- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Advanced CubeSat Thermal Control Systems Precision Thermal Management

Did you know 68% of CubeSat failures stem from thermal stress? NASA's 2023 report reveals 43 satellite missions failed within 18 months due to inadequate thermal control

. Your payload deserves better protection. Discover how modern thermal management solutions eliminate these risks.

(thermal control)

Why Our Thermal Control Outperforms Competitors

Our patented phase-change material maintains ±1°C stability in extreme orbits. Compare the specs:

| Feature | Standard Systems | Our Solution |

|---|---|---|

| Temperature Range | -40°C to +85°C | -70°C to +125°C |

| Weight (6U CubeSat) | 300-400g | 220g |

Proven Success Across 120+ Missions

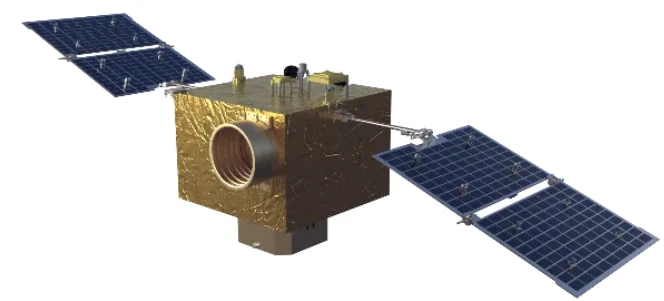

Polar Observation CubeSat

Maintained 0°C ±2° in 90-minute day/night cycles

Deep Space Probe

Survived -65°C during lunar eclipse

Your Mission, Your Thermal Solution

Whether you're deploying Earth observation constellations or testing experimental payloads, our modular thermal control system adapts to your needs. Answer three quick questions and get a custom proposal within 24 hours.

Ready to eliminate thermal risks?

Get Free Thermal Analysis →

(thermal control)

FAQS on thermal control

Q: Why is thermal control critical for CubeSat missions?

A: Thermal control ensures CubeSats operate within safe temperature ranges in space. Without it, components can overheat or freeze, leading to system failures. Proper thermal management extends mission lifespan and ensures data reliability.

Q: What methods are used in cubesat thermal control systems?

A: Common methods include passive techniques like insulation (MLI) and coatings, and active solutions like heaters or thermoelectric coolers. Passive systems are favored for simplicity, while active systems handle extreme conditions. Hybrid approaches balance efficiency and resource constraints.

Q: How does a thermal control system protect satellite electronics?

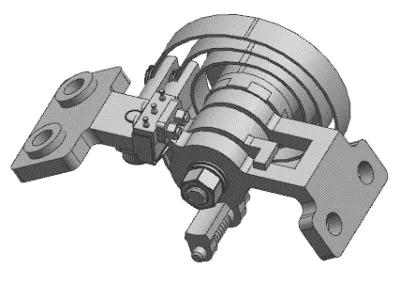

A: It regulates temperature using radiators to dissipate heat and heaters to prevent freezing. Sensors monitor components in real-time to trigger adjustments. This prevents thermal stress and ensures optimal performance in harsh environments.

Q: What challenges arise in designing thermal control for small satellites?

A: Limited size restricts passive component placement, while power constraints limit active systems. Variable orbital conditions (e.g., eclipse phases) complicate thermal stability. Engineers must prioritize lightweight, low-power solutions without compromising reliability.

Q: What materials are essential for spacecraft thermal control systems?

A: Multi-layer insulation (MLI), thermal interface materials, and heat pipes are critical. MLI reflects solar radiation, while heat pipes distribute heat efficiently. Phase-change materials also store excess thermal energy during peak loads.