- אַפְרִיקַנִי

- אלבני

- אמהרית

- עֲרָבִית

- אַרְמֶנִי

- אזרבייג'נית

- באסקית

- בלארוסית

- בנגלית

- בוסנית

- בולגרית

- קטלאנית

- סבואנו

- סִין

- קורסיקאי

- קרואטית

- צ'כית

- דַנִי

- הוֹלַנדִי

- אַנגְלִית

- אֶסְפֵּרַנְטוֹ

- אסטונית

- פִינִית

- צָרְפָתִית

- פריזית

- גליציאנית

- גרוזינית

- גֶרמָנִיָת

- יוונית

- גוג'ראטי

- קריאולי האיטי

- האוסה

- הוואי

- עִברִית

- לֹא

- מיאו

- הוּנגָרִי

- איסלנדית

- איבו

- אינדונזית

- אִירִית

- אִיטַלְקִית

- יַפָּנִית

- ג'אוואנית

- קנאדה

- קזחית

- חמר

- רואנדה

- קוריאנית

- כּוּרדִי

- קירגיזית

- עֲבוֹדָה

- לָטִינִית

- לטבית

- ליטאית

- לוקסמבורג

- מקדונית

- מלגזית

- מלאית

- מלאיאלאם

- מלטזית

- מאורי

- מראטי

- מוֹנגוֹלִי

- מיאנמר

- נפאלית

- נורבגית

- נורבגית

- אוקסיטנית

- פשטו

- פַּרסִית

- פּוֹלָנִית

- פורטוגזית

- פנג'בי

- רומנית

- רוּסִי

- סמואנית

- גאלית סקוטית

- סרבית

- אַנגְלִית

- שונה

- סינדהי

- סינהאלה

- סלובקית

- סלובנית

- סומלי

- סְפָרַדִית

- סונדני

- סוואהילית

- שוודית

- טאגלוג

- טג'יקית

- טמילית

- טטרית

- טלוגו

- תאילנדית

- טוּרקִית

- טורקמנית

- אוקראינית

- אורדו

- אויגורי

- אוזבקית

- וייטנאמית

- וולשית

- עֶזרָה

- אִידִישׁ

- יורובה

- זולו

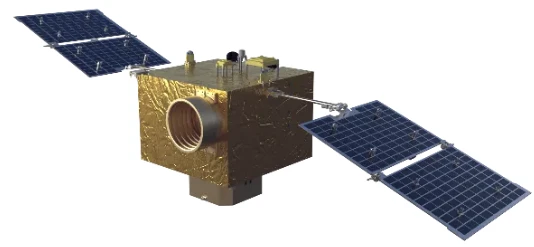

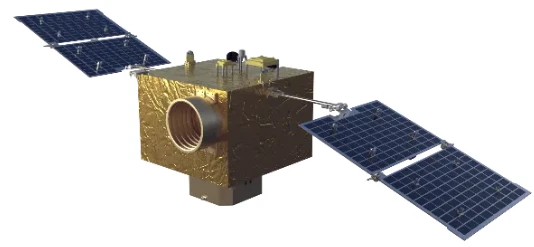

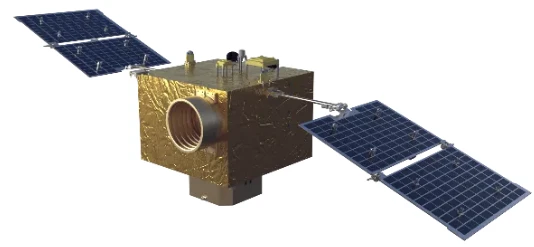

Optical Instrument Innovation Powering Satellite Excellence at SpaceNavi

In the rapidly evolving aerospace industry, precision and clarity are no longer luxuries—they are requirements. At SpaceNavi Co., Ltd., we understand that every pixel of data matters. That’s why we incorporate cutting-edge optical instrument solutions into our satellite systems, ensuring that our clients receive accurate, high-resolution information from space. From Earth observation missions to component-level analysis, SpaceNavi is redefining what optical precision means for the satellite sector.

Elevating Accuracy with Optical Profilometer and 3D Optical Profilometer

Precision surface analysis plays a vital role in ensuring the reliability and durability of satellite components. Our engineering teams employ the optical profilometer to evaluate microstructures on critical parts like mirrors, lenses, and sensor covers. This non-contact measuring system guarantees that surfaces meet the stringent criteria required for aerospace missions.

Moreover, the 3D optical profilometer offers even deeper insights. It enables three-dimensional mapping of component surfaces, capturing complex geometries that standard measurement tools cannot detect. With these tools integrated into our satellite development process, SpaceNavi ensures unmatched quality in every payload and platform we produce.

These advanced instruments are not only used during manufacturing but also as part of routine testing and validation. Through such high-level metrology, SpaceNavi significantly shortens development cycles while maintaining uncompromised performance standards.

Enhancing Spectral Performance with Optical Emission and Optical Spectrometer Systems

Spectral analysis is essential to both satellite design and function. SpaceNavi employs the optical emission spectrometer for material identification and verification during production. By analyzing the light emitted from various materials, we ensure that only the highest-grade metals and composites are used in the satellite's critical structures.

In orbit, our satellites may be equipped with an optical spectrometer for mission-specific applications such as atmospheric analysis, mineral detection, or agricultural monitoring. These spectrometers gather valuable spectral data across wide frequency bands, providing users with crucial environmental insights.

By embedding this kind of high-end optical instrument into our satellite systems, we deliver both physical quality control and functional excellence, helping government and international clients achieve mission success faster and more cost-effectively.

Advanced Particle Measurement: Optical Particle Counter and Optical Particle Sizer

The cleanroom environments where satellite components are assembled are strictly controlled, and particle contamination is a critical concern. SpaceNavi uses the optical particle counter to monitor and manage cleanliness throughout the satellite production process. These instruments detect and count airborne particles to prevent contamination of sensitive optical and electronic components.

Complementing this is the optical particle sizer, which not only counts but also measures the size of particles in real time. By using both instruments together, SpaceNavi ensures a contamination-free production workflow, which is especially crucial for optical payloads and sensors.

In addition, our satellites can be equipped with optical surface profilometer systems for in-situ diagnostics during assembly or even post-launch validation. This capability allows engineers to verify surface integrity on orbit, providing ongoing reliability assurance.