or satellite bus—is the core structural and functional unit of a satellite that houses all essential systems except the mission payload. It includes power, propulsion, attitude control, thermal systems, and communications. The platform enables the payload to function in space, making it fundamental to mission success.

Who are the leading satellite bus manufacturers today?

Top satellite bus manufacturers include companies like Airbus Defence and Space, Thales Alenia Space, Northrop Grumman, Lockheed Martin, and emerging players like Blue Canyon Technologies and NanoAvionics. These manufacturers offer a range of solutions from CubeSats to large GEO buses and focus on innovation, miniaturization, and mission versatility.

What influences the cost of a satellite bus?

The satellite bus cost depends on factors such as size, mission duration, payload requirements, orbit altitude, propulsion systems, thermal shielding, and onboard computing. Additional customization, redundancy systems, and environmental testing can increase the price significantly. Small satellite buses may cost under $1 million, while large geostationary buses can exceed $20 million.

What are the key features of an efficient satellite bus design?

A well-optimized satellite bus design includes a modular structure, reliable power distribution, advanced thermal management, compact propulsion, and fault-tolerant data systems. It must support precise payload alignment, maintain structural integrity under orbital stress, and enable long-term, autonomous operation in various space environments.

How are satellite platforms evolving with space technology?

Modern satellite platform systems are becoming smarter, lighter, and more autonomous. Innovations include AI-based telemetry, reusable structures, green propulsion, and plug-and-play payload support. Future satellite buses may even support in-orbit servicing, dynamic network participation, and distributed computing for real-time applications.