- Afrikaans

- Albanees

- Amharies

- Arabies

- Armeens

- Azerbeidjans

- Baskies

- Wit-Russies

- Bengaals

- Bosnies

- Bulgaars

- Katalaans

- Cebuano

- China

- Korsikaans

- Kroaties

- Tsjeggies

- Deens

- Nederlands

- Engels

- Esperanto

- Estnies

- Fins

- Frans

- Fries

- Galisies

- Georgies

- Duits

- Grieks

- Gujarati

- Haïtiaanse Kreools

- Hausa

- hawaiian

- Hebreeus

- Nee

- Miao

- Hongaars

- Yslands

- igbo

- Indonesies

- iers

- Italiaans

- Japannese

- Javaans

- Kannada

- kazaks

- Khmer

- Rwandese

- Koreaans

- Koerdies

- Kirgisies

- Arbeid

- Latyn

- Letties

- Litaus

- Luxemburgs

- Masedonies

- Malgassies

- Maleis

- Malabaars

- Maltees

- Maori

- Marathi

- Mongoolse

- Myanmar

- Nepalees

- Noors

- Noors

- Oksitaans

- Pasjto

- Persies

- Pools

- Portugees

- Punjabi

- Roemeens

- Russies

- Samoaans

- Skotse Gaelies

- Serwies

- Engels

- Shona

- Sindhi

- Sinhala

- Slowaaks

- Sloweens

- Somalies

- Spaans

- Soendanees

- Swahili

- Sweeds

- Tagalog

- Tadjieks

- Tamil

- Tataars

- Telugu

- Thai

- Turks

- Turkmeens

- Oekraïens

- Oerdoe

- Uighur

- Oezbeeks

- Viëtnamees

- Wallies

- Help

- Jiddisj

- Yoruba

- Zoeloe

nuus

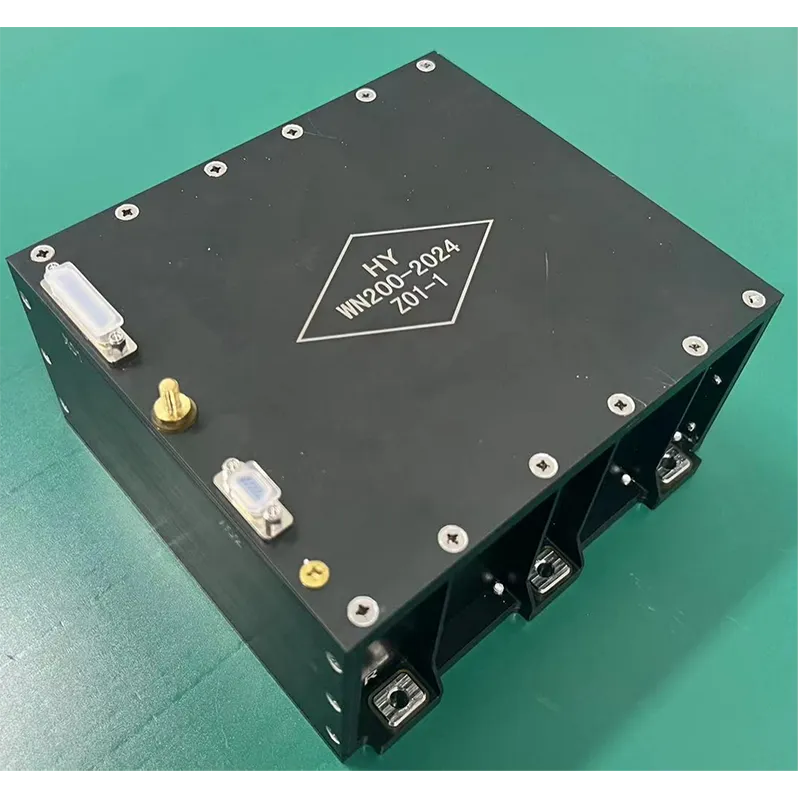

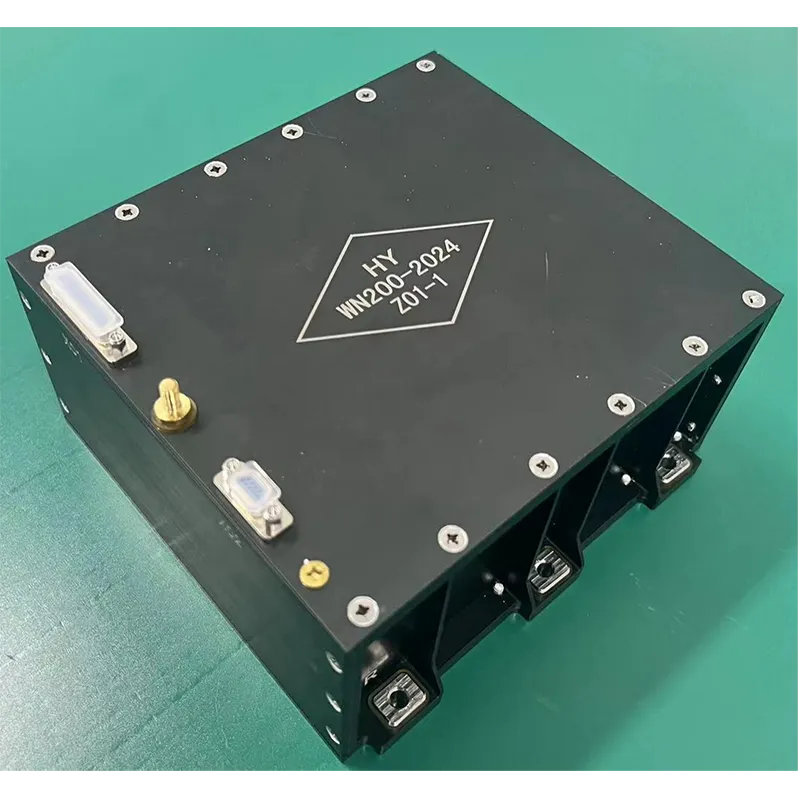

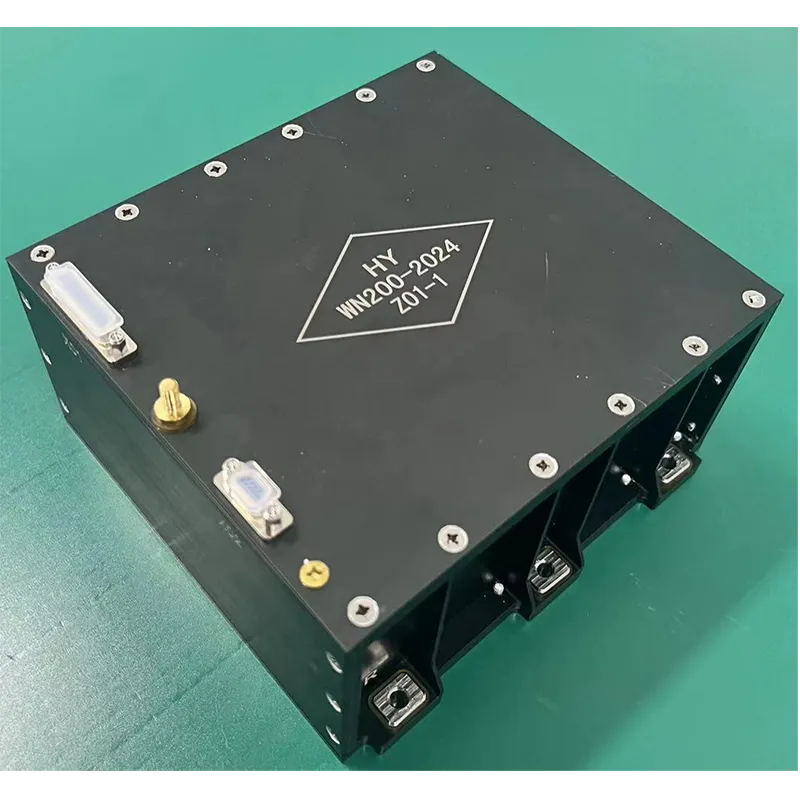

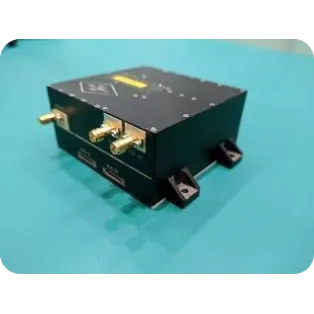

Enhancing Electronic Reliability Through Component Design And Process Control

In the precision-driven sectors of aerospace, telecommunications, and computing, long-term performance depends not only on innovation but also on the quality and design of every component. At SpaceNavi, we place strong emphasis on component design, component quality, and tightly controlled component processes to deliver reliable and scalable systems that meet the evolving demands of global industries.

Precision-Focused Component Design For Critical Systems

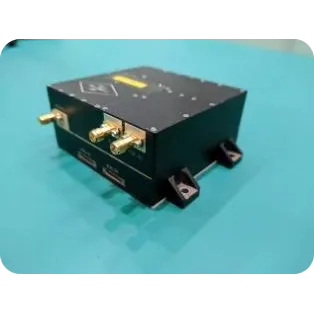

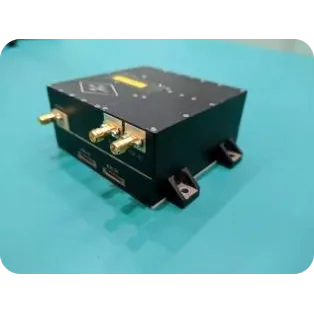

Every device starts with thoughtful component design. Whether it’s a power regulation module for a small satellite or a high-frequency signal converter for a ground station, we begin with performance objectives and environmental requirements. Our engineers evaluate thermal behavior, electromagnetic compatibility, and mechanical stability during the design phase to ensure that each component performs as expected, regardless of external stress.

SpaceNavi’s design teams work on:

Custom-shaped components for confined enclosures

Flexible component cables for dynamic installations

Interfaces that allow seamless component to HDMI conversion

Ruggedized componentry for UAV and satellite payloads

With these capabilities, our designs minimize failure points and optimize assembly efficiency.

Verified Komponent Quality For Industrial And Aerospace Use

To meet international standards and fulfill critical mission roles, we implement strict component quality assurance protocols. Every component undergoes multi-stage testing including thermal cycling, vibration tolerance, and functional analysis. We also track every part with serialized identification and supplier documentation.

Some of our verification procedures include:

ISO-compliant traceability for component supply

Environmental simulations for long-term durability

Visual and X-ray inspections of PCBs (see pcb meaning: printed circuit boards)

Current and voltage validation across various electricity circuit profiles

This ensures that whether you're assembling a UAV controller, building a computing sub assembly, or prototyping a space-grade sensor, the components you use are certified and ready for performance.

Streamlined Component Process From Assembly To Integration

A robust component process can reduce cost, prevent rework, and shorten delivery timelines. Our process begins with sourcing from verified component suppliers and flows through design approval, prototype testing, and full-scale production. We ensure proper fitment with complementary hardware, such as processing devices of computer or satellite control boards.

The component process includes:

CAD-based fit and clearance simulations

Automated pick-and-place assembly

Bonding and insulation treatments for high-stress applications

Compatibility checks with connectors like component to HDMI

Each stage is monitored and documented for traceability, allowing for faster upgrades and smoother maintenance cycles throughout a product’s lifecycle.

Partnering With Global Component Manufacturers And Suppliers

Our close cooperation with global component manufacturers allows us to deliver consistent quality and access the latest technology. This partnership model ensures your systems include components that are not only high-grade but also well-supported by a network of component suppliers across North America, Europe, and Asia.

We offer

Access to high-spec component material

Integration-ready parts from industry leaders

Responsive sourcing options in case of supply disruptions

Custom solutions based on your operation needs

Our partnerships extend beyond procurement—they’re about co-developing parts that meet your future performance targets.

Innovation Backed By Component-Level Excellence

SpaceNavi's legacy in electronics and aerospace engineering is built upon rigorous attention to every component. From specialized component design and verified component quality to a seamless, documented component process, we ensure that what goes into your systems stands up to the demands of tomorrow’s missions.

Whether you’re designing next-gen processing devices of computers, rugged satellite boards, or high-reliability sub assemblies, our integrated service model and network of top component suppliers make SpaceNavi your ideal partner.