- Afrikaan

- Albaaniyaan

- Amxaari

- Carabi

- Armeeniyaan

- Asarbayjaan

- Basque

- Belarusiyaanka

- Bengali

- Bosnia

- Bulgaariya

- Catalan

- Cebuano

- Shiinaha

- Korsican

- Croatian

- Czech

- Danish

- Dutch

- Ingiriis

- Esperanto

- Istooniyaan

- Finnish

- Faransiis

- Frisian

- Galiciyan

- Joorjiyaan

- Jarmal

- Giriig

- Gujarati

- Haitian Creole

- Hausa

- hawiye

- Cibraaniga

- Maya

- Miao

- Hungarian

- Iceland

- igbo

- Indonesian

- iriish

- Talyaani

- Jabbaan

- Javanese

- Kannada

- Kazakh

- Khmer

- Ruwanda

- Kuuriya

- Kurdish

- Kyrgyzs

- Foosha

- Laatiinka

- Latvia

- Lithuanian

- Luxembourgish

- Masedooniyaan

- Malagasy

- Malaay

- Malayalam

- Malta

- Maori

- Marathi

- Mongoliyaan

- Myanmar

- Nepali

- Noorwiiji

- Noorwiiji

- Occitan

- Pashto

- Faaris

- Polish

- Boortaqiis

- Punjabi

- Romanian

- Ruush

- Samoan

- Scottish Gaelic

- Seerbiyaan

- Ingiriis

- Shona

- Sindhi

- Sinhala

- Slovakia

- Islovenian

- Somali

- Isbaanish

- Sundanese

- Sawaaxili

- Iswidish

- Tagalog

- Taajik

- Tamil

- Tataarka

- Telugu

- Thai

- Turki

- Turkmen

- Yukreeniyaan

- Urduu

- Uighur

- Uzbekistan

- Vietnamese

- Welsh

- Caawin

- Yidish

- Yurub

- Zulu

Powering Aerospace Excellence with Specialized Mechanical Equipment Services

In the intricate world of aerospace innovation, excellence is not only measured by satellite performance in orbit but also by the reliability of systems supporting them on Earth. At SpaceNavi Co., Ltd., our commitment to building high-performance, low-cost satellite systems is made possible through cutting-edge mechanical equipment services that ensure production, integration, and testing run at optimal levels.

Through the implementation of specialized mechanical equipment and continuous system enhancement, we uphold the standards of precision required for each mission—whether developing a CubeSat or a full-scale satellite platform.

Partnering with Expert Mechanical Equipment Companies

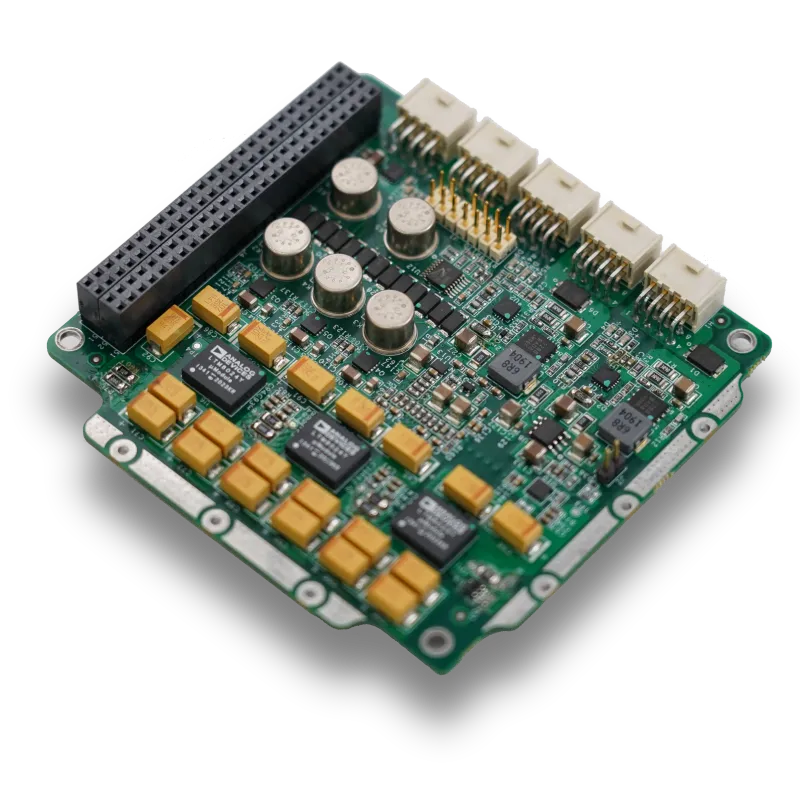

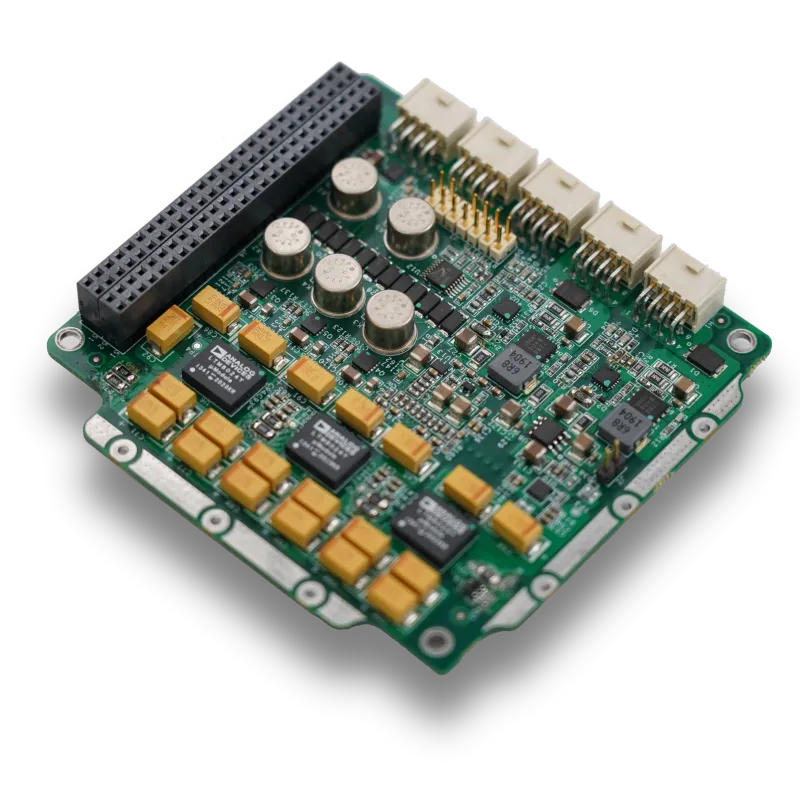

To guarantee seamless assembly and testing of satellite components, Maraakiibta hawada sare partners with leading mechanical equipment companies globally. This collaboration brings in state-of-the-art machinery used in payload integration, vibration testing, and environmental simulation. Whether it’s building a modular madal dayax-gacmeedka or preparing a ground station for communications, our infrastructure depends on equipment that is durable, customizable, and aligned with aerospace-grade requirements.

Every component, from optical sensors to propulsion modules, benefits from this mechanical precision. These partnerships allow us to shorten delivery timelines while maintaining rigorous quality assurance.

Engineering for Durability: Maximizing Mechanical Equipment Life Expectancy

Within our facilities, every machine is selected not just for performance but also for longevity. By choosing materials and design features optimized for aerospace production, Maraakiibta hawada sare extends the mechanical equipment life expectancy—ensuring consistent operation during high-volume production cycles and testing phases.

This approach minimizes maintenance interruptions and extends uptime, a crucial factor when building satellites with tight launch schedules. The long service life of tools like pressurization devices, alignment fixtures, and thermal control units directly contributes to improved satellite reliability.

Building Cleanroom Precision with Ventilating Equipment and ERV Mechanical Units

Cleanroom conditions are essential in the handling of sensitive satellite instruments, especially optical payloads. Our advanced ventilating equipment and ERV mechanical units provide consistent airflow, particulate filtration, and thermal control—creating an environment where sensors, electronic assemblies, and flight-ready modules can be integrated without risk of contamination.

These systems are also critical for ensuring that processes involving electronic components, soldering, and sensor alignment remain within strict environmental tolerances, essential for mission-critical satellite operations.

Innovation Enabled by Advanced Refrigeration Service Tools

Precision thermal control during satellite component testing and calibration requires reliable refrigeration service tools. These tools are employed during the environmental testing of satellite payloads, where systems are exposed to temperature variations mimicking the space environment. Whether measuring thermal conductivity or testing sensor response at sub-zero conditions, these tools ensure our satellites are space-ready.

SpaceNavi’s refrigeration technology also plays a role in managing payloads with temperature-sensitive optics and instruments—allowing us to lead in high-accuracy satellite deployments for remote sensing and Earth observation.

From integration bays to launchpad logistics, SpaceNavi Co., Ltd. brings together aerospace expertise and dependable mechanical equipment services to advance satellite innovation. Our approach is comprehensive: building satellite platforms backed by a robust infrastructure of cleanrooms, test chambers, and mechanical tools that stand the test of time.

By investing in expert partnerships, long-life equipment, and cutting-edge tools, Maraakiibta hawada sare ensures that every mission begins with precision—and ends in success.