- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

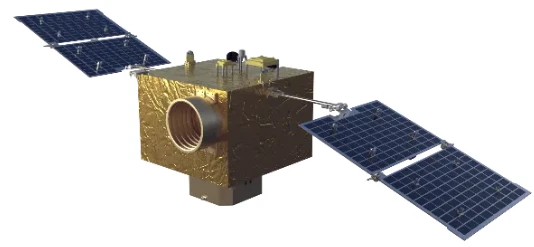

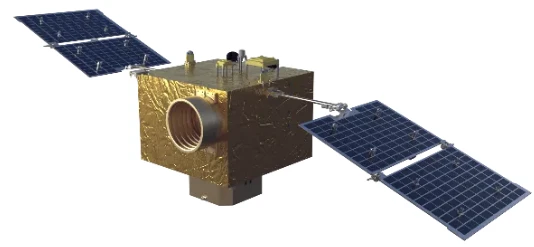

Best Thermal Control in Satellite Communication Satellite Thermal Control Handbook Advanced Thermal Control System Solutions

Imagine this: A modern satellite travels 17,500 miles per hour, beaming your data from space. But every second, it faces wild temperature swings—from -170°C in Earth's shadow to 150°C in direct sunlight. A single thermal misstep can melt circuits, freeze batteries, or even end the mission. Did you know? According to NASA, nearly 33% of critical satellite failures are due to thermal issues. As data demand explodes, so does the need for bulletproof thermal control in satellite communication

. Let's explore why this hidden tech is your best bet for mission success, robust signal, and global reach.

(thermal control in satellite communication)

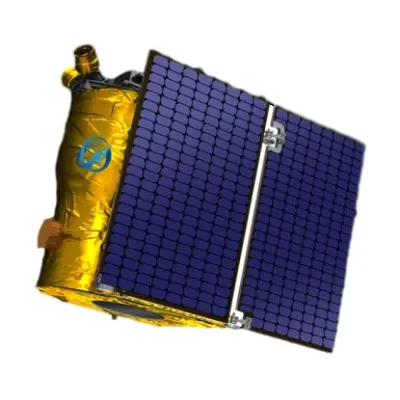

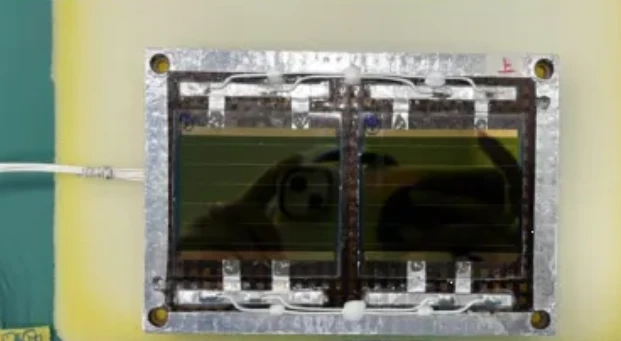

Technical Edge: How Advanced Thermal Control Transforms Satellite Communication

Modern space systems don’t just need power—they need unwavering stability. That’s where a thermal control system shines. It keeps all satellite parts—transmitters, processors, batteries—in the Goldilocks zone, no matter the space weather outside. There are two main types: passive (using radiators and insulation) and active (using heaters, pipes, and even pumped fluids).

Looking at high-end GEO, MEO, and LEO satellites, industry standards recommend operational temp variance under ±5°C for core chips. Achieving this means higher signal integrity, less downtime, and up to 22% longer equipment life.

| Specification | Passive Systems | Active Systems |

|---|---|---|

| Thermal Range | ±10°C | ±3°C |

| Typical Lifespan Impact | 8–10 years | 12–15 years |

| Mass/Size | Low | Medium |

| Failure Risk (per 5y) | 2.8% | <1.1% |

Vendor Insights: Comparing Leading Satellite Thermal Control Handbooks

Not all satellite thermal control handbook approaches are created equal. Top names like Honeywell, Airbus, and Thales boast advanced materials and precision sensors. Honeywell’s multilayer insulation? Highly reflective. Airbus? Their loop heat pipes lead in reliability. Thales? Rapid-response heaters.

| Vendor | Unique Tech | Market Share | Reliability Score |

|---|---|---|---|

| Honeywell | MLI + MiniHeater Array | 32% | 9.7/10 |

| Airbus | Advanced Heat Pipes | 27% | 9.6/10 |

| Thales | Rapid Sensors | 13% | 9.5/10 |

The best partners provide not just hardware—but a complete roadmap in their Satellites Thermal Control Handbook for full lifecycle protection.

Custom-Tailored Solutions: The Secret to Reliable Satellite Uptime

Your mission isn’t off-the-shelf. Why settle for a generic thermal control system? Today’s top engineers analyze your power profile, payload, and orbit. They use digital twins and simulation to find hotspots before launch. Then they design layer-by-layer solutions. Need battery heaters, deployable radiators, or phase-change panels? It’s all built to spec.

Most importantly—every system is tested to simulated orbital cycles. The payoff? More data. Less downtime. Fewer surprises.

- Custom systems reduce in-orbit temperature spikes by up to 68%.

- Integrated approaches delay component aging by over two years.

- Advanced analytics allow 24/7 thermal health monitoring anywhere in orbit.

Real-World Impact: Satellite Communication Enhanced by Smart Thermal Control

Take OneWeb’s LEO satellite fleet as a prime example. By integrating Honeywell’s next-gen thermal control, they saw a 21% drop in in-orbit anomalies. Inmarsat, using Airbus systems, now delivers global maritime IoT with an incredible >99.999% transmission uptime. And NASA’s ISS comms module? Its hybrid active/passive thermal assembly extends hardware life by five years.

Each success story starts with rigorous engineering, tested handbooks, and proven custom solutions—delivering unbeatable data rates and signal quality, day after day.

Elevate Your Satellite Success—Act Now!

At ThermaConX Solutions, we deliver mission-critical thermal control in satellite communication. Drawing on decades of industry leadership and insights from the world’s most trusted satellite thermal control handbooks, our engineered solutions unlock unrivaled uptime and peak performance.

Ready for flawless satellite communications? Contact ThermaConX Now—let’s power the next leap in connectivity, together!

(thermal control in satellite communication)