- ஆப்பிரிக்க

- அல்பேனியன்

- அம்ஹாரிக்

- அரபு

- ஆர்மேனியன்

- அஜர்பைஜானி

- பாஸ்க்

- பெலாரஷ்யன்

- வங்காளம்

- போஸ்னியன்

- பல்கேரியன்

- கேட்டலான்

- செபுவானோ

- சீனா

- கோர்சிகன்

- குரோஷியன்

- செக்

- டேனிஷ்

- டச்சு

- ஆங்கிலம்

- எஸ்பெராண்டோ

- எஸ்டோனியன்

- பின்னிஷ்

- ஃபிரெஞ்சு

- ஃப்ரிஷியன்

- காலிசியன்

- ஜார்ஜியன்

- ஜெர்மன்

- கிரேக்கம்

- குஜராத்தி

- ஹைட்டியன் கிரியோல்

- ஹௌசா

- ஹவாய்

- ஹீப்ரு

- இல்லை

- மியாவோ

- ஹங்கேரியன்

- ஐஸ்லாந்து

- இக்போ

- இந்தோனேசியன்

- ஐரிஷ்

- இத்தாலியன்

- ஜப்பானியர்கள்

- ஜாவனீஸ்

- கன்னடம்

- கசாக்

- கெமர்

- ருவாண்டன்

- கொரியன்

- குர்திஷ்

- கிர்கிஸ்

- உழைப்பு

- லத்தீன்

- லாட்வியன்

- லிதுவேனியன்

- லக்சம்பர்கிஷ்

- மாசிடோனியன்

- மலகாஸி

- மலாய்

- மலையாளம்

- மால்டிஸ்

- மாவோரி

- மராத்தி

- மங்கோலியன்

- மியான்மர்

- நேபாளி

- நார்வேஜியன்

- நார்வேஜியன்

- ஆக்ஸிடன்

- பாஷ்டோ

- பாரசீக

- போலிஷ்

- போர்ச்சுகீஸ்

- பஞ்சாபி

- ருமேனியன்

- ரஷ்யன்

- சமோவான்

- ஸ்காட்டிஷ் கேலிக்

- செர்பியன்

- ஆங்கிலம்

- ஷோனா

- சிந்தி

- சிங்களம்

- ஸ்லோவாக்

- ஸ்லோவேனியன்

- சோமாலி

- ஸ்பானிஷ்

- சுண்டனீஸ்

- சுவாஹிலி

- ஸ்வீடிஷ்

- டலாக்

- தாஜிக்

- தமிழ்

- டாடர்

- தெலுங்கு

- தாய்

- துருக்கியம்

- துர்க்மென்

- உக்ரைனியன்

- உருது

- உய்குர்

- உஸ்பெக்

- வியட்நாமிய

- வெல்ஷ்

- உதவி

- இத்திஷ்

- யோருபா

- ஜூலு

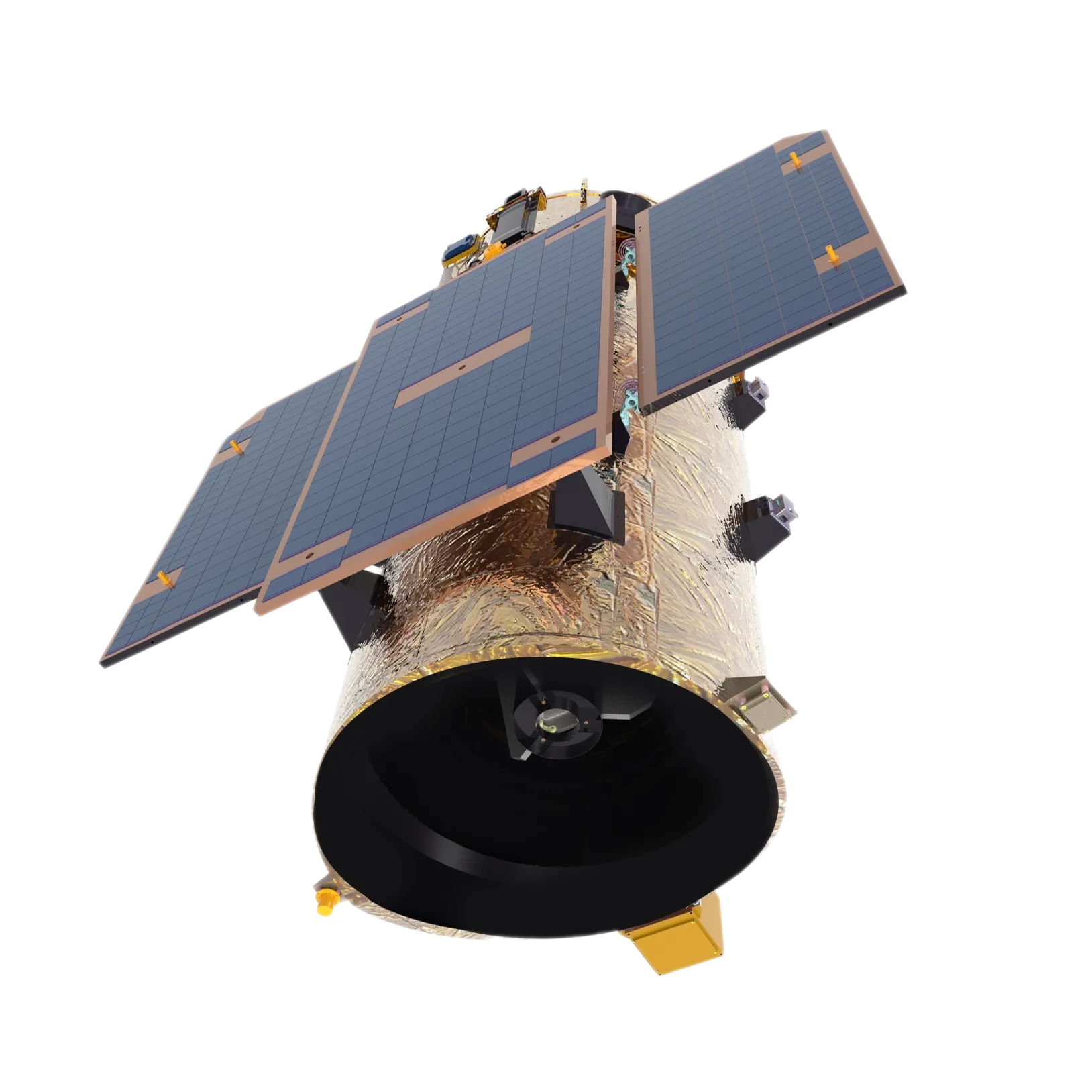

Optical Precision in Aerospace: Empowering Satellite Systems with Advanced Surface Profiling

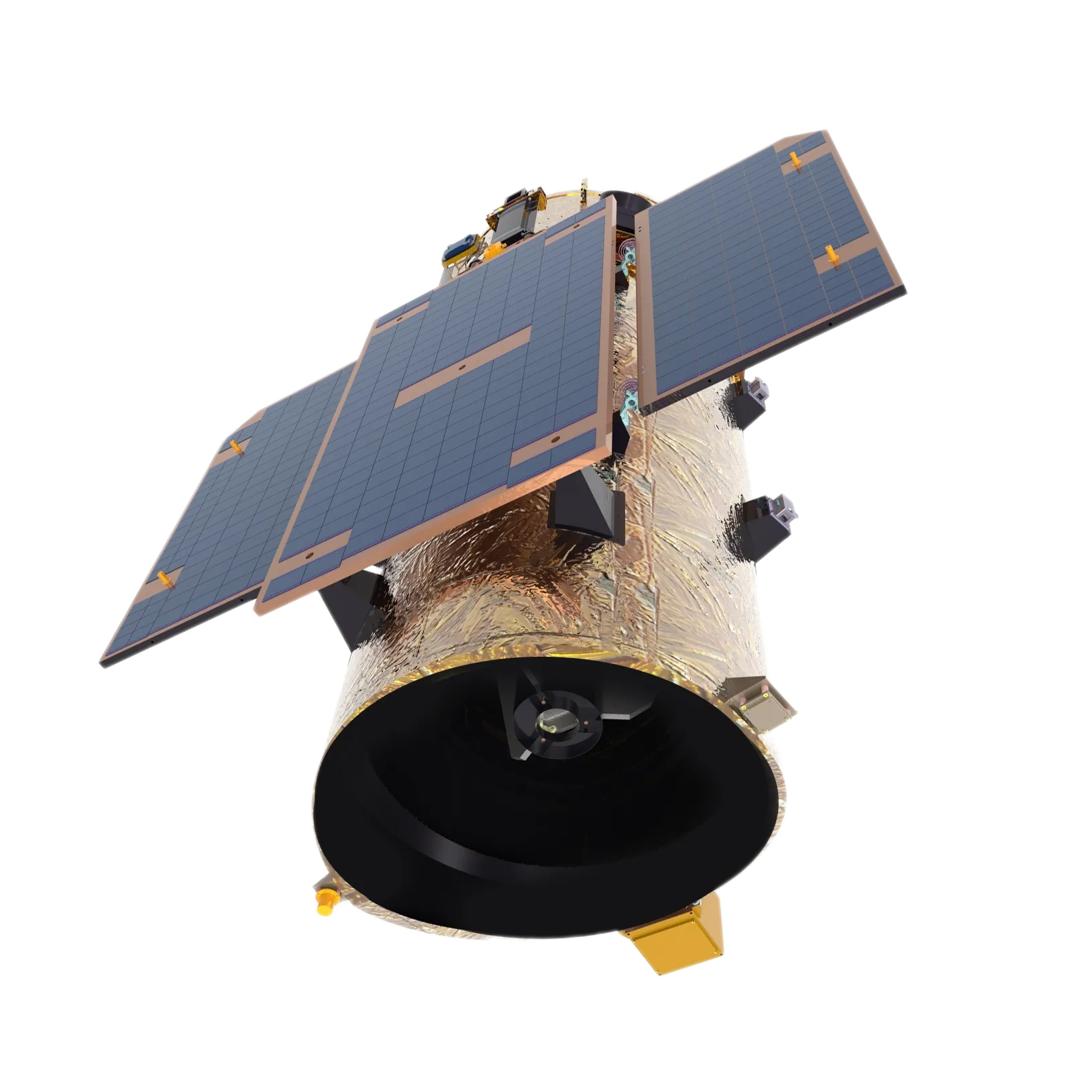

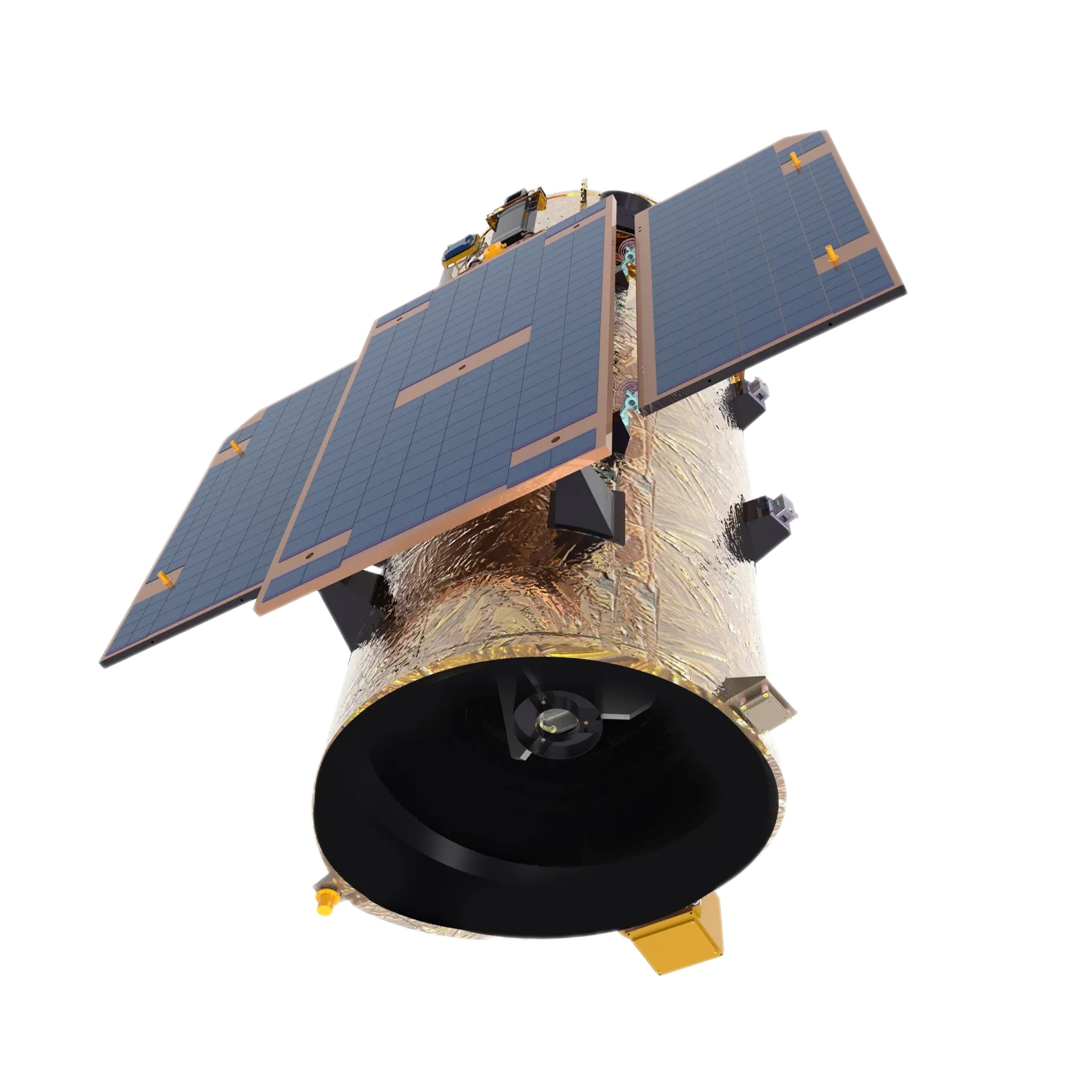

Surface accuracy plays a critical role in aerospace performance—particularly in the development of advanced satellite systems. At SpaceNavi Co., Ltd., we understand that excellence in satellite technology begins with microscopic precision. Utilizing advanced tools like the optical surface profiler and optical surface roughness tester, we ensure that each component, from optical sensors to payload modules, is crafted with accuracy that meets orbital demands.

Our precision approach contributes directly to structural resilience, image clarity, and system longevity across our செயற்கைக்கோள் தளம், CubeSat payloads, and airborne instruments.

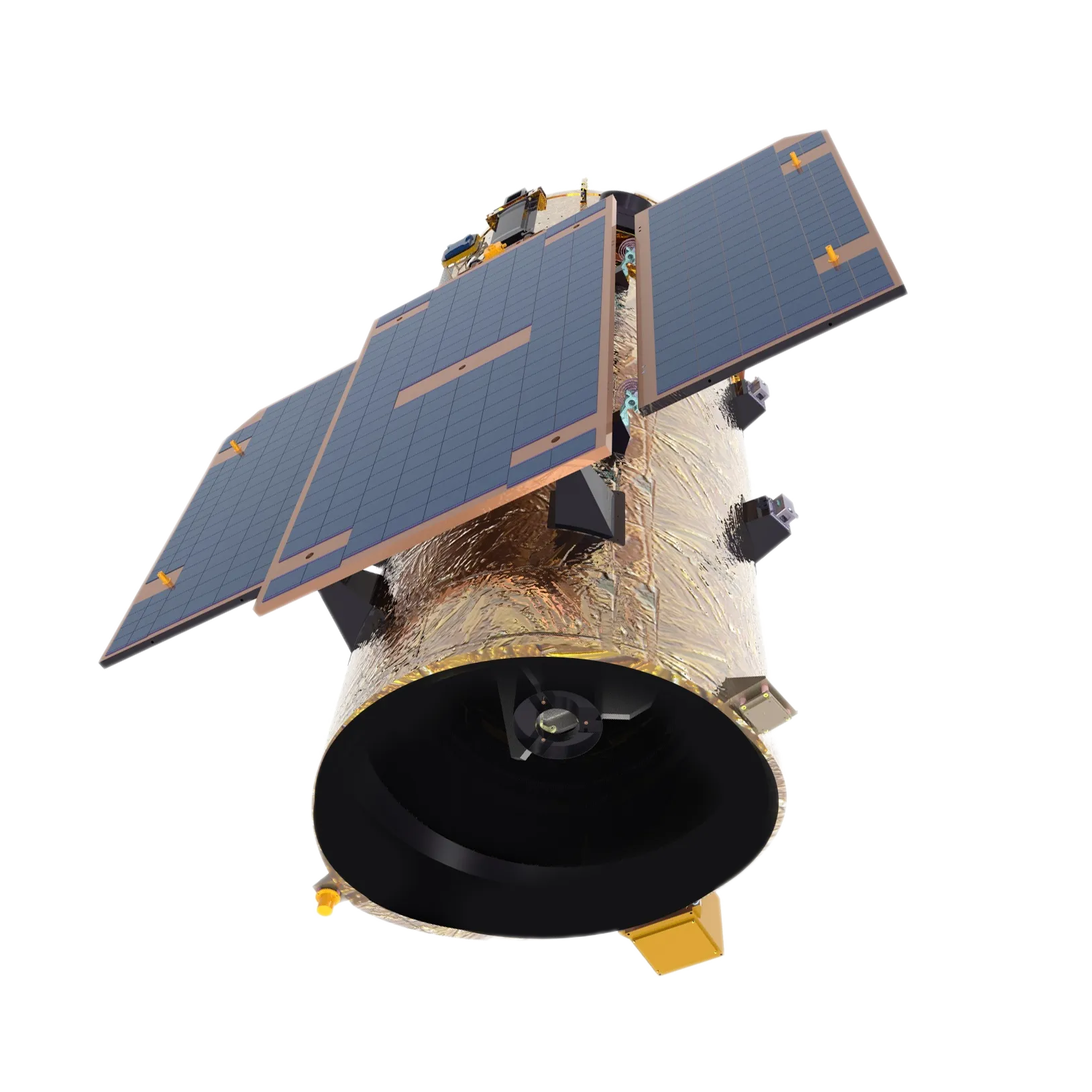

Precision Meets Innovation: The Role of the Optical Surface Profiler

In the space environment, surface finish is not just an aesthetic detail—it influences performance, heat dissipation, and mechanical stability. The optical surface profiler is essential to our satellite production process, allowing us to measure and map surface deviations at nanometer-level precision without damaging delicate parts.

This non-contact tool is especially vital in the inspection of reflective surfaces within our optic camera/payload systems, which require flawless finishes to capture high-resolution imagery in orbit. Whether preparing sensor housings or lens mounts, SpaceNavi relies on optical surface profiler data to verify perfection before integration.

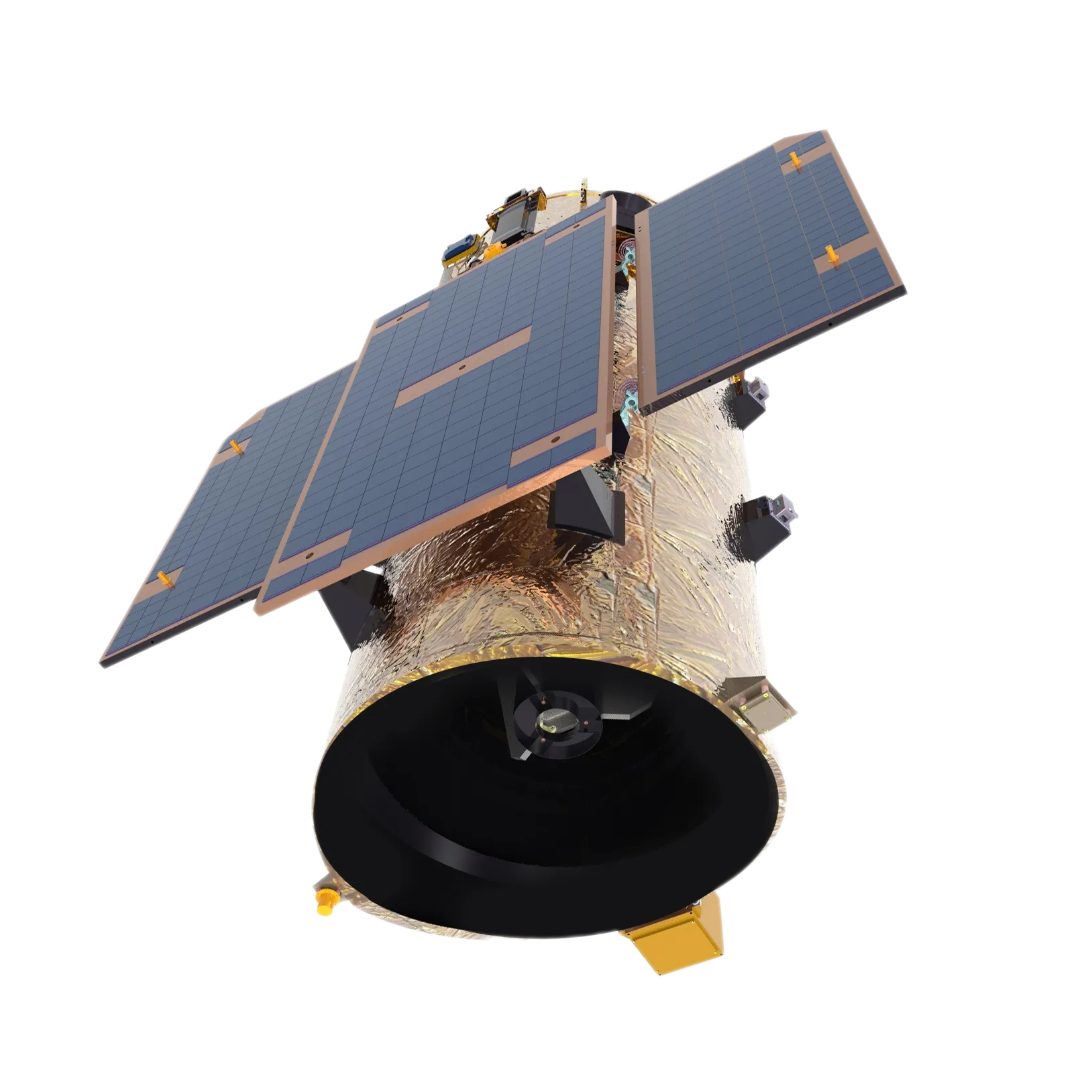

High-Resolution Analysis With the Optical Surface Roughness Tester

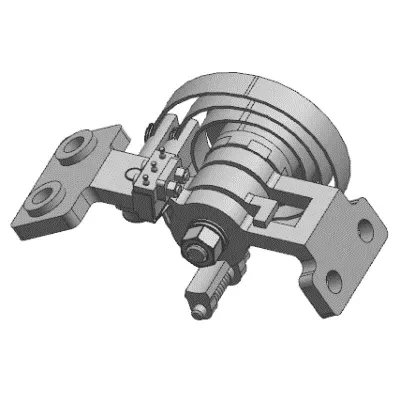

To ensure uninterrupted operation in extreme environments, SpaceNavi implements rigorous surface validation with the optical surface roughness tester. Every critical interface—be it part of the satellite bus structure or an embedded communication module—is tested for acceptable roughness tolerances.

The tester delivers real-time, high-definition analysis that supports our quality assurance objectives. Especially during vibration testing and fault detection simulations, knowing the exact surface conditions helps prevent mechanical stress fractures and resonance-based failures during flight.

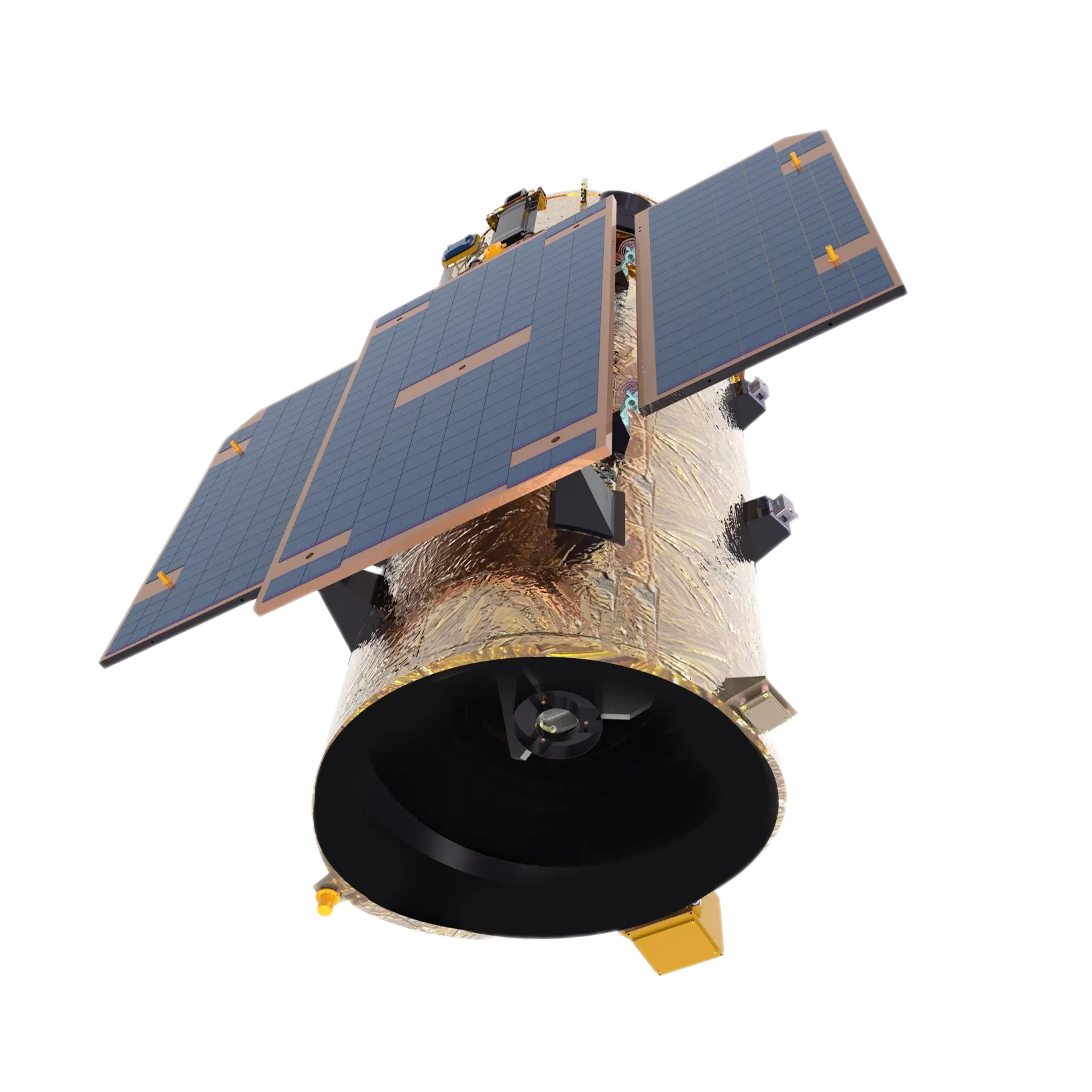

Full-Spectrum Capabilities with Optical Measuring Instruments

Supporting all our testing and R&D initiatives is a suite of specialized optical measuring instruments. These include optical profilometer resolution tools and optical lab equipment capable of examining coatings, material density, and structural response.

We also incorporate the optical dissolved oxygen meter for chemical stability monitoring in materials used for long-duration missions, and advanced optical profilometer surface roughness analysis for components exposed to cosmic conditions. Together, these instruments support the creation of robust, high-functioning satellite systems that perform reliably in orbit.

SpaceNavi Co., Ltd. continues to lead in satellite innovation through unmatched precision and technical rigor. With our mastery of optical surface profiler, optical surface roughness tester, and an extensive array of optical measuring instruments, we deliver aerospace components ready for the complexities of launch, orbit, and beyond.

From CubeSat payloads to advanced earth observation modules, SpaceNavi ensures that every detail meets the highest standards—because in space, there is no margin for error.