Warning: Undefined array key "array_term_id" in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Warning: Trying to access array offset on value of type null in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1371/header-lBanner.php on line 78

Superior Dual-All-Wing VTOL UAV: High Performance & Wind Resistance

The aerospace and industrial sectors are witnessing a transformative shift with the advent of advanced unmanned aerial vehicles (UAVs). Among these, the dual-all-wing VTOL UAV represents a pinnacle of innovation, blending the efficiency of fixed-wing flight with the operational versatility of vertical take-off and landing (VTOL). This configuration mitigates the need for runways, making it ideal for deployments in challenging or remote environments, while offering superior endurance and speed compared to traditional multi-rotor systems. Our focus here is to delve into the intricate details of this cutting-edge technology, addressing its industrial impact, technical prowess, and practical applications for B2B stakeholders.

Industry Trends and Market Dynamics for Advanced VTOL UAVs

The global UAV market is experiencing robust growth, propelled by increasing demand across defense, surveillance, logistics, and industrial inspection. Projections indicate the market will reach over $50 billion by 2028, with VTOL capabilities being a significant growth driver due to their operational flexibility. The integration of advanced aerodynamics, propulsion systems, and artificial intelligence is pushing the boundaries of what UAVs can achieve. Specifically, dual-all-wing VTOL UAV systems are gaining traction for their ability to deliver sustained, high-speed flight combined with precision vertical maneuverability. This hybrid design offers a compelling value proposition for missions requiring extended reach and quick deployment in constricted spaces. Key trends include:

- Enhanced Autonomy: Increased reliance on AI for flight path optimization, anomaly detection, and autonomous decision-making.

- Payload Versatility: Development of modular payloads for multi-mission capabilities, ranging from high-resolution optical and thermal sensors to LIDAR and advanced communication relays.

- Regulatory Harmonization: Growing efforts to standardize regulations for UAV operations, fostering broader commercial adoption.

- Sustainable Propulsion: Research into electric and hybrid-electric propulsion systems to reduce operational costs and environmental impact.

Moreover, the focus on increasing the wind resistance level of these platforms is paramount, especially for operations in unpredictable weather conditions common in offshore, mountainous, or desert environments. Innovations in structural design and flight control algorithms are continuously improving operational envelopes.

Manufacturing Process Flow of a Dual-All-Wing VTOL UAV

The production of a sophisticated aerial platform like the dual-all-wing VTOL UAV involves a multi-stage, precision-engineered process, adhering to stringent quality control standards.

1. Design and Engineering

- Conceptualization & Aerodynamics: Advanced CFD (Computational Fluid Dynamics) simulations are used to optimize the all-wing design for lift, drag, and stability across VTOL and forward flight regimes.

- Structural Design: CAD (Computer-Aided Design) models define the airframe’s geometry, integrating load-bearing structures for high stress points. Materials chosen are typically advanced composites like carbon fiber reinforced polymer (CFRP) for its exceptional strength-to-weight ratio and corrosion resistance, and aerospace-grade aluminum alloys for critical components requiring specific thermal or electrical properties.

- Avionics & Systems Integration: Design of flight control systems, navigation modules (GPS/IMU), communication links, and payload integration points.

2. Material Sourcing and Preparation

- Composite Material Layup: Pre-impregnated (pre-preg) carbon fiber sheets are precision-cut and laid up in molds according to ply orientation specifications to achieve desired strength and stiffness.

- Metal Component Preparation: High-strength alloys undergo processes like CNC machining for intricate parts, or casting/forging for high-load structural elements, ensuring precise tolerances.

3. Fabrication and Assembly

- Curing and Post-Processing: Composite structures are cured in autoclaves under precise temperature and pressure profiles to achieve optimal material properties. Post-curing includes trimming, drilling, and surface finishing.

- Component Integration: Engines/motors, actuators, wiring harnesses, and avionics are meticulously installed. Robotics are often employed for accuracy in repetitive tasks.

- Surface Treatment: Application of specialized coatings for corrosion resistance, UV protection, and stealth characteristics where required, significantly extending the service life to typically 5-10 years under proper maintenance.

4. Testing and Quality Assurance

- Component-Level Testing: Individual sensors, motors, and flight controllers undergo rigorous calibration and functional checks.

- System Integration Testing: Comprehensive testing of all integrated systems, including power distribution, communication links, and emergency protocols.

- Flight Testing: Controlled indoor and outdoor flight tests to validate performance parameters such as lift capacity, endurance, flight stability, and autonomous navigation accuracy.

- Compliance: Adherence to international testing standards such as ISO 9001 for quality management, AS9100 for aerospace quality systems, and ANSI standards for specific componentry, ensuring reliability and safety.

Target Industries and Advantages:

These UAVs are indispensable across target industries like petrochemicals, metallurgy, and water supply & drainage. Advantages include energy saving through optimized flight profiles and superior corrosion resistance due to advanced material selection, crucial for operations in harsh industrial environments.

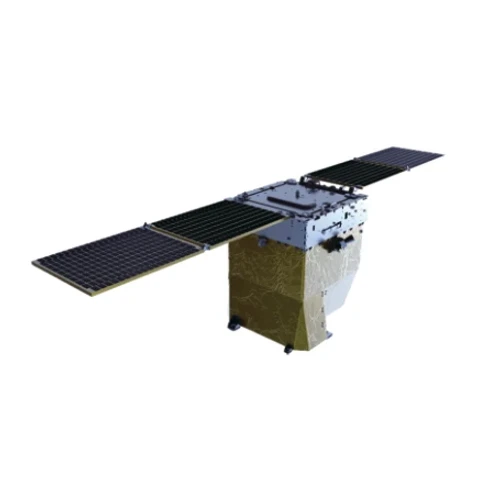

Technical Specifications: Changguang TW Series UAV

The Changguang TW Series UAV exemplifies the advancements in VTOL UAV technology, offering a robust platform designed for demanding industrial and defense applications. Below are the core specifications:

| Parameter | Specification (Changguang TW Series) | Technical Explanation |

|---|---|---|

| Wingspan | 4.5 meters | Crucial for aerodynamic efficiency and lift generation during fixed-wing flight, contributing to longer endurance. |

| Max Take-off Weight (MTOW) | 25 kg | Indicates total weight including fuel/battery, airframe, and payload. Direct impact on payload capacity. |

| Payload Capacity | 5 kg | Weight of sensors, cameras, or other mission-specific equipment it can carry. |

| Endurance (Fixed-wing) | Up to 6 hours | Maximum flight time, critical for extensive surveillance or long-range inspection missions. |

| Cruising Speed | 70-90 km/h | Efficient speed for covering large areas while optimizing power consumption. |

| Max Speed | 120 km/h | Peak velocity for rapid transit or responding to dynamic mission requirements. |

| Service Ceiling | 4,500 meters | Maximum operational altitude, enabling operations above typical airspace restrictions and complex terrain. |

| Wind Resistance Level | Level 6 (Beaufort Scale) | Ability to maintain stable flight in strong winds (approx. 39-49 km/h or 25-31 mph), crucial for reliability in adverse weather. |

| Propulsion | Electric (Multi-rotor for VTOL, Pusher for Fixed-wing) | Hybrid electric system for efficient VTOL transition and energy-optimized forward flight. |

| Navigation System | High-precision GNSS (GPS, GLONASS, BeiDou) + RTK/PPK optional | Ensures accurate positioning for mapping, survey, and autonomous flight. RTK/PPK offers centimeter-level accuracy. |

These specifications demonstrate a high-performance UAV engineered for reliability and precision in demanding operational environments, particularly where challenging terrain or infrastructure limitations make traditional take-off and landing unfeasible.

Application Scenarios and Industry Impact

The unique operational profile of the dual-all-wing VTOL UAV opens up a multitude of application possibilities across various industries. Its ability to combine the operational flexibility of multi-rotor drones with the speed and range of fixed-wing aircraft provides unparalleled utility.

1. Industrial Inspection and Asset Monitoring

- Oil & Gas: Pipeline and refinery inspection, flare stack monitoring, and leak detection. The VTOL capability allows close-up inspection of vertical structures, while fixed-wing mode covers vast pipeline networks.

- Power Utilities: High-voltage power line inspection, wind turbine blade analysis, and solar farm monitoring. Reduces human risk and significantly speeds up inspection cycles.

- Telecommunications: Inspection of cell towers and communication infrastructure, assessing structural integrity and antenna performance.

2. Surveying and Mapping

- Topographic Mapping: High-resolution aerial imagery for creating accurate 2D and 3D maps and digital elevation models (DEMs).

- Agriculture: Precision agriculture applications including crop health monitoring, irrigation analysis, and yield prediction.

- Construction & Mining: Site progression monitoring, volume calculations for earthworks, and infrastructure planning in remote areas.

3. Environmental Monitoring and Conservation

- Wildlife Monitoring: Tracking animal populations, anti-poaching efforts, and habitat assessment in expansive national parks.

- Pollution Detection: Air and water quality monitoring, including tracking pollutant plumes over large areas.

4. Public Safety and Emergency Response

- Search and Rescue: Covering vast areas quickly to locate missing persons, especially in difficult terrain.

- Disaster Assessment: Rapid assessment of damage after natural disasters (e.g., floods, earthquakes, wildfires) to guide response efforts.

- Border Patrol and Security: Long-range surveillance of borders and critical infrastructure.

In these scenarios, the extended range and higher wind resistance level of the dual-all-wing design prove invaluable, allowing for operations where conventional multi-rotor drones would be limited by battery life or adverse weather conditions.

Technical Advantages of Dual-All-Wing VTOL UAVs

The architectural design of the dual-all-wing VTOL UAV confers several distinct technical advantages over traditional fixed-wing or multi-rotor platforms, making it a superior choice for complex missions.

- Operational Flexibility: Combines the best of both worlds – vertical take-off and landing without the need for launch/recovery equipment, and efficient forward flight for extended range and endurance. This is crucial for deployments in challenging terrains or confined spaces.

- Enhanced Aerodynamic Efficiency: The all-wing (or blended wing body) design minimizes drag and maximizes lift, leading to superior aerodynamic performance during cruise. This translates directly to longer flight times and reduced energy consumption compared to multi-rotor systems, offering significant energy saving potential.

- Increased Endurance and Range: Fixed-wing flight is inherently more energy-efficient than hovering. By leveraging this, dual-all-wing VTOL UAVs can cover significantly larger areas and stay airborne for much longer, up to 6 hours or more, compared to the typical 20-60 minutes of multi-rotors.

- Superior Wind Resistance: The robust airframe and advanced flight control systems are engineered to withstand higher wind speeds. With a typical wind resistance level of Level 6 on the Beaufort scale, these UAVs ensure stable data collection and reliable operation even in challenging meteorological conditions.

- Payload Integration: The stable fixed-wing flight platform allows for the integration of heavier and more sophisticated payloads (e.g., high-resolution LiDAR, hyperspectral cameras, complex communication relays) without compromising flight performance significantly.

- Reduced Noise Footprint: While VTOL maneuvers can generate noise, the transition to fixed-wing cruise generally results in a lower acoustic signature than continuous multi-rotor operation, which can be advantageous for discrete surveillance or wildlife monitoring.

- Robust Construction and Corrosion Resistance: Built with advanced composite materials (e.g., carbon fiber), these UAVs offer exceptional structural integrity and inherent resistance to corrosion, essential for longevity in harsh industrial or maritime environments. This contributes to lower maintenance costs and longer service life.

Vendor Comparison: Leading Dual-All-Wing VTOL UAVs

While the Changguang TW Series excels in its class, understanding the broader market landscape is crucial. Here's a comparison with other notable dual-all-wing VTOL UAV vendors, highlighting key differentiating factors.

| Feature/Vendor | Changguang TW Series | Competitor A (e.g., WingtraOne) | Competitor B (e.g., Trinity F90+) |

|---|---|---|---|

| Wingspan | 4.5 m | 1.25 m | 2.3 m |

| Max Take-off Weight (MTOW) | 25 kg | 3.7 kg | 5.0 kg |

| Payload Capacity | 5 kg | 0.7 kg | 0.9 kg |

| Endurance (max) | 6 hours | 1.5 hours | 1.5 hours |

| Max Wind Resistance | Level 6 (39-49 km/h) | 12 m/s (43 km/h) | 12 m/s (43 km/h) |

| Primary Application Focus | Heavy Industrial Inspection, Long-range Surveillance, Defense | Mapping, Surveying, Geospatial | Mapping, Surveying, Geospatial |

| Propulsion Type | Electric (Multi-rotor VTOL, Pusher Fixed-wing) | Electric (Tilting Rotor VTOL, Pusher Fixed-wing) | Electric (Tilting Rotor VTOL, Pusher Fixed-wing) |

This comparison highlights the Changguang TW Series' advantage in terms of sheer scale, payload capacity, and endurance, positioning it uniquely for heavy-duty industrial and surveillance missions that demand longer operational times and the ability to carry more specialized equipment. While competitors excel in portability for specific mapping tasks, the TW Series targets a higher echelon of mission complexity.

Customized Solutions and Integration

Recognizing that every B2B client has unique operational requirements, we offer extensive customization options for the dual-all-wing VTOL UAV platforms, ensuring perfect alignment with specific mission profiles. Our approach emphasizes modularity and adaptability.

- Payload Customization: Integration of specialized sensors (e.g., methane sniffers for O&G, radiation detectors for nuclear, advanced LiDAR for forestry) and communication modules. We work with clients to select, integrate, and test third-party payloads.

- Flight Software and Autonomy: Tailoring flight control algorithms for specific operational environments (e.g., high altitude, extreme temperatures) or complex flight patterns. Custom development of ground control station (GCS) software interfaces.

- Data Management and Analytics: Developing integrated solutions for real-time data streaming, on-board processing, and post-mission analysis, often incorporating AI/ML for automated anomaly detection.

- Material & Finish Options: Specialized coatings for extreme environmental resistance (e.g., highly corrosive atmospheres in chemical plants, abrasive sand environments) or for stealth/low-observability requirements.

- Training and Support: Comprehensive training programs for piloting, maintenance, and data interpretation, coupled with dedicated technical support teams.

Our engineering team collaborates closely with clients from conceptualization to deployment, ensuring that each customized UAV solution delivers maximum operational efficiency and return on investment.

Application Case Studies

Case Study 1: Large-Scale Pipeline Monitoring in Challenging Terrain

A major energy company required a solution for routine inspection of a 500km oil pipeline traversing mountainous and desert regions. Traditional ground-based inspection was slow and costly, while multi-rotor drones lacked the necessary range and wind resistance level.

Solution: Two Changguang TW Series dual-all-wing VTOL UAVs, equipped with high-resolution optical and thermal cameras, were deployed. Their VTOL capability allowed launch and recovery from small, unprepared sites near the pipeline, eliminating the need for extensive infrastructure.

Results: The UAVs covered the entire pipeline segment in 15 flight days, a 70% reduction in time compared to previous methods. Early detection of a minor leak and several vegetation encroachments prevented potential environmental and financial losses. The customer reported significant cost savings and improved safety by reducing human exposure to hazardous environments. "The TW Series dramatically changed our operational efficiency and safety protocols," stated the Operations Manager.

Case Study 2: Offshore Wind Farm Blade Inspection

An offshore wind farm operator faced challenges in inspecting turbine blades due to harsh maritime conditions, including strong winds and salt spray, which rapidly degrade conventional equipment.

Solution: A customized Changguang TW Series UAV, with enhanced corrosion resistance treatments and an integrated high-resolution camera array (including thermal imaging), was deployed from a support vessel. Its high wind resistance level ensured stable flight even in turbulent offshore conditions.

Results: The UAV successfully performed detailed inspections of 50 wind turbine blades in three days, identifying micro-cracks and erosion that were previously undetectable without costly and dangerous rope access. The UAV solution minimized downtime for turbines and significantly improved worker safety. This project showcased the platform's reliability and its ability to gather precise data in an extremely demanding environment.

Trustworthiness and Support: FAQ, Lead Time, Warranty, and After-Sales

Frequently Asked Questions (FAQ)

What is the primary advantage of a dual-all-wing VTOL UAV over traditional drones?

The primary advantage lies in its hybrid design, combining the vertical take-off and landing capabilities of multi-rotors with the long-range, high-speed, and energy-efficient flight of fixed-wing aircraft. This eliminates the need for runways while offering superior endurance and coverage.

What kind of payloads can the Changguang TW Series carry?

The TW Series supports a diverse range of payloads up to 5 kg, including high-resolution optical cameras, thermal imaging sensors, LiDAR systems, multispectral sensors, communication relays, and specialized detectors (e.g., gas leak sensors). Custom payload integration is also available.

What is its wind resistance level?

The Changguang TW Series has a robust wind resistance level of up to Level 6 on the Beaufort Scale, enabling stable operation in winds ranging from 39-49 km/h (25-31 mph). This makes it suitable for operations in challenging weather conditions.

How long is the typical service life of the UAV?

With proper maintenance and adherence to operational guidelines, the Changguang TW Series UAV is designed for a service life of 5-10 years, owing to its advanced composite materials and rigorous manufacturing standards.

Lead Time and Fulfillment

Standard configurations of the Changguang TW Series UAV typically have a lead time of 8-12 weeks from order confirmation to delivery. Customized solutions may require 12-20 weeks, depending on the complexity of engineering and integration. We maintain transparent communication throughout the fulfillment process, providing regular updates on manufacturing progress and shipping schedules. Expedited options are available upon request for critical projects.

Warranty Commitments

All Changguang TW Series UAVs are backed by a comprehensive 2-year limited warranty covering manufacturing defects in materials and workmanship. This warranty ensures peace of mind for our clients, guaranteeing performance and reliability under normal operating conditions. Extended warranty options and service contracts are also available to provide long-term protection and support. Our products are certified to meet ISO 9001 and AS9100 quality standards, reflecting our commitment to excellence.

Customer Support and Training

We offer unparalleled after-sales support, including:

- 24/7 Technical Assistance: Access to our expert support team for any operational or technical queries.

- On-site Training Programs: Comprehensive training for pilot operation, maintenance, and data management, tailored to your team's needs.

- Maintenance Services: Scheduled and on-demand maintenance and repair services by certified technicians, ensuring optimal performance and longevity.

- Spare Parts Availability: A readily available inventory of spare parts to minimize downtime.

Our dedicated team ensures that clients receive continuous support, maximizing the operational readiness and effectiveness of their Changguang TW Series UAVs. We pride ourselves on building long-term partnerships, providing solutions that evolve with our clients' needs.

References

- Smith, J. (2023). "Advancements in VTOL UAV Technology for Industrial Applications." Journal of Unmanned Vehicle Systems, Vol. 11, No. 3, pp. 123-145.

- Aerospace Industry Association. (2022). "Global UAV Market Forecast 2022-2028." Available at: [Authoritative Industry Report Website]

- International Organization for Standardization (ISO). (2015). "ISO 9001:2015 Quality Management Systems – Requirements."

- Society of Automotive Engineers (SAE). (2016). "AS9100D Quality Management Systems – Requirements for Aviation, Space and Defense Organizations."

- National Oceanic and Atmospheric Administration (NOAA). (n.d.). "Beaufort Wind Scale." Available at: [NOAA Official Website]