- afrikanska

- albanska

- amhariska

- arabiska

- armeniska

- azerbajdzjanska

- baskiska

- vitryska

- bengaliska

- bosniska

- bulgariska

- katalanska

- Cebuano

- Kina

- korsikanska

- Kroatisk

- tjeckiska

- danska

- holländska

- engelska

- esperanto

- estniska

- finska

- franska

- frisiska

- galiciska

- georgiska

- tyska

- grekiska

- Gujarati

- haitisk kreol

- Hausa

- hawaiianska

- hebreiska

- Inga

- Miao

- ungerska

- isländska

- igbo

- indonesiska

- irländsk

- italienska

- japanska

- javanesiska

- Kannada

- kazakiska

- Khmer

- rwandiska

- koreanska

- kurdiska

- kirgiziska

- Arbetskraft

- latin

- lettiska

- litauiska

- Luxemburgiska

- makedonska

- Madagaskar

- malajiska

- Malayalam

- maltesiska

- Maori

- Marathi

- mongoliska

- Myanmar

- nepalesiska

- norska

- norska

- occitanska

- Pashto

- persiska

- polska

- portugisiska

- Punjabi

- rumänska

- ryska

- Samoan

- skotsk gaeliska

- serbiska

- engelska

- Shona

- Sindhi

- singalesiska

- slovakiska

- slovenska

- somaliska

- spanska

- Sundanesiska

- Swahili

- svenska

- Tagalog

- tadzjikiska

- Tamil

- tatariska

- Telugu

- Thai

- turkiska

- turkmeniska

- ukrainska

- Urdu

- Uigur

- uzbekiska

- vietnamesiska

- walesiska

- Hjälp

- jiddisch

- Yoruba

- Zulu

Enhancing Aerospace Reliability with Advanced Mechanical Equipment

In the development and deployment of high-performance satellite systems, behind-the-scenes infrastructure often determines mission success. At SpaceNavi Co., Ltd., we recognize the vital role that ground support and assembly processes play in aerospace innovation. Central to this infrastructure is our investment in high-grade mechanical equipment, ensuring every satellite component is built, tested, and maintained with precision and stability.

From assembly lines to vibration test facilities, the performance of mechanical equipment directly affects the quality, safety, and durability of satellites launched into orbit.

The Role of ERV Mechanical Unit in Satellite Component Testing

The ERV mechanical unit (Energy Recovery Ventilation) has emerged as a crucial part of our satellite manufacturing environment. As satellites require cleanroom-level environmental control during sensitive phases such as sensor integration or payload assembly, ERV mechanical units ensure controlled ventilation, stable humidity, and consistent temperature.

This controlled environment safeguards critical elements like optical sensors and avionics from contamination or thermal distortion—preserving both their integrity and functionality before launch.

Precision Handling with Refrigeration Service Tools and Ventilating Equipment

Temperature control is vital in the processing and calibration of delicate satellite instruments. That’s why Rymdskepp implements advanced refrigeration service tools in its satellite subsystem production lines, particularly when dealing with thermal payloads and cryogenic components.

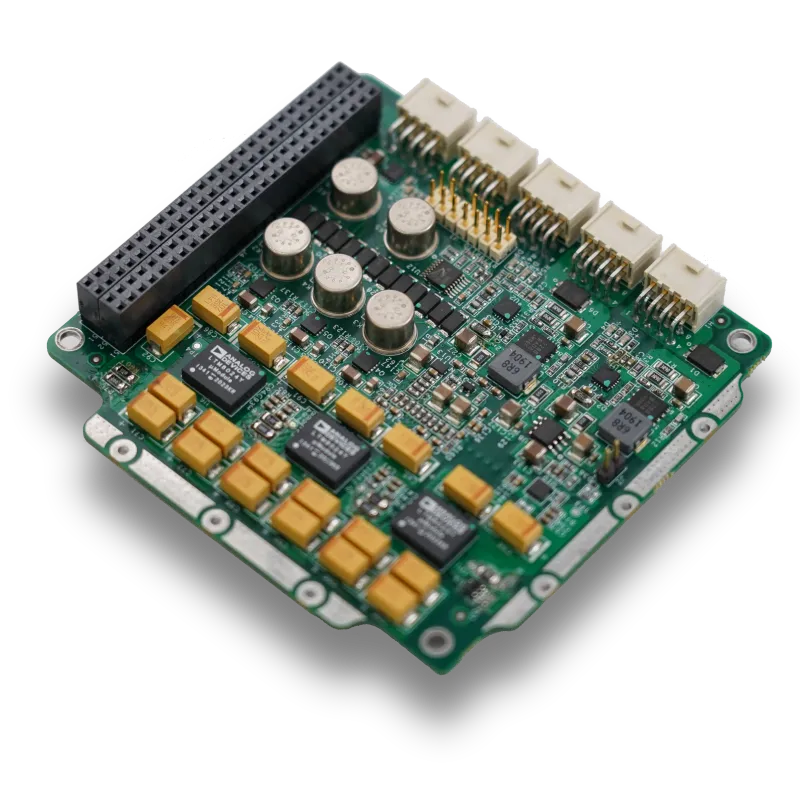

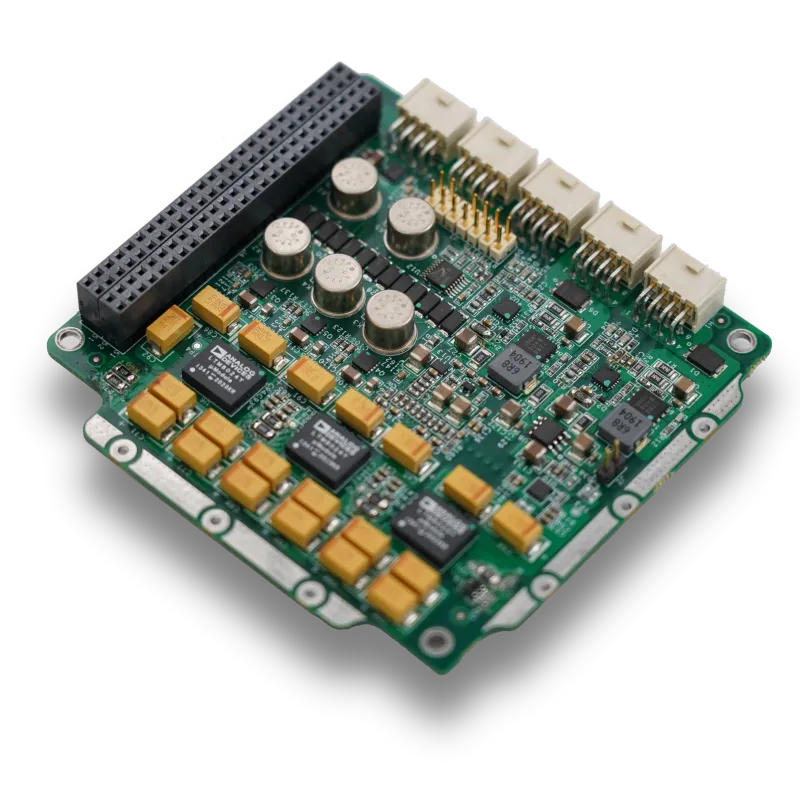

Coupled with industrial-grade ventilating equipment, we simulate and regulate environmental conditions that satellites may face in space or during transport. These systems also ensure safe working conditions for technicians operating on electronic components, circuit boards, and optic camera/payload modules under strict aerospace quality standards.

Extending the Mechanical Equipment Life Expectancy Through Engineering Excellence

At Rymdskepp, we don’t just use machinery—we engineer efficiency. By optimizing the maintenance schedules and structural design of our support systems, we increase the mechanical equipment life expectancy, reducing downtime and ensuring long-term reliability in satellite production.

Each satellitplattform must go through extensive integration and stress testing. Durable, low-maintenance mechanical equipment ensures uninterrupted processes during long-term satellite programs, including CubeSat manufacturing and component validation cycles.

Dependable Support from a Trusted Mechanical Equipment Company

As a leading aerospace innovator, SpaceNavi Co., Ltd. collaborates with top-tier mechanical equipment companies to source, customize, and maintain the machinery required for satellite assembly and validation. This includes robust mechanical equipment services that cover everything from system diagnostics to emergency repairs and replacement parts.

By leveraging third-party expertise alongside in-house engineering talent, we ensure that our production line operates at maximum efficiency—delivering satellite components that meet global space agency standards.

At Rymdskepp, satellite manufacturing is not just about electronic sophistication—it’s also about dependable, high-quality infrastructure. Through our integration of advanced mechanical equipment, including ERV mechanical units, refrigeration service tools, and customized ventilating equipment, we uphold the standards that space demands.

Our satellites begin with precision on the ground—powered by systems designed to last, operate efficiently, and meet the challenges of modern aerospace.