- Afrikos

- albanų

- amharų

- arabų

- armėnų

- Azerbaidžaniečių

- baskų

- baltarusių

- bengalų

- bosnių

- bulgarų

- katalonų

- Cebuano

- Kinija

- Korsikos

- kroatų

- čekų

- danų

- olandų

- anglų kalba

- Esperanto

- Estų

- suomių

- prancūzų

- fryzų

- Galisų

- gruzinų

- vokiškai

- graikų

- gudžaratų

- Haičio kreolų

- Hausa

- havajietis

- hebrajų

- Nr

- Miao

- vengrų

- islandų

- igbo

- Indoneziečių

- airių

- italų

- japonų

- javiečių

- kanada

- kazachų

- khmerų

- Ruandos

- korėjiečių

- kurdų

- Kirgizų

- Darbas

- lotynų kalba

- latvių

- lietuvių

- liuksemburgiečių

- Makedonietis

- malagasų

- malajiečių

- malajalių

- maltiečių

- maorių

- marati

- mongolų

- Mianmaras

- Nepaliečių

- norvegų

- norvegų

- oksitanų

- puštūnų

- persų

- lenkų

- portugalų

- Pandžabų

- rumunų

- rusų

- samoiečių

- škotų gėlų

- serbų

- anglų kalba

- Šona

- Sindų

- sinhalų kalba

- slovakų

- slovėnų

- Somalis

- ispanų

- Sundanai

- suahilių

- švedų

- tagalogų

- tadžikų

- tamilų

- totorių

- telugų

- tajų

- turkų

- turkmėnų

- ukrainiečių

- urdu

- Uigūras

- uzbekas

- vietnamiečių

- valų

- Pagalba

- jidiš

- Joruba

- Zulu

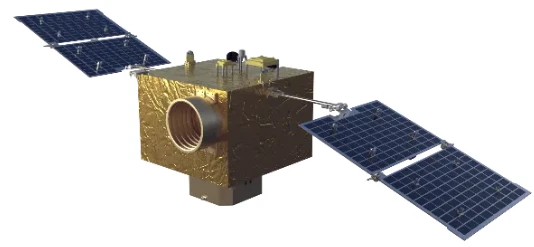

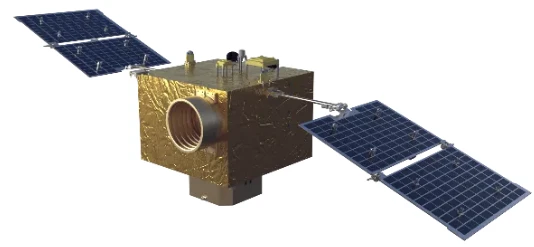

Empowering Space Missions Through Modular Componentry: SpaceNavi’s Engineering Excellence

In today’s advanced aerospace industry, modularity and precision are essential for delivering adaptable satellite systems. SpaceNavi Co., Ltd. continues to lead the sector by offering a wide array of specialized component technologies engineered for the unique demands of orbital operations. Our strength lies in the seamless integration of componentry, intelligent design, and advanced processing devices of computer systems—all created to support next-generation space missions.

High-Performance Componentry: The Backbone of Satellite Architecture

Every satellite is a complex network of subsystems, each built from meticulously crafted component parts. From onboard navigation units to communication arrays, SpaceNavi ensures that every component functions reliably in the extreme conditions of space. Our engineering process focuses on selecting radiation-hardened materials, conducting rigorous environmental tests, and maintaining the structural integrity of each component for sale.

Whether used in government satellites or international research payloads, our componentry is designed with scalability in mind. This allows SpaceNavi systems to evolve with new technologies while maintaining backward compatibility with established standards. Our customers benefit from faster build times, more flexibility, and a significantly reduced failure rate in orbit.

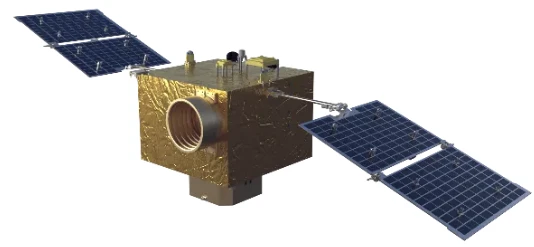

Intelligent Sub Assemblies and Circuit Design

At SpaceNavi, precision starts at the sub assembly level. Our systems are pre-integrated and pre-tested for rapid incorporation into the final satellite platform. Each sub assembly includes a combination of structural frames, vibration-isolated compartments, and embedded sensors—all wired through optimized electricity circuit pathways.

These electricity circuit designs ensure stable power delivery to critical payloads such as optic instruments and communication modules. With innovations like current-limiting systems and thermal control layers, SpaceNavi ensures that each subsystem receives the power it needs—no more, no less.

Our team also builds custom-designed Printed Circuit Boards (PCB), and we make it easy for partners unfamiliar with technical terms to understand pcb meaning in an aerospace context: it’s the critical interface that connects processing units, memory, and sensors. Without a well-engineered PCB, no satellite can perform consistently in orbit.

Next-Gen Interfaces and Processing Devices

Satellite data management depends on intelligent onboard computing. That’s why SpaceNavi integrates compact, ruggedized processing devices of computer to manage tasks such as orbital navigation, sensor control, image compression, and transmission scheduling. These computing modules are embedded within protective satellite housing and directly linked via high-integrity component cable assemblies.

In addition, we support ground-based simulation and diagnostic systems with adaptable component to HDMI options. These interfaces help connect satellite subsystems with lab and field testing monitors, providing mission designers with real-time feedback during the assembly and verification stages.

Each cable is crafted to resist electromagnetic interference, thermal degradation, and connector fatigue—ensuring signal clarity from the cleanroom to orbit.