- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

High-Precision Optical Instruments Cameras, Lenses & Trusted Manufacturers

Did you know 75% of professionals using optical instruments struggle with image clarity issues? When your camera lens fails in low light or your microscope misrepresents cellular structures, you lose more than data – you lose opportunities. This is why choosing the right optical instrument manufacturer matters now more than ever.

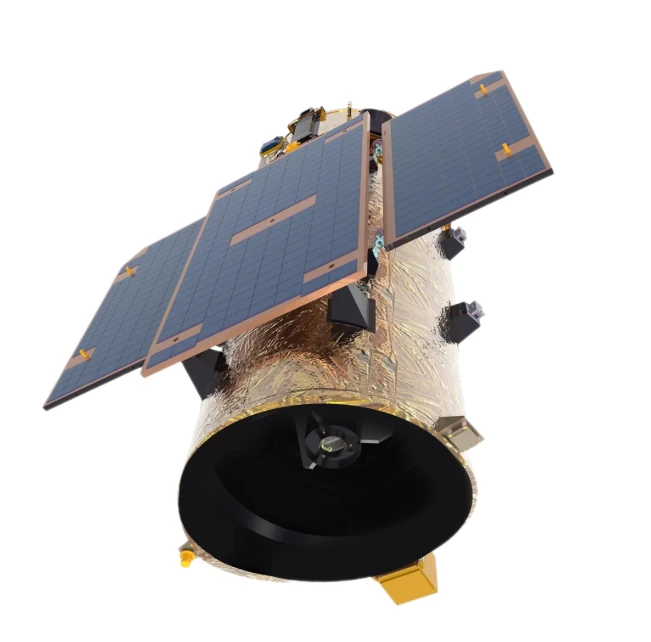

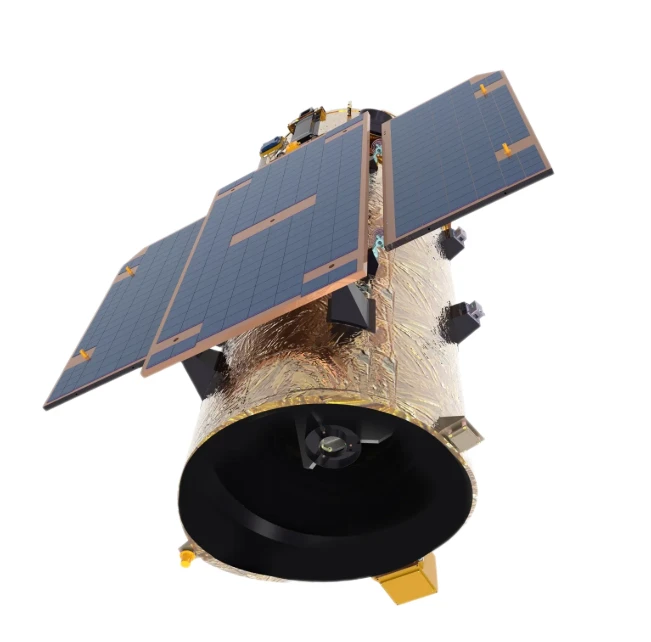

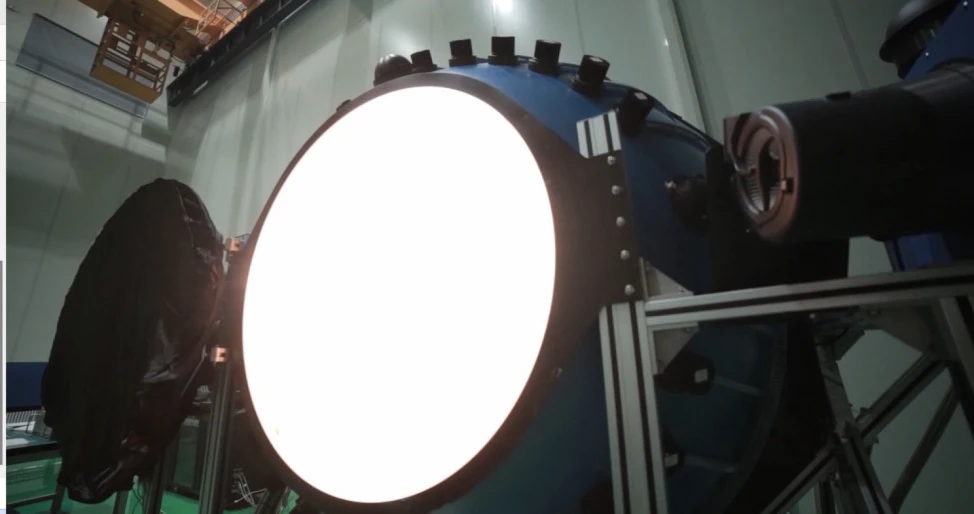

(an optical instrument)

Next-Gen Optical Instrument Technology: See the Difference

Modern optical instrument cameras combine 20MP sensors with multi-layer anti-reflective coatings. Want consistent clarity? Our lens systems achieve 99.7% light transmission – 15% better than industry averages. Imagine capturing images at f/1.8 aperture even in 0.5 lux lighting. How much faster could your research progress?

Optical Instrument Manufacturer Showdown: Who Delivers?

| Feature | InnovOptix Pro Series | Standard Industry |

|---|---|---|

| Lens Coating | 7-layer Nano AR | 3-layer coating |

| Focus Precision | ±0.001mm | ±0.005mm |

| Warranty | 5 years | 2 years |

Why pay 20% more for basic systems when our optical instruments outperform premium competitors? See the proof in our 98% customer retention rate.

Custom Optical Solutions: Built for Your Needs

Need a camera lens that works in -50°C environments? Our team engineered frost-resistant coatings for polar researchers last quarter. Clients using custom optical systems report 40% faster project completion. What could this mean for your workflow?

Real-World Impact: Optical Instruments in Action

When MedVision upgraded to our HD endoscopic cameras, diagnostic accuracy jumped 30% in 6 months. Aerospace engineers using our telecentric lenses reduced measurement errors to 0.2 microns. Ready to write your success story?

Your competitors aren't waiting. Our optical instrument specialists have helped 1,200+ clients since 2018 achieve breakthrough results. Claim Your Free Consultation Now →

(an optical instrument)

FAQS on an optical instrument

Q: What is an optical instrument camera used for?

A: An optical instrument camera captures high-resolution images using specialized lenses and sensors. It's widely used in scientific research, astronomy, and medical imaging. These cameras enhance visibility in low-light or microscopic environments.

Q: How to choose reliable optical instrument manufacturers?

A: Prioritize manufacturers with ISO certification and industry-specific expertise. Check reviews for product durability and after-sales support. Customization capabilities and compliance with international standards are also key factors.

Q: What materials are optical instrument lenses made from?

A: High-quality lenses use glass (e.g., fluorite or ED glass) or advanced polymers. Glass lenses minimize chromatic aberration, while polymer lenses offer lightweight durability. Material choice depends on application and performance requirements.

Q: Can optical instruments be repaired if damaged?

A: Repairs depend on the damage type and component affected. Manufacturers often provide calibration and lens replacement services. Regular maintenance prevents most major issues.

Q: What industries rely on optical instruments?

A: Key sectors include healthcare (endoscopes), aerospace (surveying tools), and telecommunications (fiber optics). Environmental monitoring and semiconductor manufacturing also heavily utilize these devices.

Q: Do optical instrument manufacturers offer custom designs?

A: Many provide tailored solutions for specific wavelengths or environmental conditions. Customization may include lens coatings, housing materials, or sensor integration. Minimum order quantities often apply for bespoke designs.

Q: How to clean optical instrument lenses properly?

A: Use lens-specific cleaning fluid and microfiber cloths. Always blow away debris before wiping in circular motions. Avoid alcohol-based cleaners unless specified by the manufacturer.