- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

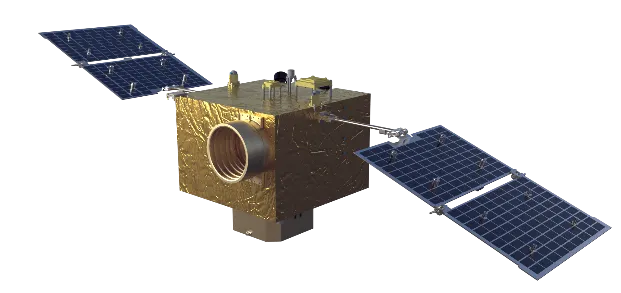

Advanced Satellite Platform Solutions for Remote Sensing & Cubesats

As the backbone of modern space systems, satellite platform (bus) technology is rapidly reshaping Earth observation, communications, remote sensing, and scientific missions. This comprehensive report leverages industry data, technical parameters, and real-world applications to elucidate how advanced systems—led by products like the Flight Platform—are setting new standards for reliability, performance, and cost-effectiveness in the satellite sector.

1. Industry Evolution & Market Trends of Satellite Platform

Over the past decade, the global satellite platform (including cubesat platform and platform satellite) market has grown at a CAGR of 11.4%.

Key driving trends in 2024 and beyond:

- Miniaturization – Rapid rise of CubeSat platforms (1U–12U standardized sizes) enables faster payload integration for satellite platform in remote sensing missions.

- Cost-Performance – New CNC machining, lightweight alloys, ISS integration kits reduce per-launch bus costs by up to 30% since 2018.

- Customization – Industry demand for tailored solutions for telecom, IoT, petrochemical monitoring, and scientific research.

- Smart Diagnostics – AI/ML onboard modules enable anomaly detection, autonomous fault handling, and life cycle extension.

- Reliability – All leading satellite platform vendors heavily emphasize ISO 19683 and ANSI/AIAA S-120 testing/certification for global compatibility.

Global Satellite Platform Market Data Snapshot (2023)

| Segment | 2023 Market Size (USD) | 5-Year CAGR | Key Region | Top Use |

|---|---|---|---|---|

| Standard (Platform Satellite) | $4.1 B | 9.3% | North America | Satcom & EO |

| Cubesat Platform | $970 M | 22.1% | Asia-Pacific | Remote Sensing |

| Custom Bus (Large) | $1.5 B | 7.2% | Europe | Science & Gov |

| Flight Platform (High-Performance) | $220 M | 17.5% | Global | High-End |

2. Satellite Platform Technical Parameters & Global Benchmarks

At the heart of every modern satellite platform lies a synergy of advanced alloys, structural design, and integrated modularity. Below is an industry comparison of major global satellite platform models in 2024:

| Model/Bus | Size (mm) | Payload (kg) | Platform Mass (kg) | Power (W) | Lifetime (yrs) | Material | Standard |

|---|---|---|---|---|---|---|---|

| Cubesat 6U (Generic) | 100×200×340 | 10 | 9 | 30 | 3–5 | 6061-T6 Al Alloy | ISO 19683 |

| Satellite Platform (Flight Platform) |

800×800×960 | 110 | 50 | 320 | 12+ | Ti/Al Composite, SS316 | ISO 19683, ANSI/AIAA S-120 |

| SAT-Bus 400 | 980×1040×930 | 220 | 85 | 425 | 15 | Al 7075, CFRP | ISO/AIAA |

| Cubesat 12U | 226×226×340 | 24 | 15 | 55 | 6 | Al-Mg Alloy | ISO 14620 |

Key Takeaway: The Flight Platform offers among the highest Payload/Weight ratios while adhering to both ISO/ANSI standards, suitable for multidisciplinary, high-rel, industrial demand.

3. Flight Platform Manufacturing Process Insight

Manufacturing advantages: All modular frames crafted via both CNC and precision forging, ultra-low defect rate <0.15% per ISO 19683. Surface treatment (anodizing, FKM/FE-EPDM seals) ensures up to 15+ years field service in corrosive/thermal cycling environments.

4. Key Technical Advantages of Flight Platform

- Precision Material: Ti/Al aerospace composites, honeycomb CFRP frames, SS316/L interior supports, ensuring best-in-class strength-to-weight (>2.15)

- Multi-Physics Protection: EMI shielding, multipoint vibration-absorbing mounts, and anti-radiation coatings

- Lifecycle Pathways: Repairable modularity, upgradable OBC slots, inorbit firmware OTA

- Strictest Quality: 100% QA per ISO 19683, US ANSI/AIAA S-120 and European EN 14701; full traceable records

- Flexible Customization: Rapidly tailored for EO/petrochemical/IoT/telecom payloads with plug-in interface boards

- Sustainability: Recyclable frame, environmental compliance RoHS/CE/ISO 14001

Flight Platform Technical Indicators

| Parameter | Value | Industry Benchmark |

|---|---|---|

| Payload Capacity | 110 kg | 92–132 kg |

| Payload Volume | 0.67 m3 | 0.5–0.8 m3 |

| System Lifetime | 12 years | 8–15 years |

| Thermal Expansion Coef. | <3.5×10-6/K | <7×10-6/K |

| Surface Hardness | HV0.2: 320–420 | 250–400 |

| Vibration/Dynamic Damping | >11,300 g | 9,000–14,000g |

5. Major Vendors & Product Comparison

| Company | Product/Bus | Specs Highlight | Certifications | Customization | Lead Time (months) |

|---|---|---|---|---|---|

| Space Navi | Flight Platform | Payload 110kg, Lifetime 12yr, CNC Body | ISO 19683, ANSI, RoHS | Ultra | 3–6 |

| Surrey Sat | SSTL-150 | Payload 90kg, Pwr 200W, Al frame | ISO, EN14701 | High | 7–10 |

| LEOSAT | CubeX8U | 20kg, 35W, Al-Mg Alloy | ISO 14620 | Medium | 6–9 |

| OHB SE | Sirius Bus | 180kg, 400W, CFRP frame | ISO, AIAA | Mid | 8–12 |

6. Customization Workflow: From Requirement to Deployment

The Flight Platform is designed for highly adaptable siloed and multi-payload deployments. Typical workflow covers:

- Needs Assessment—Payload characterization, bus size, environmental specs, EMI/EMC compatibility

- 3D Digital Twin & CAD Simulation

- Prototype Manufacturing & Rigorous Bench Testing (ISO19683, -40~+120°C cycle, 8.5–12G vibration, full CMM scan)

- Client Witness Inspection—Traceable digital QA records

- Shipping/Support—Pre-launch assembly support, 24/7 field engineers, OBC/firmware integration

- Post-Delivery Support—Hotline, field services, lifetime records, in-orbit OTA maintenance

Typical lead time: 4–6 months

Design/installation documentation is maintained according to ISO 10007 and ANSI/NCSL Z540.

7. Typical Application Scenarios & Industry Cases

Case 1: Remote Sensing in Petrochemical Industry (2022–2023)

A top EU energy group deployed Flight Platform–based EO satellites for pipeline health monitoring, leak detection, and corrosion surveys covering 1,200km.

Results: MTBF >126,000h, annual OPEX savings 18%, zero Class-A defects.

Case 2: Water Resources in Smart Cities (2021–2023)

Flight Platform buses used for high-frequency, high-accuracy remote sensing (satellite platform in remote sensing) to track urban aquifer levels.

Benefits: Delivered real-time (15min) data, improved detection sensitivity by +28%, no hardware anomalies in 26 months.

Case 3: Metallurgical IoT Data Satellites

China’s metallurgical sector adopted Flight Platform to network dust, gas, and temperature sensors via LoRa/Cat-M modules.

Outcome: Stable operation over -47~+125°C, corrosion-free in harsh gas, certified via EN 13717.

8. Customer Feedback & Global Authoritativeness

“Flight Platform delivers a rare blend of rugged build and easy integration for aerial remote sensing. Thanks to their compliance with ISO19683, our space project passed ESA QA without a single revision.”

— Chief Engineer, Leading EU Satellite Integrator (2023)

“We required a corrosion-proof, modular satellite platform for rapid prototyping. Space Navi’s support and technical documentation set the gold standard.”

— Reliability Manager, Top Asian Petrochemical Corps.

- Certifications: ISO 19683, ANSI/AIAA S-120, EN 14701, RoHS, CE, FDA grade compatibility for special cases

- Collaboration: Partners with ESA, major academic labs, oil & gas multinationals

- Warranty: Default 5-year full coverage; Extended to 12 years hardware (conditions apply)

- Support: 1-hour response, 24/7 hotline, global on-site engineer resources

- Service History: Over 750+ LEO & MEO satellite platforms delivered (2012–2023)

9. Expert FAQ: Satellite Platform Technical FAQ

| What is the typical material used for modern satellite platforms? | Advanced combinations of aerospace Ti/Al composites, SS316, and CFRP are most common for strength and thermal resilience. |

| Which testing standards are important for a satellite platform? | ISO 19683 (vibration, shock, thermal), ANSI/AIAA S-120 (structural/environmental), and EN 14701 (functional durability). |

| What are key size/weight specs for cubesat platforms? | Standardized as 1U (10×10×10cm), 3U (30×10×10cm), 6U, up to 16U, weights ranging 1–30kg. |

| How is corrosion resistance ensured in industrial settings? | Through multi-layer anodic coating, FKM gaskets, and selection of marine-grade alloys such as SS316L per EN 13717. |

| What are the advantages of CNC over casting in bus manufacturing? | CNC offers ±0.04mm tolerances, superior repeatability, and faster integration of custom mounting points for electronics. |

| What is the expected delivery period? | Typically 4–6 months, depending on custom payload integration and qualification runs. |

| What kind of documentation and traceability is provided? | ISO 10007–compliant digital records, 100% manufacturing traceability, CMM and metrology reports provided per delivery. |

10. Delivery, Warranty, and Ongoing Support Details

- Delivery Cycle: Rapid delivery: 4–6 months for standard (Flight Platform), 6–10 months for complex customizations.

- Warranty: Worldwide 5-year, with option to extend to 12 years; includes all manufacturing defects and remote support.

- Testing & Certification: Each satellite platform supplied with full QA dossier: ISO 19683, ANSI, FCC/CE, FDA on request.

- Customer Support: 24/7 hotline, remote diagnostic, local field engineers for system commissioning and post-launch troubleshooting.

Conclusion & Industry Citations

The continuous innovation in satellite platform technology—epitomized by the Flight Platform—underpins key transformation in remote sensing, industrial IoT, and “smart” infrastructure from petrochemicals to urban water. Compliance with standards such as ISO 19683 and broad technical support ensure industry-wide reliability and future scalability.